Technical Contents

Engineering Guide: Diffuser For Lighting

Engineering Insight: Material Selection in Diffusers for Lighting

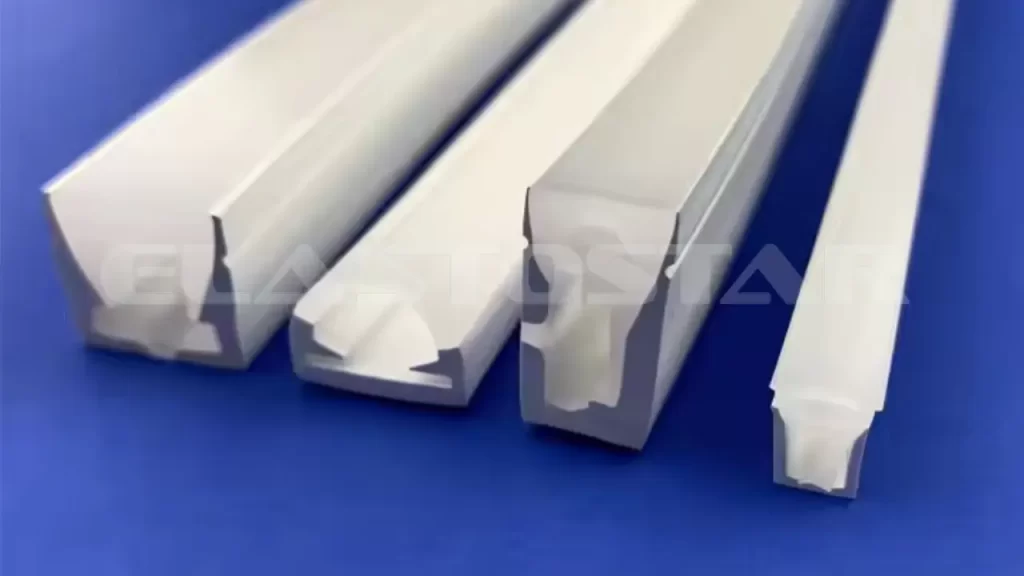

In industrial lighting applications, the diffuser serves as a critical interface between light source and environment. Its primary function extends beyond mere light distribution—it influences optical performance, thermal stability, mechanical durability, and long-term reliability. While many manufacturers default to off-the-shelf polymer solutions such as standard polycarbonate or acrylic, these materials frequently fail under sustained industrial operating conditions. The root cause lies in inadequate material engineering for real-world stressors including UV exposure, thermal cycling, chemical contamination, and mechanical deformation.

Standard thermoplastics used in consumer-grade diffusers exhibit rapid photodegradation when exposed to high-intensity LED arrays or UV-rich environments. This leads to yellowing, reduced light transmission, and compromised aesthetic integrity. Furthermore, these materials often possess low heat deflection temperatures, making them prone to warping in enclosed or high-ambient-temperature fixtures. Industrial lighting systems, particularly those deployed in manufacturing, warehousing, or outdoor infrastructure, demand materials engineered to withstand continuous thermal loads exceeding 85°C.

At Suzhou Baoshida Trading Co., Ltd., we emphasize the strategic use of engineered rubber-polycarbonate composites and thermoplastic elastomer (TPE) hybrids tailored for optical diffusion. These formulations provide superior balance between optical clarity, impact resistance, and thermal resilience. Unlike conventional plastics, our custom-compounded materials incorporate UV stabilizers, anti-yellowing agents, and nano-dispersed fillers that maintain luminous efficacy over 50,000+ hours of operation.

A key differentiator lies in the interfacial compatibility between rubber phase and rigid polymer matrix. Poorly dispersed elastomeric domains scatter light non-uniformly, creating hotspots or glare. Our precision compounding process ensures sub-micron dispersion, enabling consistent Lambertian diffusion while retaining mechanical toughness. This level of control is unattainable with generic materials, where batch variability and unoptimized morphology lead to field failures.

Below is a comparative specification table highlighting performance differences between standard materials and Baoshida-engineered solutions:

| Property | Standard Polycarbonate | Acrylic (PMMA) | Baoshida Rubber-PC Composite |

|---|---|---|---|

| Light Transmission (%) | 88–90 | 92–94 | 85–88 |

| Haze (%) | 0.5–1.0 | 0.8–1.2 | 65–75 |

| Heat Deflection Temperature (°C) | 115 | 90 | 135 |

| Tensile Strength (MPa) | 60–65 | 50–55 | 55–60 |

| Elongation at Break (%) | 100–120 | 30–50 | 180–220 |

| UV Resistance (QUV, 1000h) | Moderate degradation | Severe yellowing | <5% ΔYI |

| Impact Strength (kJ/m²) | 60–70 | 15–20 | 85–95 |

The data illustrates that while off-the-shelf materials may offer higher initial transparency, they lack the holistic performance profile required in industrial settings. Baoshida’s engineered diffuser materials prioritize functional durability over nominal clarity, ensuring consistent optical output and structural integrity across extended service life. Material selection is not a cost-driven compromise—it is a precision engineering decision with direct impact on system reliability.

