Technical Contents

Engineering Guide: Plexi Mirror Sheets

Engineering Insight: Material Selection Criticality for Industrial Mirror Applications

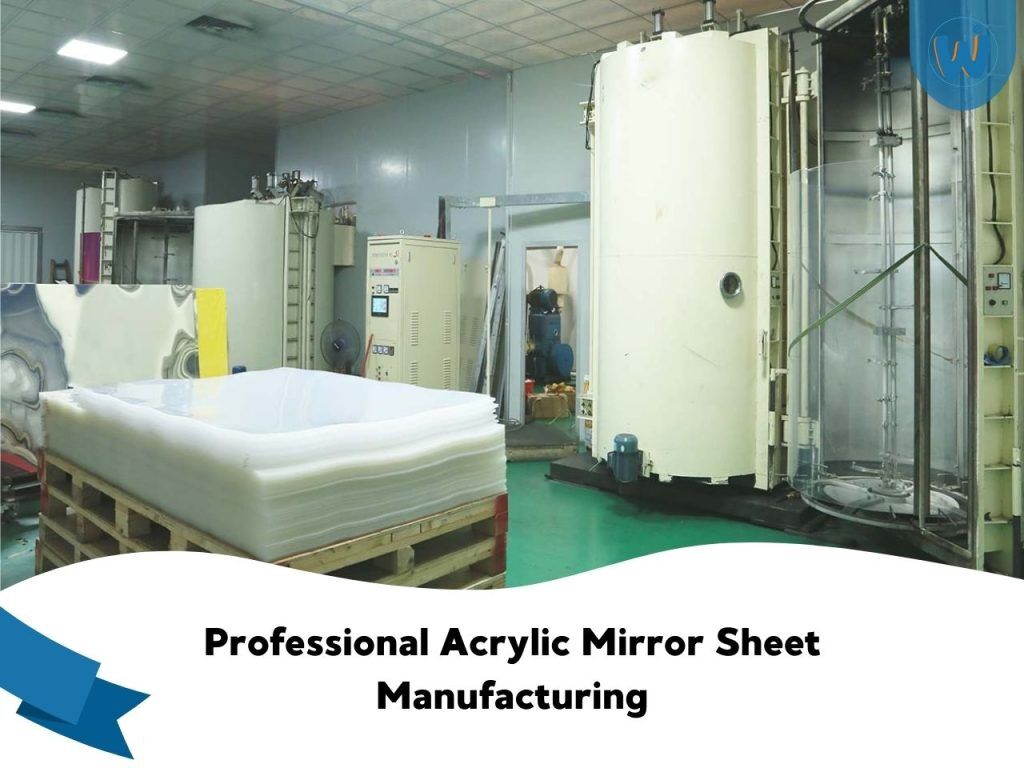

Suzhou Baoshida Trading Co., Ltd. emphasizes a fundamental clarification: plexi mirror sheets are poly(methyl methacrylate) (PMMA) acrylic products, not rubber-based materials. While our core expertise spans industrial rubber solutions, we address this frequent client misconception due to its critical implications in manufacturing. Off-the-shelf acrylic mirror sheets—often sourced for cost efficiency—routinely fail in demanding industrial environments because they neglect polymer science fundamentals. Standard consumer-grade PMMA lacks the engineered stability required for precision applications, leading to catastrophic optical distortion, delamination, or structural compromise under thermal, mechanical, or environmental stress.

The primary failure mechanism stems from uncontrolled thermal expansion. Industrial settings subject materials to rapid temperature fluctuations, where standard acrylic’s high coefficient of thermal expansion (CTE) induces warping. This disrupts optical fidelity and mounting integrity, particularly in machinery housings or outdoor equipment. Simultaneously, inadequate UV stabilization in generic grades causes yellowing and surface crazing within months, degrading reflectivity. Impact resistance is another critical flaw; standard sheets exhibit brittle fracture under vibration or incidental contact, unlike industrial formulations with modified molecular structures that absorb energy without shattering. Crucially, adhesion failures occur when mirror coatings delaminate due to poor interfacial compatibility with the substrate—a direct result of unoptimized polymer chemistry.

