Technical Contents

Engineering Guide: Anchoring Pins

Engineering Insight: The Critical Role of Material Selection in Anchoring Pins for Precision Rubber Seals

Anchoring pins serve as the mechanical backbone in precision rubber seal assemblies, ensuring positional integrity under dynamic operational stresses. While often overlooked, the material selection for these components directly influences the longevity, reliability, and performance of the entire sealing system. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf anchoring pins frequently fail due to a fundamental mismatch between generic material properties and the specific chemical, thermal, and mechanical demands of industrial environments.

Standard anchoring pins are typically manufactured from low-grade stainless steel or plated carbon steel, optimized for cost rather than performance. In aggressive media such as high-pressure hydraulic fluids, ozone-rich atmospheres, or elevated temperature zones, these materials exhibit rapid degradation. Corrosion initiates at micro-interfaces between the pin and elastomer, leading to interfacial delamination, loss of adhesion, and ultimately, seal extrusion or blowout. Furthermore, differential thermal expansion between dissimilar materials can induce micro-movements that compromise bond integrity over repeated thermal cycles.

In contrast, engineered anchoring pins designed for precision rubber seals utilize high-performance alloys such as 17-4 PH precipitation-hardened stainless steel or Alloy 625 (Inconel). These materials offer superior tensile strength, pitting resistance, and thermal stability. When bonded within fluorocarbon (FKM), hydrogenated nitrile (HNBR), or perfluoroelastomer (FFKM) seals, they maintain dimensional stability across temperature ranges from -40°C to over 300°C, depending on the elastomer system. Surface treatments such as passivation, electropolishing, or ceramic coating further enhance corrosion resistance and promote optimal adhesion with rubber compounds.

Another critical factor is coefficient of thermal expansion (CTE) compatibility. A mismatch between the pin and the surrounding elastomer generates internal stresses during thermal transients, accelerating fatigue. Precision pins are engineered with controlled surface roughness and tailored geometries to maximize mechanical interlock, reducing reliance on adhesive bonding alone. This hybrid approach—combining metallurgical compatibility with mechanical anchoring—delivers robust performance in aerospace, oil & gas, and high-performance automotive applications.

The failure of generic anchoring pins is not a flaw of design but of material misapplication. Each sealing environment presents unique challenges that demand a holistic engineering approach, where the anchoring pin is treated as an integral component rather than a passive insert.

Below is a comparative overview of common anchoring pin materials used in precision rubber seals:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Max Continuous Temp (°C) | Typical Elastomer Pairing |

|---|---|---|---|---|

| 304 Stainless Steel | 515 | Moderate | 870 | NBR, EPDM |

| 17-4 PH Stainless Steel | 1000–1200 | High | 315 | FKM, HNBR |

| Alloy 625 (Inconel) | 930 | Exceptional | 980 | FFKM, Aflas® |

| Titanium Grade 5 | 900 | High | 450 | Silicone, FVMQ |

| Carbon Steel (Zn-plated) | 400–550 | Low | 150 | NR, SBR |

Material Specifications

Material Specifications for Precision Rubber Anchoring Pins

Material selection for anchoring pins directly impacts seal integrity, service life, and operational safety in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber seals using rigorously tested elastomers to meet OEM specifications. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core formulations, each optimized for distinct chemical, thermal, and mechanical challenges. Understanding their intrinsic properties ensures optimal performance in critical applications such as automotive fuel systems, aerospace hydraulics, and semiconductor manufacturing.

Viton excels in extreme chemical resistance and high-temperature stability. Our FKM compounds withstand continuous exposure to -20°C to +230°C, with short-term peaks up to 300°C. They resist aggressive media including jet fuels, mineral oils, and aromatic hydrocarbons, maintaining seal integrity where lesser materials degrade. Typical tensile strength ranges from 15–20 MPa (ASTM D412), with elongation at break of 150–250%. Viton’s low gas permeability makes it indispensable for vacuum and high-pressure fluid systems, though it carries a premium cost versus NBR.

Nitrile remains the industry standard for cost-sensitive oil and fuel applications. Our custom NBR blends operate effectively from -40°C to +120°C, with specialized grades extending to 150°C. They deliver exceptional resistance to aliphatic hydrocarbons, hydraulic fluids, and greases, supported by tensile strengths of 10–25 MPa and elongation of 200–500%. NBR’s abrasion resistance and compression set performance (typically 15–25% per ASTM D395 after 70 hrs at 100°C) ensure longevity in dynamic sealing applications like engine crankcases and transmission systems.

