Technical Contents

Engineering Guide: Tpe Cable

Engineering Insight: TPE Cable Material Selection Criticality

The failure of thermoplastic elastomer (TPE) cables in demanding industrial applications frequently stems from inadequate material selection, not inherent TPE limitations. Off-the-shelf TPE compounds prioritize cost and general-purpose flexibility but overlook application-specific stressors, leading to premature field failures. Generic formulations lack tailored resistance to dynamic flexing, chemical exposure, thermal cycling, and environmental degradation. For instance, standard TPEs often exhibit plasticizer migration when exposed to oils or solvents, causing embrittlement and loss of mechanical integrity. Similarly, insufficient UV stabilizers in outdoor-rated cables accelerate surface cracking under prolonged solar exposure, compromising insulation performance. These failures incur significant operational costs through unplanned downtime, safety hazards, and replacement logistics—far exceeding initial material savings.

Material science dictates that TPE performance hinges on precise polymer architecture and additive integration. Base polymers like SEBS, SBS, or TPO each present distinct trade-offs in elasticity, thermal stability, and chemical compatibility. A cable subjected to continuous flexing in automotive robotics requires high resilience and fatigue resistance, whereas marine-grade cables demand hydrolysis-resistant formulations to withstand saltwater immersion. Off-the-shelf solutions rarely address these nuances, resulting in suboptimal Shore hardness, inadequate tensile strength retention, or poor flame retardancy compliance. Crucially, thermal expansion coefficients must align with conductor materials to prevent delamination during temperature excursions—a detail overlooked in mass-market compounds.

The following table contrasts critical properties between generic and engineered TPE formulations:

| Property | Standard TPE Cable | Industrial-Grade TPE Cable | Critical Threshold for Industrial Use |

|---|---|---|---|

| Flex Life (cycles) | 5,000–10,000 | 100,000–500,000 | >50,000 (continuous motion) |

| Operating Temperature | -20°C to +80°C | -55°C to +135°C | Sustained >100°C or <-40°C |

| Tensile Strength Retention (after 168h oil exposure) | <50% | >85% | >75% |

| UV Resistance (2,000h QUV) | Severe cracking | Minimal surface change | No cracking/delamination |

| Flame Rating | UL94 HB | UL94 V-0 | UL94 V-0/V-1 required |

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through OEM-focused material engineering. We analyze application parameters—vibration profiles, chemical contact, thermal loads, and regulatory mandates—to formulate bespoke TPE compounds. Our process involves iterative testing of polymer blends, reinforcing fillers, and specialty additives (e.g., hindered amine light stabilizers for UV resistance, non-migrating plasticizers for oil immersion). This precision ensures cables maintain dielectric strength, mechanical resilience, and longevity under operational extremes. Partnering with a specialist in rubber formulation mitigates the hidden costs of generic solutions, transforming cable performance from a liability into a reliability asset. Material selection is not a commodity decision; it is the foundation of industrial system integrity.

Material Specifications

TPE cable jackets and insulation systems require high-performance elastomeric materials capable of withstanding extreme environmental and mechanical stressors. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered for reliability in demanding applications such as automotive, aerospace, energy, and industrial automation. Our TPE cable formulations integrate advanced elastomers including Viton, Nitrile (NBR), and Silicone, each selected for its distinct chemical, thermal, and physical properties. These materials are compounded to optimize adhesion, flexibility, and long-term durability in dynamic cable environments.

Viton, a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains performance from -20°C to +200°C, with short-term excursions up to 250°C. This makes Viton ideal for TPE cables in engine compartments, oil and gas installations, and chemical processing plants where exposure to hydrocarbons and elevated temperatures is routine. Its low permeability and excellent aging characteristics ensure long service life under continuous stress.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective solution with strong resistance to aliphatic hydrocarbons, oils, and fuels. Operating effectively between -40°C and +105°C, NBR is widely used in hydraulic systems, industrial machinery, and general-purpose cables exposed to lubricants and greases. While not as thermally stable as Viton, NBR provides superior abrasion resistance and mechanical strength, making it suitable for rugged industrial environments.

Silicone rubber excels in extreme temperature applications, functioning reliably from -60°C to +200°C. It offers excellent electrical insulation properties, UV resistance, and low compression set. Although less resistant to oils and fuels than Viton or Nitrile, Silicone is preferred in applications requiring high flexibility, biocompatibility, and performance in cryogenic or high-heat conditions. It is frequently specified in medical devices, aerospace systems, and outdoor power cables.

