Technical Contents

Engineering Guide: Freeze Plug Purpose

Engineering Insight: The Critical Role of Material Selection in Freeze Plug Applications

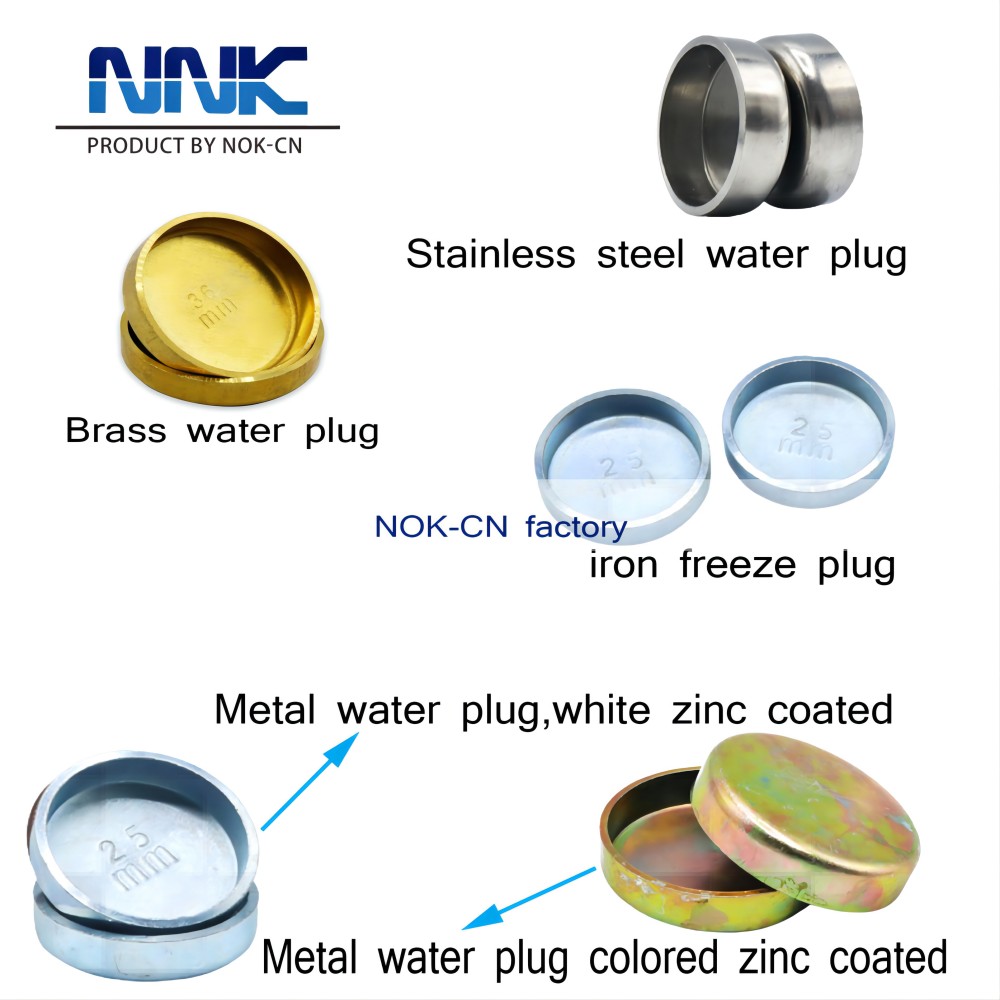

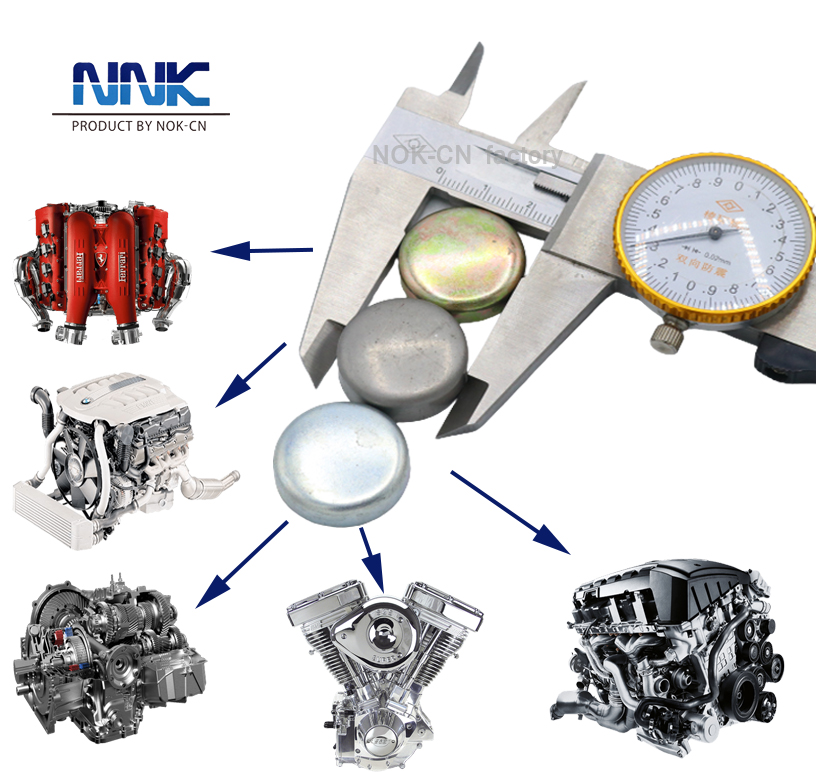

In industrial manufacturing and automotive engineering, freeze plugs—also known as core plugs or expansion plugs—are essential components used to seal openings in engine blocks, transmission housings, and other cast metal assemblies created during the casting process. While their function appears straightforward, the performance and longevity of freeze plugs are heavily dependent on material selection. Off-the-shelf solutions, often made from generic elastomers or metals, frequently fail under real-world operating conditions due to inadequate compatibility with thermal cycling, fluid exposure, and mechanical stress.

The primary purpose of a freeze plug is to maintain a hermetic seal under variable pressure and temperature conditions, particularly in environments exposed to coolant, oil, or antifreeze agents. Standard rubber materials such as natural rubber (NR) or low-grade nitrile (NBR) are commonly used in mass-produced plugs, but these exhibit poor resistance to oxidation, ozone, and swelling when exposed to modern glycol-based coolants. Over time, this leads to hardening, cracking, or extrusion, resulting in coolant leakage and potential engine damage.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions tailored to the operational demands of the application. For instance, hydrogenated nitrile rubber (HNBR) offers superior thermal stability (up to 150°C continuously) and enhanced resistance to oils and