Silicone offers unparalleled flexibility across extreme temperatures (-60°C to +200°C continuous, +230°C intermittent) but limited mechanical strength. Its biocompatibility and resistance to ozone/UV make it ideal for medical, food-grade, and outdoor applications. Tensile strength averages 5–8 MPa, with elongation exceeding 400%. While vulnerable to tear and petroleum-based fluids, silicone’s electrical insulation properties and non-toxicity support critical uses in electronics and life sciences.

The following table summarizes key comparative specifications for precision anchoring pin applications:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Fluid Resistance | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | 15–20 | 150–250 | Jet fuels, acids, aromatics | Aerospace hydraulics, chemical processing, high-performance automotive |

| Nitrile (NBR) | -40 to +120 | 10–25 | 200–500 | Mineral oils, hydraulic fluids, greases | Automotive fuel systems, industrial machinery, hydraulic seals |

| Silicone (VMQ) | -60 to +200 | 5–8 | 400–600 | Water, alcohols, ozone | Medical devices, food processing, electronics insulation |

Selection must align with fluid compatibility, thermal cycling, and mechanical stress profiles. Suzhou Baoshida Trading Co., Ltd. provides material certification per ASTM D2000 and custom compound validation to eliminate field failures. Partner with our engineering team to specify the optimal elastomer for your anchoring pin requirements, ensuring precision, durability, and compliance with global OEM standards.

Manufacturing Capabilities

Engineering Capability: Anchoring Pins for Precision Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in the design and production of anchoring pins for precision rubber seals is anchored in a deep integration of material science, mold technology, and OEM-driven innovation. With a dedicated team comprising five specialized mold engineers and two certified rubber formula engineers, we maintain full in-house control over the entire development cycle—from concept and material formulation to mold design, prototyping, and mass production. This vertical integration ensures precision, repeatability, and rapid response to client-specific requirements.

Our mold engineers bring over 60 combined years of experience in precision tooling for rubber-to-metal bonding applications. They utilize advanced CAD/CAM systems (SolidWorks, AutoCAD, and UG NX) to design anchoring pins with exacting tolerances, optimized undercuts, and enhanced mechanical retention features. Each pin geometry is validated through finite element analysis (FEA) to simulate stress distribution and bonding integrity under operational loads, ensuring long-term reliability in dynamic sealing environments. We support multi-cavity molds for high-volume production, with tolerances held to ±0.02 mm on critical dimensions.

Complementing our mold expertise, our two rubber formula engineers specialize in compounding elastomers for optimal adhesion to metal substrates. They formulate custom rubber compounds—based on NBR, EPDM, FKM, and silicone—that are chemically and thermally compatible with the anchoring pin’s base material (typically low-carbon steel, stainless steel, or plated variants). Surface energy optimization, crosslink density control, and primer adhesion promotion are systematically engineered to achieve bond strengths exceeding 12 MPa in peel and shear testing. This synergy between metal geometry and rubber formulation is critical in preventing delamination under thermal cycling, vibration, and fluid exposure.

We operate as a full-service OEM partner, supporting clients from initial technical consultation through to serial supply. Our engineering team collaborates directly with customer R&D departments to co-develop anchoring pin designs that meet exact performance criteria—whether for automotive transmission seals, industrial hydraulic systems, or aerospace actuators. Prototypes are typically delivered within 15 business days, with full DFMEA and PPAP documentation available upon request.

All anchoring pins are manufactured under ISO 9001-certified processes, with 100% visual inspection and batch traceability. We maintain a comprehensive material database and tooling archive, enabling seamless reorders and long-term supply continuity.

