Technical Contents

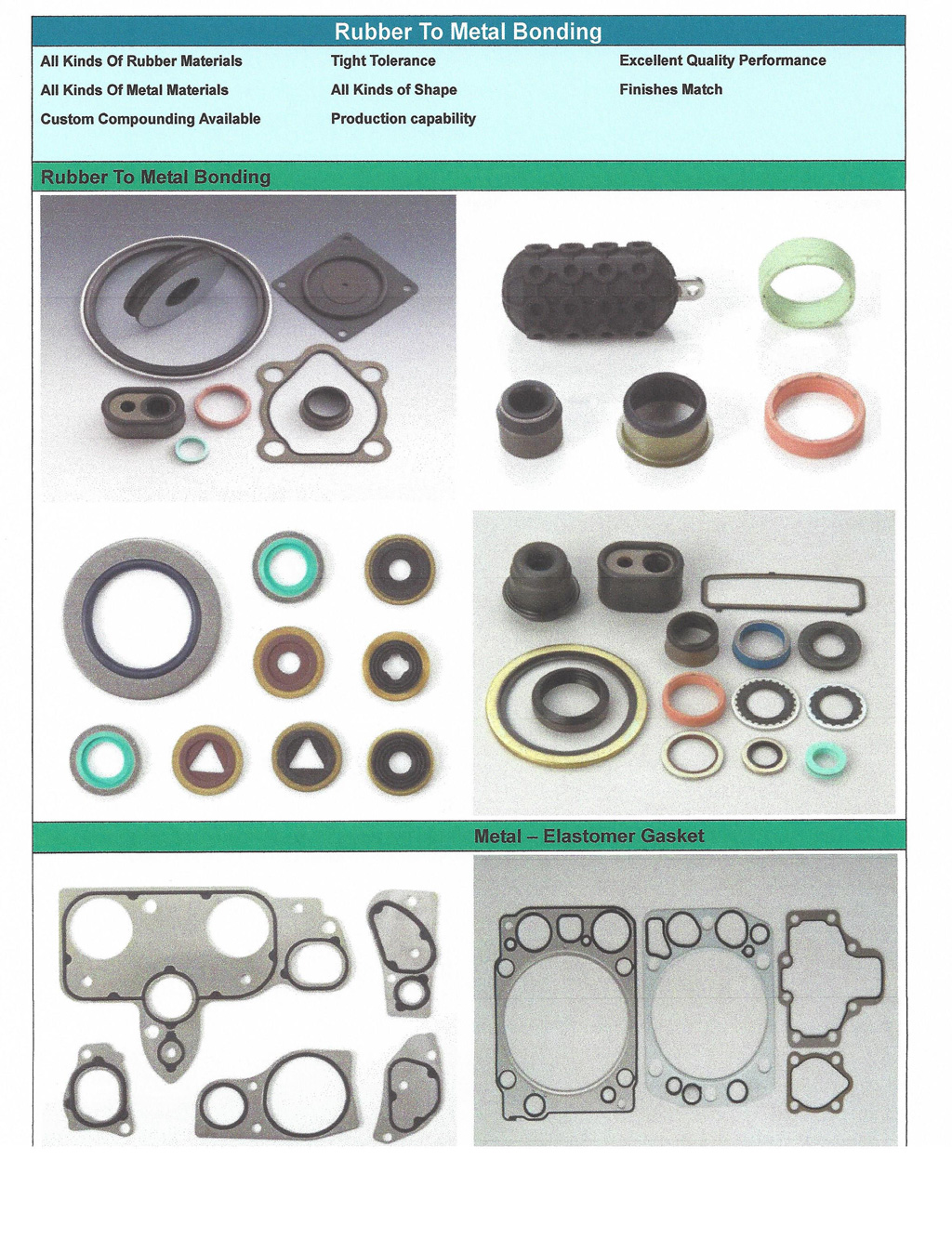

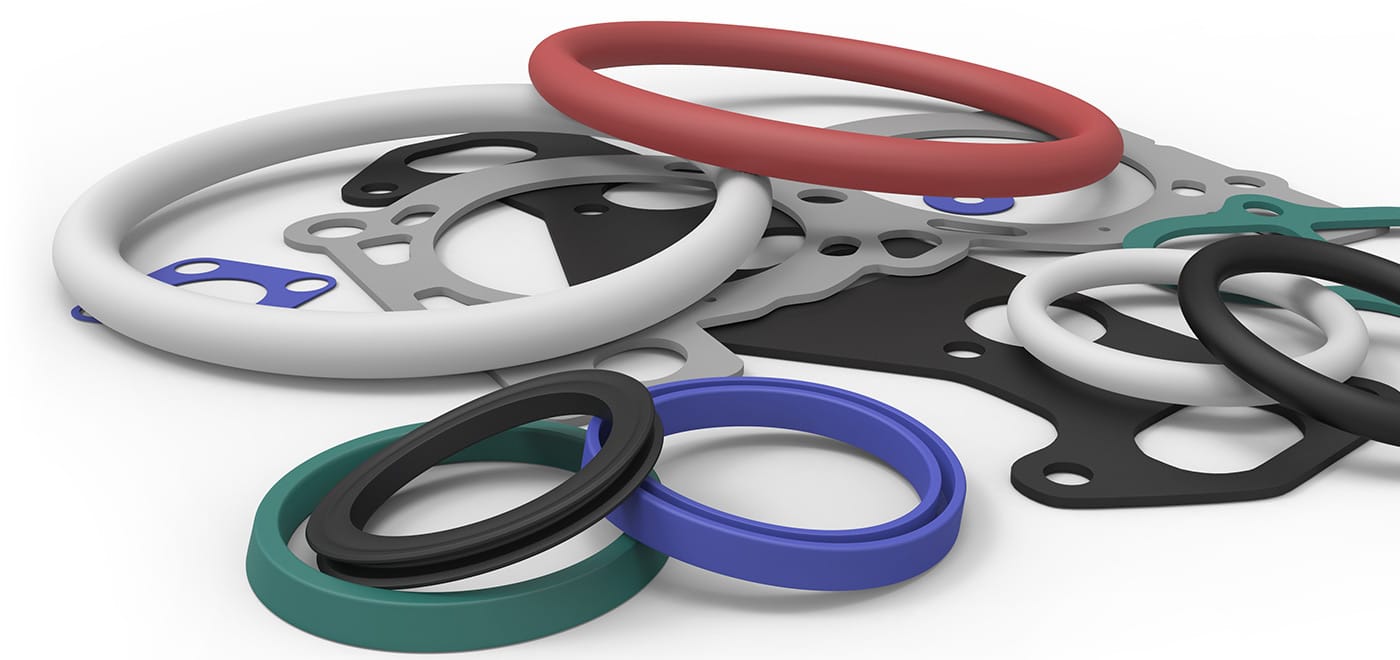

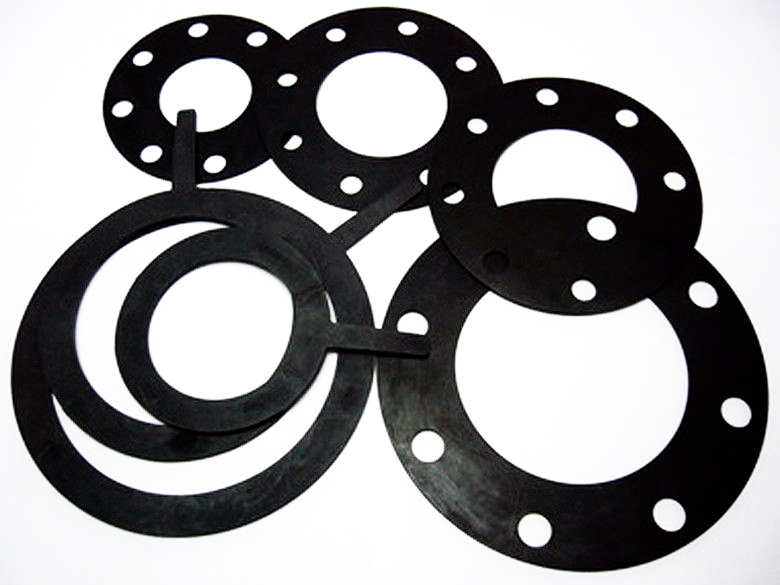

Engineering Guide: Custom Rubber Gaskets

Engineering Insight: The Critical Role of Material Selection in Custom Rubber Gaskets

In precision sealing applications, the performance and longevity of rubber gaskets are fundamentally determined by material selection. Off-the-shelf gaskets, while convenient and cost-effective in non-critical environments, frequently fail under demanding operational conditions due to mismatched material properties. These pre-manufactured solutions are typically designed for general-purpose use and lack the tailored characteristics required for specific industrial challenges such as extreme temperatures, aggressive chemical exposure, or dynamic mechanical stress. As a result, premature degradation, leakage, and system failure are common outcomes when standard gaskets are deployed without rigorous engineering evaluation.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration but a foundational element of gasket design. Each elastomer exhibits unique physical and chemical behaviors that must align precisely with the application’s environmental and mechanical demands. For instance, nitrile rubber (NBR) offers excellent resistance to oils and fuels, making it ideal for automotive and hydraulic systems, but it performs poorly in ozone-rich or high-temperature environments above 120°C. In contrast, fluorocarbon rubber (FKM) maintains integrity at temperatures up to 250°C and resists a broad spectrum of chemicals, including acids and aromatic hydrocarbons—critical for chemical processing and semiconductor manufacturing.

