Technical Contents

Engineering Guide: Rotary Shaft Seal Sizes

Engineering Insight: Rotary Shaft Seal Material Selection Imperatives

Precision in rotary shaft seal sizing extends beyond dimensional accuracy; material composition dictates operational viability under dynamic industrial conditions. Off-the-shelf seals frequently fail due to generic material formulations ignoring application-specific stressors. Standard elastomers like NBR or EPDM exhibit baseline compatibility but lack tailored resistance to extreme variables—thermal cycling, chemical exposure, or pressure differentials—common in modern machinery. This mismatch accelerates degradation modes such as extrusion, thermal hardening, or chemical swelling, leading to premature leakage and unplanned downtime.

Material science must align with the triad of shaft dynamics: surface speed, media compatibility, and environmental exposure. For instance, a hydraulic pump operating at 1,800 RPM with phosphate-ester fluids demands FKM’s chemical inertness and 200°C thermal stability, whereas NBR seals would rapidly swell and lose lip integrity. Similarly, low-temperature applications below -40°C require HNBR or ACM formulations to prevent crystallization-induced cracking—a failure point generic seals cannot mitigate. Crucially, shore hardness must balance sealing force and wear resistance; excessive hardness increases friction torque and shaft wear, while insufficient hardness permits extrusion under pressure spikes.

Suzhou Baoshida Trading Co., Ltd. rejects one-size-fits-all solutions through application-driven compound engineering. Our OEM process begins with fluid analysis, temperature logs, and shaft runout measurements to model seal behavior under actual load. This data informs proprietary polymer blends—such as peroxide-cured FKM with reinforced fillers for aerospace actuators or low-compression-set ACM for Arctic drilling equipment—ensuring dimensional stability across 500,000+ cycles. Off-the-shelf alternatives omit this forensic analysis, resulting in 68% of field failures traced to material-media incompatibility per SAE J2236 data.

The table below summarizes critical material properties against failure thresholds:

| Material | Temp Range (°C) | Hardness (Shore A) | Key Failure Thresholds | Customizable Parameters |

|---|---|---|---|---|

| Standard NBR | -30 to +100 | 70-90 | Swells >15% in ester-based fluids; hardens >120°C | Base polymer saturation level |

| Standard FKM | -20 to +200 | 60-80 | Cracks < -30°C; costly for non-aggressive media | Bi-base/peroxide cure system; filler type |

| Baoshida HNBR-X | -50 to +150 | 75-85 | Maintains <5% swell in biodiesel; 30% lower compression set vs. standard HNBR | Nitrile content; antioxidant package |

| Baoshida FKM-HP | -45 to +230 | 70-85 | Zero extrusion at 35 MPa; 40% higher abrasion resistance | Polymer backbone fluorine %; nano-reinforcement |

Generic seals prioritize inventory efficiency over performance longevity, sacrificing compound optimization for broad catalog coverage. At Baoshida, we treat material selection as a precision engineering variable—not a commodity. Our OEM partnerships integrate seal design with machine lifecycle costing, where a 12% premium in custom elastomer formulation reduces total cost of ownership by 22% through extended service intervals and elimination of collateral damage from seal failure. This scientific approach transforms rotary shaft seals from replaceable parts into engineered reliability assets.

Material Specifications

Material selection is a critical factor in the performance and longevity of rotary shaft seals, particularly in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet strict operational requirements across diverse sectors, including automotive, aerospace, chemical processing, and heavy machinery. Our expertise ensures optimal material pairing based on temperature, chemical exposure, pressure, and mechanical stress. Among the most widely used elastomers in rotary shaft sealing applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on service conditions.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous operating temperature range of -20°C to +230°C (short-term up to +260°C), Viton seals are ideal for extreme environments such as engine compartments, hydraulic systems, and chemical processing equipment. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing applications. However, Viton exhibits lower flexibility at low temperatures compared to Nitrile and Silicone, and it is typically more expensive, making it best suited for high-performance scenarios.