coolants, making it ideal for high-performance automotive and industrial systems. Similarly, fluorocarbon rubber (FKM) provides exceptional chemical inertness and temperature resistance (up to 200°C), suitable for extreme environments such as heavy-duty machinery or marine propulsion systems.

Metallic freeze plugs, typically made from stamped steel or stainless steel, are often used in high-pressure zones but are prone to galvanic corrosion when mismatched with the base metal of the housing. This underscores the need for precise material pairing and protective coatings, such as electrophoretic deposition (EPD) or rubber overmolding, to prevent electrochemical degradation.

A comparative analysis of common freeze plug materials highlights these performance differentials:

| Material | Temperature Range (°C) | Coolant Resistance | Compression Set Resistance | Typical Use Case |

|---|---|---|---|---|

| Natural Rubber (NR) | -40 to +100 | Poor | Low | Low-cost, short-life applications |

| Standard NBR | -30 to +120 | Moderate | Moderate | General-purpose automotive |

| HNBR | -40 to +150 | Excellent | High | High-performance engines |

| FKM | -20 to +200 | Outstanding | Very High | Heavy-duty industrial, marine |

| Stainless Steel | -50 to +400 | Good (with passivation) | N/A | High-pressure mechanical systems |

Material selection must also consider installation method—press-fit, expanding, or weld-in—as improper fit can induce stress concentrations that accelerate failure, regardless of base material quality. Custom-engineered solutions from Suzhou Baoshida integrate material science with dimensional precision to ensure long-term sealing integrity.

