Technical Contents

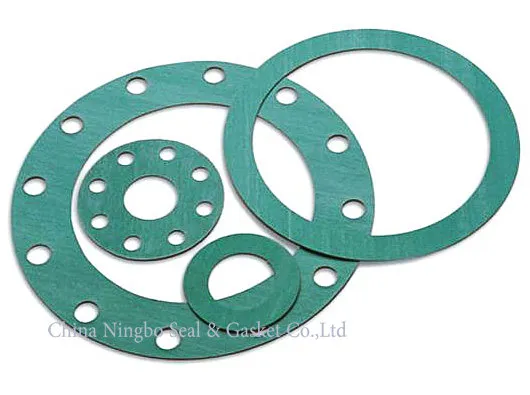

Engineering Guide: Asbestos Gaskets

Engineering Insight: Material Selection Imperatives for Critical Sealing Applications

Historical asbestos-based gasket materials are obsolete and prohibited in modern industrial applications due to severe health hazards and global regulatory bans including OSHA and REACH directives. Suzhou Baoshida Trading Co., Ltd. emphasizes this context to underscore a fundamental engineering principle: generic sealing solutions fail catastrophically when material properties mismatch operational demands. Off-the-shelf gaskets frequently ignore thermomechanical degradation thresholds, chemical compatibility, and dynamic stress factors inherent in precision systems. This oversight leads to premature seal failure through extrusion, creep relaxation, or polymer chain scission—resulting in costly downtime, safety incidents, and environmental contamination.

Critical failure mechanisms originate from inadequate material characterization. Standard gaskets often utilize low-cost elastomers with narrow thermal windows. For instance, NBR compounds degrade rapidly above 120°C in steam environments, while generic compressed fiber sheets exhibit poor resilience against cyclic pressure loads. Chemical exposure further accelerates deterioration; aromatic hydrocarbons swell conventional nitrile rubbers, compromising compression recovery. Crucially, OEM specifications rarely account for synergistic stressors—such as simultaneous high temperature, vibration, and corrosive media—that exponentially accelerate material fatigue.

Suzhou Baoshida’s engineering protocol mandates application-specific formulation. We evaluate five non-negotiable parameters: maximum intermittent temperature, fluid compatibility spectrum, flange surface finish, bolt load retention requirements, and regulatory compliance (e.g., FDA, TA-Luft). This data informs polymer selection from advanced alternatives, ensuring molecular stability under operational extremes. Below is a comparative analysis of contemporary high-performance materials we engineer for critical seals:

| Material | Max Continuous Temp (°C) | Key Chemical Resistances | Compression Set @ 22h/150°C (%) | Typical Industrial Applications |

|---|---|---|---|---|

| Expanded Graphite | 550 (inert) / 450 (oxid) | Acids, alkalis, solvents | <15 | Petrochemical reactors, exhaust systems |

| PTFE-Encapsulated | 260 | All chemicals except molten alkali metals | <10 | Semiconductor, pharmaceutical |

| Flexible Graphite | 500 (inert) | Strong acids, cryogenics | <20 | Power generation, LNG |

| High-Temp Silicone | 230 | Water, ozone, brake fluids | <25 | Aerospace hydraulics, medical |

| Aramid-Reinforced | 300 | Oils, fuels, moderate acids | <18 | Automotive turbochargers, marine |

Generic gaskets omit such granular property mapping, relying on nominal pressure-temperature ratings that ignore real-world cycling effects. At Suzhou Baoshida, we deploy DMA (Dynamic Mechanical Analysis) and ASTM F38 creep testing to simulate 10,000+ operational cycles, validating seal integrity before deployment. Our OEM partnerships begin with flange stress modeling—not catalog number selection—to eliminate field failures. Material science is not a cost center; it is the engineering safeguard preventing million-dollar leakage events. Contact our formulation team with your operational parameters for a failure-mode analysis tailored to your system.

Material Specifications

Material Specifications for Precision Rubber Seals

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber gaskets engineered for critical sealing applications across industrial, automotive, and chemical processing sectors. As part of our Precision Rubber Seals product line, we offer gaskets manufactured from Viton, Nitrile (NBR), and Silicone—each selected for its distinct chemical resistance, thermal stability, and mechanical performance. These materials serve as advanced alternatives to legacy asbestos-based gaskets, delivering superior safety, compliance, and durability without compromising sealing integrity.

Viton, a fluorocarbon-based elastomer (FKM), is engineered for extreme environments involving high temperatures and aggressive chemical exposure. It exhibits exceptional resistance to oils, fuels, acids, and ozone, making it ideal for aerospace, petrochemical, and high-temperature engine applications. With continuous service capability up to 230°C and short-term resistance to temperatures exceeding 300°C, Viton ensures reliable performance under thermal cycling and pressure fluctuations. Its low gas permeability further enhances sealing efficiency in dynamic systems.

