Technical Contents

Engineering Guide: 5 Mm Plastic Sheets

Engineering Insight: Material Selection Criticality for 5 mm Plastic Sheets in Industrial Applications

The selection of 5 mm plastic sheets represents a pivotal engineering decision far beyond mere dimensional specification. Industrial environments impose complex, simultaneous stresses—thermal cycling, chemical exposure, mechanical load, and environmental factors—that generic off-the-shelf sheets frequently cannot withstand. Failure to rigorously match material properties to the operational profile inevitably leads to premature degradation, catastrophic component failure, and significant unplanned downtime. Standard catalog offerings, optimized for broad market appeal and cost minimization, lack the tailored polymer morphology and additive packages required for demanding industrial use cases. This results in compromised performance where precision and reliability are non-negotiable.

Material science dictates that polymer choice fundamentally governs sheet behavior under stress. An unmodified polyethylene sheet may exhibit adequate initial flexibility but succumb rapidly to environmental stress cracking when exposed to common hydrocarbons or cleaning agents. Similarly, a standard PVC formulation might meet initial flame retardancy specs but degrade under prolonged UV exposure or elevated temperatures, leading to embrittlement and loss of structural integrity. Off-the-shelf solutions often utilize recycled content or basic stabilizer systems insufficient for continuous industrial service, introducing unpredictable variability in mechanical properties and accelerated aging. The consequence is not merely sheet replacement but potential damage to integrated machinery, safety hazards, and production line stoppages costing orders of magnitude more than the initial material savings.

Critical evaluation requires analyzing the specific application triad: chemical milieu, thermal profile, and mechanical demands. A sheet functioning adequately in a dry assembly jig may fail within weeks in a chemical processing plant due to solvent permeation and swelling. Temperature excursions beyond the material’s glass transition point (Tg) or continuous use temperature can cause irreversible creep, dimensional instability, or loss of load-bearing capacity, even if brief. Relying solely on nominal thickness (5 mm) ignores these intrinsic material limitations. Precision engineering demands sheets formulated with purpose-specific polymers, reinforced additives, and advanced stabilizers to resist the exact combination of stresses encountered.

Suzhou Baoshida Trading Co., Ltd. leverages deep OEM formulation expertise to move beyond commodity sheet limitations. We analyze your operational parameters to prescribe engineered compounds—be it cross-linked polyethylene for chemical resistance, glass-filled nylon for structural stability, or specialized fluoropolymers for extreme environments. Our 5 mm sheets are not cut from generic stock rolls; they are precision-engineered solutions where every additive serves a defined function against your failure modes.

Key Material Properties for Industrial 5 mm Sheet Selection

| Material Type | Tensile Strength (MPa) | Max Continuous Temp (°C) | Chemical Resistance (Typical Industrial) | Key Industrial Limitation |

|---|---|---|---|---|

| Standard ABS | 40-50 | 80 | Poor (Hydrocarbons, Esters) | Low UV resistance, Creep under load |

| General Purpose PVC | 50-60 | 60 | Moderate (Acids, Bases) | Plasticizer migration, UV degradation |

| Homopolymer PP | 30-35 | 100 | Excellent (Acids, Bases, Solvents) | Poor impact at low temp, UV sensitive |

| UHMWPE | 20-30 | 80 | Excellent (Hydrocarbons, Electrolytes) | Low stiffness, Creep susceptibility |

| Glass-Filled Nylon | 120-150 | 120 | Good (Oils, Fuels) | Moisture absorption, Hydrolysis risk |

| Baoshida Engineered Compound | Custom 80-180 | Custom 100-200 | Application-Specific Optimization | Designed to Eliminate Critical Failure Mode |

Material selection is not a cost line item but a foundational element of system reliability. Suzhou Baoshida provides the formulation precision necessary to transform 5 mm plastic sheets from potential failure points into engineered components ensuring operational continuity and longevity. Demand sheets engineered for your reality, not generic specifications.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered industrial rubber solutions tailored for high-performance applications across automotive, aerospace, chemical processing, and semiconductor manufacturing sectors. Our 5 mm plastic sheets are formulated from advanced elastomeric compounds, specifically Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected for distinct chemical, thermal, and mechanical properties. These sheets are manufactured under strict quality control standards to ensure dimensional accuracy, consistency, and reliability in demanding operational environments.

Viton 5 mm sheets offer exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. With continuous service capabilities up to 230°C and intermittent resistance to 260°C, Viton is ideal for sealing applications in fuel systems, engine compartments, and chemical exposure zones. Its low gas permeability and outstanding ozone and UV resistance further enhance durability in outdoor and high-stress environments.