In conclusion, relying on generic freeze plugs risks system reliability and increases lifecycle costs. Precision material engineering is not an enhancement—it is a necessity for durable, high-performance sealing in modern industrial applications.

Material Specifications

Material Specifications for Freeze Plug Applications

Freeze plugs, also known as expansion or core plugs, serve as critical fail-safes in engine blocks and hydraulic housings to prevent catastrophic damage from freezing coolant. Material selection directly impacts service life under cyclic thermal stress, chemical exposure, and mechanical deformation. At Suzhou Baoshida Trading Co., Ltd., we engineer freeze plugs to ASTM D2000 standards, prioritizing resilience against glycol-based coolants, oils, and extreme temperature gradients. Below we detail three premium elastomers for this application, emphasizing performance boundaries relevant to OEM manufacturing tolerances.

Viton (FKM) remains the benchmark for high-stress environments. Its fluorocarbon structure delivers exceptional resistance to oxygenated fuels, acids, and coolants at temperatures spanning -20°C to +230°C. With a typical durometer of 70–90 Shore A, Viton maintains seal integrity under 1.5 MPa pressure without permanent set, even after 1,000+ thermal cycles between -30°C and +150°C. This material is optimal for turbocharged engines or military-grade equipment where coolant formulations include aggressive inhibitors. However, its higher compound cost necessitates precise cavity design to minimize material waste during molding.

Nitrile (NBR) offers a cost-efficient solution for standard automotive applications. Operating effectively between -40°C and +120°C, NBR with 60–80 Shore A hardness provides robust resistance to aliphatic hydrocarbons and ethylene glycol. Its tensile strength (15–25 MPa) ensures reliable expansion into casting holes during installation, though prolonged exposure above 100°C accelerates compression set. We recommend NBR for passenger vehicles with conventional coolant systems, where production volumes justify optimized tooling for consistent 0.15 mm dimensional tolerances.

Silicone (VMQ) excels in extreme low-temperature scenarios down to -60°C but faces limitations in freeze plug service. While its 40–70 Shore A variants resist ozone and steam, silicone exhibits poor tear strength (<12 kN/m) and swells excessively in glycol mixtures. This compromises dimensional stability during thermal cycling, risking extrusion under pressure. Consequently, silicone is reserved for non-critical auxiliary housings—not primary engine blocks—where flexibility outweighs chemical demands.

The comparative analysis below summarizes critical parameters for OEM validation:

| Material | Durometer Range (Shore A) | Temperature Range (°C) | Key Fluid Resistance | Critical Limitation |

|---|---|---|---|---|

| Viton (FKM) | 70–90 | -20 to +230 | Glycol coolants, acids, fuels | High material cost; requires precision molding |

| Nitrile (NBR) | 60–80 | -40 to +120 | Ethylene glycol, oils, water | Degrades above 120°C; moderate ozone resistance |

| Silicone (VMQ) | 40–70 | -60 to +200 | Steam, ozone, water | Swells in glycol; low tear strength; poor pressure retention |

Suzhou Baoshida’s OEM partners specify Viton for premium applications demanding 150,000-mile warranties, while NBR dominates high-volume production where cost-per-part is critical. Material validation must include ASTM D395 compression set testing after 72 hours at 150°C and immersion in ASTM Type 2 coolant. Our technical team provides compound-specific cure kinetics data to synchronize with your production line cycle times, ensuring zero-defect freeze plug integration. Selecting the correct elastomer prevents field failures directly tied to material-environment mismatches.

Manufacturing Capabilities

Engineering Capability: Precision in Freeze Plug Development and OEM Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to industrial rubber solutions. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we deliver high-integrity freeze plug components tailored to exact OEM specifications. Our engineering synergy ensures that material science, dimensional accuracy, and production efficiency converge to meet the rigorous demands of automotive, marine, and industrial engine applications.

Freeze plugs—also known as core plugs or expansion plugs—are critical components in engine block and radiator assemblies, designed to seal casting holes and prevent coolant leakage. Their performance under thermal cycling, pressure fluctuations, and exposure to corrosive fluids demands precise material formulation and dimensional control. Our formula engineers specialize in developing custom elastomer compounds that balance resilience, temperature resistance, and long-term sealing performance. Utilizing advanced polymer blends such as NBR, EPDM, and silicone, we formulate rubber compounds that maintain integrity across -40°C to +150°C operational ranges, depending on application requirements.