Silicone rubber (VMQ) provides outstanding flexibility and thermal stability from -60°C to 200°C, making it suitable for aerospace and medical devices, yet it exhibits poor tensile strength and abrasion resistance compared to ethylene propylene diene monomer (EPDM). EPDM, while excellent in steam, water, and alkali resistance, swells in petroleum-based fluids, rendering it unsuitable for fuel systems. These nuanced differences underscore why a one-size-fits-all approach is inherently flawed.

Below is a comparative overview of common elastomers used in custom rubber gasket manufacturing, highlighting key performance parameters:

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Applications |

|---|---|---|---|---|

| NBR | -30 to 120 | Oils, fuels, aliphatic hydrocarbons | Poor ozone and UV resistance; limited high-temp performance | Automotive, hydraulics |

| FKM | -20 to 250 | Acids, aromatic hydrocarbons, fuels, steam | High cost; poor low-temperature flexibility | Chemical processing, aerospace |

| VMQ | -60 to 200 | Ozone, UV, steam, water | Low tensile strength; poor abrasion resistance | Medical devices, electronics |

| EPDM | -50 to 150 | Water, steam, alkalis, oxygenated solvents | Swells in oils and hydrocarbons | HVAC, pharmaceutical, water treatment |

Custom rubber gaskets engineered with application-specific materials mitigate the risks associated with seal failure. At Baoshida, our technical team collaborates with OEMs to analyze operating conditions, fluid compatibility, compression set requirements, and regulatory standards to recommend optimal elastomer formulations. This precision-driven approach ensures reliability, reduces downtime, and extends service life—key metrics in industrial performance and cost efficiency.

Material Specifications

Material Specifications for Precision Rubber Gaskets

Selecting the optimal elastomer is critical for gasket performance, longevity, and system integrity under operational stress. At Suzhou Baoshida Trading Co., Ltd., we engineer custom rubber gaskets using rigorously tested formulations of Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each tailored to specific environmental and mechanical demands. Material properties directly influence sealing efficacy, chemical compatibility, and thermal stability, necessitating precise specification alignment with application parameters.

Viton (FKM)

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. Its molecular structure provides stability in aerospace, petrochemical, and semiconductor applications where exposure to jet fuels, acids, and halogenated solvents occurs. Standard formulations withstand continuous service from -20°C to +230°C, with specialized grades extending to +300°C. Viton exhibits low gas permeability and outstanding resistance to compression set, ensuring reliable sealing in dynamic or high-pressure systems. However, its higher cost and limited flexibility at sub-zero temperatures necessitate careful application evaluation.

Nitrile (NBR)

Nitrile butadiene rubber remains the industry standard for oil and fuel resistance due to its cost-effectiveness and balanced mechanical properties. With acrylonitrile content dictating oil resistance levels, standard grades (e.g., 34% ACN) operate effectively between -30°C and +120°C. NBR excels in automotive fuel systems, hydraulic seals, and industrial machinery exposed to mineral oils, greases, and aliphatic hydrocarbons. Its high abrasion resistance and tensile strength support durability in dynamic sealing applications. Limitations include poor ozone/weathering resistance and degradation when exposed to polar solvents, ketones, or chlorinated compounds.

Silicone (VMQ)

Silicone rubber provides unparalleled thermal stability across extreme ranges (-60°C to +230°C continuous, with brief excursions to +300°C). Its inert, biocompatible nature makes it ideal for medical, food-grade, and high-purity applications. Silicone maintains flexibility at cryogenic temperatures and resists UV, ozone, and ionizing radiation. However, its relatively low tensile strength, poor tear resistance, and permeability to gases require design compensation. It is incompatible with concentrated acids, alkalis, and non-polar solvents like gasoline.

