Technical Contents

Engineering Guide: 1 4 Rubber

Engineering Insight: The Critical Role of Material Selection in 1 4 Rubber Applications

In industrial manufacturing, the term “1 4 rubber” often refers to a class of synthetic rubber compounds engineered for specific mechanical and environmental performance thresholds. While it may appear interchangeable with generic elastomers in low-demand applications, the failure of off-the-shelf rubber solutions in critical systems underscores the necessity of precise material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that 1 4 rubber is not a commodity—it is a performance specification defined by compression set resistance, thermal stability, and chemical compatibility.

Standard rubber products are typically formulated for broad applicability, sacrificing optimized performance in extreme conditions. In dynamic sealing, vibration damping, or high-pressure environments, this compromise leads to premature degradation, leakage, or system failure. For instance, an off-the-shelf nitrile (NBR) seal may function adequately at room temperature but rapidly hardens or swells when exposed to ozone, hydraulic fluids, or sustained heat above 100°C. In contrast, a properly engineered 1 4 rubber formulation—such as hydrogenated nitrile (HNBR) or fluorocarbon (FKM)—delivers targeted resilience under defined operational parameters.

Material selection must account for service temperature, fluid exposure, mechanical stress, and lifecycle expectations. A mismatch, even within seemingly similar rubber families, can result in accelerated aging, loss of tensile strength, or extrusion under pressure. This is particularly critical in sectors such as automotive hydraulics, oil and gas equipment, and industrial automation, where downtime carries significant financial and safety implications.

At Baoshida, our approach integrates application-specific testing with OEM design requirements to ensure that each 1 4 rubber compound meets or exceeds performance benchmarks. We collaborate with material scientists and end-users to tailor polymer architecture, filler systems, and cure chemistry—transforming rubber from a passive component into a reliable engineering element.

The following table outlines key performance characteristics of common 1 4 rubber compounds used in industrial applications:

| Property | NBR (Standard) | HNBR (Enhanced) | FKM (High-Performance) | Silicone (Thermal Focus) |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +100 | -40 to +150 | -20 to +200 | -60 to +230 |

| Tensile Strength (MPa) | 15–20 | 25–30 | 12–18 | 6–10 |

| Compression Set (%) @ 70h, 100°C | 25–35 | 15–25 | 15–20 | 20–30 |

| Fluid Resistance (Oil/Fuel) | Good | Excellent | Outstanding | Poor |

| Ozone Resistance | Poor | Good | Excellent | Excellent |

Selecting the appropriate 1 4 rubber compound is not a matter of cost optimization alone—it is a technical decision with direct consequences on system integrity and longevity. Off-the-shelf solutions fail because they are not engineered for your application. At Suzhou Baoshida Trading Co., Ltd., we deliver engineered rubber solutions, not just materials.

Material Specifications

Material Specifications for Critical Sealing Applications

Selecting the appropriate elastomer is paramount for industrial sealing performance under demanding operational conditions. At Suzhou Baoshida Trading Co., Ltd., we rigorously evaluate Viton (fluoroelastomer), Nitrile (NBR), and Silicone based on ASTM D2000 and ISO 37 standards to ensure compatibility with temperature extremes, chemical exposure, and mechanical stress. Each material exhibits distinct molecular properties dictating its suitability for specific OEM applications. Viton excels in high-temperature hydrocarbon environments due to its fluorine content, while Nitrile offers cost-effective resilience against oils and fuels. Silicone provides unmatched flexibility across broad thermal ranges but requires reinforcement for dynamic sealing. Understanding these specifications prevents premature failure in automotive, aerospace, and chemical processing systems.

The following comparative analysis details critical physical and chemical properties essential for engineering validation. All data reflects standard-grade compounds cured to optimal tensile properties.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Shore A Hardness Range | 60–90 | 50–90 | 30–80 |

| Continuous Temp Range | -20°C to +230°C | -40°C to +120°C | -60°C to +200°C |

| Tensile Strength (MPa) | 10–20 | 15–25 | 5–12 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Compression Set (70 hrs) | 15–25% @ 150°C | 20–40% @ 100°C | 10–25% @ 150°C |

| Key Chemical Resistance | Fuels, acids, ozone | Aliphatic oils, water | Ozone, steam, oxygen |

| Key Limitations | Ketones, amines, low temps | Aromatics, HNO₃, ozone | Poor tear strength, fuels |

Viton demonstrates superior resistance to aggressive chemicals including jet fuels and hydraulic fluids, maintaining integrity up to 230°C. Its high fluorine composition minimizes swelling in non-polar media but increases cost versus alternatives. Nitrile remains the industry standard for oil-handling systems due to balanced acrylonitrile content optimizing fuel resistance versus low-temperature flexibility. Standard NBR grades degrade above 120°C and exhibit poor ozone resistance without protective additives. Silicone’s siloxane backbone enables extreme low-temperature performance down to -60°C and biocompatibility for medical uses, yet its low tensile strength necessitates design adjustments for high-pressure dynamic seals.