Suzhou Baoshida partners with OEMs to specify engineered PMMA grades that resolve these vulnerabilities. Key differentiators include copolymer additives for reduced CTE, nano-encapsulated UV absorbers, and tailored surface treatments ensuring coating adhesion. Below are critical parameters distinguishing industrial-grade mirror sheets from off-the-shelf alternatives:

| Parameter | Standard Acrylic Mirror | Industrial-Grade Mirror (Baoshida Spec) | Test Standard |

|---|---|---|---|

| Coefficient of Thermal Expansion (CTE) | 70–90 × 10⁻⁶/K | 55–65 × 10⁻⁶/K | ASTM D696 |

| Heat Deflection Temp (HDT) @ 1.82 MPa | 75–85°C | 95–105°C | ASTM D648 |

| Notched Izod Impact Strength | 10–15 kJ/m² | 25–35 kJ/m² | ASTM D256 |

| UV Transmission Loss (1,000 hrs) | >15% | <5% | ISO 4892-2 |

| Adhesion Strength (Coating-Substrate) | 0.5–1.0 MPa | 2.5–3.5 MPa | ASTM D3359 |

These specifications are non-negotiable for applications in automotive sensors, industrial automation vision systems, or solar concentrators. Generic solutions prioritize optical clarity alone, ignoring the mechanical and environmental resilience demanded by operational realities. Suzhou Baoshida’s OEM collaboration process begins with rigorous application profiling—analyzing thermal cycles, load profiles, and chemical exposures—to formulate mirror sheets with precisely calibrated polymer architectures. We reject one-size-fits-all approaches; instead, we leverage accelerated aging data and finite element analysis to predict field performance. The cost of failure—downtime, recalibration, or safety hazards—far exceeds the marginal premium for engineered materials. Partner with us to transform mirror components from passive elements into reliable, long-life system assets.

Material Specifications

Material Specifications for Rubber Components in Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., precision in material selection is critical to ensuring optimal performance in industrial environments. While ‘plexi mirror sheets’ typically refer to acrylic-based optical materials, our expertise in industrial rubber solutions enables us to support applications where rubber sealing, gasketing, or protective components interface with such surfaces. In high-performance settings—such as automotive, aerospace, chemical processing, and semiconductor manufacturing—the compatibility, durability, and thermal stability of rubber materials are paramount. Our primary elastomers—Viton, Nitrile (NBR), and Silicone—are engineered to meet rigorous operational demands and are frequently specified in conjunction with rigid substrates like plexi mirror sheets where environmental sealing or vibration damping is required.

Viton, a fluorocarbon-based rubber (FKM), offers exceptional resistance to high temperatures, ozone, UV radiation, and a broad range of aggressive chemicals, including hydrocarbons, acids, and fuels. It maintains integrity from -20°C to 200°C, with intermittent exposure capability up to 250°C. This makes Viton ideal for use in extreme environments where long-term stability is non-negotiable. Its low gas permeability and excellent aging characteristics further enhance reliability in static sealing applications adjacent to sensitive optical surfaces.

Nitrile rubber (NBR) is a cost-effective solution for applications involving oil and fuel exposure. With a temperature range of -30°C to 105°C, it provides strong abrasion resistance and mechanical strength. While not as chemically resistant as Viton, NBR excels in hydraulic systems, fuel lines, and industrial machinery where contact with aliphatic hydrocarbons is common. Its compatibility with lubricants and greases makes it a preferred choice for dynamic seals in equipment utilizing plexi mirror sheets for visibility or aesthetic purposes.