The following table summarizes critical performance specifications for comparative analysis:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Tensile Strength (MPa) | 8–15 | 10–25 | 5–12 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +230 |

| Key Fluid Resistance | Fuels, Acids, Solvents | Oils, Fuels, Water | Water, Steam, Alcohols |

| Key Limitations | Cost, Low-Temp Flex | Ozone, Polar Solvents | Tear Strength, Gas Permeability |

Material selection must account for fluid exposure, temperature cycling, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. leverages OEM-grade compound data and application modeling to specify formulations that prevent extrusion, compression set, or chemical degradation. Partner with our engineering team to validate material suitability against your operational profile, ensuring gasket reliability and compliance with ISO 3601 and AS568 standards. Precision sealing begins with uncompromised material science.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Gasket Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our custom rubber gasket manufacturing excellence. With a dedicated team of five specialized mould engineers and two advanced formula engineers, we offer fully integrated development services that span material formulation, tooling design, and production optimization. This multidisciplinary approach enables us to deliver precision rubber seals tailored to the exact performance, environmental, and dimensional requirements of our industrial clients.

Our formula engineers possess deep expertise in polymer chemistry and compounding, allowing for the development of custom rubber formulations that meet stringent OEM specifications. Whether the application demands resistance to extreme temperatures, aggressive chemicals, or dynamic mechanical stress, we formulate elastomers based on silicone, EPDM, NBR, FKM, and other specialty materials. Each compound is engineered for optimal compression set, tensile strength, and sealing integrity under real-world operating conditions. Rigorous in-house testing ensures repeatability and compliance with international standards such as ASTM, ISO, and RoHS.

Complementing our formulation expertise is a team of five precision mould engineers who specialize in designing and refining gasket tooling for high-volume and low-volume production. Utilizing advanced CAD/CAM software and CNC machining, our engineers develop multi-cavity, cold-runner, and hot-runner mould systems that ensure dimensional accuracy down to ±0.05 mm. We optimize gating, venting, and ejection mechanisms to minimize flash, reduce cycle times, and enhance part consistency. Our moulds are constructed from high-grade tool steel with surface treatments for extended service life, particularly critical in long-run OEM manufacturing.

We are fully equipped to support OEM clients through every phase of product development—from initial concept and material selection to prototyping, validation, and serial production. Our closed-loop feedback system integrates data from quality control and field performance to continuously refine both formulations and tooling. This enables rapid iteration and ensures that every custom gasket meets or exceeds functional expectations.

Our engineering team also supports Design for Manufacturability (DFM) analysis, offering clients actionable insights to improve part geometry, reduce material waste, and lower total production costs. By proactively addressing potential manufacturing challenges during the design stage, we minimize delays and tooling rework, accelerating time-to-market for new products.

The synergy between our formula and mould engineering teams ensures a holistic approach to rubber gasket development—one where material behavior informs tool design and vice versa. This integration is essential for producing high-performance seals used in automotive, medical devices, industrial machinery, and electronics.

| Specification | Capability |

|---|---|

| Mould Tolerance | ±0.05 mm |

| Material Types | Silicone, EPDM, NBR, FKM, CR, ACM, HNBR |

| Compound Development | Custom formulations for heat, oil, ozone, and chemical resistance |

| Mould Types | Single-cavity, multi-cavity, cold-runner, hot-runner |

| CAD/CAM Systems | SolidWorks, UG NX, AutoCAD, Mastercam |

| Testing Standards | ASTM D2000, ISO 3601, ISO 2230, GB/T 5720 |

| OEM Support | Full product lifecycle management, DFM, PPAP documentation |

Customization Process

Custom Rubber Gasket Manufacturing: Precision Engineering Process

Suzhou Baoshida Trading Co., Ltd. executes a rigorously defined customization pathway for precision rubber gaskets, ensuring optimal performance and manufacturability for demanding industrial applications. This structured methodology minimizes risk and accelerates time-to-market for OEM partners. The process commences with comprehensive Drawing Analysis, where our engineering team meticulously reviews client-provided CAD files or technical sketches against ISO 3601 and AS568 standards. We validate critical dimensions, surface finish requirements, geometric tolerances (GD&T), and material callouts, identifying potential manufacturability conflicts or sealing performance limitations early. This phase includes collaborative consultation to resolve ambiguities and optimize the design for cost-effective production without compromising functional integrity.

Following design validation, our Rubber Formula Engineering team initiates Material Formulation Development. Leveraging extensive compound databases and application-specific performance criteria, we select the optimal base polymer (NBR, EPDM, FKM, FFKM, Silicone, or specialty blends) and engineer a custom compound. This involves precise balancing of vulcanization systems, fillers, plasticizers, and additives to achieve target properties such as compression set resistance, fluid compatibility, thermal stability, and hardness. Each formulation undergoes predictive modeling for expected service life under specified environmental stressors before physical prototyping begins.

The Prototyping & Validation stage utilizes precision tooling to produce functional samples. Prototypes undergo rigorous in-house testing per ASTM D2000 and client-specific protocols, including compression set (ASTM D395), tensile strength (ASTM D412), fluid immersion resistance, and dimensional verification. We provide detailed test reports and facilitate joint evaluation with the client. Iterative refinements to the compound or geometry occur here based on empirical data, ensuring the prototype meets all functional and durability requirements prior to tooling finalization.