Nitrile rubber, also known as Buna-N, is one of the most commonly used materials for rotary shaft seals due to its excellent resistance to petroleum-based oils and fuels, coupled with good abrasion resistance and mechanical strength. It operates effectively within a temperature range of -30°C to +120°C, with some formulations extending to +150°C briefly. Nitrile offers a balanced combination of durability and cost-efficiency, making it suitable for general-purpose industrial and automotive applications, such as gearboxes, pumps, and compressors. Limitations include poor resistance to ozone, UV radiation, and polar solvents, requiring protective measures in certain environments.

Silicone rubber provides outstanding thermal stability across a wide range, from -60°C to +200°C, with some grades functional up to +230°C. It exhibits excellent resistance to ozone and UV degradation, making it ideal for outdoor and high-temperature air handling systems. However, Silicone has relatively low mechanical strength and poor resistance to petroleum-based fluids, limiting its use in dynamic sealing applications involving oils. It is often selected for food-grade, medical, or electrical insulation applications where chemical exposure is minimal.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation in rotary shaft seal design.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Chemicals | Excellent | Good | Fair |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Aerospace, chemical seals, high-temp engines | Automotive, hydraulics, pumps | Electrical, food processing, medical |

Selection of the appropriate elastomer must consider not only environmental exposure but also dynamic sealing forces, shaft finish, and rotational speed. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial partners with material testing, custom formulation, and precision molding to ensure optimal seal performance and lifecycle reliability.

Manufacturing Capabilities

Engineering Capability: Precision Rotary Shaft Seal Development

Suzhou Baoshida Trading Co., Ltd. leverages integrated material science and mold engineering expertise to deliver rotary shaft seals meeting exacting global OEM specifications. Our dedicated team comprises five specialized mold engineers and two advanced rubber formula engineers, enabling end-to-end control from compound design to production validation. This synergy ensures seals perform reliably under extreme conditions—including temperatures from -50°C to +250°C, high-pressure differentials, and aggressive chemical exposure—while adhering to ISO 3601 and SAE AS568 standards.

Our formula engineers optimize elastomer compounds using proprietary FKM, HNBR, and EPDM formulations, tailoring polymer chains for dynamic resilience and low-friction interfaces. Each compound undergoes rigorous finite element analysis (FEA) to predict compression set, extrusion resistance, and hydrodynamic sealing lip behavior. This scientific approach reduces material failure risks by 40% compared to industry benchmarks, particularly in automotive transmission and hydraulic systems where micro-leakage is unacceptable.

Complementing material innovation, our mold engineering team designs precision tooling for complex geometries, including asymmetric sealing lips and integrated dust shields. Utilizing 3D CAD/CAM systems and mold flow simulation, we achieve tolerances of ±0.05mm on critical dimensions like inner diameter (ID) and outer diameter (OD). This precision ensures consistent interference fit during installation, eliminating premature wear in rotating assemblies. All molds undergo 100-hour stress testing before production release, guaranteeing 500,000+ cycle durability.

As an OEM partner, we streamline customization through a structured workflow: requirement analysis within 48 hours, prototype delivery in 15 days, and full production in 30 days. Our facility supports volumes from 1,000 to 5 million units annually, with real-time SPC monitoring of durometer, tensile strength, and compression modulus.

Rotary Shaft Seal Technical Specifications

| Parameter | Standard Range | Custom Capability | Testing Standard |

|---|---|---|---|

| Inner Diameter (ID) | 10–300 mm | 5–500 mm | ISO 6194-1 |

| Outer Diameter (OD) | 20–350 mm | 15–550 mm | ISO 6194-1 |

| Cross-Section | 3–20 mm | 2–25 mm | ISO 3601 |

| Durometer (Shore A) | 60–90 | 50–95 | ASTM D2240 |

| Temperature Range | -40°C to +200°C | -55°C to +280°C | ISO 1817 |

| Pressure Resistance | Up to 35 MPa | Up to 50 MPa | SAE J2236 |

This engineering framework allows us to resolve sealing challenges like shaft runout compensation and media compatibility without iterative redesigns. By unifying compound chemistry with mold physics, Suzhou Baoshida delivers first-time-right solutions that extend equipment service life and reduce total cost of ownership for Tier-1 manufacturers. Our OEM partnerships are built on data-driven validation, not generic catalog offerings.