Our five in-house mould engineers bring extensive experience in precision tooling design and process optimization. Each freeze plug mould is engineered using 3D CAD systems and validated through finite element analysis (FEA) to ensure uniform wall thickness, minimal flash, and repeatable cavity filling. We maintain strict control over shrinkage factors, parting lines, and ejection systems to guarantee consistency across production runs. This level of technical oversight enables us to produce freeze plugs with tight tolerances and superior surface finish—critical for leak-free performance in end-use environments.

OEM collaboration is central to our operational model. We support full design-for-manufacturability (DFM) reviews, rapid prototyping, and first-article inspection (FAI) reporting. Our engineering team works directly with client design specifications to refine geometries, recommend material upgrades, and optimize production cycles—ensuring seamless integration into existing assembly lines. With in-house tooling, material development, and quality testing, we offer a vertically integrated solution that reduces time-to-market and ensures supply chain stability.

The following table outlines key technical specifications for our standard freeze plug offerings:

| Parameter | Specification |

|---|---|

| Material Options | NBR, EPDM, Silicone, HNBR |

| Hardness Range (Shore A) | 50–80 |

| Temperature Resistance | -40°C to +150°C (varies by compound) |

| Standard Diameters | 1.0″ to 3.5″ (25 mm to 89 mm) |

| Tolerance (Diameter) | ±0.1 mm |

| Production Process | Compression Molding, Transfer Molding |

| OEM Customization | Full geometric and material customization |

| Testing Standards | ASTM D2000, ISO 3302, ISO 2230 |

Suzhou Baoshida Trading Co., Ltd. combines formula intelligence with precision engineering to deliver freeze plugs that exceed performance expectations. Our OEM-ready capabilities ensure reliability, scalability, and technical partnership at every stage of product development.

Customization Process

Customization Process for Industrial Freeze Plugs

Precision-engineered freeze plugs demand rigorous customization to withstand extreme thermal cycling, fluid exposure, and mechanical stress in automotive and industrial cooling systems. At Suzhou Baoshida Trading Co., Ltd., our OEM-driven process ensures optimal performance through four integrated phases, eliminating field failures through scientific material science and manufacturing control.

Drawing Analysis

We initiate with comprehensive dimensional and environmental validation of client-supplied technical drawings. Critical parameters include sealing surface geometry, interference fit tolerances (±0.05mm), and fluid compatibility requirements per ASTM D2000. Our engineers cross-reference operational conditions—such as coolant types (ethylene glycol, propylene glycol, or oil-based fluids), temperature excursions (-40°C to 150°C), and pressure cycles—to define material behavior boundaries. This phase identifies risks like extrusion gaps or thermal contraction mismatches before formulation begins.

Formulation Development

Leveraging 15+ years of rubber compound expertise, we select base polymers and additives to meet exact performance thresholds. Freeze plugs require exceptional low-temperature flexibility, compression set resistance, and fluid impermeability. Our proprietary NBR or EPDM formulations incorporate specialized fillers, anti-degradants, and vulcanization systems tailored to the client’s thermal profile. For instance, glycol-resistant compounds use carboxylated NBR with controlled acrylonitrile content (34-38%), while high-temperature variants employ peroxide-cured EPDM with synergistic antioxidant packages. All formulations undergo predictive modeling for compression set (ASTM D395) and fluid swell (ASTM D471) prior to prototyping.

Prototyping and Validation

Molded prototypes are subjected to accelerated life testing simulating 10,000+ thermal cycles (-40°C to 125°C) and 500-hour fluid immersion. Key metrics include burst pressure (minimum 1.5x operating pressure), compression set (<25% at 100°C/22h), and dimensional stability after aging. We provide clients with full material test reports (MTRs) and coordinate dimensional inspections via CMM. Iterations focus on resolving micro-shrinkage or surface defects, ensuring zero porosity in critical sealing zones.