| Specification | Detail |

|---|---|

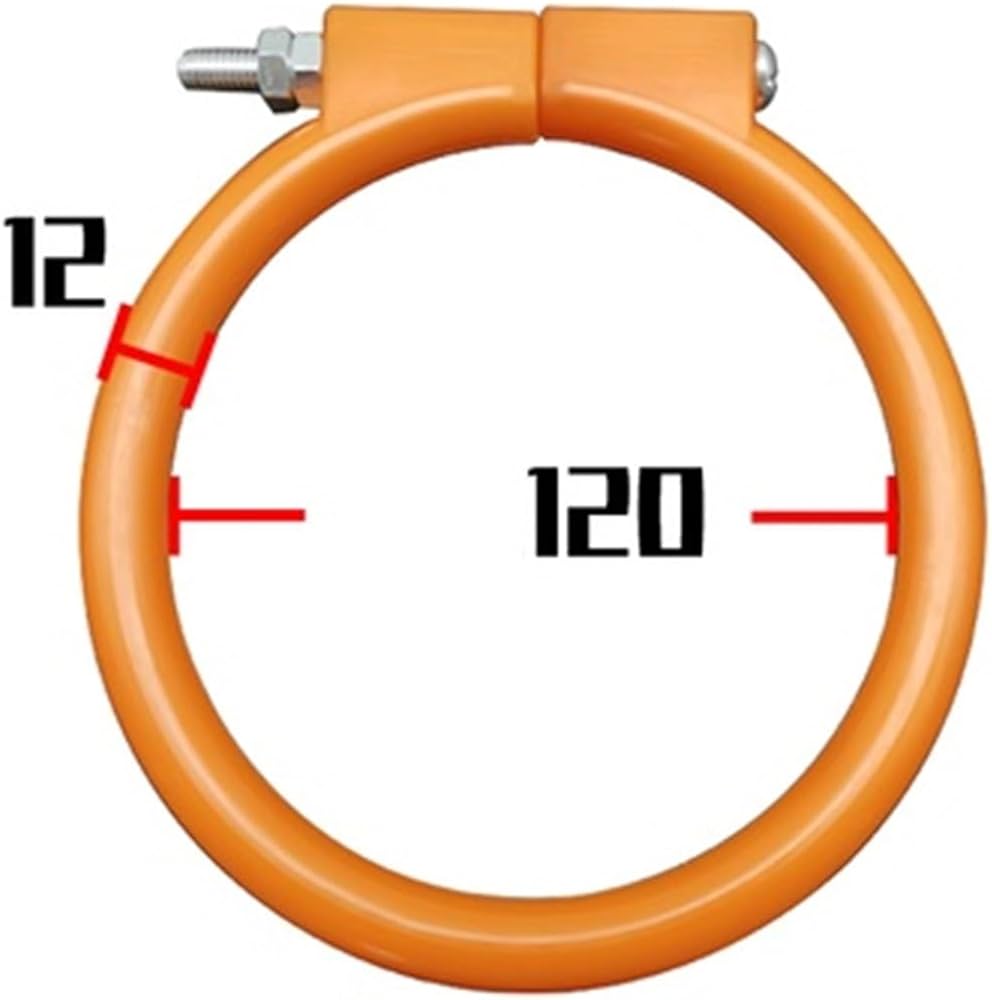

| Pin Diameter Range | 3.0 – 12.0 mm |

| Length Range | 5.0 – 50.0 mm |

| Tolerance | ±0.02 mm (critical dimensions) |

| Materials | Low-carbon steel, 304/316 stainless steel, zinc-plated steel |

| Rubber Compatibility | NBR, EPDM, FKM, Silicone, ACM |

| Bond Strength (Typical) | ≥12 MPa (peel and shear) |

| Surface Treatments | Phosphating, zinc plating, passivation |

| Production Capacity | Up to 5 million units/month |

| Lead Time (Prototype) | 10–15 days |

| Standards Compliance | ISO 9001, RoHS, REACH |

Our engineering framework ensures that every anchoring pin we produce is not just a component, but a precisely engineered system interface—delivering durability, sealing integrity, and OEM-grade performance.

Customization Process

Customization Process for Precision Anchoring Pins

Anchoring pins serve as critical retention components in dynamic sealing systems, requiring exact dimensional stability and material resilience to prevent rotational displacement under operational stress. At Suzhou Baoshida Trading Co., Ltd., our OEM customization process follows a rigorously defined sequence to ensure compliance with automotive and industrial sector demands. This methodology eliminates design ambiguities while optimizing material performance for high-cycle applications.

Drawing Analysis

Client technical drawings undergo multi-departmental scrutiny by our engineering and production teams. Key parameters including geometric tolerances (ISO 2768-mK), interface surface finishes (Ra ≤ 3.2 μm), and load-bearing profiles are validated against functional requirements. We identify potential molding challenges such as draft angles below 1° or critical wall thickness variations exceeding ±0.05 mm. This phase concludes with a formal Design for Manufacturability (DFM) report, highlighting modifications to enhance producibility without compromising sealing integrity.

Formulation Development

Material selection is driven by application-specific stressors. For anchoring pins subjected to hydraulic fluid exposure and 120°C continuous operation, we formulate hydrogenated nitrile rubber (HNBR) compounds with controlled acrylonitrile content (34±2%). The polymer matrix incorporates nano-silica reinforcement (BET surface area: 200 m²/g) and peroxide curing systems to achieve target compression set resistance. All formulations adhere to ASTM D2000 classification standards, with stringent control over cure kinetics (t90 ≤ 90 seconds at 170°C) to ensure dimensional repeatability during high-speed molding.