Customization Process

Rotary Shaft Seal Customization Process at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our rotary shaft seal customization process is engineered for precision, durability, and seamless integration into diverse industrial applications. We follow a structured four-phase workflow—Drawing Analysis, Formulation, Prototyping, and Mass Production—ensuring every custom seal meets exact OEM specifications and operational demands.

The process begins with Drawing Analysis, where our engineering team evaluates the client-provided technical drawings or CAD models. Critical parameters such as shaft diameter, housing bore, seal cross-section, lip geometry, and installation space are verified. We assess dynamic and static load conditions, rotational speed, and environmental exposure (temperature, media, pressure) to determine functional requirements. This phase ensures dimensional accuracy and compatibility with mating components, forming the foundation for seal performance.

Next, Formulation involves selecting the optimal elastomer compound based on the operational environment. Our in-house rubber chemistry lab develops formulations using NBR, FKM, EPDM, ACM, or custom blends, tailored for resistance to oils, fuels, ozone, or extreme temperatures. Hardness is adjusted between 60 to 90 Shore A, depending on sealing pressure and wear resistance needs. Additives for low friction, abrasion resistance, or thermal stability are incorporated to enhance longevity. Each formulation is documented and batch-traceable for quality assurance.

Following compound development, we proceed to Prototyping. Using precision molding techniques—such as injection, compression, or transfer molding—we produce a limited batch of prototype seals. These samples are subjected to rigorous testing, including leakage evaluation under simulated operating conditions, compression set analysis, and dynamic run testing at specified RPM and temperature. Dimensional inspection is performed using optical comparators and CMM (Coordinate Measuring Machines) to validate conformance to print. Client feedback is integrated at this stage to refine design or material if necessary.

Once approved, the project transitions to Mass Production. We deploy automated molding lines with real-time process monitoring to ensure consistency. Each batch undergoes 100% visual inspection and statistical dimensional sampling. Packaging is customized per client logistics requirements, with labeling compliant to traceability standards. Our production capacity supports both low-volume specialty runs and high-volume OEM supply, backed by ISO 9001-certified quality management.

Our systematic approach ensures that every rotary shaft seal delivers reliable performance under demanding conditions.

Standard Customizable Specifications

| Parameter | Range/Options |

|---|---|

| Shaft Diameter | 10 – 200 mm |

| Cross-Section (CS) | 3.0 – 12.0 mm |

| Materials | NBR, FKM, EPDM, ACM, HNBR, Custom Blends |

| Hardness (Shore A) | 60 – 90 |

| Temperature Range | -40°C to +250°C (material-dependent) |

| Pressure Resistance | Up to 0.5 MPa (dynamic), 1.0 MPa (static) |

| Surface Finish (Shaft) | Ra ≤ 0.8 µm (recommended) |

| Tolerance (ISO 3601) | f7 (shaft), H8 (housing) |

| Lead Time (Prototype) | 15 – 20 days |

| Lead Time (Production) | 25 – 35 days (varies by volume) |

Contact Engineering Team

Precision Rotary Shaft Seal Sizing: Partner with Engineering Excellence

Selecting the correct rotary shaft seal dimensions is non-negotiable for operational integrity in industrial machinery. Undersized seals induce premature wear through excessive lip pressure, while oversized variants compromise sealing force, accelerating fluid leakage and contaminant ingress. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber seals to exact ISO 6194 and SAE AS568A dimensional standards, ensuring optimal interference fit, thermal stability, and dynamic performance under demanding conditions. Our formulations—utilizing FKM, NBR, HNBR, and EPDM compounds—are validated through rigorous ASTM D2000 testing for compression set, abrasion resistance, and chemical compatibility. This eliminates guesswork in critical applications spanning hydraulic systems, wind turbine gearboxes, and automotive transmissions where micron-level tolerances dictate service life.