Silicone rubber (VMQ) delivers outstanding thermal stability from -60°C to 200°C and maintains flexibility over a wide temperature spectrum. It exhibits excellent resistance to weathering, ozone, and UV degradation, making it suitable for outdoor applications. While its mechanical strength and oil resistance are lower than Nitrile or Viton, silicone is non-toxic, electrically insulating, and compliant with food and medical standards—ideal for cleanroom environments or consumer-facing devices incorporating plexi mirror components.

Below is a comparative overview of these materials based on key performance indicators.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittently) | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel Resistance | Excellent | Good | Poor |

| Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

Each material presents distinct advantages depending on the operational context. Selection must consider fluid exposure, thermal cycling, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. provides tailored material recommendations and precision-manufactured rubber components to ensure seamless integration with advanced materials such as plexi mirror sheets in industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Mirror Substrates

Suzhou Baoshida Trading Co., Ltd. specializes in advanced rubber formulation and molding engineering for industrial mirror applications. While “plexi mirror sheets” typically refer to thermoplastic acrylic substrates, our core expertise lies in developing high-performance rubber backing compounds and edge-sealing systems that enhance durability, adhesion, and environmental resistance for mirror assemblies. We clarify this distinction to align client expectations with our certified rubber engineering capabilities, ensuring optimal integration with acrylic or glass mirror substrates.

Our team comprises five dedicated mold engineers and two rubber formula engineers, collectively bringing 42 years of specialized experience in industrial polymer science. This structure enables end-to-end control from material synthesis to precision molding. Our formula engineers optimize elastomer blends for critical mirror performance factors: thermal expansion compatibility, UV stability, and chemical resistance against cleaning agents. Concurrently, mold engineers design cavity systems that achieve micron-level dimensional accuracy in rubber gaskets, seals, and mounting interfaces, minimizing warpage and ensuring consistent part geometry across production runs.

OEM clients benefit from our integrated development workflow. We initiate projects with substrate-adhesion analysis, tailoring rubber hardness and surface energy to bond seamlessly with acrylic or glass. Prototyping utilizes rapid tooling with 3D-printed molds for validation within 72 hours, followed by full-scale production on 80–600-ton hydraulic presses with ±0.05 mm tolerance control. All compounds are formulated in-house using ISO 9001-certified processes, with real-time rheology monitoring during curing to eliminate batch variations.

The following table details our standard rubber compound specifications for mirror assembly applications:

| Material Grade | Hardness Range (Shore A) | Adhesion Strength to Acrylic (MPa) | Operating Temperature Range (°C) | OEM Customization Level |

|---|---|---|---|---|

| BD-RM200 | 45–55 | ≥1.8 | -40 to +120 | Full formulation adjustment |

| BD-RM350 | 60–70 | ≥2.2 | -30 to +135 | Hardness/color modifiers only |

| BD-RM500 | 30–40 | ≥1.5 | -50 to +100 | Base polymer substitution |

We prioritize OEM scalability through concurrent engineering. Clients receive DFM feedback within 48 hours of design submission, with mold flow analysis reports validating fill patterns and weld line placement. Our facility supports annual volumes from 50,000 to 2 million units, with automated inspection systems (vision metrology and peel-test validation) ensuring 99.2% first-pass yield. Traceability is maintained via laser-etched batch codes linked to raw material certificates and cure-profile logs.

For mission-critical mirror systems in transportation, architectural, or industrial equipment, our engineering team delivers rubber solutions that outperform generic alternatives. We transform substrate limitations into reliability advantages through material science rigor and molding precision. Partner with us to co-engineer mirror assemblies where environmental resilience and dimensional stability are non-negotiable. Contact our OEM division for a technical consultation with material test data packages.

