Technical Contents

Engineering Guide: Rubber Gaskit

Engineering Insight: The Critical Role of Material Selection in Rubber Gasket Performance

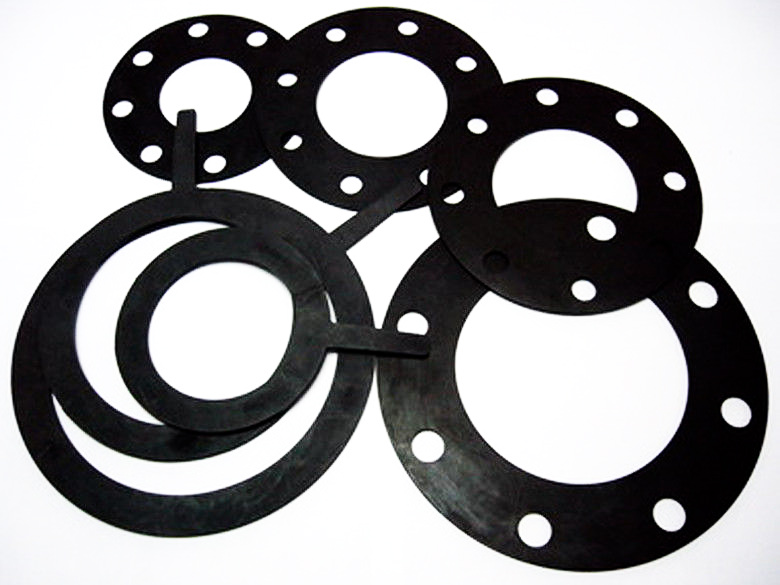

In industrial sealing applications, the rubber gasket serves as a critical interface between mating surfaces, ensuring leak-free performance under pressure, temperature fluctuations, and chemical exposure. Despite its seemingly simple form, the functional reliability of a rubber gasket is profoundly dependent on precise material selection. Off-the-shelf gasket solutions, while cost-attractive and readily available, frequently fail in demanding environments due to a fundamental mismatch between standardized material properties and application-specific requirements.

Generic gaskets are typically manufactured from common elastomers such as natural rubber or low-grade NBR (nitrile butadiene rubber), optimized for broad compatibility rather than targeted performance. These materials may suffice in benign conditions—moderate temperatures, non-aggressive media, and low cyclic stress. However, in industrial environments involving extreme temperatures, ozone exposure, hydraulic fluids, or corrosive chemicals, such materials degrade rapidly. Swelling, compression set, cracking, and loss of sealing force are common failure modes directly attributable to inappropriate elastomer selection.

Material selection must begin with a comprehensive assessment of the operational environment. Key parameters include fluid media, temperature range, pressure dynamics, and exposure to environmental factors such as UV radiation or ozone. For example, fluorocarbon rubber (FKM) offers superior resistance to high temperatures and aggressive chemicals, making it ideal for automotive and chemical processing applications. Conversely, EPDM (ethylene propylene diene monomer) excels in steam and hot water environments but performs poorly with hydrocarbon oils, highlighting the necessity of chemical compatibility analysis.

Another often-overlooked factor is compression set resistance—the ability of a gasket to maintain sealing force after prolonged compression. In high-cycle or high-temperature applications, materials with poor compression set resistance will permanently deform, leading to seal failure. Silicone rubber, while excellent for wide temperature ranges and food-grade applications, may exhibit higher compression set compared to FKM or HNBR (hydrogenated nitrile), making it less suitable for long-term static sealing under load.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered solutions over generic alternatives. Our technical team collaborates with OEMs to analyze application data, recommend optimal elastomers, and validate performance through material testing protocols. This precision-driven approach ensures extended service life, reduced downtime, and compliance with industry standards.