Nitrile rubber sheets exhibit superior resistance to oils, fuels, and aliphatic hydrocarbons, making them a preferred choice for hydraulic seals, gaskets, and industrial machinery components. Operating effectively within a temperature range of -30°C to 100°C, NBR maintains mechanical integrity under dynamic compression and repeated stress. Its abrasion resistance and cost-efficiency position Nitrile as a reliable solution for medium-duty industrial applications.

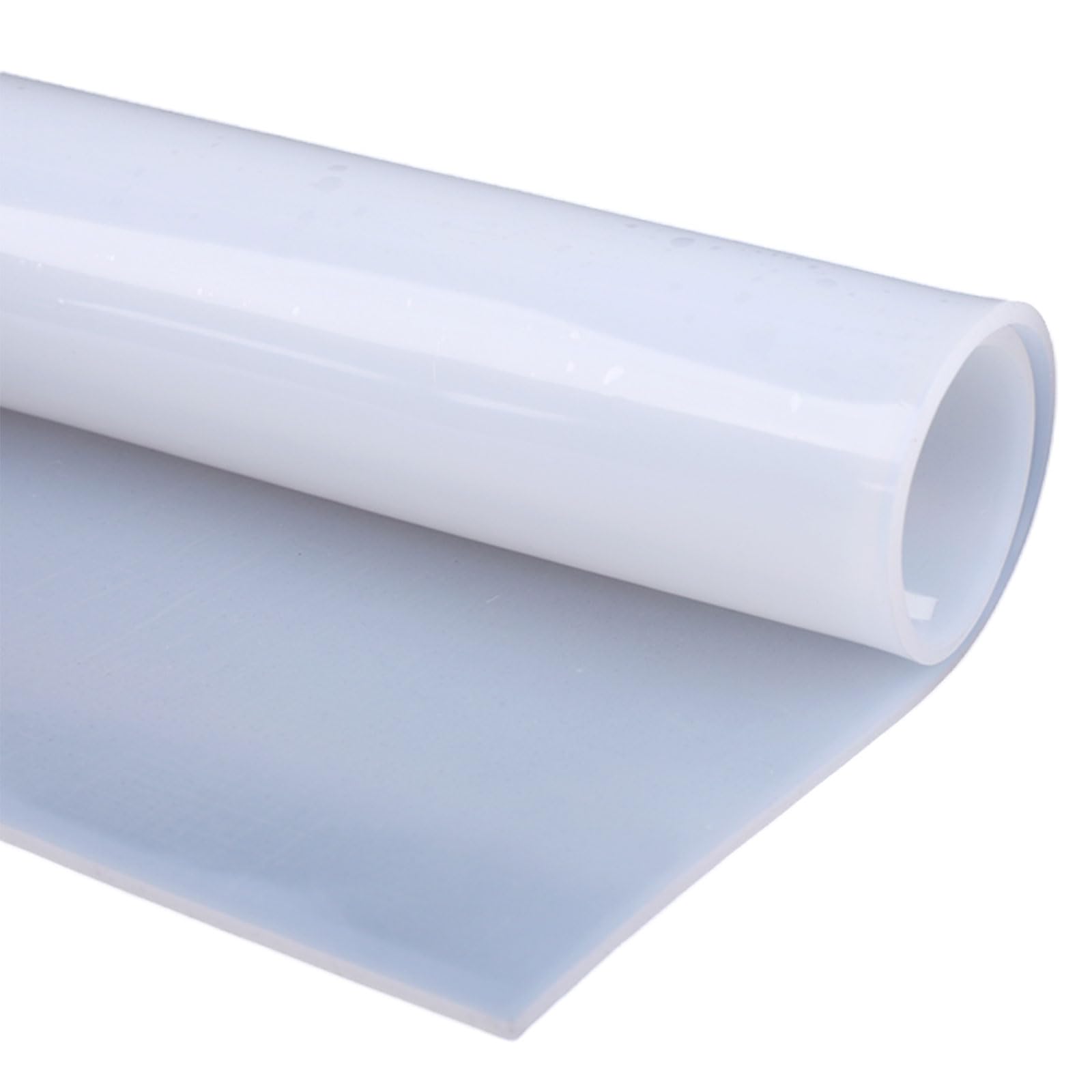

Silicone rubber 5 mm sheets are engineered for extreme temperature stability, functioning reliably from -60°C to 200°C. While possessing lower tensile strength compared to Viton and Nitrile, silicone excels in applications requiring flexibility at low temperatures, electrical insulation, and biocompatibility. It is widely used in medical devices, food processing equipment, and electronic enclosures where cleanliness and thermal cycling are critical.

All three materials are available in standard 5 mm thickness with tight tolerance control (±0.2 mm), smooth surface finish, and customizable sheet dimensions to meet OEM specifications. Each compound undergoes rigorous testing for hardness, elongation at break, tensile strength, and compression set in accordance with ASTM and ISO standards.