Material Specifications

Material Specifications for Lighting Diffuser Applications

Selecting the optimal elastomer for lighting diffusers requires precise evaluation of thermal stability, optical properties, and environmental resistance. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber compounds to meet stringent OEM performance criteria under continuous thermal cycling and UV exposure. Diffusers must maintain structural integrity while ensuring uniform light distribution without degradation-induced discoloration or haze. Viton, Nitrile (NBR), and Silicone represent three critical material solutions, each with distinct advantages for specific lighting architectures.

Viton (FKM) excels in high-temperature LED environments exceeding 200°C, leveraging its fluoropolymer backbone for exceptional resistance to thermal oxidation and non-polar solvents. Its low gas permeability prevents outgassing that could cloud optical surfaces, though inherent stiffness limits thin-section molding flexibility. Nitrile (NBR) offers cost-effective resilience against oils and greases encountered in industrial fixtures, with acrylonitrile content adjustable to balance fuel resistance and low-temperature flexibility down to -30°C. However, NBR’s unsaturated backbone necessitates robust antioxidant packages to mitigate UV-induced cracking in outdoor applications. Silicone (VMQ) provides superior optical clarity (transmittance >92%) and extreme temperature tolerance from -60°C to 230°C, with inherent UV stability eliminating yellowing risks. Its low compression set ensures long-term sealing force retention but requires specialized adhesion promoters for metal housing integration.

Critical performance parameters are quantified below per ASTM D2000 and ISO 188 standards:

| Material | Temperature Range (°C) | Key Properties | Limitations | Best Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 (continuous) | Exceptional chemical/solvent resistance; Low compression set; Minimal outgassing | High cost; Limited optical clarity; Stiff at low temps | High-intensity discharge (HID) lamps; Aerospace lighting; Chemical plant fixtures |

| Nitrile (NBR) | -30 to +120 (continuous) | Excellent oil/fuel resistance; Good abrasion resistance; Cost-efficient | Moderate UV resistance; Degrades in ozone; Limited high-temp stability | Industrial work lights; Automotive under-hood lighting; Machinery task lighting |

| Silicone (VMQ) | -60 to +230 (continuous) | Superior optical clarity; Outstanding UV/ozone resistance; Flexible at extreme temps | Lower tensile strength; Requires adhesion promoters; Higher compression set than FKM | Architectural LED panels; Medical lighting; Outdoor signage; Consumer smart lighting |

Material selection directly impacts diffuser service life and optical consistency. Viton suits extreme thermal/chemical exposure but requires cost justification. NBR delivers optimal value for oil-contaminated environments yet demands UV stabilization for exterior use. Silicone remains the benchmark for optical performance and weatherability across consumer and commercial segments. Suzhou Baoshida Trading Co., Ltd. validates all formulations through accelerated aging per IEC 60598-1, ensuring compliance with UL 94 V-0 flammability ratings and ISO 4835 light transmission standards. Consult our technical team to match compound chemistry to your thermal management and regulatory requirements.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Rubber Diffusers in Lighting Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance diffusers for lighting systems. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we deliver technically robust, application-specific components that meet the rigorous demands of modern LED and industrial lighting environments. Our integrated engineering approach ensures seamless alignment between material science, precision tooling, and manufacturing scalability.

Our two rubber formula engineers bring deep expertise in polymer chemistry and material behavior under thermal, optical, and mechanical stress. They formulate custom rubber compounds tailored to lighting diffuser requirements, focusing on optical clarity, UV resistance, thermal stability (up to 150°C), and flame retardancy (UL94 V-0 compliance). These formulations are engineered to maintain consistent light diffusion properties over extended operational cycles while resisting yellowing and degradation under prolonged exposure to high-intensity light sources. The precise balance of elastomeric properties ensures durability without compromising on optical performance.

Complementing material development, our five mould engineers specialize in high-precision tooling for complex diffuser geometries. Utilizing advanced CAD/CAM software and CNC machining, they design and fabricate multi-cavity silicone and EPDM rubber moulds with tight tolerances (±0.05 mm). Their expertise includes optimizing gating systems, venting, and ejection mechanisms to minimize flash, ensure uniform curing, and support high-volume production efficiency. This precision engineering reduces cycle times and enhances part-to-part consistency, critical for OEM clients requiring large-scale supply with zero deviation.

