Technical Contents

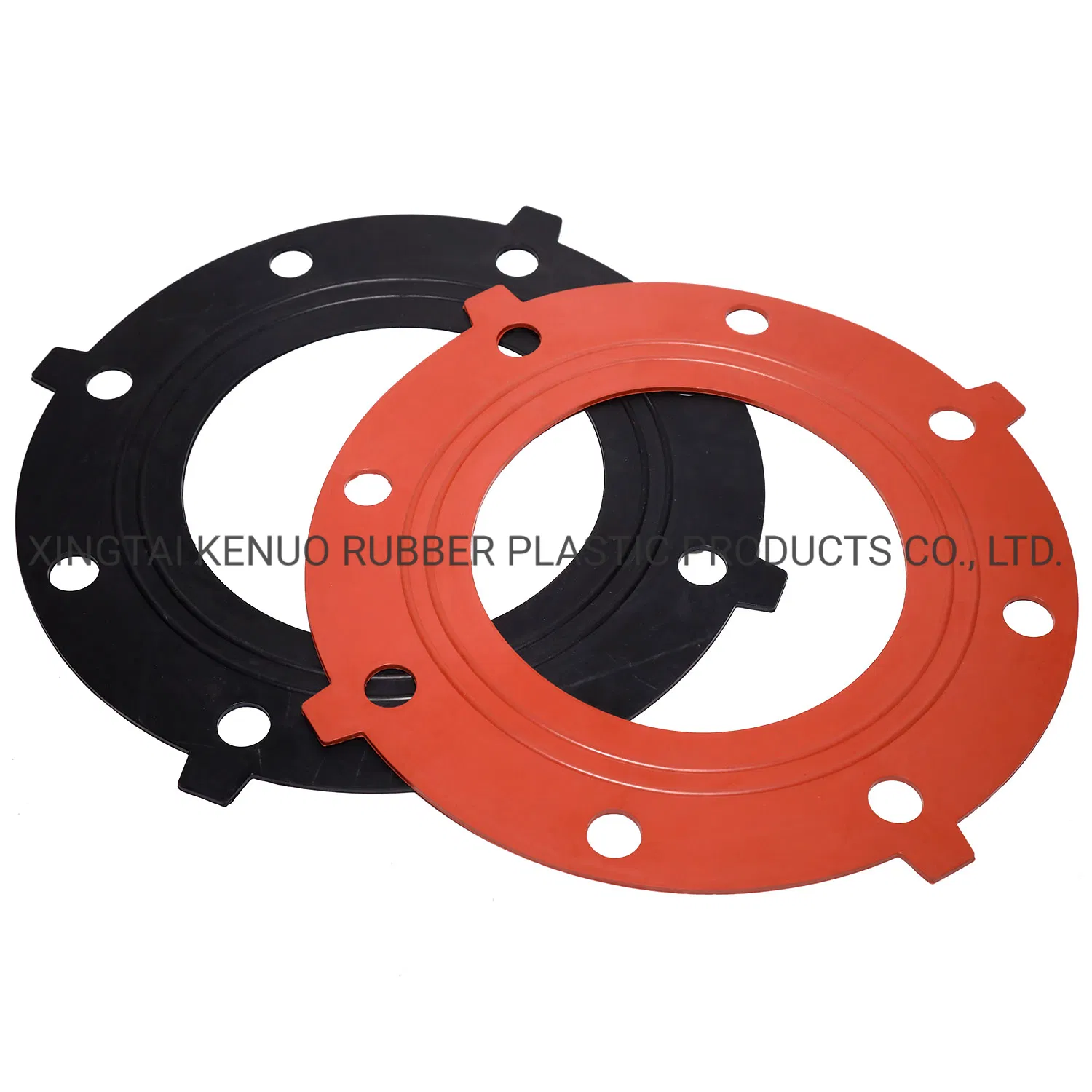

Engineering Guide: Flange Gasket

Engineering Insight: Material Selection Criticality in Flange Gasket Performance

Flange gasket failure remains a leading cause of industrial system downtime, often traceable to inadequate material selection. Off-the-shelf gaskets, while cost-attractive, frequently lack the precision engineering required for demanding operational environments. Generic solutions assume uniform conditions, yet real-world applications involve complex, dynamic variables—chemical exposure, thermal cycling, pressure fluctuations, and mechanical stress—that standard formulations cannot reliably withstand. Material mismatch directly compromises seal integrity, leading to leaks, contamination, or catastrophic joint failure.