The following table outlines key elastomer properties for common industrial gasket materials:

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Applications |

|---|---|---|---|---|

| NBR | -30 to +100 | Oils, fuels, water | Poor ozone and UV resistance | Hydraulic systems, automotive seals |

| FKM | -20 to +200 | Acids, oils, solvents | High cost, poor low-temp flexibility | Chemical processing, aerospace |

| EPDM | -50 to +150 | Steam, water, alkalis | Swells in hydrocarbons | HVAC, water treatment |

| Silicone | -60 to +200 | Oxygen, UV, hot water | Low tensile strength, high compression set | Medical devices, food processing |

| HNBR | -40 to +150 | Oils, ozone, hot water | Limited resistance to polar solvents | Industrial machinery, oil & gas |

Material selection is not a commodity decision—it is an engineering imperative. The consequences of gasket failure extend beyond leakage to include safety hazards, environmental violations, and costly equipment damage. By prioritizing application-specific material engineering, manufacturers can achieve reliable, long-term sealing performance that off-the-shelf solutions simply cannot deliver.

Material Specifications

Material Specifications for Industrial Rubber Gaskets

Selecting the optimal elastomer for rubber gaskets is critical for ensuring long-term sealing integrity under operational stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science precision to match gasket performance with application demands. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three cornerstone materials, each engineered for distinct environmental challenges. Viton excels in extreme chemical and thermal resistance, making it indispensable for aerospace and chemical processing where exposure to aggressive fuels, acids, and temperatures up to 230°C occurs. Its molecular stability prevents degradation under sustained stress, though higher cost necessitates justified use cases. Nitrile remains the industry standard for oil and fuel applications due to its exceptional hydrocarbon resistance and cost efficiency. With a balanced tensile strength of 15–20 MPa and operational range from -40°C to 120°C, it performs reliably in automotive and hydraulic systems where petroleum-based fluids dominate. Silicone offers unparalleled flexibility across extreme temperatures (-60°C to 200°C) and biocompatibility, ideal for medical, food-grade, and high-temperature electrical applications. Its low compression set ensures consistent sealing force retention, though limited tear strength requires careful design in high-abrasion environments.

Material selection must align with fluid compatibility, thermal cycling, pressure loads, and regulatory requirements. Misalignment risks premature failure through extrusion, hardening, or swelling. Below is a technical comparison of key properties per ASTM D2000 standards:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12–18 | 15–20 | 6–10 |

| Elongation at Break (%) | 150–250 | 200–350 | 300–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Resistances | Fuels, acids, ozone | Oils, fuels, water | Ozone, steam, radiation |

| Key Limitations | Poor ketone resistance; high cost | Limited heat resistance; poor ozone resistance | Low tear strength; permeable to gases |

Viton’s fluorocarbon backbone delivers unmatched resilience against aromatic hydrocarbons and chlorinated solvents but requires careful evaluation for ketone exposure. Nitrile’s acrylonitrile content directly correlates with oil resistance—higher ACN grades (e.g., 40–50%) suit severe fuel contact but reduce low-temperature flexibility. Silicone’s siloxane bonds provide thermal stability yet demand reinforcement for dynamic sealing applications. Each material undergoes rigorous batch testing for consistency in compression set, fluid immersion, and aging per OEM specifications. Suzhou Baoshida Trading Co., Ltd. provides certified material data sheets and application engineering support to validate gasket performance against your operational parameters. Consult our technical team to optimize material grade selection, avoiding over-engineering while ensuring safety and compliance in critical sealing interfaces.

Manufacturing Capabilities

Engineering Excellence in Rubber Gasket Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver precision-engineered rubber gaskets tailored to the exact performance demands of diverse industrial applications. Our integrated approach ensures that material science and mechanical design are developed in parallel, resulting in optimized product performance, longevity, and reliability under extreme operational conditions.

Our formula engineers possess deep expertise in polymer chemistry and compound formulation. They develop custom rubber compounds using materials such as NBR, EPDM, silicone, FKM, and CR, selecting base polymers, fillers, accelerators, and vulcanizing agents to achieve specific physical and chemical properties. Whether the requirement is resistance to high temperature, oil, ozone, or compression set, our formulations are rigorously tested to meet international standards including ASTM D2000 and ISO 3302. This scientific approach ensures that every gasket performs consistently across dynamic sealing environments.