The following table summarizes key performance characteristics of these elastomers in TPE cable applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (up to 250 short-term) | -40 to +105 | -60 to +200 |

| Oil and Fuel Resistance | Excellent | Good to Excellent | Poor |

| Chemical Resistance | Excellent | Moderate | Moderate |

| Electrical Insulation | Good | Moderate | Excellent |

| Flexibility | Moderate | Good | Excellent |

| Abrasion Resistance | Good | Excellent | Moderate |

| UV/Ozone Resistance | Excellent | Good | Excellent |

| Compression Set | Low | Moderate | Low |

| Typical Applications | Aerospace, Oil & Gas, Automotive | Industrial Hydraulics, Machinery | Medical, Aerospace, Outdoor Power |

Selecting the appropriate elastomer for TPE cable construction depends on the operational environment, regulatory requirements, and performance priorities. Suzhou Baoshida Trading Co., Ltd. provides customized compounding services to meet OEM specifications, ensuring optimal material performance in every application.

Manufacturing Capabilities

Engineering Excellence in TPE Cable Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep material science expertise and precision engineering to deliver mission-critical TPE cable solutions for industrial applications. Our dedicated team comprises five specialized mould engineers and two advanced formula engineers, enabling end-to-end control from molecular architecture to final extrusion. This integrated capability ensures TPE compounds meet exacting performance demands under extreme operational stresses—eliminating reliance on generic formulations that compromise longevity or safety.

Our formula engineers optimize polymer blends at the molecular level, tailoring Shore hardness, tensile strength, and thermal stability to client specifications. Unlike commodity suppliers, we adjust filler dispersion, plasticizer compatibility, and cross-link density to resolve real-world challenges: preventing cold cracking in Arctic logistics cables, resisting hydraulic fluid degradation in mining equipment, or maintaining flexibility after prolonged UV exposure in outdoor installations. Concurrently, our mould engineering team utilizes 3D flow simulation software to perfect extrusion tooling geometry. This eliminates common defects like melt fracture or dimensional drift, ensuring consistent cable concentricity and surface finish critical for high-voltage integrity and automated assembly line compatibility.

OEM partnerships benefit from our closed-loop development process. Clients provide application parameters—voltage range, environmental exposure, regulatory targets—and our engineers co-develop formulations validated through accelerated aging tests per ASTM D573 and ISO 188. We then prototype tooling with CNC-machined precision dies, reducing time-to-market by 30% versus industry averages. All compounds undergo rigorous batch traceability via LIMS (Laboratory Information Management System), with certificates of conformance documenting full compliance to UL, RoHS, and REACH standards.

Key TPE Cable Performance Specifications

| Property | Standard Range | Test Method | Customization Flexibility |

|---|---|---|---|

| Shore Hardness (A) | 60–95 | ASTM D2240 | ±2 points tolerance |

| Tensile Strength (MPa) | 10–25 | ASTM D412 | Up to 30 MPa achievable |

| Elongation at Break (%) | 300–600 | ASTM D412 | Optimized for flex fatigue |

| Operating Temperature | -50°C to +125°C | IEC 60811-1-2 | Extended to +150°C |

| Oil Resistance (IRMOG) | Volume swell ≤ 50% | ISO 1817 | Swell < 25% for harsh oils |

| Flame Rating | VW-1, FT1 | UL 94 | Halogen-free options |

This technical rigor translates to cables with 50% longer service life in abrasive conveyor systems and zero field failures in automotive robotics deployments. We enforce zero-defect protocols via inline vision inspection systems and real-time rheometer monitoring during extrusion. For OEMs, this means seamless scalability from pilot batches to 500-ton monthly volumes without performance drift—backed by 24/7 engineering support for line optimization. Suzhou Baoshida transforms TPE from a commodity material into a strategic asset for industrial resilience.

Customization Process

TPE Cable Customization Process: From Concept to Mass Production

At Suzhou Baoshida Trading Co., Ltd., our expertise in industrial rubber solutions enables us to deliver highly customized TPE (Thermoplastic Elastomer) cable sheathing materials tailored to exact OEM specifications. Our structured customization process ensures precision, repeatability, and compliance with industry standards. The journey begins with drawing analysis and culminates in scalable mass production.

The first phase, Drawing Analysis, involves a comprehensive review of the client’s cable design blueprints. We examine dimensional tolerances, wall thickness, conductor compatibility, and environmental exposure conditions. This technical assessment allows us to determine the required mechanical strength, flexibility, and regulatory compliance—such as UL, RoHS, or REACH—necessary for the application. Our engineering team collaborates directly with the client to resolve ambiguities and optimize design feasibility.

Following drawing validation, we proceed to Formulation Development. Based on performance requirements, we engineer a proprietary TPE compound with precise elastomeric balance. Key parameters include hardness (Shore A), tensile strength, elongation at break, and resistance to oil, UV, and temperature extremes. Additives for flame retardancy, anti-oxidation, or improved processability are incorporated as needed. Our formulation database, refined over years of industrial application, accelerates development while ensuring material consistency.