The core issue lies in the oversimplification of service conditions. A gasket exposed to intermittent hydrocarbon solvents at 120°C requires fundamentally different polymer chemistry than one handling steam at 180°C in a food processing line. Standard NBR gaskets degrade rapidly in ozone-rich environments, while basic EPDM variants fail under hydraulic fluid exposure. Compression set—the permanent loss of elasticity after compression—is a critical failure mode often overlooked in non-customized products. Poor resistance leads to irreversible deformation, eliminating the sealing force needed to maintain joint integrity over time. Chemical permeation further accelerates degradation, allowing media to migrate through the polymer matrix, causing swelling, embrittlement, or extraction of critical additives.

Material selection must align with four non-negotiable parameters: media compatibility, temperature extremes, pressure profile, and regulatory compliance. Below is a comparative analysis of common elastomers under industrial stressors:

| Material | Continuous Temp Range (°C) | Key Chemical Resistance | Critical Limitation | Typical Failure Mode in Mismatched Applications |

|---|---|---|---|---|

| NBR | -30 to +100 | Oils, fuels, aliphatic hydrocarbons | Poor ozone/weathering resistance | Swelling in polar solvents; rapid cracking in outdoor ozone exposure |

| EPDM | -50 to +150 | Steam, water, alkalis, ketones | Limited oil/fuel resistance | Severe swelling in hydraulic oils; loss of sealing force |

| FKM | -20 to +230 | Acids, fuels, aromatics, high-temp oils | Poor low-temp flexibility; high cost | Brittleness below -15°C; inadequate for cryogenic cycling |

| FFKM | -15 to +325 | Virtually all chemicals, extreme temps | Exceptional cost; complex fabrication | Economic inefficiency in mild-service applications |

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through application-specific compound development. Our engineering process begins with rigorous media immersion testing per ASTM D471 and thermal aging validation per ISO 188. We formulate proprietary blends—such as peroxide-cured EPDM for steam systems or specialty FKM with enhanced low-temperature flexibility—tailored to the client’s exact pressure-temperature envelope and chemical exposure profile. This precision prevents the false economy of off-the-shelf gaskets, where initial savings are dwarfed by maintenance costs, environmental penalties, and production losses from preventable failures.

Material science is not a commodity. In flange sealing, the margin between success and failure is defined by molecular-level compatibility. Partnering with an OEM focused on engineered elastomer solutions ensures gaskets perform as integral system components, not disposable weak points. Suzhou Baoshida delivers this assurance through data-driven formulation and relentless application validation.

Material Specifications

Flange gaskets are critical sealing components in industrial systems where reliability under pressure, temperature, and chemical exposure is essential. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet stringent operational demands across oil & gas, chemical processing, automotive, and pharmaceutical industries. The performance of a flange gasket is inherently tied to its material composition. Our primary elastomer offerings—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are selected based on compatibility with media, thermal stability, and mechanical resilience.

Viton, a fluorocarbon-based rubber, exhibits exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains integrity from -20°C to +200°C, with intermittent exposure capability up to 230°C. This makes Viton ideal for sealing applications in refining, petrochemical, and aerospace environments where exposure to aromatic hydrocarbons and chlorinated solvents is common. Its low gas permeability and excellent aging characteristics ensure long-term reliability in dynamic and static flange joints.

Nitrile rubber, also known as Buna-N, is a cost-effective solution for applications involving petroleum-based fluids, hydraulic oils, and aliphatic hydrocarbons. With a service temperature range of -30°C to +100°C (up to 120°C intermittently), NBR offers strong abrasion resistance and mechanical strength. It is widely used in automotive, hydraulics, and general industrial systems. While not suitable for ozone or weathering exposure without special compounding, standard NBR formulations provide dependable performance in oil-handling equipment and compressed air systems.

Silicone rubber excels in extreme temperature environments, operating reliably from -60°C to +200°C. It demonstrates outstanding resistance to UV, ozone, and weathering, making it suitable for outdoor and high-purity applications. Silicone is commonly specified in food, pharmaceutical, and medical industries due to its inertness, low toxicity, and compliance with FDA and USP Class VI standards. While it has relatively lower tensile strength and abrasion resistance compared to Viton or Nitrile, its flexibility at low temperatures and biocompatibility are unmatched.

Material selection must consider not only chemical and thermal exposure but also compression set, sealing force, and flange surface finish. All gaskets from Suzhou Baoshida are manufactured under ISO 9001-certified processes, ensuring dimensional accuracy and repeatability.