Suzhou Baoshida Trading Co., Ltd. provides certified material test reports (MTRs) for all elastomer batches, validating conformance to OEM technical drawings. We recommend Viton for aerospace fuel systems, NBR for automotive transmission seals, and Silicone for pharmaceutical diaphragm valves. Material selection must account for simultaneous exposure factors—e.g., NBR’s tensile strength declines 40% when immersed in aromatic hydrocarbons at 100°C. Our engineering team collaborates with clients to simulate service conditions through accelerated aging per ASTM D573, ensuring optimal compound formulation for lifecycle reliability. Contact our technical department for application-specific validation protocols.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver precision, durability, and performance across diverse OEM applications. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, combining expertise in material science, precision tooling, and manufacturing optimization to meet the most demanding industrial requirements.

Our formula engineers focus on the molecular architecture of rubber compounds, tailoring formulations to achieve specific mechanical, thermal, and chemical resistance properties. With deep experience in NBR, EPDM, silicone, FKM, and natural rubber systems, they develop custom compounds that meet exacting standards for compression set, tensile strength, elongation, and resistance to oils, ozone, and extreme temperatures. Each formulation is validated through rigorous laboratory testing, including rheometry, thermogravimetric analysis (TGA), and accelerated aging, ensuring long-term reliability in operational environments.

Complementing this material expertise, our five mould engineers bring advanced design and manufacturing proficiency to every project. Utilizing CAD/CAM software such as AutoCAD, SolidWorks, and UG NX, they develop precision moulds optimized for dimensional accuracy, cycle efficiency, and part consistency. Specialized in multi-cavity, cold-runner, and insert moulding techniques, the team ensures seamless scalability from prototype to mass production. Finite element analysis (FEA) is routinely applied to predict flow behavior and minimize defects such as flash, voids, or incomplete curing.

Our integrated engineering approach enables full-cycle OEM support—from initial concept and material selection to tooling design, prototyping, and serial production. We maintain strict adherence to ISO 9001 quality standards, with documented traceability for every batch produced. This end-to-end control ensures repeatability and compliance, particularly critical in automotive, aerospace, and industrial sealing applications.

Suzhou Baoshida Trading Co., Ltd. is equipped to handle complex technical challenges, including tight-tolerance components, multi-material bonding, and regulatory compliance (e.g., FDA, ROHS, REACH). Our engineering team collaborates directly with clients to refine specifications, conduct Design for Manufacturability (DFM) reviews, and accelerate time-to-market without compromising performance.

The following table outlines key technical capabilities and specifications supported by our engineering team:

| Parameter | Capability Range |

|---|---|

| Rubber Hardness (Shore A) | 30 – 90 Shore A |

| Mould Tolerances | ±0.05 mm (standard), ±0.02 mm (precision) |

| Compound Types | NBR, EPDM, FKM, Silicone, NR, CR, SBR |

| Temperature Resistance | -60°C to +300°C (depending on compound) |

| Mould Complexity | Up to 16 cavities, insert & overmoulding |

| Production Volume | Prototype to 5 million units/month |

| Testing Standards | ASTM D2000, ISO 3302, ISO 2768 |

| Regulatory Compliance | FDA, ROHS, REACH, UL (on request) |

This robust engineering infrastructure positions Suzhou Baoshida as a trusted technical partner in industrial rubber manufacturing, delivering engineered solutions that meet the highest standards of quality, consistency, and innovation.

Customization Process

Customization Process: Precision Engineering for 1 4 Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber customization process for 1 4 rubber compounds follows a rigorously defined engineering pathway. This ensures seamless translation from client specifications to high-performance, volume-ready components. The process eliminates ambiguity through systematic technical validation at each critical phase.

Initial engagement centers on comprehensive Drawing Analysis. Our engineering team dissects provided technical drawings, focusing on dimensional tolerances, critical sealing surfaces, and geometric complexities. We assess manufacturability constraints, identifying potential challenges in mold flow dynamics or ejection. Material compatibility with the intended operating environment—considering fluid exposure, temperature extremes, and mechanical stress—is evaluated against baseline 1 4 rubber properties. This phase establishes the non-negotiable performance envelope for the final part.

Subsequent Formulation leverages our proprietary compound database and deep polymer science expertise. Based on the validated requirements from Drawing Analysis, we architect the precise 1 4 rubber compound. This involves selecting base polymers, optimizing filler systems for reinforcement, and calibrating curatives for target cure kinetics. Critical properties like Shore A hardness, tensile strength, elongation, compression set resistance, and fluid compatibility are engineered to meet or exceed the application’s demands. Formulation is not generic; it is a tailored molecular solution.

Rigorous Prototyping validates the engineered compound and process parameters. We produce functional samples using client-specified tooling or precision-machined prototype molds. Each prototype undergoes stringent in-house testing per international standards (ASTM D2000, ISO 37, ISO 1817). Key metrics include physical property verification, dimensional stability checks, and simulated service condition trials. Client feedback on prototype performance is integrated iteratively. Only upon mutual sign-off confirming all technical and functional criteria are met does the project advance.

