Technical Contents

Engineering Guide: Hdpe Cutting Board Material

Engineering Insight: HDPE Cutting Board Material

In industrial food processing and commercial kitchen environments, the selection of cutting board material is not merely a matter of convenience—it is a critical engineering decision that directly impacts hygiene, blade longevity, operational efficiency, and compliance with food safety standards. High-Density Polyethylene (HDPE) is widely marketed as a standard solution for cutting boards due to its chemical resistance, low moisture absorption, and ease of fabrication. However, not all HDPE formulations are created equal. Off-the-shelf cutting boards often fail under sustained industrial use because they are manufactured using reprocessed resins, inconsistent melt indices, and inadequate additives, leading to premature wear, surface gouging, and bacterial harborage.

The root cause of failure in generic HDPE boards lies in uncontrolled material sourcing and suboptimal processing parameters. Recycled HDPE, while cost-effective, introduces variability in molecular weight distribution and contaminant load, compromising impact strength and surface integrity. Furthermore, many commercial boards lack UV stabilizers, anti-static agents, or mold-release additives that are essential for long-term performance in high-throughput environments. This results in rapid surface degradation, increased knife resistance, and microfissure formation—ideal conditions for biofilm development.

At Suzhou Baoshida Trading Co., Ltd., we approach HDPE cutting board material as an engineered system. Our formulations are based on virgin, FDA-compliant HDPE resins with tightly controlled melt flow rates (MFR) to ensure uniform extrusion and homogenous density. We incorporate proprietary additive packages that enhance surface lubricity, reduce static charge accumulation, and improve dimensional stability under thermal cycling. This precision engineering translates into cutting boards that maintain a smooth, non-porous surface over thousands of cutting cycles, minimizing knife dulling and simplifying sanitation protocols.

Material consistency is further validated through rigorous quality control, including density profiling, Charpy impact testing, and accelerated aging simulations. Our in-house testing confirms that custom-formulated HDPE outperforms standard commercial boards by up to 60% in edge retention and 40% in impact resistance under identical operational loads.

The table below outlines key material specifications that differentiate industrial-grade HDPE cutting board material from commodity alternatives.

| Property | Industrial-Grade HDPE (Baoshida) | Standard Commercial HDPE |

|---|---|---|

| Resin Type | Virgin FDA-Compliant | Recycled/Blended |

| Density (g/cm³) | 0.95–0.96 | 0.94–0.95 |

| Melt Flow Rate (g/10 min) | 0.3–0.5 (ASTM D1238) | 0.8–1.2 |

| Tensile Strength (MPa) | ≥30 | 20–25 |

| Impact Strength (kJ/m²) | ≥45 (Notched Izod) | 25–35 |

| Water Absorption (%) | <0.01 | 0.02–0.05 |

| Additives | UV Stabilizer, Anti-static, Slip | None or Minimal |

Selecting the appropriate HDPE formulation is not a cost-driven compromise—it is a performance-driven necessity. By prioritizing material integrity and process control, industrial operators can eliminate premature board replacement, reduce cross-contamination risks, and enhance overall operational uptime.

Material Specifications

Material Specifications for Industrial Rubber Cutting Board Components

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction: HDPE (High-Density Polyethylene) is a thermoplastic polymer, not a rubber compound. Our expertise in industrial rubber solutions addresses elastomeric materials for seals, gaskets, and hygienic interfaces in food processing equipment—not cutting board substrates. For OEMs requiring rubber components in cutting board assemblies (e.g., non-slip bases, edge guards, or sealing elements), precise elastomer selection is vital for chemical resistance, temperature stability, and compliance. Viton, Nitrile, and Silicone represent optimal solutions where rubber integration is necessary, each with defined performance boundaries in food-contact environments. Misapplication risks premature failure under oils, sanitizers, or thermal cycling. Below, we detail technical specifications for these elastomers per ASTM D2000 and FDA 21 CFR 177.2600 standards.

Elastomer Comparison for Cutting Board Ancillary Components

| Material | Temperature Range (°C) | Key Chemical Resistances | Typical Hardness (Shore A) | Primary Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Concentrated acids, oils, fuels, steam | 60–90 | High-heat sealing edges, chemical-exposed bases |

| Nitrile (NBR) | -40 to 120 | Aliphatic hydrocarbons, water, vegetable oils | 50–90 | Cost-effective non-slip pads, general food-contact zones |

| Silicone (VMQ) | -60 to 200 | Water, ozone, mild acids, steam | 30–80 | Flexible edge guards, FDA-compliant food-contact surfaces |

Viton excels in extreme chemical and thermal environments but carries premium costs. Its resistance to aggressive sanitizers (e.g., quaternary ammonium compounds) makes it suitable for commercial kitchen equipment requiring frequent high-temperature washdowns. Nitrile offers balanced performance for oil and water exposure at economical rates, though it degrades under ozone or strong acids—limiting use in harsh sterilization cycles. Silicone provides superior flexibility and biocompatibility for direct food-contact zones but exhibits lower tensile strength and higher compression set than Viton or NBR. Hardness selection (Shore A) directly impacts grip retention and wear life; 70–80 Shore A is standard for non-slip bases to balance durability and shock absorption.