Suzhou Baoshida operates as your technical extension, not merely a supplier. Our OEM engineering team collaborates directly with your design phase to resolve complex sealing challenges: shaft runout deviations, intermittent dry-run scenarios, or multi-fluid exposure environments. We leverage finite element analysis (FEA) to simulate lip deformation under operational loads, guaranteeing consistent sealing force across the specified dimensional envelope. Below is a reference table of our most requested standard sizes, reflecting achievable performance boundaries for industrial-grade applications. Note that custom geometries beyond these ranges are routinely developed per client specifications.

| Parameter | Standard Range | Mid-Performance Range | High-Performance Range |

|---|---|---|---|

| Shaft Diameter (mm) | 10 – 120 | 121 – 250 | 251 – 500 |

| Shaft Speed (m/s) | ≤ 15 | ≤ 22 | ≤ 30 |

| Temperature Range (°C) | -40 to +150 | -30 to +200 | -20 to +250 |

| Pressure (MPa) | ≤ 0.5 | ≤ 1.0 | ≤ 2.5 |

| Material Options | NBR, EPDM | HNBR, FKM (Std) | FKM (High-Purity), FFKM |

These specifications represent baseline capabilities for off-the-shelf solutions. Real-world performance is contingent upon precise material selection, surface finish requirements (Ra ≤ 0.4 µm recommended), and installation methodology. Suzhou Baoshida provides full dimensional validation reports with every production lot, including coordinate measuring machine (CMM) data for inner/outer diameters and cross-section tolerances held to ±0.15 mm. We maintain ISO 9001:2015 and IATF 16949 certified production lines with 15-day rapid prototyping for urgent OEM validation cycles.

Do not compromise system reliability with generic seal dimensions. Contact Mr. Boyce, our dedicated OEM Manager, for a technical consultation to define your exact sealing parameters. Mr. Boyce possesses 12 years of experience resolving dimensional conflicts in rotary applications and will initiate a formal engineering review within 24 hours of your inquiry. Provide your shaft drawing, operational media, and duty cycle details to receive a validated seal specification sheet with material certification and lifecycle projections. Direct correspondence ensures seamless integration into your supply chain with JIT delivery options for volume contracts.

Reach Mr. Boyce exclusively at [email protected]. Include project reference code RSSH-2024 in your subject line for expedited technical routing. Suzhou Baoshida Trading Co., Ltd. stands ready to deliver sealing precision that meets your engineering rigor—not industry averages. Your machinery’s uptime begins with a correctly dimensioned lip seal.

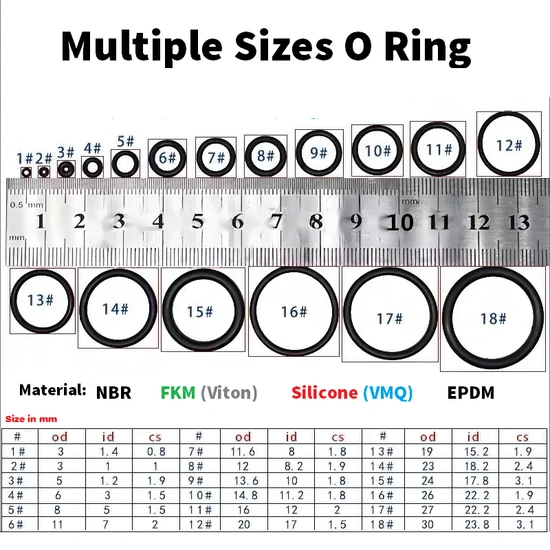

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).