Technical Contents

Engineering Guide: Window Channel Seal

Material Selection in Window Channel Seals: A Precision Engineering Imperative

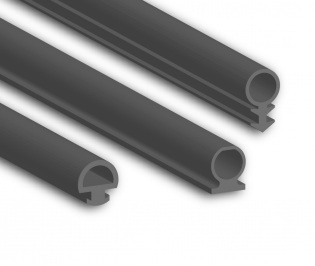

In the domain of automotive and industrial glazing systems, the window channel seal performs a dual mechanical and environmental function: it must secure the glass firmly while enabling smooth vertical movement, all while resisting degradation from UV exposure, ozone, temperature extremes, and repeated mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is the foundation of seal longevity and system reliability. Off-the-shelf rubber profiles often fail prematurely because they employ generic elastomers optimized for cost, not performance under specific operational conditions.

Standard window channel seals frequently utilize reprocessed EPDM or low-grade TPE compounds that lack consistency in crosslink density and polymer chain uniformity. These materials exhibit rapid compression set, reduced tensile strength, and poor recovery after deformation. In dynamic applications where the window cycles hundreds or thousands of times, such deficiencies manifest as binding, tearing, or loss of glass retention. Furthermore, inadequate resistance to ozone and UV radiation leads to surface cracking—a failure mode commonly observed in seals exposed to direct sunlight in automotive side windows.

Precision-engineered seals require purpose-formulated elastomers. For high-temperature environments exceeding 120°C, such as in engine compartment adjacent glazing or in tropical climates, hydrogenated nitrile (HNBR) offers superior thermal stability and oil resistance. For general automotive applications, peroxide-cured EPDM with controlled molecular weight distribution ensures optimal balance between flexibility and durability. Our proprietary formulations incorporate reinforcing fillers and advanced anti-degradant packages to extend service life beyond 100,000 cycles under accelerated testing.

The mechanical behavior of the seal is equally dependent on compound rheology. A material with improper hardness or elastic modulus will either over-compress, causing excessive friction, or under-compress, leading to glass rattle and water ingress. Shore A hardness must be tailored to the glass thickness and channel geometry, typically ranging between 55 and 75. Tear strength should exceed 25 kN/m to resist nick propagation during installation or operation.

Below is a comparative analysis of elastomer performance characteristics relevant to window channel applications:

| Material | Shore A Hardness Range | Tensile Strength (MPa) | Elongation at Break (%) | Heat Resistance (°C) | Ozone Resistance | Cycle Life (Est.) |

|---|---|---|---|---|---|---|

| Standard EPDM | 50–65 | 8–12 | 250–350 | 100–120 | Good | 30,000–50,000 |

| High-Grade EPDM | 55–75 | 15–18 | 400–500 | 130–150 | Excellent | 80,000–120,000 |

| HNBR | 60–80 | 20–25 | 300–400 | 150–180 | Excellent | 100,000–150,000 |

| TPE (Low-Grade) | 50–60 | 6–9 | 200–300 | 80–100 | Poor | 10,000–20,000 |

Generic solutions fail because they ignore the interdependence of material properties and application dynamics. At Suzhou Baoshida, we engineer seals based on comprehensive OEM specifications, ensuring compatibility with glass surface coatings, door assembly tolerances, and environmental exposure profiles. Material selection is not a compromise—it is a calculated engineering decision that defines system integrity.

Material Specifications

Material Specifications for Precision Window Channel Seals

Material selection for window channel seals directly impacts sealing integrity, service life, and environmental compatibility. At Suzhou Baoshida Trading Co., Ltd., we engineer compounds to meet stringent OEM performance thresholds under dynamic compression, UV exposure, and chemical contact. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three critical elastomer families, each optimized for distinct operational profiles. Understanding their intrinsic properties ensures alignment with application demands in automotive, architectural, and industrial glazing systems.

Viton fluoroelastomers deliver exceptional resistance to high temperatures (up to 250°C continuous), ozone, and aggressive automotive fluids including brake fluids, fuels, and lubricants. This makes Viton ideal for under-hood window mechanisms or high-exposure exterior channels where thermal degradation and chemical swelling must be minimized. Its superior compression set resistance maintains seal force over extended cycles, though higher raw material costs necessitate targeted use in critical sealing zones.