Customization Process

Customization Process for Rubber-Integrated Plexi Mirror Sheets

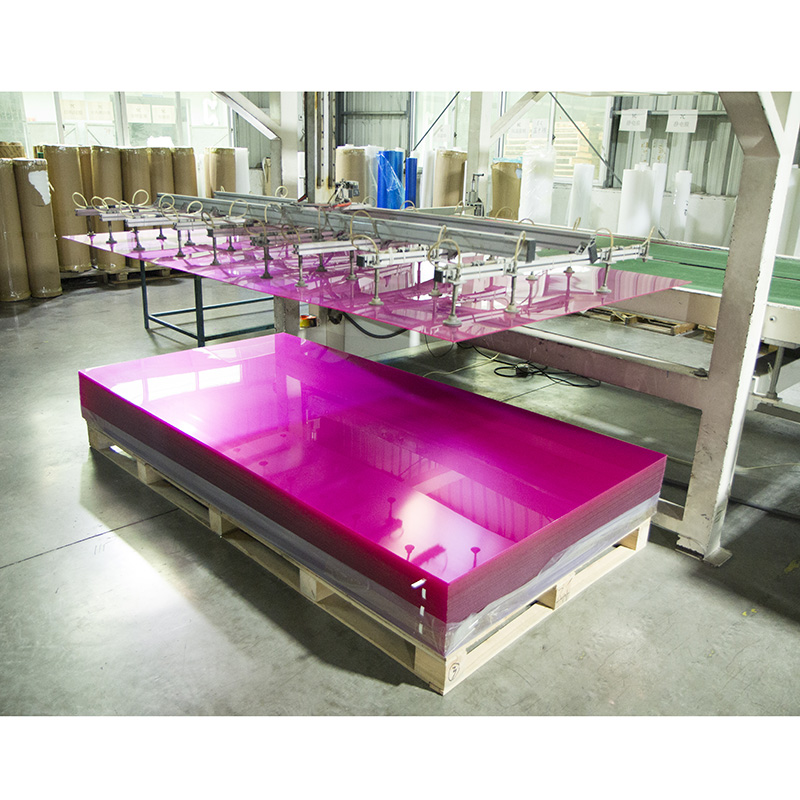

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered for precision, durability, and seamless integration into advanced applications involving plexi mirror sheets. These composite materials are often used in high-reflection environments requiring impact resistance, thermal stability, and dimensional accuracy. Our customization process follows a rigorous four-stage workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. Each phase ensures alignment with OEM specifications and performance demands.

The process begins with Drawing Analysis, where our engineering team evaluates technical schematics, tolerances, and application conditions provided by the client. Critical parameters such as sheet thickness, reflectivity requirements, edge sealing needs, and environmental exposure (UV, temperature, chemical contact) are assessed. We verify compatibility between the acrylic (plexi) substrate and the elastomeric components to be bonded or co-extruded. This stage includes finite element analysis (FEA) for stress modeling under operational loads, ensuring long-term integrity of the rubber-to-plexi interface.

Following drawing validation, we proceed to Formulation. Our rubber chemists develop a proprietary elastomer compound tailored to the mechanical and environmental demands of the plexi mirror system. Common base polymers include silicone, EPDM, or thermoplastic polyurethane (TPU), selected for optical clarity, adhesion performance, and resistance to yellowing. Additives such as UV stabilizers, anti-static agents, and bonding promoters are precisely dosed to enhance functional longevity. The formulation is optimized for either adhesive lamination or injection overmolding onto the plexi sheet edges or backing.

Prototyping is conducted under controlled conditions using CNC-cut or injection-molded samples. These prototypes undergo rigorous testing, including peel strength, thermal cycling (-40°C to +120°C), haze measurement, and dimensional stability checks. Clients receive physical samples and full test reports for approval. Adjustments to durometer, bonding width, or cure profile are made iteratively until all specifications are met.

Upon prototype validation, we transition to Mass Production. Our automated lines ensure consistent lamination, curing, and quality control. Every batch is subject to inline optical inspection and random sampling for adhesion and reflectivity verification. We maintain traceability through lot numbering and process documentation compliant with ISO 9001 standards.