Mass Production commences under Suzhou Baoshida’s certified quality management system (ISO 9001). We implement Statistical Process Control (SPC) monitoring for critical parameters like compound viscosity, cure time, and post-cure dimensions. Full traceability from raw material batch to finished component is maintained. Production runs undergo 100% visual inspection and systematic sampling for physical property revalidation. PPAP documentation, including material certifications and test reports, is provided, ensuring seamless integration into the client’s supply chain with zero quality disruption.

The table below illustrates typical performance ranges for common 1 4 rubber compound types engineered during Formulation:

| Property | NBR (Standard) | EPDM (Weather Resistant) | FKM (High Temp) | Units |

|---|---|---|---|---|

| Temperature Range | -30°C to +100°C | -50°C to +150°C | -20°C to +230°C | °C |

| Fluid Resistance (Oil) | Good | Poor | Excellent | – |

| Tensile Strength (Min) | 15 | 10 | 12 | MPa |

| Elongation at Break (Min) | 250 | 200 | 150 | % |

| Compression Set (70h/70°C) | 25 | 20 | 20 | % |

This structured, science-driven approach de-risks customization, guaranteeing that every 1 4 rubber component delivered from Suzhou Baoshida meets the exacting demands of industrial OEM applications.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of material innovation and technical reliability. As a specialized provider in the field of industrial rubber compounds, we deliver high-performance elastomeric materials tailored to meet the rigorous demands of automotive, aerospace, construction, and heavy machinery sectors. Our expertise in formulating and supplying custom rubber compounds ensures optimal performance under extreme thermal, mechanical, and chemical conditions.

At the core of our offering is the development and supply of advanced rubber materials, including formulations based on nitrile (NBR), ethylene propylene diene monomer (EPDM), silicone (VMQ), fluorocarbon (FKM), and natural rubber (NR). Each compound is engineered to exacting standards, balancing tensile strength, elongation, compression set, and resistance to oils, ozone, and temperature extremes. Our technical team works closely with OEMs and Tier suppliers to align material properties with functional requirements, ensuring seamless integration into final component designs.

One of our most widely specified materials is the 1 4 rubber compound, a high-resilience elastomer engineered for dynamic sealing and vibration damping applications. This compound exhibits excellent fatigue resistance, low compression set, and stable performance across a broad temperature range. It is particularly suited for use in hydraulic systems, gasketing, and industrial rollers where dimensional stability and long service life are critical.

The following table outlines the key physical and mechanical properties of the 1 4 rubber compound:

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 70 ± 5 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥350% |

| Compression Set (22 hrs at 70°C) | ASTM D395 | ≤20% |

| Temperature Range | — | -30°C to +100°C |

| Specific Gravity | ASTM D297 | 1.15 ± 0.03 |

| Tear Resistance | ASTM D624 | ≥30 kN/m |

| Fluid Resistance (IRMO 901, 70°C) | ASTM D471 | Volume Change: +5% to +12% |

All batches undergo stringent quality control in accordance with ISO 9001 standards, with full traceability and material certification available upon request. Suzhou Baoshida maintains a responsive manufacturing and logistics network to support just-in-time delivery for global clients.

For technical inquiries, material sampling, or custom formulation development, contact Mr. Boyce, our designated Rubber Formula Engineer and OEM Manager. He brings over 15 years of experience in elastomer science and industrial application engineering, ensuring clients receive not only materials but also comprehensive technical support.

Reach out directly via email at [email protected] to discuss your project specifications, request product data sheets, or initiate a material qualification process. Our team is equipped to provide rapid prototyping assistance, failure analysis, and on-site consultation for high-volume production integration. Partner with Suzhou Baoshida Trading Co., Ltd. to advance your manufacturing capabilities with scientifically optimized rubber solutions.

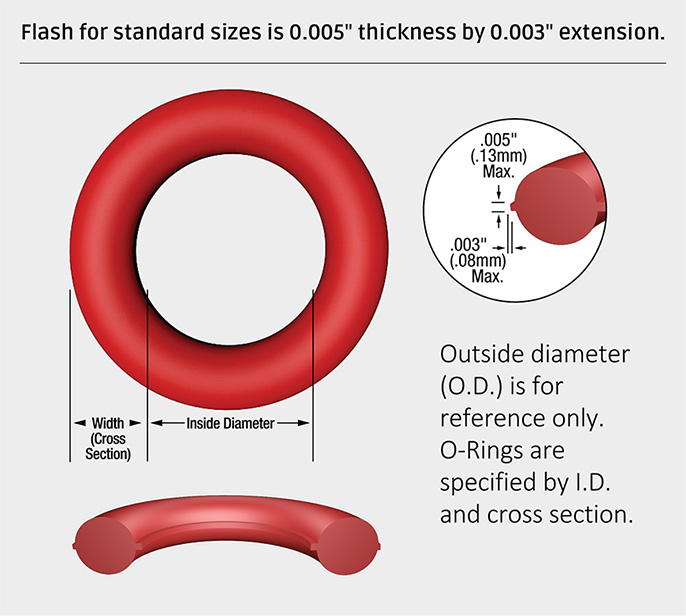

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).