The following table summarizes key material properties for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 300–600 |

| Continuous Use Temp (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Chemical Resistance | Excellent (acids, fuels, oils) | Good (oils, fuels) | Fair (water, mild chemicals) |

| Compression Set Resistance | Excellent | Good | Moderate |

| Electrical Insulation | Moderate | Moderate | Excellent |

| FDA Compliance Available | Yes (specific grades) | No | Yes |

Suzhou Baoshida ensures material traceability, batch certification, and technical support for integration into high-specification industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and Mould Design for 5 mm Industrial Rubber Sheets

Suzhou Baoshida Trading Co., Ltd. delivers exceptional engineering rigor specifically for the demanding production of 5 mm thick industrial rubber sheets. Our core strength lies in the integrated expertise of our dedicated technical team, comprising five specialized Mould Engineers and two advanced Rubber Formula Engineers. This structure ensures seamless collaboration from material science through to precision manufacturing, directly addressing the critical challenges inherent in consistent, high-tolerance sheet production at this specific thickness. Achieving uniform physical properties, dimensional stability, and surface integrity across large-format 5 mm sheets requires deep understanding of both compound behavior and mould dynamics, which our team provides.

Our Rubber Formula Engineers focus intensely on optimizing vulcanization kinetics and filler dispersion for 5 mm cross-sections. Standard compounds often exhibit core-cure deficiencies or surface scorch at this thickness; our engineers precisely adjust accelerator systems, curative ratios, and thermal conductivity modifiers to ensure homogeneous cure throughout the sheet profile. Simultaneously, our Mould Engineers design and validate tooling with sophisticated thermal management systems. This includes strategically placed cooling channels and pressure distribution analysis to counteract warpage and shrinkage, guaranteeing flatness tolerances within ±0.15 mm and eliminating knit lines critical for sealing or bonding applications. This dual-engineering approach prevents common failures like internal porosity, inconsistent durometer, or edge curling that compromise performance in hydraulic, gasket, or vibration damping roles.

Material performance is non-negotiable for industrial 5 mm sheets. Below is a comparison of standard specifications achievable versus the enhanced capabilities unlocked through our co-engineering process with OEM partners. The OEM Advantage column demonstrates tangible value derived from our integrated team’s intervention.

| Parameter | Standard Specification Range | Custom Range via Baoshida Engineering | OEM Advantage |

|---|---|---|---|

| Hardness (Shore A) | 50 – 90 | 45 – 95 | Target-specific resilience for dynamic loads |

| Tensile Strength | 8 – 20 MPa | 6 – 25 MPa | Enhanced durability in high-stress interfaces |

| Elongation at Break | 150% – 400% | 100% – 500% | Optimized flexibility for complex installations |

| Compression Set (70h/70°C) | ≤ 25% | ≤ 15% | Superior long-term seal retention |

| Thickness Tolerance | ±0.30 mm | ±0.15 mm | Precision fit for automated assembly lines |

Our OEM capabilities extend beyond specification fulfillment to true co-development partnership. We engage early in the design phase, utilizing finite element analysis (FEA) for stress prediction in the end application and tailoring compound morphology accordingly. Full material traceability, batch-specific certification (including ASTM D2000 callouts), and rigorous in-process QA at critical control points are standard. Crucially, we implement robust intellectual property protection protocols for proprietary formulations, ensuring client confidentiality while delivering sheets that meet exact performance envelopes. This engineering-led OEM model minimizes time-to-market, reduces scrap rates through predictive process control, and guarantees supply chain resilience for mission-critical rubber components. Partner with Baoshida to transform 5 mm sheet requirements into engineered reality.

Customization Process

Customization Process for 5 mm Plastic Sheets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our customization process for 5 mm plastic sheets is engineered to meet the exact functional and environmental demands of industrial applications. This structured workflow ensures precision, repeatability, and compliance with OEM specifications. The process begins with Drawing Analysis, followed by Rubber Formulation, Prototyping, and culminates in Mass Production.

Drawing Analysis serves as the foundational step, where technical blueprints and CAD models are rigorously evaluated. Our engineering team assesses dimensional tolerances, surface finish requirements, and geometric complexity. Critical parameters such as flatness, edge definition, and hole placement are cross-referenced with material behavior models. This phase also includes a feasibility review to confirm manufacturability within standard process capabilities. Any deviations or design optimizations are communicated directly to the client for approval before proceeding.

Following drawing validation, the Rubber Formulation stage is initiated. Based on the application environment—such as exposure to oils, UV radiation, or extreme temperatures—a proprietary elastomer compound is selected or developed. Our in-house compounding laboratory tailors formulations using SBR, NBR, EPDM, or specialty polymers to achieve target hardness (Shore A), tensile strength, elongation, and compression set resistance. For 5 mm sheets, we optimize filler dispersion and curing kinetics to ensure uniform cross-linking through the entire thickness, minimizing internal stress and warpage.