Prototyping & Validation

Initial prototypes are produced using production-intent tooling on 80-ton electric injection molding presses. Each batch undergoes accelerated life testing per SAE J2236 protocols, including 50,000-cycle torsion fatigue trials at 15° amplitude. Dimensional conformity is verified via coordinate measuring machine (CMM) scans against CAD models, with statistical process control (SPC) data provided to clients. Iterative adjustments to gate locations or cure profiles are implemented until all geometric and mechanical specifications are consistently met across three consecutive prototype runs.

Mass Production

Transition to full-scale manufacturing occurs only after client sign-off on validation data. Production lines implement real-time cavity pressure monitoring and automated vision inspection systems detecting sub-0.1 mm defects. Every lot undergoes batch traceability through QR-coded material passports, with hardness (Shore A), tensile strength, and compression set values documented per ASTM D395 Method B. Our facility maintains IATF 16949-certified processes, ensuring anchoring pins achieve ≤0.5% defect rates at volumes exceeding 500,000 units monthly.

Material performance specifications for standard anchoring pin formulations are summarized below:

| Property | Test Standard | Typical Value | Tolerance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 70 | ±5 |

| Tensile Strength | ASTM D412 | 22 MPa | Min. 20 MPa |

| Compression Set (22h/100°C) | ASTM D395 B | 18% | Max. 25% |

| Operating Temperature | ISO 1817 | -50°C to +150°C | Continuous |

| Fluid Resistance (ATF) | ASTM D471 | Volume swell ≤ 8% | After 70h |

This structured approach guarantees anchoring pins deliver fail-safe retention in critical sealing assemblies, with Suzhou Baoshida providing full technical documentation from compound certification to production validation reports.

Contact Engineering Team

For manufacturers and engineering teams seeking high-performance anchoring pins tailored for precision rubber seals, Suzhou Baoshida Trading Co., Ltd. stands as a trusted OEM partner with deep expertise in material science, dimensional accuracy, and industrial application support. Anchoring pins are critical components in sealing systems, ensuring secure retention of rubber elements within housings under dynamic pressure, thermal cycling, and mechanical stress. Our engineered solutions are developed to meet exacting standards across automotive, aerospace, hydraulics, and industrial equipment sectors.

At Suzhou Baoshida, we specialize in the design, material selection, and production of anchoring pins that integrate seamlessly with custom rubber seals. Our engineering team works directly with clients to analyze load requirements, environmental exposure, and assembly methods, ensuring that each pin delivers optimal performance in its operational context. Whether you require corrosion-resistant stainless steel, high-strength alloy steel, or precision-machined brass pins, we provide material certification, dimensional validation, and batch traceability as standard.

We understand that reliability in sealing systems begins with component integrity. Our anchoring pins are manufactured using CNC machining and cold-forming technologies, achieving tight tolerances down to ±0.02 mm. Surface treatments such as zinc plating, passivation, or phosphate coating are applied to enhance durability and prevent galling during installation. Each batch undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify conformance to ISO 9001 and IATF 16949 quality protocols.

Below are representative specifications for our standard anchoring pin configurations. Custom geometries, lengths, diameters, and head profiles are available upon request.

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel (304, 316), Alloy Steel (SCR435, SCM435), Brass (C3604), Carbon Steel |

| Diameter Range | 2.0 mm – 12.0 mm |

| Length Range | 5.0 mm – 100.0 mm |

| Tolerance | ±0.02 mm (diameter), ±0.1 mm (length) |

| Surface Finish | Ra ≤ 0.8 μm (machined), Ra ≤ 1.6 μm (cold-formed) |

| Coating Options | Zinc Plating (8–12 μm), Black Oxide, Passivation, Phosphating |

| Hardness | HRC 28–38 (alloy steel), HB 150–200 (brass), HRC 40–50 (stainless steel, optional) |

| Standards Compliance | ISO 875, DIN 1481, GB/T 880, Custom OEM Drawings |

Collaboration with Suzhou Baoshida ensures access to full technical documentation, including 2D/3D drawings, material data sheets (MDS), and test reports. Our global supply chain supports JIT delivery models, container consolidation, and labeling per customer requirements.

To discuss your anchoring pin application or request a technical quotation, contact Mr. Boyce, OEM Manager, directly at [email protected]. We respond to all inquiries within 12 business hours and offer sample builds for validation within 7–10 working days. Partner with Suzhou Baoshida Trading Co., Ltd. for precision-engineered components backed by scientific rigor and industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).