Complementing our material expertise, our five mould engineers bring advanced design and tooling capabilities in-house. Utilizing CAD/CAM software such as AutoCAD, SolidWorks, and UG NX, they develop precision moulds with tight tolerances, optimized flow channels, and efficient venting systems to ensure defect-free production. Our team applies finite element analysis (FEA) to simulate compression behavior and sealing performance, reducing prototyping cycles and accelerating time-to-market. From initial concept to final validation, we maintain full control over the tooling process, enabling rapid iteration and strict adherence to OEM specifications.

Our OEM manufacturing capability is built on this dual foundation of material and mechanical engineering. We support global clients in automotive, aerospace, energy, and industrial equipment sectors by providing fully customized gasket solutions. From low-volume prototypes to high-volume production runs, our facility integrates automated compression, transfer, and injection moulding lines with real-time quality monitoring. This allows us to maintain batch consistency and traceability, critical for industries requiring full compliance with ISO 9001 and IATF 16949 standards.

The synergy between our formula and mould engineering teams enables us to solve complex sealing challenges where standard off-the-shelf products fail. We collaborate closely with clients during the design phase to recommend optimal materials, geometries, and manufacturing methods—ensuring cost efficiency without compromising performance.

Key Engineering Specifications

| Parameter | Capability |

|---|---|

| Material Development | NBR, EPDM, FKM, Silicone, CR, NR, IIR |

| Hardness Range (Shore A) | 30 to 90 |

| Tolerance Compliance | ISO 3302, ASTM D3183 |

| Mould Design Software | SolidWorks, AutoCAD, UG NX |

| Production Moulding Methods | Compression, Transfer, Injection Moulding |

| Sample Development Lead Time | 7–15 days (depending on complexity) |

| Standard Compliance | ASTM, ISO, ROHS, FDA (upon request) |

Through advanced engineering integration and a client-centric development process, Suzhou Baoshida delivers technically superior rubber gaskets that meet the evolving demands of modern industry.

Customization Process

Customization Process for Precision Rubber Gaskets

Industrial gasket performance hinges on exact material properties and dimensional accuracy tailored to operational demands. At Suzhou Baoshida Trading Co., Ltd., our OEM-driven customization process systematically transforms client specifications into validated solutions. This ensures leak-proof integrity under extreme pressure, temperature, and chemical exposure while minimizing lifecycle costs.

Drawing Analysis

Our engineering team initiates with rigorous dissection of client-provided CAD drawings or physical samples. Critical parameters—including groove dimensions, surface finish tolerances (per ISO 3601), and flange geometry—are cross-referenced against application media (e.g., hydraulic fluid, steam, or corrosive chemicals). Finite element analysis (FEA) identifies stress concentration zones, while compression set calculations predict long-term sealing force retention. Any deviations from manufacturable tolerances (±0.05mm for critical diameters) are flagged for collaborative redesign, preventing costly field failures.

Formulation Development

Material selection transitions from theoretical analysis to molecular engineering. Based on media compatibility charts and thermal profiling, our rubber chemists design proprietary compounds. For instance, NBR formulations prioritize acrylonitrile content for oil resistance, while EPDM variants incorporate terpolymer ratios optimizing ozone stability. Key properties—tensile strength, elongation, and compression set—are fine-tuned via sulfur vs. peroxide curing systems. All formulations adhere to ASTM D2000 classification standards, with traceable batch documentation for aerospace or automotive OEMs.

Prototyping & Validation

Precision-molded prototypes undergo accelerated lifecycle testing in simulated operating conditions. We execute 3x validation cycles: initial compression deflection checks per ASTM F36, followed by 72-hour immersion in target fluids at elevated temperatures, and final leak-rate quantification via helium mass spectrometry (detection limit: 1×10⁻⁹ atm·cm³/s). Client feedback on prototype performance triggers iterative refinements—adjusting durometer (40–90 Shore A) or filler loading—until all KPIs are met.