Upon successful prototype approval, we transition seamlessly to Controlled Mass Production. Utilizing automated molding presses with real-time process monitoring (temperature, pressure, cure time), we maintain strict adherence to the validated process window. Statistical Process Control (SPC) is implemented on critical dimensions, with 100% visual inspection and periodic destructive testing per AQL 1.0 standards. Dedicated production cells ensure traceability from raw material batch to finished gasket, with comprehensive documentation supporting each shipment for OEM quality assurance systems.

Key material properties achieved through our formulation science are critical for gasket reliability. The following table summarizes core performance specifications for common compounds:

| Material Type | Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Fluid Resistance | Compression Set (ASTM D395, 70h) | Test Standard Reference |

|---|---|---|---|---|---|

| NBR | 50 – 90 | -30 to +100 | Oils, Fuels, Water | ≤ 25% (70°C) | ASTM D2000 AA Grade |

| EPDM | 50 – 90 | -50 to +150 | Water, Steam, Brake Fluid | ≤ 20% (150°C) | ASTM D2000 EB Grade |

| FKM (Viton®) | 60 – 90 | -20 to +230 | Aggressive Chemicals, Fuels | ≤ 25% (200°C) | ASTM D2000 FK Grade |

| Silicone | 30 – 80 | -60 to +200 | Water, Ozone, Steam | ≤ 30% (200°C) | ASTM D2000 GE Grade |

This end-to-end engineering approach, grounded in material science and process control, guarantees Suzhou Baoshida delivers custom rubber gaskets that consistently exceed OEM performance expectations while optimizing lifecycle costs.

Contact Engineering Team

For mission-critical sealing applications across aerospace, automotive, semiconductor, and industrial machinery sectors, precision-engineered rubber gaskets are not just components—they are performance determinants. At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and manufacturing of custom rubber gaskets tailored to exact OEM specifications, environmental conditions, and regulatory standards. Our expertise spans material science, compression set resistance, and long-term sealing integrity under extreme temperatures, pressures, and chemical exposures.

When standard off-the-shelf gaskets fail to meet your operational demands, our engineering team stands ready to collaborate on a fully customized solution. From initial concept and material selection to prototyping, validation testing, and high-volume production, we provide end-to-end support with a focus on dimensional accuracy, repeatability, and compliance. Whether your application requires fluorosilicone for low-temperature flexibility in aerospace systems, EPDM for steam resistance in industrial processing, or FKM (Viton®) for aggressive chemical environments in semiconductor tooling, our formulation database and in-house mixing capabilities ensure optimal compound performance.

We understand that sealing failure can result in costly downtime, safety risks, and regulatory non-compliance. That is why every custom gasket we produce undergoes rigorous quality control, including durometer testing, tensile strength analysis, and compression deflection verification. Our manufacturing processes—ranging from precision die-cutting and waterjet cutting to injection and compression molding—allow us to achieve tolerances as tight as ±0.1 mm, ensuring seamless integration into your assembly lines.

Below are representative specifications for common elastomers used in our custom gasket solutions:

| Material | Temperature Range (°C) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|

| Nitrile (NBR) | -30 to +100 | 50–90 | Oil, fuel, hydraulic fluids |

| EPDM | -50 to +150 | 50–80 | Steam, ozone, weathering |

| Silicone (VMQ) | -60 to +200 | 40–80 | Extreme temperatures, UV |

| Fluorosilicone (FVMQ) | -55 to +175 | 50–80 | Fuels, solvents, low temp |

| FKM (Viton®) | -20 to +200 | 60–90 | Acids, hydrocarbons, oxidizers |

| Neoprene (CR) | -40 to +120 | 50–80 | Flame, sunlight, moderate oils |

All materials are available in FDA, USP Class VI, ROHS, and REACH-compliant formulations upon request. We also offer conductive, anti-static, and flame-retardant variants for specialized applications.

To initiate a technical consultation or request a quotation for your next gasket project, contact Mr. Boyce, OEM Account Manager and Rubber Formulation Engineer, directly at [email protected]. Please include your application requirements, environmental conditions, dimensional drawings (if available), and target volumes to accelerate the evaluation process. Our team responds to all inquiries within 12 business hours and supports English, Mandarin, and technical German communication.

Partner with Suzhou Baoshida Trading Co., Ltd. for gasket solutions where precision, durability, and material intelligence converge. Your sealing challenge is our engineering mandate.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).