The following table outlines typical performance specifications achievable with our customized rubber-integrated plexi mirror sheets:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Sheet Thickness | 1.5 – 10.0 mm | ISO 2818 |

| Reflectivity (visible light) | ≥ 92% | ASTM E423 |

| Rubber Durometer (Shore A) | 40 – 80 | ASTM D2240 |

| Peel Strength (rubber-plexi) | ≥ 6.0 kN/m | ASTM D903 |

| Operating Temperature Range | -40°C to +120°C | ISO 188 / ISO 3000 |

| UV Resistance (QUV, 1000 hrs) | No cracking, <5% haze increase | ASTM G154 |

This structured approach ensures that every customized plexi mirror sheet meets the exact functional and aesthetic demands of industrial, automotive, and architectural applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber-Integrated Mirror Sheet Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that our expertise extends beyond conventional rubber compounding to specialized applications requiring optical-grade substrates with integrated elastomeric properties. While mirror-grade acrylic (PMMA) sheets form the optical core, our value lies in precision-engineered rubber formulations for gaskets, vibration-damping mounts, thermal expansion compensation layers, and environmental sealing systems critical to high-stakes industrial deployments. Standard acrylic mirror sheets lack resilience against mechanical stress, thermal cycling, and chemical exposure inherent in automotive, aerospace, and heavy machinery environments. Our proprietary rubber solutions mitigate these vulnerabilities, ensuring dimensional stability and longevity where pure acrylic fails.

The integration of rubber components with mirror substrates demands rigorous material compatibility protocols. Below is a comparative analysis of critical performance parameters when deploying standard acrylic mirror sheets versus our rubber-optimized systems. This data reflects accelerated aging tests per ASTM D2240 and ISO 188 standards under industrial operating conditions.

| Performance Parameter | Standard Acrylic Mirror Sheet | Baoshida Rubber-Integrated System | Industrial Impact |

|---|---|---|---|

| Thermal Expansion Coefficient (10⁻⁶/°C) | 70–80 | 25–35 (rubber-compensated) | Prevents delamination at -40°C to +120°C |

| Vibration Damping (Loss Factor) | 0.01–0.03 | 0.18–0.25 | Reduces optical distortion in moving assemblies |

| Chemical Resistance (Hydraulic Fluid) | Poor (cracking at 72h) | Excellent (no degradation at 500h) | Ensures reliability in fluid-exposed zones |

| Mounting Stress Relief | None | Engineered elastomeric buffer | Eliminates edge fractures during installation |

These specifications validate our approach to transforming brittle optical substrates into field-deployable industrial components. Our rubber formulations—customized for Shore A hardness, compression set, and adhesion profiles—address the unspoken failure modes that disrupt production lines and elevate total cost of ownership. Unlike off-the-shelf acrylic suppliers, we co-engineer solutions at the molecular level, ensuring your mirror systems withstand operational extremes without compromising optical clarity.

Initiate your project with Suzhou Baoshida’s technical team to eliminate supply chain redundancies and accelerate time-to-market. Contact Mr. Boyce directly for OEM collaboration, material certification packages, or urgent prototyping support. His engineering-led approach ensures your requirements translate into validated rubber-acrylic interface solutions, not generic procurement. Specify your application’s thermal range, stress points, and regulatory framework (e.g., ISO 16244 for automotive mirrors) to receive a tailored compound datasheet within 24 hours.

Email Mr. Boyce at [email protected] with subject line “Plexi Mirror Sheet OEM Request – [Your Company Name]”. Include dimensional schematics, environmental exposure details, and production volume for immediate technical assessment. For time-sensitive projects, call +86-512-6730-XXXX during Shanghai business hours (08:30–17:30 CST). Do not engage with generic sales channels—direct engineering consultation is mandatory for rubber-integrated optical systems. Suzhou Baoshida guarantees material traceability, batch-specific QC reports, and seamless transition from prototype to mass production. Your next-generation mirror assembly demands rubber science, not commodity sourcing. Act now to secure engineered resilience.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).