Nitrile rubber remains the industry standard for cost-sensitive applications requiring robust oil and fuel resistance. With a functional temperature range of -40°C to 120°C, NBR formulations balance tensile strength (15–25 MPa) and abrasion resistance for sliding window channels. Standard grades resist hydraulic fluids and aliphatic hydrocarbons but exhibit limitations against polar solvents, ketones, and prolonged high-temperature exposure. Custom hydrogenated NBR (HNBR) variants extend thermal stability to 150°C while improving ozone resistance.

Silicone elastomers excel in extreme temperature environments (-60°C to 230°C), offering unmatched flexibility at cryogenic conditions and stability under intense solar radiation. Low compression set and excellent weathering resistance make Silicone suitable for architectural curtain walls and sunroof channels exposed to thermal cycling. However, its lower tensile strength (5–10 MPa) and susceptibility to tearing require careful profile design. Silicone also demonstrates poor resistance to concentrated acids and hydrocarbon fuels.

The following table summarizes key comparative specifications for engineered window channel applications:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 12–20 | 15–25 | 5–10 |

| Compression Set (ASTM D395, 22h/150°C) | ≤25% | ≤35% | ≤20% |

| Key Chemical Resistance | Fuels, oils, acids | Oils, aliphatic fuels | Ozone, UV, water |

| Key Limitations | Cost, low-temp flexibility | Poor ketone/solvent resistance | Low tear strength, hydrocarbon vulnerability |

| Primary Applications | High-temp automotive channels, aerospace | Standard automotive glass channels, industrial machinery | Architectural glazing, extreme climate exposure |

Suzhou Baoshida prioritizes material-validation through ISO 1817 fluid immersion testing and dynamic compression set analysis per SAE J2236. Our OEM partnerships leverage this data to prescribe application-specific compounds, ensuring window channel seals maintain dimensional stability and sealing force across 100,000+ operational cycles. Material choice must correlate with fluid exposure profiles, thermal loads, and lifecycle cost analysis—not solely initial procurement price. Consult our engineering team for ASTM D2000-compliant compound certification and accelerated aging protocols tailored to your sealing architecture.

Manufacturing Capabilities

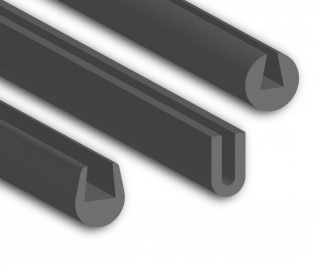

Engineering Capability in Precision Rubber Sealing for Window Channel Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in precision rubber sealing solutions, particularly in the development and production of window channel seals for the automotive and transportation industries. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we combine material science with advanced tooling design to deliver high-performance, application-specific sealing systems.

Our formula engineers possess deep expertise in elastomer chemistry, focusing on optimizing rubber compounds for dynamic sealing environments. They formulate custom EPDM, silicone, and TPE blends tailored to meet stringent OEM requirements for compression set resistance, UV stability, low-temperature flexibility, and long-term durability. Each formulation is developed with lifecycle performance in mind, ensuring consistent sealing force, minimal friction, and resistance to weathering and ozone degradation—critical attributes for window channel functionality.

Complementing our material innovation is our in-house mould engineering team. These professionals specialize in the design and refinement of precision extrusion and splicing tooling used in window channel seal manufacturing. Their work ensures tight dimensional tolerances, seamless corner splicing, and consistent cross-sectional profiles—key factors in achieving smooth glass movement and effective environmental sealing. Utilizing advanced CAD/CAM software and GD&T principles, our engineers translate customer specifications into robust, production-ready tooling with rapid prototyping cycles.

We operate as a full-service OEM partner, capable of managing projects from concept to mass production. Our vertical integration allows seamless coordination between formula development, tooling design, and manufacturing execution. This integrated approach reduces development lead times, enhances quality control, and ensures traceability across batches—essential for automotive Tier 1 suppliers and OEMs requiring IATF 16949 compliance.

Our engineering team routinely collaborates with client R&D departments to co-develop seals that meet exact performance envelopes, including acoustic insulation, force-to-extract (FTE) optimization, and aesthetic integration with window frames. With full material testing capabilities—including tensile strength, elongation at break, Shore A hardness, and thermal aging—we validate every formulation and design iteration under real-world conditions.