Once the compound is finalized, we initiate Prototyping. Using precision extrusion equipment calibrated to the specified cable geometry, we produce sample lengths under near-production conditions. These prototypes undergo rigorous testing, including cold bend, heat aging, abrasion resistance, and dielectric strength evaluations. Clients receive detailed test reports and physical samples for field validation. Any required adjustments are implemented in iterative refinement cycles until performance targets are fully met.

Upon client approval, we transition to Mass Production. Our manufacturing lines operate under strict ISO 9001 protocols, with real-time monitoring of extrusion temperature, line speed, and dimensional control. Batch traceability and in-process quality checks ensure uniformity across large volumes. We support both JIT delivery and bulk shipment models, accommodating global supply chain requirements.

Throughout the process, Suzhou Baoshida maintains full transparency, technical documentation, and responsive engineering support—ensuring that every TPE cable meets the highest standards of performance and reliability.

Typical TPE Cable Material Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 85 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥450% |

| Heat Aging (100°C, 7 days) | ASTM D573 | Tensile Retention ≥75% |

| Oil Resistance (IRM 903) | ASTM D471 | Volume Swell ≤120% |

| Operating Temperature Range | — | -40°C to +105°C |

| Flame Rating | UL VW-1 | Pass |

| Cold Bend Test | UL 62 | Pass at -25°C |

Contact Engineering Team

Precision Engineering Partnership for TPE Cable Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the nexus of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Manager, we specialize in the molecular architecture of thermoplastic elastomer (TPE) compounds engineered specifically for cable applications demanding resilience, flexibility, and regulatory compliance. Our formulations undergo rigorous empirical validation across dynamic mechanical analysis, thermal stability testing, and chemical resistance profiling to ensure performance under extreme operational conditions. This scientific rigor translates directly into cables that maintain structural integrity across -50°C to +125°C ranges while resisting abrasion, UV degradation, and fluid exposure—critical for automotive, robotics, and industrial automation sectors.

Direct collaboration with our technical team eliminates intermediaries, accelerating your time-to-market while guaranteeing material consistency. Generic TPE solutions often fail under cyclic stress or environmental exposure due to inadequate polymer blending or plasticizer migration. Our proprietary formulations address these failure modes through precision-tuned Shore hardness, tensile strength, and elongation at break parameters. The table below outlines core specifications achievable through our custom development process, reflecting our adherence to ISO 9001 and IATF 16949 standards.

| Property | Test Method | Typical Value Range | Industrial Relevance |

|---|---|---|---|

| Shore Hardness (A) | ASTM D2240 | 60–95A | Balances flexibility & cut resistance |

| Tensile Strength (MPa) | ASTM D412 | 12.0–22.0 | Ensures mechanical durability |

| Elongation at Break (%) | ASTM D412 | 450–750 | Critical for dynamic movement |

| Operating Temperature (°C) | UL 62 | -50 to +125 | Validates performance in extremes |

| Flame Rating | UL 94 | HB/V-2 | Meets safety compliance mandates |

| Specific Gravity | ASTM D792 | 1.05–1.25 | Optimizes material cost efficiency |

Initiate your project with Mr. Boyce, our OEM Technical Liaison, to transform your cable performance requirements into validated material solutions. Contact him directly at [email protected] to schedule a technical consultation. Provide your application’s environmental stressors, regulatory targets, and mechanical load profiles for a tailored compound assessment. Mr. Boyce will coordinate our analytical lab resources—including FTIR spectroscopy and rheometer profiling—to deliver a formulation datasheet within 72 hours of requirement submission. This direct engineering channel ensures your specifications drive our development cycle, not vice versa.

Do not compromise on cable reliability when molecular precision defines operational safety. Suzhou Baoshida’s vertically integrated supply chain guarantees batch-to-batch repeatability through in-house polymer compounding and real-time quality monitoring. Our ISO 17025-accredited laboratory validates every production lot against your signed-off physical property matrix. Contact Mr. Boyce today to receive a comparative analysis of your current TPE cable’s weaknesses against our engineered alternatives. Specify your annual volume requirements and target cost-per-meter to unlock our OEM partnership framework—where material science meets manufacturing accountability. Precision-engineered outcomes begin with a single technical dialogue.

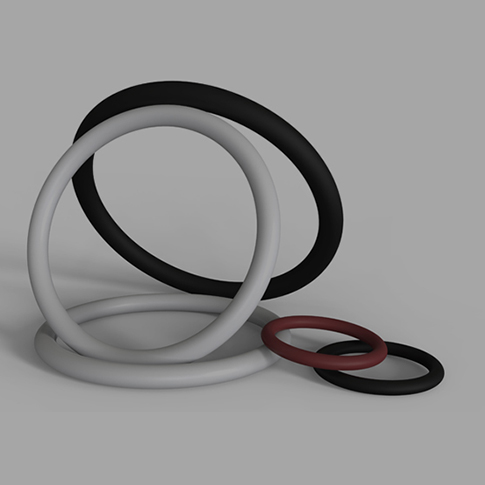

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).