OEMs must validate material compliance with regional food safety regulations. Viton and Silicone inherently meet FDA/EC 1935/2004 for repeated food contact, while NBR formulations require peroxide curing and additive certification to avoid plasticizer migration. Accelerated aging tests at 100°C for 72 hours are recommended to simulate 5-year service life under cyclic thermal stress. For cutting board systems, rubber components should maintain ≤15% volume swell after 72-hour immersion in 90% isopropyl alcohol—a critical benchmark for seal integrity in sanitized environments. Suzhou Baoshida provides custom durometer adjustments and FDA masterbatch certification to align with your assembly tolerances and regulatory frameworks. Always prioritize material-specific compression set data (<25% at 100°C) to prevent permanent deformation in load-bearing interfaces.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial polymer engineering, delivering high-performance HDPE cutting board materials tailored to the rigorous demands of food processing, commercial kitchens, and industrial workspaces. Our Engineering Capability division is anchored by a dedicated team of five Mould Engineers and two specialized Rubber and Polymer Formula Engineers, enabling us to offer fully integrated OEM solutions from concept to mass production.

Our Formula Engineers possess deep expertise in polyolefin chemistry, with a focused specialization in high-density polyethylene (HDPE) formulation. They optimize material performance by fine-tuning molecular weight distribution, impact modifiers, and anti-microbial additives, ensuring that each cutting board meets stringent standards for durability, chemical resistance, and food safety compliance. This precise formulation control allows us to develop custom compounds that resist knife scarring, inhibit bacterial growth, and maintain structural integrity under repeated thermal cycling—critical attributes for commercial-grade applications.

Complementing our formulation expertise, our team of five Mould Engineers brings extensive experience in precision tooling design and injection molding process optimization. They utilize advanced 3D modeling software and mold flow simulation tools to design robust, high-cavitation molds that ensure consistent part geometry, minimize flash, and reduce cycle times. This synergy between material science and mold engineering enables us to deliver HDPE cutting boards with tight dimensional tolerances, superior surface finish, and long-term repeatability across production batches.

As an OEM partner, Suzhou Baoshida provides end-to-end manufacturing support. From initial prototype development and material testing to full-scale production and packaging customization, we align our engineering resources directly with client specifications. Our facility supports multi-color co-injection, embedded branding, and ergonomic feature integration, allowing for differentiated product designs that meet both functional and aesthetic requirements.

We maintain rigorous quality control protocols, including ASTM and ISO-compliant testing for impact strength, tensile properties, and food contact safety. Our HDPE formulations are certified for compliance with FDA 21 CFR 177.1520 and EU 10/2011 regulations, ensuring suitability for direct food contact environments.

The following table outlines the key technical specifications of our standard and custom-engineered HDPE cutting board materials:

| Property | Standard HDPE | Enhanced Impact Grade | Anti-Microbial HDPE |

|---|---|---|---|

| Density (g/cm³) | 0.94 – 0.96 | 0.95 – 0.97 | 0.95 – 0.96 |

| Tensile Strength (MPa) | ≥30 | ≥35 | ≥32 |

| Impact Strength (Izod, J/m) | ≥50 | ≥80 | ≥60 |

| Hardness (Shore D) | 65 – 70 | 68 – 72 | 66 – 70 |

| Operating Temperature Range (°C) | -40 to +80 | -40 to +80 | -40 to +80 |

| FDA / EU Compliance | Yes | Yes | Yes |

| Anti-Microbial Additive | No | Optional | Yes (Silver ion based) |

This combination of advanced formulation science, precision mold engineering, and full OEM service capability positions Suzhou Baoshida as a trusted partner for industrial clients seeking high-performance, compliant, and customizable HDPE cutting board solutions.

Customization Process

HDPE Cutting Board Material Customization Process

Suzhou Baoshida Trading Co., Ltd. applies rigorous polymer engineering protocols to customize HDPE (High-Density Polyethylene) cutting board materials for industrial foodservice and manufacturing clients. Our process integrates material science with precision manufacturing to ensure compliance with FDA 21 CFR §177.1520 and NSF/ANSI 2 standards. Below is our four-phase customization workflow.