The following table outlines key engineering specifications and performance parameters typical of our window channel seals:

| Parameter | Typical Value / Range | Test Standard |

|---|---|---|

| Material Type | EPDM, TPE, Silicone | ASTM D1418 |

| Shore A Hardness | 55–75 | ASTM D2240 |

| Tensile Strength | ≥9.0 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Temperature Range | -40°C to +125°C (EPDM) | ISO 1817 |

| Splice Strength | ≥85% of base material | Internal Test Method |

| UV/Ozone Resistance | Pass (1000h) | ISO 105-B02 / ISO 1431 |

Through a disciplined fusion of material science and precision engineering, Suzhou Baoshida delivers window channel seals that meet the highest standards of performance, reliability, and manufacturability in global automotive applications.

Customization Process

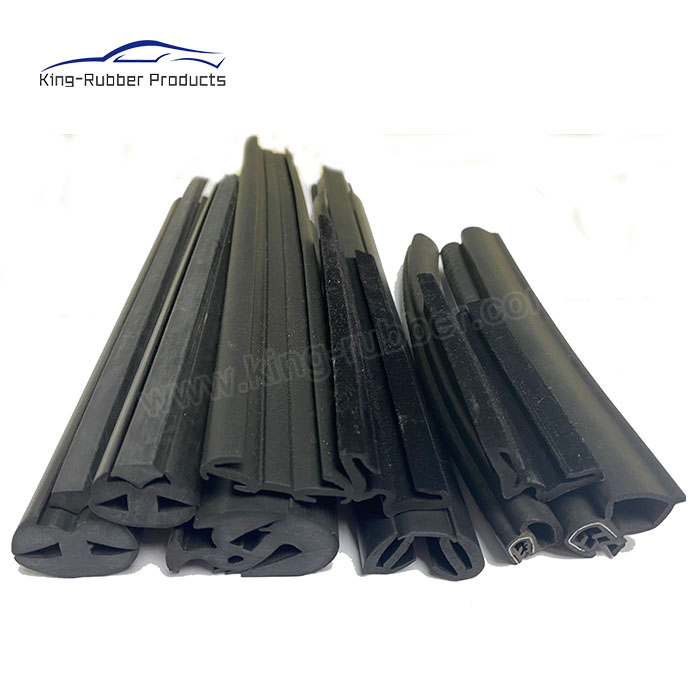

Precision Customization Process for Automotive Window Channel Seals

At Suzhou Baoshida Trading Co., Ltd., our window channel seal customization follows a rigorously controlled engineering pathway to ensure dimensional accuracy, environmental resilience, and seamless OEM integration. This four-phase methodology eliminates guesswork and accelerates time-to-market for automotive clients requiring mission-critical sealing performance.

Drawing Analysis and Feasibility Assessment

Our engineering team initiates every project with a granular review of client CAD drawings and technical specifications. We validate critical parameters including cross-sectional tolerances (typically ±0.1mm), installation force requirements, and dynamic deflection profiles against SAE J1047 and ISO 11445 standards. Finite element analysis (FEA) simulates compression set behavior under real-world thermal cycling (-40°C to +120°C) and UV exposure. Any geometric conflicts with extrusion tooling or splicing methodologies are flagged within 72 hours, accompanied by data-driven redesign recommendations to prevent downstream production failures.

Material Formulation Development

Leveraging 15+ years of compound expertise, we engineer proprietary EPDM formulations tailored to the seal’s operational environment. Key performance targets—such as ozone resistance (ASTM D1149), low-temperature flexibility (ASTM D746), and adhesion to glass coatings—are achieved through precise polymer selection (e.g., terpolymer vs. quadpolymer EPDM), filler systems, and cure package optimization. All formulations undergo accelerated aging tests per ASTM D2000 to validate 10-year service life under automotive hood conditions. Critical material properties are documented in the table below.

| Specification Parameter | Standard Range (EPDM) | Test Method | Customization Limit |

|---|---|---|---|

| Shore A Hardness | 60–75 | ASTM D2240 | ±2 units |

| Tensile Strength (MPa) | ≥10.0 | ASTM D412 | Up to 15.0 MPa |

| Elongation at Break (%) | ≥250 | ASTM D412 | Up to 400% |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395 | ≤18% achievable |

| Temperature Range (°C) | -50 to +135 | ISO 188 | -55 to +150 |

Prototyping and Validation

Prototypes are manufactured using production-intent tooling on our 90mm rubber extruders with laser-guided cutoff systems. Each sample undergoes:

Dimensional verification via CMM against the original drawing with GD&T callouts.