Prototyping is conducted using precision compression or injection molding, depending on part geometry and volume projections. Small-batch samples are produced under controlled conditions that simulate mass production parameters. Each prototype undergoes rigorous quality testing, including dimensional inspection, durometer measurement, and application-specific performance trials. Feedback from this stage is used to fine-tune both formulation and process settings, ensuring the final product meets all functional criteria.

Upon client approval of the prototype, the project transitions into Mass Production. Our automated production lines operate under strict ISO-compliant quality control protocols. Real-time monitoring of temperature, pressure, and cure time ensures batch-to-batch consistency. Finished 5 mm sheets are inspected for visual defects, thickness variation, and mechanical properties before packaging and shipment.

The following table outlines key technical specifications achievable for customized 5 mm plastic sheets:

| Property | Typical Range | Test Standard |

|---|---|---|

| Thickness Tolerance | ±0.15 mm | ISO 3302 |

| Hardness (Shore A) | 40–90 | ISO 868 |

| Tensile Strength | 8–25 MPa | ISO 37 |

| Elongation at Break | 150–600% | ISO 37 |

| Compression Set (22h, 70°C) | ≤25% | ISO 815 |

| Operating Temperature | -40°C to +130°C (varies by compound) | — |

This systematic approach enables Suzhou Baoshida to deliver high-performance, application-specific 5 mm plastic sheets with reliability and industrial precision.

Contact Engineering Team

Contact Suzhou Baoshida for Precision 5 mm Rubber Sheet Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive partner for engineered 5 mm rubber sheets, delivering uncompromising precision for demanding industrial applications. Our technical expertise spans material formulation, vulcanization control, and dimensional stability assurance, ensuring sheets meet exacting OEM specifications. Unlike generic plastic alternatives, our rubber compounds provide superior resilience against abrasion, chemical exposure, and thermal cycling—critical for automotive sealing, machinery isolation, and fluid handling systems. Each 5 mm sheet undergoes rigorous in-house testing for consistency in durometer, tensile strength, and compression set, eliminating field failure risks in high-stakes operations.

Key technical parameters for our standard 5 mm rubber sheet offerings are summarized below. These values reflect baseline performance; custom formulations adjust properties to match your operational environment.

| Property | Standard Nitrile (NBR) | EPDM Variant | Silicone Option | Test Method |

|---|---|---|---|---|

| Thickness Tolerance | ±0.15 mm | ±0.15 mm | ±0.10 mm | ASTM D3770 |

| Durometer (Shore A) | 70 ±5 | 65 ±5 | 50 ±5 | ASTM D2240 |

| Tensile Strength (MPa) | 18.0 min | 15.0 min | 7.0 min | ASTM D412 |

| Elongation at Break (%) | 300 min | 250 min | 200 min | ASTM D412 |

| Temperature Range (°C) | -30 to +100 | -50 to +130 | -60 to +200 | ISO 188 |

| Compression Set (22h) | 25% max @ 70°C | 20% max @ 100°C | 15% max @ 150°C | ASTM D395 Method B |

These sheets are not off-the-shelf commodities. As your OEM manager, I oversee end-to-end production—from raw material sourcing to final inspection—guaranteeing lot-to-lot repeatability. Our facility supports custom color matching, conductive or anti-static additives, and flame-retardant modifications without sacrificing extrusion tolerance. For example, automotive clients specify NBR sheets with integrated fabric reinforcement for hydraulic manifold gaskets, while semiconductor manufacturers require ultra-pure silicone variants with particulate levels below ISO Class 5. This adaptability stems from our in-house compounding lab, where rubber formulas are iterated against real-world stress profiles.

Procurement teams benefit from our lean inventory system, holding 50+ metric tons of 5 mm sheet stock in common grades for 72-hour dispatch. Yet true value emerges in collaborative engineering: share your failure mode analysis or CAD drawings, and our team will propose material optimizations—reducing your total cost of ownership through extended service life and simplified assembly. We reject one-size-fits-all approaches; every order is validated against your performance KPIs.

Initiate your project with a technical consultation led by Mr. Boyce, our dedicated OEM liaison. Email [email protected] with your application requirements, volume forecasts, and critical performance thresholds. Mr. Boyce will coordinate material samples, 3D-printed prototype validation, and volume pricing within 48 business hours. Specify your industry and target standards (e.g., ISO 3601 for fluid power, SAE J20 for automotive) to expedite the response. For urgent RFQs, include your facility location to optimize logistics planning. Suzhou Baoshida transforms rubber sheet specifications into operational reliability—contact us to engineer the difference.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).