Drawing Analysis

Initial technical review focuses on dimensional tolerances, surface finish requirements, and geometric complexity per client CAD files. We validate critical features such as knife-surface interaction zones, drainage channels, and ergonomic grips using GD&T (Geometric Dimensioning and Tolerancing) standards. Material thickness uniformity (±0.2 mm) and edge radius specifications are cross-referenced against FDA food-contact safety thresholds. Non-compliant design elements—such as crevice depths exceeding 0.5 mm that risk bacterial entrapment—are flagged for redesign consultation.

Formulation Development

Based on analysis outcomes, our rubber formula engineering team tailors HDPE compound composition. Virgin HDPE resin (density 0.941–0.965 g/cm³) is fortified with FDA-compliant additives:

Antimicrobial agents (e.g., silver-ion masterbatches at 0.3–0.8 wt%)

UV stabilizers (HALS-type at 0.15–0.25 wt%) for outdoor applications

High-melt-strength modifiers to prevent warpage during thermoforming

Recycled content (up to 30% post-industrial HDPE) with strict VOC validation

Formulation balances impact resistance (Izod impact ≥5.0 kJ/m² at -20°C) against machinability, avoiding excessive filler content that compromises knife-edge retention.

Prototyping & Validation

Pre-production samples undergo accelerated lifecycle testing:

500+ simulated knife-stab cycles to assess surface gouging

72-hour immersion in 75°C aqueous NaCl solution for dimensional stability

Colorfastness validation per AATCC Test Method 61

Critical physical properties are verified against target ranges in the table below. Non-conformities trigger iterative formula adjustments before client approval.

| Property | Target Range | Test Method | Critical Tolerance |

|---|---|---|---|

| Density | 0.945–0.955 g/cm³ | ASTM D792 | ±0.005 g/cm³ |

| Melt Flow Index (190°C) | 0.3–0.8 g/10 min | ASTM D1238 | ±0.1 g/10 min |

| Tensile Strength | ≥22 MPa | ASTM D638 | ±1.5 MPa |

| Food Simulant Migration | ≤0.5 mg/dm² | FDA 21 CFR §175.300 | Zero exceedance |

Mass Production Execution

Approved formulations transition to ISO 9001-certified production lines with real-time process control. Extrusion parameters (barrel zones 180–210°C, die gap 3.2 mm ±0.1) are monitored via SCADA systems. Each batch undergoes:

In-line thickness profiling (laser micrometry)

Spectroscopic verification of additive dispersion

Lot traceability via blockchain-enabled batch coding

Final inspection includes 100% visual surface grading and random destructive testing per AQL 1.0 standards. All documentation—including FDA Letter of Guarantee and ISO 10993 biocompatibility reports—is provided for audit readiness.

This end-to-end methodology ensures HDPE cutting boards meet exact operational demands while adhering to global food safety regulations. Suzhou Baoshida’s engineering oversight minimizes time-to-market without compromising material integrity.

Contact Engineering Team

For industrial manufacturers seeking high-performance HDPE cutting board materials engineered for durability, chemical resistance, and long-term operational efficiency, Suzhou Baoshida Trading Co., Ltd. delivers precision-crafted polymer solutions tailored to demanding environments. As a specialized provider in industrial rubber and polymer composites, we integrate material science with manufacturing expertise to supply HDPE (High-Density Polyethylene) sheets that meet stringent hygiene, wear, and structural requirements across food processing, pharmaceutical, packaging, and material handling industries.