Functional testing on OEM-simulated window regulators measuring insertion force, water retention (SAE J2803), and acoustic leakage.

Material certification through third-party labs for REACH/ELV compliance.

Client feedback is incorporated within 10 business days, with iterative adjustments to compound or profile geometry until all KPIs are met.

Controlled Mass Production

Upon prototype sign-off, we transition to ISO/TS 16949-certified production lines with real-time SPC monitoring. Extrusion speed, vulcanization temperature (160–180°C), and splice integrity are continuously tracked via IoT sensors. Each production batch includes:

In-process checks of durometer and visual defects at 30-minute intervals.

Full material property revalidation per ASTM D2000 every 500kg.

Traceability via laser-etched batch codes linking to raw material COAs and process parameters.

This closed-loop system ensures ≤50 PPM defect rates while maintaining ±0.05mm profile consistency across 500,000+ units.

Suzhou Baoshida’s engineering-led customization guarantees window channel seals that meet exact OEM performance envelopes—reducing assembly line downtime and eliminating field warranty risks through material science precision.

Contact Engineering Team

For manufacturers and OEMs requiring high-performance window channel seals, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber sealing solutions tailored to automotive, construction, and industrial applications. Our window channel seals are designed to ensure optimal fit, durability, and weather resistance, meeting the exacting standards of global clients. As a trusted partner in rubber component manufacturing, we combine advanced material science with strict quality control to produce seals that perform under extreme environmental conditions.

Our production process leverages high-quality EPDM, silicone, and thermoplastic rubber compounds, selected for their resilience, UV resistance, and long-term compression set performance. Each window channel seal is extruded with micron-level accuracy, ensuring dimensional consistency and seamless integration into glazing systems. Whether you require custom profiles, co-extruded variants with fabric reinforcement, or seals with integrated adhesive backing, Suzhou Baoshida provides scalable manufacturing solutions with rapid prototyping and tooling support.

We understand that reliability in sealing performance directly impacts end-product longevity and user safety. That is why all our window channel seals undergo rigorous testing for tensile strength, elongation, temperature resistance, and adhesion durability. Our in-house laboratory validates performance against international standards, including ISO 3302, ISO 4095, and ASTM D2000, ensuring compliance with automotive OEM specifications.

To support global supply chains, we offer just-in-time delivery, comprehensive documentation (including material certifications and PPAP files), and full traceability across production batches. Our technical team works closely with engineering partners to optimize seal geometry, durometer, and compound formulation based on application-specific load and environmental exposure requirements.

For immediate technical consultation or to initiate a project, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in rubber formulation and industrial sealing solutions, Mr. Boyce leads client engagement for custom development and volume manufacturing programs. Reach him directly via email at [email protected] to discuss material selection, prototype timelines, or qualification testing protocols.

Below are key technical specifications for our standard window channel seal offerings:

| Property | Test Method | Value |

|---|---|---|

| Material Type | – | EPDM, Silicone, TPE |

| Hardness (Shore A) | ISO 868 | 55–85 ±5 |

| Tensile Strength | ISO 37 | ≥8.0 MPa |

| Elongation at Break | ISO 37 | ≥250% |

| Temperature Range | – | -50°C to +150°C |

| Compression Set (22 hrs, 100°C) | ISO 815 | ≤25% |

| UV Resistance | ISO 4892-2 | Pass (5000 hrs) |

| Adhesion Strength (to glass) | Internal | ≥8 N/cm |

| Extrusion Tolerance | ISO 3302 | ±0.2 mm |

Partner with Suzhou Baoshida for technically advanced, consistently manufactured window channel seals. Initiate your project today by contacting Mr. Boyce at [email protected].

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).