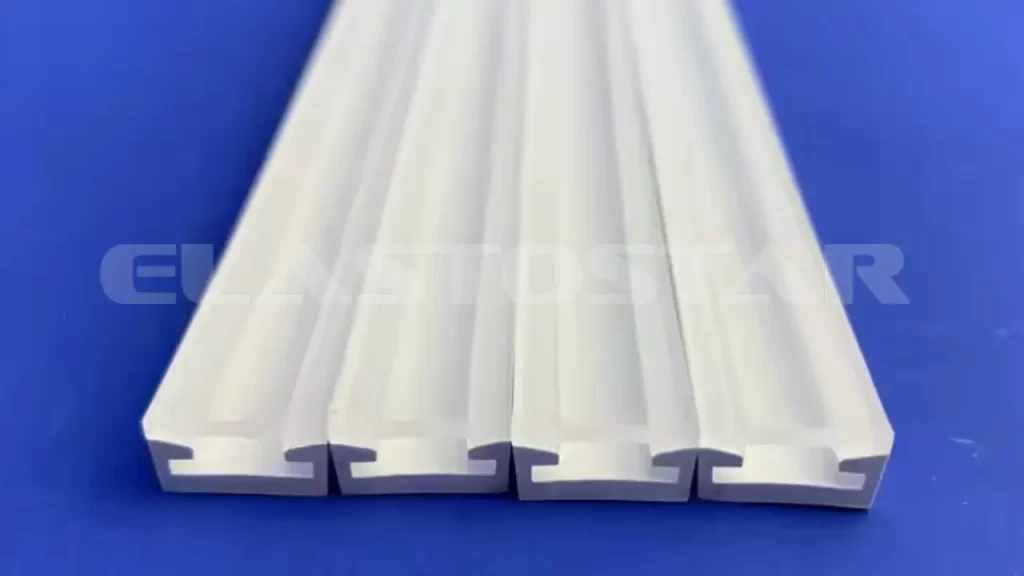

Our end-to-end OEM capability enables full-service collaboration from concept to mass production. Clients benefit from rapid prototyping, Design for Manufacturability (DFM) analysis, and iterative testing under real-world lighting conditions. We support customization in hardness (40–80 Shore A), color (including translucent and opal variants), and surface finish (matte, textured, or polished), ensuring compatibility with diverse fixture designs and photometric requirements.

The integration of formula and mould engineering within a single technical framework allows us to resolve interface challenges—such as adhesion between rubber and polycarbonate lenses or aluminum housings—through co-curing techniques and surface energy optimization. This holistic approach reduces assembly complexity and improves long-term reliability in demanding environments such as outdoor, industrial, and commercial lighting.

Below are key technical specifications achievable through our engineering platform:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Material Types | Silicone, EPDM, Custom-modified Rubber | RoHS, REACH, UL94 V-0 |

| Hardness (Shore A) | 40 – 80 | ASTM D2240 |

| Operating Temperature | -40°C to +150°C | IEC 60598 |

| Tolerance (Linear Dimensions) | ±0.05 mm | ISO 2768 |

| Optical Transmission | 85% – 92% (at 1mm thickness, diffused) | ASTM D1003 |

| Production Cycle Time | 60 – 180 seconds (per cavity) | Optimized for high volume |

| Tool Life | 500,000+ cycles (steel moulds) | H13, S136, or equivalent |

Suzhou Baoshida Trading Co., Ltd. leverages its dual-engineering strength to deliver technically superior rubber diffusers that enhance lighting efficiency, longevity, and design flexibility. Our OEM partnerships are built on precision, innovation, and repeatable quality—cornerstones of industrial leadership.

Customization Process

Customization Process for Industrial Lighting Diffusers

At Suzhou Baoshida Trading Co., Ltd., our customization process for rubber diffusers in lighting applications integrates material science with precision manufacturing. This ensures optimal light diffusion, thermal stability, and longevity under demanding operational conditions. The four-phase workflow begins with rigorous drawing analysis to translate client specifications into actionable engineering parameters.

Drawing Analysis

We initiate by dissecting technical drawings to assess critical dimensions, optical clarity requirements, and environmental exposure factors such as operating temperature ranges (typically -40°C to +150°C) and UV resistance needs. Tolerance validation against ISO 2768-mK standards is performed, with particular attention to surface texture (Ra ≤ 0.8 µm) to prevent light scattering anomalies. Material compatibility with adjacent components (e.g., LED housings, adhesives) is cross-referenced against chemical resistance databases to eliminate delamination risks.