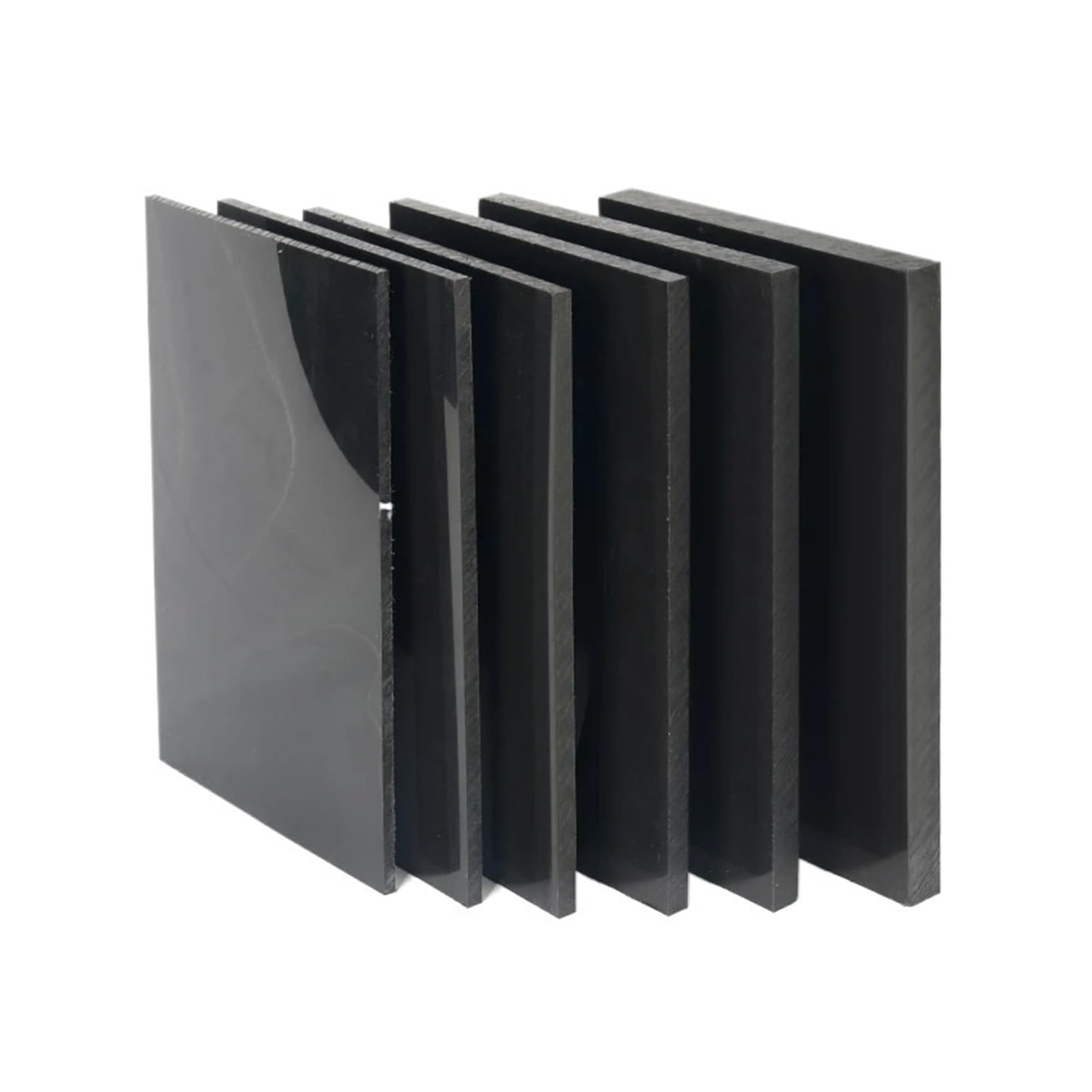

Our HDPE cutting board material is formulated to resist impact, moisture, and microbial growth, ensuring compliance with food safety standards while maintaining dimensional stability under repeated mechanical stress. Each sheet is manufactured under controlled conditions to guarantee uniform density, low moisture absorption, and excellent machinability for custom fabrication. Whether used in conveyor systems, protective linings, or industrial work surfaces, our HDPE material provides a resilient, low-maintenance solution that reduces downtime and extends service life.

To ensure optimal performance, we subject our HDPE formulations to rigorous quality control, including tensile strength testing, hardness verification, and thermal stability analysis. Our production process eliminates voids and inconsistencies, resulting in a homogeneous structure ideal for heavy-duty applications. Clients benefit from scalable supply capabilities, consistent batch-to-batch repeatability, and technical documentation supporting regulatory compliance and traceability.

The following specifications represent the standard technical profile of our industrial-grade HDPE cutting board material:

| Property | Test Method | Value |

|---|---|---|

| Density | ASTM D792 | 0.95–0.96 g/cm³ |

| Tensile Strength at Yield | ASTM D638 | ≥21 MPa |

| Flexural Modulus | ASTM D790 | ≥1.1 GPa |

| Izod Impact Strength (Notched) | ASTM D256 | ≥45 J/m |

| Hardness (Shore D) | ASTM D2240 | 65–70 |

| Maximum Continuous Use Temperature | — | 80°C (176°F) |

| Water Absorption (24 hrs) | ASTM D570 | <0.01% |

| Color Options | — | White, Black, Blue (custom colors available) |

| Sheet Dimensions (Standard) | — | Up to 2000 x 1000 mm, thickness 10–100 mm |

For application-specific requirements, including anti-static formulations, UV-stabilized variants, or FDA-compliant grades, Suzhou Baoshida offers customized development and rapid prototyping. Our engineering team collaborates directly with OEMs and industrial designers to align material properties with functional demands.

To discuss your HDPE cutting board material needs or request samples for evaluation, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. Direct correspondence to [email protected] ensures prompt technical consultation, pricing, and logistical support. We provide global shipping, volume discounts, and material certification packages upon request. Partner with us to integrate high-integrity HDPE solutions into your next industrial design.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).