Nitrile rubber (NBR) remains one of the most widely used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils and hydraulic fluids. It offers good abrasion resistance and mechanical strength across a service range of -30°C to 120°C, with some formulations extending to 150°C. Nitrile gaskets are commonly deployed in automotive fuel systems, hydraulic equipment, and general-purpose machinery where cost-efficiency and oil resistance are paramount. However, performance diminishes in the presence of polar solvents, ozone, and extreme heat.

Silicone rubber (VMQ) provides outstanding thermal stability and flexibility across a broad temperature spectrum, from -60°C to 200°C. It is particularly suited for applications requiring long-term resilience to weathering, UV exposure, and sterilization processes. While not as oil-resistant as Viton or Nitrile, silicone excels in food-grade, medical, and electrical insulation applications due to its inertness, low toxicity, and excellent dielectric properties. It is also frequently used in HVAC systems and sensitive electronic enclosures.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Resistance to Acids/Bases | Good to Excellent | Fair | Good |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Petrochemical, Aerospace | Automotive, Hydraulics | Medical, Food, Electrical |

Selection of the appropriate elastomer requires alignment with operational parameters including media exposure, temperature profile, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial partners with material validation, custom formulation, and precision manufacturing to ensure optimal gasket performance and regulatory compliance.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Excellence for Asbestos-Free Gaskets

Suzhou Baoshida Trading Co., Ltd. operates with strict adherence to global safety and environmental regulations, including the complete exclusion of asbestos in all gasket manufacturing. Our engineering division specializes in developing high-performance, asbestos-free alternatives that meet rigorous industrial sealing demands. With a dedicated team of five Mold Design Engineers and two Rubber Formula Engineers, we deliver scientifically validated solutions tailored to extreme operational conditions. Our expertise spans material science, finite element analysis (FEA), and iterative prototyping to ensure optimal compression set resistance, thermal stability, and chemical compatibility.

Our Formula Engineers leverage advanced polymer chemistry to formulate custom elastomer compounds for critical applications. Each formulation undergoes systematic testing for tensile strength, elongation, fluid resistance, and aging properties per ASTM D2000 and ISO 3601 standards. Concurrently, our Mold Engineers utilize CAD/CAM systems and mold-flow simulation software to optimize cavity design, runner systems, and ejection mechanisms. This integrated approach minimizes flash, ensures dimensional accuracy within ±0.1 mm tolerances, and extends tool life by 30% compared to industry averages.

As an OEM partner, we provide end-to-end engineering support from concept to量产. Clients supply performance requirements or legacy specifications; our team reverse-engineers material compositions and geometries to develop compliant, high-reliability replacements. We maintain ISO 9001-certified processes for traceability, including batch-specific cure kinetics documentation and accelerated life testing under simulated service conditions. This capability enables seamless transition from obsolete asbestos-based gaskets to modern, sustainable alternatives without compromising system integrity.

The table below summarizes key properties of our engineered asbestos-free compounds:

| Material Type | Temperature Range (°C) | Tensile Strength (MPa) | Fluid Resistance | Compression Set (22h, 150°C) |

|---|---|---|---|---|

| NBR/Graphite | -40 to +200 | 18.5 | Oil, Water | ≤25% |

| EPDM/PTFE | -55 to +180 | 15.2 | Steam, Alkalis | ≤20% |

| FKM/Aramid | -20 to +250 | 12.8 | Fuels, Acids | ≤18% |

| Flexible Graphite | -200 to +550 | 8.0 | All Chemicals | ≤15% |

Our OEM workflow begins with client-specific requirement analysis, followed by material selection via our proprietary database of 200+ validated formulations. Mold Engineers then develop 3D-printed prototypes for fitment validation within 72 hours. Full-scale production employs hydraulic presses with ±1°C temperature control and in-line vision systems for defect detection. Every batch includes a Certificate of Conformance with hardness, density, and fluid immersion results.

Suzhou Baoshida’s engineering synergy ensures gaskets that exceed OEM performance benchmarks while eliminating hazardous materials. We partner with clients to solve complex sealing challenges through data-driven material innovation and precision manufacturing—proving that safety and performance are not compromises, but engineered outcomes.

Customization Process

Customization Process for Asbestos Gaskets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our approach to manufacturing customized asbestos gaskets follows a rigorous, science-driven process designed to meet the exact performance requirements of industrial clients. We specialize in precision rubber seals and apply stringent engineering protocols to ensure reliability under extreme conditions. Our four-phase customization workflow—Drawing Analysis, Formulation, Prototyping, and Mass Production—ensures dimensional accuracy, material integrity, and long-term sealing performance.

The process begins with Drawing Analysis, where our engineering team evaluates customer-provided technical drawings or CAD models. We assess critical parameters such as inner and outer diameters, thickness, bolt-hole patterns, surface finish requirements, and application environment (e.g., pressure, temperature, media exposure). This phase ensures compatibility with flange systems and adherence to international standards such as ASME, DIN, or JIS. Any discrepancies or optimization opportunities are communicated to the client before proceeding.