The following table summarizes key physical and chemical properties of the three elastomers:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–450 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliance | Optional | Limited | Standard |

Proper material selection ensures optimal sealing performance, longevity, and system safety. Our engineering team supports OEMs and industrial clients in matching gasket materials to application-specific requirements.

Manufacturing Capabilities

Engineering Capability: Precision Flange Gasket Development & OEM Execution

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise to deliver flange gaskets meeting the most stringent industrial sealing demands. Our core strength resides in the integrated capabilities of our dedicated engineering team, comprising five specialized Mould Engineers and two advanced Rubber Formula Engineers. This structure ensures seamless synergy between material science and precision manufacturing, eliminating traditional silos that compromise performance. Our Formula Engineers develop proprietary elastomer compounds tailored to specific chemical, thermal, and pressure environments, utilizing accelerated aging tests and dynamic mechanical analysis to validate long-term resilience. Concurrently, Mould Engineers optimize tooling geometry, flow dynamics, and cure profiles to achieve micron-level dimensional accuracy and eliminate flash or knit lines—critical for zero-leakage performance in high-integrity flange joints.

This cross-functional rigor directly enables our robust OEM partnership model. We manage the entire product lifecycle in strict confidentiality, from initial material specification and CAD-based gasket design to production validation and volume manufacturing. Clients benefit from our ability to reverse-engineer legacy gaskets, enhance existing formulations for extended service life, or co-develop novel solutions for emerging applications. Our OEM process includes comprehensive Failure Mode and Effects Analysis (FMEA) at the design stage and full material traceability via integrated ERP systems, ensuring compliance with ISO 9001 and industry-specific standards like API 607/6FA. Crucially, all intellectual property remains the client’s exclusive asset, protected under rigorous non-disclosure frameworks with a zero-history of leakage.

Material and dimensional precision are non-negotiable. Below outlines key specifications achievable through our engineered approach:

| Parameter | Standard Capability | Precision Tier Capability | Testing Standard |

|---|---|---|---|

| Material Types | NBR, EPDM, FKM, HNBR, Silicone | Custom peroxide-cured FKM/FFKM | ASTM D2000, ISO 3601 |

| Hardness Range | 50–90 Shore A | 45–95 Shore A ±2 | ASTM D2240 |

| Temp Range | -40°C to +230°C | -55°C to +325°C | ASTM D573 |

| Pressure Rating | Up to 420 bar | Up to 700 bar | EN 1591-1 |

| Dimensional Tolerance | ±0.25 mm | ±0.05 mm (critical zones) | ISO 3302 |

Validation protocols exceed baseline requirements. Every gasket batch undergoes compression set testing per ASTM D395, fluid resistance evaluation in client-specified media, and 100% visual inspection for surface defects. For critical OEM programs, we implement in-process statistical process control (SPC) monitoring of key dimensions and hardness, with real-time data shared via secure client portals. This granular oversight—paired with our engineers’ ability to rapidly iterate designs based on field feedback—ensures consistent performance in demanding applications across oil & gas, semiconductor, and chemical processing sectors. Suzhou Baoshida transforms sealing challenges into engineered advantages through material mastery and manufacturing discipline.

Customization Process

Flange Gasket Customization Process: From Design to Production

At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for critical flange sealing applications across industrial, automotive, and energy sectors. Our customization process ensures that each flange gasket meets exact operational demands, including pressure, temperature, chemical exposure, and mechanical stress. The process follows a structured workflow: Drawing Analysis, Formulation Development, Prototyping, and Mass Production—each phase designed to deliver optimal performance and reliability.

The first step, Drawing Analysis, involves a comprehensive review of customer-provided technical drawings and specifications. Our engineering team evaluates critical dimensions, surface finish requirements, bolt hole patterns, and flange standards (e.g., ASME, DIN, JIS). We assess sealing surface geometry and operating conditions to identify potential compression set risks, creep relaxation, or extrusion vulnerabilities. This stage ensures dimensional accuracy and compatibility with mating components, forming the foundation for material and design decisions.

Following drawing validation, we proceed to Formulation Development. Based on the application environment, our rubber chemists select the optimal elastomer compound. Common base materials include Nitrile (NBR) for oil resistance, EPDM for weather and steam resistance, Fluorocarbon (FKM) for high-temperature and chemical stability, and Silicone (VMQ) for extreme temperature flexibility. Additives such as reinforcing fillers, antioxidants, and processing aids are precisely blended to achieve target hardness (Shore A 50–90), tensile strength, and compression set performance. Each formulation is documented and batch-traceable to ensure consistency.