Mass Production Assurance

Approved formulations enter ISO 9001-certified production with embedded quality gates. Every lot undergoes real-time rheometry monitoring to ensure cure consistency (Δ torque ≤ 0.5 dNm). Dimensional verification employs automated optical comparators, while destructive testing samples are archived for 5 years. For high-volume OEM contracts, we implement SPC charts tracking critical-to-quality (CTQ) parameters, guaranteeing ≤ 50 PPM defect rates.

Key Material Specifications

| Material Type | Hardness (Shore A) | Temp Range (°C) | Compression Set (B) | Fluid Resistance |

|—————|——————-|—————–|———————|——————|

| NBR | 50–90 | -30 to +120 | ≤ 25% @ 70°C/22h | Oils, Fuels |

| EPDM | 50–80 | -50 to +150 | ≤ 20% @ 100°C/22h | Steam, Alkalis |

| FKM | 60–85 | -20 to +230 | ≤ 15% @ 150°C/70h | Aggressive Chem |

| Silicone | 40–70 | -60 to +200 | ≤ 30% @ 150°C/22h | Food, Pharma |

This phased methodology eliminates guesswork, transforming complex sealing challenges into repeatable manufacturing excellence. Suzhou Baoshida’s integration of material science and process control delivers gaskets that exceed OEM durability expectations while accelerating time-to-market.

Contact Engineering Team

For precision-engineered industrial rubber gaskets designed to meet the rigorous demands of modern manufacturing, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in high-performance sealing solutions. With extensive expertise in rubber formulation and OEM manufacturing, we deliver custom gasket products tailored to exact client specifications, ensuring optimal performance across diverse operating environments. Our commitment to material science, dimensional accuracy, and long-term reliability has positioned us as a preferred supplier for industries ranging from automotive and aerospace to petrochemical and heavy machinery.

At the core of our manufacturing capability is a deep understanding of elastomer behavior under stress, temperature fluctuation, and chemical exposure. We specialize in selecting and compounding rubber materials such as NBR, EPDM, silicone, FKM (Viton), and neoprene, ensuring each gasket performs reliably in its intended application. Whether you require resistance to extreme heat, aggressive fluids, or dynamic mechanical loads, our engineering team works closely with clients to formulate the ideal material matrix and design the appropriate compression set, hardness, and sealing profile.

All gaskets produced by Suzhou Baoshida are manufactured under strict quality control protocols, adhering to international standards including ISO 9001 and ASTM D2000. Our production processes include precision die-cutting, water-jet cutting, and CNC molding, enabling tight tolerances and repeatable consistency across both prototype and high-volume orders. We support custom geometries, multi-layer constructions, and specialty surface finishes to meet exact OEM requirements.

Below is a representative specification table for a standard industrial rubber gasket. All parameters are customizable based on application demands.

| Property | Value | Test Method |

|---|---|---|

| Material | NBR (Nitrile Butadiene Rubber) | ASTM D2000 |

| Hardness (Shore A) | 70 ±5 | ASTM D2240 |

| Tensile Strength | ≥15 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h at 100°C) | ≤25% | ASTM D395 |

| Operating Temperature Range | -30°C to +120°C | ISO 1817 |

| Fluid Resistance | Excellent against oils, fuels, water | ASTM D471 |

| Thickness Tolerance | ±0.1 mm (for 3mm nominal) | ISO 3302 |

To initiate a technical consultation or request a quotation for custom rubber gasket solutions, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. With direct oversight of material development and client engineering integration, Mr. Boyce ensures that every project receives expert attention from concept to delivery. Reach out via email at [email protected] to discuss your sealing challenges, share technical drawings, or request sample submissions. Our team responds promptly to all inquiries, providing detailed feedback on material selection, manufacturability, and lead times.

Partner with Suzhou Baoshida for technically advanced, application-specific rubber gaskets backed by engineering rigor and industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).