Mass Production Execution

Upon client sign-off, production commences under IATF 16949-certified protocols. Each batch undergoes real-time SPC monitoring of Mooney viscosity (ML 1+4 @ 100°C), cure characteristics (t90), and durometer (Shore A ±2 points). Freeze plugs are molded in temperature-controlled cavities with automated ejection to prevent distortion. 100% visual inspection and statistical sampling for critical dimensions (per ASME Y14.5) guarantee consistency. Traceability is maintained via lot-coded documentation, including raw material certificates and process parameter logs.

Material performance specifications for common freeze plug applications are summarized below:

| Material Type | Temperature Range | Key Fluid Resistance | Compression Set (100°C/22h) | Typical Applications |

|---|---|---|---|---|

| Carboxylated NBR | -40°C to 125°C | Ethylene/Propylene Glycol, Oils | ≤22% | Automotive Engine Blocks, Transmissions |

| Peroxide-Cured EPDM | -50°C to 150°C | Hot Water, Steam, Brake Fluid | ≤18% | Heavy-Duty Radiators, Hydraulic Systems |

| HNBR | -40°C to 175°C | Aggressive Coolants, Fuels | ≤20% | High-Performance EV Cooling Systems |

This structured approach transforms theoretical requirements into field-proven components, reducing client warranty costs through scientifically validated rubber solutions. Suzhou Baoshida ensures every freeze plug meets the uncompromising demands of modern thermal management systems.

Contact Engineering Team

Contact Suzhou Baoshida for Expert Rubber Solutions in Freeze Plug Applications

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber components engineered for reliability, durability, and precision. Our expertise in freeze plug technology supports a broad range of manufacturing, automotive, and heavy equipment applications where sealing integrity under extreme conditions is non-negotiable. Whether you are developing new engine blocks, transmission housings, or industrial machinery requiring controlled expansion and permanent sealing, our freeze plugs offer a proven solution backed by rigorous material science and OEM-level quality control.

Freeze plugs, also known as expansion or core plugs, are critical components used to seal openings in cast metal parts created during the molding process. These plugs are designed to expand hydraulically or mechanically, forming a permanent, leak-proof seal that withstands thermal cycling, vibration, and internal pressure. At Suzhou Baoshida, we produce freeze plugs using advanced elastomeric formulations tailored to meet specific environmental and operational demands. Our materials include nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and fluorocarbon (FKM), each selected for optimal resistance to oil, coolant, ozone, and temperature extremes.

We understand that performance consistency is paramount in industrial applications. That’s why every freeze plug we manufacture undergoes stringent dimensional verification, compression set testing, and burst pressure validation. Our production lines are ISO 9001-certified, ensuring traceability, repeatability, and compliance with international standards. Additionally, we support custom tooling and formulation development to meet unique OEM specifications, including non-standard sizes, durometer ratings, and low-outgassing requirements.

To ensure seamless integration into your production workflow, we provide comprehensive technical documentation, including material certifications, test reports, and installation guidelines. Our engineering team is available for direct consultation to assist in material selection, failure analysis, and process optimization.

Below is a representative specification table for our standard freeze plug offerings:

| Parameter | NBR (Nitrile) | EPDM | FKM (Viton®) |

|---|---|---|---|

| Hardness (Shore A) | 60–90 ±5 | 65–85 ±5 | 70–80 ±5 |

| Temperature Range | -30°C to +125°C | -50°C to +150°C | -20°C to +200°C |

| Tensile Strength | ≥12 MPa | ≥10 MPa | ≥11 MPa |

| Elongation at Break | ≥250% | ≥200% | ≥180% |

| Fluid Resistance | Oil, fuel, water-glycol | Coolant, steam, water | Aggressive chemicals, oils |

| Compression Set (70h, 100°C) | ≤30% | ≤25% | ≤20% |

For custom projects or high-volume OEM supply agreements, we offer rapid prototyping, on-site QA support, and just-in-time logistics to maintain your production efficiency.

To discuss your freeze plug requirements with a qualified Rubber Formula Engineer, contact Mr. Boyce directly at [email protected]. We respond to all technical inquiries within 24 business hours and provide sample kits upon request. Partner with Suzhou Baoshida Trading Co., Ltd. for engineered rubber solutions that meet the highest industrial standards.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).