Formulation Development

Based on the analysis, our rubber formula engineering team designs a proprietary elastomer compound. Standard formulations leverage silicone rubber (VMQ) for superior thermal stability, but custom variants may incorporate fluorosilicone (FVMQ) for extreme UV resistance or EPDM for cost-sensitive indoor applications. Key properties are optimized through polymer matrix adjustments, filler selection (e.g., fumed silica for clarity), and additive dosing. The table below outlines typical specification targets:

| Property | Standard VMQ Diffuser | Custom High-Performance Variant |

|---|---|---|

| Shore A Hardness | 55 ± 5 | 65 ± 3 |

| Tensile Strength (MPa) | ≥ 6.0 | ≥ 8.5 |

| Elongation at Break (%) | ≥ 300 | ≥ 250 |

| Light Transmission (%) | ≥ 90 | ≥ 92 |

| UV Resistance (ASTM G154) | 1,000 hrs (ΔE < 3) | 3,000 hrs (ΔE < 2) |

Prototyping and Validation

Prototypes are produced via precision injection molding using client-approved tooling. Each unit undergoes accelerated aging tests (85°C/85% RH for 1,000 hours), optical profiling via spectrophotometry, and mechanical validation per ASTM D2240/D412. Diffusion uniformity is quantified using goniophotometers to ensure luminance deviation remains below ±5%. Client feedback on optical performance and fitment triggers iterative refinements until all KPIs are met.

Mass Production

Upon prototype sign-off, we transition to IATF 16949-certified mass production. Real-time process monitoring tracks cavity pressure, cure time, and temperature gradients to maintain ±0.1 mm dimensional accuracy. Every batch undergoes 100% visual inspection for surface defects and抽样 testing for critical properties. Traceability is enforced via laser-etched batch codes, with full documentation including CoA, RoHS/REACH compliance certificates, and aging test reports provided per shipment.

This systematic approach minimizes time-to-market while guaranteeing diffusers withstand 50,000+ hours of operational stress. Suzhou Baoshida’s OEM framework ensures your lighting solution achieves uncompromised optical performance and reliability through scientifically validated rubber engineering.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Rubber Diffusers in Lighting Applications

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions engineered for precision applications, including optical diffusers used in modern LED and industrial lighting systems. As a trusted OEM partner, we combine material science expertise with advanced manufacturing capabilities to deliver diffuser components that meet stringent optical, thermal, and mechanical requirements. Our rubber-based diffusers are designed to provide uniform light distribution, enhanced durability, and long-term stability under extreme operating conditions.

We understand that lighting manufacturers demand consistency, clarity, and reliability from their optical components. That’s why our diffuser solutions are formulated using proprietary silicone and thermoplastic rubber (TPR) compounds that offer superior light diffusion, UV resistance, and thermal stability up to 200°C. Whether you require custom shapes, specific transmittance levels, or compliance with international safety standards such as UL94 V-0 or RoHS, our engineering team works closely with clients to tailor material properties and geometries to exact application needs.

Our production processes include precision injection molding, compression molding, and extrusion techniques, all conducted under ISO 9001-certified quality control systems. This ensures every diffuser component meets tight tolerance specifications and performs reliably across millions of lighting units. From prototyping to full-scale production, Suzhou Baoshida provides end-to-end support, reducing time-to-market and minimizing supply chain complexity.

Below are key technical specifications representative of our standard rubber diffuser offerings. Custom formulations are available upon request.

| Property | Value | Test Method |

|---|---|---|

| Material Type | Silicone Rubber / TPR | Internal Specification |

| Light Transmittance (550 nm) | 85% – 92% | ASTM D1003 |

| Diffusion Angle (Half Intensity) | 30° – 60° adjustable | Gonio-Photometry |

| Hardness (Shore A) | 40 – 70 | ASTM D2240 |

| Operating Temperature Range | -40°C to +200°C | Thermal Cycling Test |

| Thermal Conductivity | 0.25 – 0.45 W/m·K | ISO 22007-2 |

| Flame Rating | UL94 V-0 | UL94 |

| Color Options | Translucent White, Opal, Custom Tints | Pantone Matching |

| Tolerance (Dimensional) | ±0.1 mm | CMM Inspection |

For lighting OEMs seeking a reliable, responsive, and technically capable partner, Suzhou Baoshida delivers performance-driven rubber diffuser solutions backed by rigorous quality assurance and global logistics support. We serve clients across Europe, North America, and Asia, offering localized technical service and just-in-time delivery models.

To discuss your next-generation lighting project or request material samples and test reports, contact Mr. Boyce directly at [email protected]. Our engineering team is ready to collaborate on material selection, design optimization, and prototyping to ensure your diffuser meets both functional and commercial objectives. Partner with Suzhou Baoshida and leverage our industrial rubber expertise to enhance the performance and reliability of your lighting systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).