Prototyping is the next critical phase. Using precision die-cutting or molded manufacturing techniques, we produce a limited run of gaskets for functional testing. These prototypes undergo rigorous evaluation, including compression testing, leak rate analysis under simulated operating conditions, and chemical immersion trials. We collaborate with clients to validate fit, form, and function, making iterative adjustments if necessary. This stage minimizes risk before full-scale production and confirms compliance with industry standards.

Upon approval, we transition to Mass Production. Our automated production lines, supported by strict quality control protocols, ensure high repeatability and efficiency. Each batch is inspected for dimensional accuracy, visual defects, and material consistency. Final products are packaged to prevent deformation and shipped with material certifications and test reports.

The following table summarizes typical specifications for custom flange gaskets:

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Material Types | NBR, EPDM, FKM, VMQ, CR, SBR | Blends, specialty compounds |

| Hardness (Shore A) | 50–90 | ±5 Shore A tolerance |

| Thickness | 0.5 mm – 6.0 mm | Up to 10 mm with support rings |

| Temperature Range | -40°C to +250°C (material-dependent) | Extended ranges with FKM/PTFE |

| Pressure Resistance | Up to 40 bar (seal-dependent) | Higher with reinforced designs |

| Standards Compliance | ASTM D2000, ISO 3601, ASME B16.21 | Customer-specific certifications |

Through this disciplined customization pathway, Suzhou Baoshida delivers flange gaskets that ensure long-term sealing integrity, reduce downtime, and meet the highest industrial standards.

Contact Engineering Team

Initiate Precision Flange Gasket Engineering Collaboration with Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial sealing reliability. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that flange gasket performance hinges on material composition rigorously aligned with operational parameters—not generic specifications. Our formulations undergo iterative validation against ASTM D2000 classification standards, fluid compatibility per ISO 1817, and compression set testing under ISO 3386 conditions. This ensures dimensional stability under cyclic thermal loads and prevents critical failure modes like extrusion or stress relaxation in high-pressure systems. Generic gasket suppliers cannot replicate the molecular crosslinking precision required for your unique media exposure and flange geometry.

Material selection must address your specific chemical environment, temperature transients, and surface finish tolerances. For instance, standard NBR compounds fail catastrophically in ozone-rich settings, while improperly cured FKM exhibits excessive compression set above 180°C. Our laboratory utilizes DMA (Dynamic Mechanical Analysis) to map viscoelastic behavior across your operational spectrum, enabling bespoke polymer blends that maintain seal integrity where off-the-shelf products degrade. Consider the following baseline specifications for common industrial scenarios—actual formulations are engineered per your technical dossier:

| Material | ASTM D2000 Line Callout | Temp Range (°C) | Compression Set (70h/100°C) | Max Continuous Pressure (MPa) |

|---|---|---|---|---|

| Hydrogenated NBR | AG 714 | -40 to 150 | ≤18% | 25 |

| Peroxide-Cured EPDM | BE 744 | -55 to 165 | ≤22% | 18 |

| Low-Temp FKM | CF 7575 | -25 to 230 | ≤15% | 30 |

These values represent minimum validated performance thresholds; final compounds are optimized for your flange class (ASME B16.5), bolt torque sequence, and fugitive emission requirements per ISO 15848. We reject one-size-fits-all solutions—every gasket is a system component requiring co-engineering.

Partnering with Suzhou Baoshida means direct access to our material science team for root-cause analysis of field failures, accelerated aging protocols simulating 10+ years of service, and seamless transition from prototype to serial production under IATF 16949 controls. Our OEM framework includes joint DFMEA development and real-time process capability monitoring (CpK ≥1.67) at our Suzhou manufacturing facility. Do not compromise sealing integrity with unverified material substitutions or inadequate compression characteristics.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Engineering Liaison, to discuss your flange gasket requirements. Provide your operational parameters, fluid composition data, and flange assembly specifications for a material suitability assessment within 72 hours. Mr. Boyce possesses direct authority to mobilize our compounding laboratory and will coordinate cross-functional review with our quality engineering and production teams. Contact him exclusively at [email protected] with subject line: “Flange Gasket Engineering Request – [Your Company Name]”. Include your target service life, regulatory certifications (e.g., TA-Luft, PED 2014/68/EU), and dimensional drawings for immediate technical triage. Suzhou Baoshida delivers not gaskets, but engineered sealing assurance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).