Next, Formulation Development is conducted in our materials laboratory. Although traditional asbestos-based compounds are being phased out globally due to health regulations, we offer high-performance alternative formulations using aramid fibers, graphite, and nitrile rubber (NBR) or EPDM matrices that replicate the thermal stability and mechanical strength of asbestos. The selection of elastomer matrix, filler type, and reinforcing fibers is tailored to operational conditions such as chemical exposure, temperature range, and compression load. Our rubber compounding process follows ASTM D2000 standards for material classification and aging resistance.

Once the formulation is finalized, we proceed to Prototyping. Using precision die-cutting or hot-molding techniques, small-batch samples are produced for validation. Each prototype undergoes comprehensive testing, including compression set (ASTM F36), tensile strength (ASTM D412), fluid resistance, and leak testing under simulated service conditions. Dimensional verification is performed using coordinate measuring machines (CMM) to ensure tolerances are maintained within ±0.1 mm.

Upon client approval, we transition to Mass Production. Our automated production lines ensure consistency across large volumes, supported by in-line quality control checks and batch traceability. Finished gaskets are packaged per client specifications and shipped with material test reports (MTRs) and certificates of conformance.

The table below outlines typical technical specifications for our high-temperature sealing gaskets:

| Parameter | Standard Value | Test Method |

|---|---|---|

| Temperature Resistance | -40°C to +300°C (short-term up to 500°C) | ASTM D573 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥150% | ASTM D412 |

| Compression Set (22h, 200°C) | ≤35% | ASTM F36 |

| Hardness (Shore A) | 65–85 | ASTM D2240 |

| Fluid Resistance (oil, water, steam) | Excellent | ASTM D471 |

All products are developed in compliance with ISO 9001 quality management systems. Suzhou Baoshida Trading Co., Ltd. remains committed to delivering technically superior, application-specific sealing solutions with precision and industrial reliability.

Contact Engineering Team

Critical Advisory on Asbestos Gasket Materials and Modern Sealing Solutions

Suzhou Baoshida Trading Co., Ltd. operates with strict adherence to global industrial safety standards and regulatory frameworks. We must emphasize that asbestos-containing gaskets are prohibited for new manufacturing and installation in China under the State Council’s Notice on Banning Asbestos (2011) and are classified as carcinogenic by the WHO and IARC. Legacy asbestos gaskets pose severe health risks and legal liabilities; retrofitting with modern alternatives is non-negotiable for operational compliance and personnel safety. At Baoshida, we specialize exclusively in advanced asbestos-free precision rubber seals engineered for extreme industrial environments. Our formulations leverage high-performance elastomers and composite reinforcements to deliver superior sealing integrity without compromising human or environmental health.

For mission-critical applications requiring chemical resistance, thermal stability, and mechanical resilience, our engineered alternatives outperform obsolete asbestos-based materials. Below is a comparative specification table of Baoshida’s core non-asbestos gasket materials:

| Material Composition | Temperature Range (°C) | Pressure Rating (MPa) | Key Chemical Resistance |

|---|---|---|---|

| Expanded Graphite Reinforced | -200 to +650 | 25.0 | Acids, Alkalis, Steam, Hydrocarbons |

| Aramid Fiber/PTFE Hybrid | -150 to +280 | 18.0 | Solvents, Oils, Mild Acids |

| High-Purity NBR/EPDM Blend | -40 to +150 | 15.0 | Water, Glycols, Aliphatic Hydrocarbons |

| Flexible Graphite/Foam Core | -200 to +450 | 12.0 | Cryogenics, High-Purity Steam |

| Ceramic Fiber-Reinforced Silicone | -60 to +300 | 10.0 | Ozone, UV, Moderate Acids |

These materials undergo rigorous ISO 9001-certified testing for compression set, tensile strength, and fluid compatibility per ASTM F104 and EN 1514 standards. Each formulation is optimized for specific OEM requirements, including nuclear-grade purity, food-contact safety (FDA 21 CFR 177.2600), and aerospace fluid resistance. Our engineering team collaborates directly with clients to validate material selection against operational parameters—preventing premature failure, reducing maintenance cycles, and ensuring compliance with ISO 14001 and OSHA guidelines.

Initiate Your Sealing Solution Transition Today

Do not risk operational continuity or regulatory penalties with outdated sealing technologies. Contact Mr. Boyce, our dedicated OEM Solutions Manager, for immediate technical consultation. Mr. Boyce holds 18 years of precision rubber compound development experience and will provide:

Material compatibility analysis for your specific media and operating conditions

Custom formulation prototyping with accelerated lifecycle validation testing

Seamless integration support for existing flange systems without downtime

Full traceability documentation for audit and compliance reporting

Reach Mr. Boyce directly via email at [email protected] to schedule a confidential engineering review. Include your application parameters (media type, temperature/pressure profiles, flange dimensions) for a targeted solution proposal within 24 business hours. Suzhou Baoshida Trading Co., Ltd. operates ISO 17025-accredited testing facilities in Suzhou Industrial Park, enabling rapid validation of bespoke sealing solutions for global OEMs. Trust our scientific approach to eliminate asbestos-related liabilities while achieving uncompromised sealing performance. Your transition to safer, smarter gasket technology begins with one email.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).