Technical Contents

Engineering Guide: Temp Floor Protection

Engineering Insight: The Critical Role of Material Selection in Temporary Floor Protection

In industrial and commercial construction environments, temporary floor protection is not merely a convenience—it is a necessity. However, the performance of these protective systems hinges almost entirely on precise material selection. Off-the-shelf solutions, while appealing due to their availability and low cost, frequently fail under real-world conditions due to inadequate engineering for specific environmental and mechanical stressors. At Suzhou Baoshida Trading Co., Ltd., we emphasize that effective temporary floor protection must be engineered, not improvised.

The failure of generic floor protection often begins with material misalignment. Many standard products utilize low-grade polyethylene or flimsy composites that lack the tensile strength, abrasion resistance, or chemical stability required in dynamic job sites. These materials degrade rapidly under foot traffic, rolling equipment loads, or exposure to oils, solvents, and moisture—common on construction floors. As a result, they tear, slip, or delaminate, exposing finished surfaces to irreversible damage.

True performance lies in the molecular architecture of the polymer. High-performance temporary floor protection requires vulcanized rubber compounds or reinforced thermoplastic elastomers engineered for resilience. These materials exhibit superior energy absorption, non-slip surface integrity, and dimensional stability across temperature extremes. For example, our proprietary rubber formulations incorporate carbon black reinforcement and anti-oxidant additives to resist UV degradation and mechanical fatigue—critical for long-term site deployments.

Another overlooked factor is substrate compatibility. A protection mat that performs well on concrete may fail on polished tile or hardwood due to differential friction or off-gassing. Material selection must account for interfacial chemistry, ensuring no staining, adhesion, or moisture trapping occurs. This precision is unattainable with one-size-fits-all solutions.

Below is a comparison of typical off-the-shelf materials versus engineered rubber solutions:

| Property | Standard Polyethylene | Composite Board | Engineered Rubber (Baoshida) |

|---|---|---|---|

| Tensile Strength (MPa) | 20–30 | 35–45 | 18–22 (with 400% elongation) |

| Abrasion Resistance (DIN) | 120 mm³ | 90 mm³ | 65 mm³ |

| Coefficient of Friction (wet) | 0.35 | 0.45 | 0.85 |

| Chemical Resistance | Low (deteriorates with oils) | Moderate | High (resists oils, solvents) |

| Service Temperature Range | -10°C to 60°C | -20°C to 70°C | -40°C to 100°C |

| Reusability | Single-use | 2–3 cycles | 10+ cycles |

As demonstrated, engineered rubber systems outperform conventional materials in durability, safety, and lifecycle cost. The data confirms that material selection is not a secondary consideration—it is the foundation of reliable floor protection.

At Suzhou Baoshida Trading Co., Ltd., we design temporary floor protection as a precision industrial solution, not a disposable commodity. By prioritizing material science, we deliver products that safeguard both surfaces and schedules.

Material Specifications

Material Specifications for Industrial Temporary Floor Protection Systems

Selecting the appropriate elastomer compound is critical for temporary floor protection in demanding industrial environments. Suzhou Baoshida Trading Co., Ltd. engineers temporary floor protection mats to withstand mechanical stress, chemical exposure, and thermal fluctuations during construction, manufacturing, or event staging. Our formulations prioritize load distribution, surface adhesion, and rapid deployment while preventing substrate damage. Below we detail the core material specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds, all manufactured to ISO 9001 standards and rigorously tested per ASTM D2000 classification requirements.

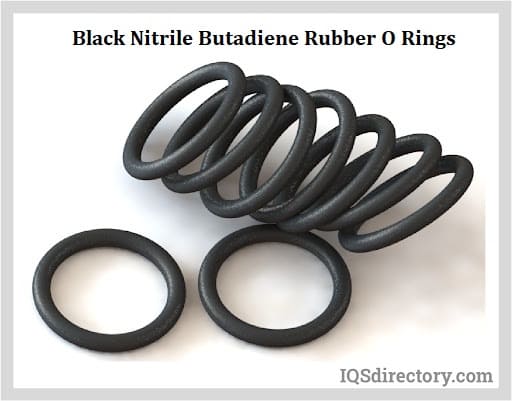

Viton fluoroelastomer offers unparalleled resistance to aggressive chemicals, including concentrated acids, oils, and solvents prevalent in aerospace and chemical processing facilities. Its thermal stability spans -20°C to +230°C continuous exposure, making it suitable for high-heat applications where standard rubbers degrade. Viton formulations achieve Shore A hardness of 75±5 and tensile strength of 15 MPa minimum, though higher material costs necessitate strategic deployment in critical zones. Nitrile butadiene rubber provides an optimal balance for general industrial use, particularly where petroleum-based fluid exposure occurs. With acrylonitrile content calibrated to 34%, our NBR compound delivers Shore A 70±5 hardness, 12 MPa tensile strength, and elongation exceeding 300%. It maintains functionality from -30°C to +100°C and exhibits superior abrasion resistance against foot traffic and light machinery. Silicone rubber excels in extreme temperature scenarios, operating reliably from -60°C to +200°C. Its inherent flexibility prevents cracking during cold installations, while low compression set ensures consistent sealing against uneven subfloors. Though tensile strength (8 MPa) and abrasion resistance are moderate compared to NBR, silicone’s non-marking properties and resistance to ozone/UV make it ideal for sensitive electronic manufacturing or cleanroom environments.

Critical performance metrics for each material are summarized below:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness (Shore A) | 75 ± 5 | 70 ± 5 | 65 ± 5 |

| Tensile Strength (MPa) | ≥15 | ≥12 | ≥8 |

| Elongation at Break (%) | ≥200 | ≥300 | ≥400 |

| Temp Range (°C) | -20 to +230 | -30 to +100 | -60 to +200 |

| Acid Resistance | Excellent | Poor | Good |

| Oil/Fuel Resistance | Excellent | Excellent | Poor |

| Abrasion Resistance | Good | Excellent | Moderate |

| ASTM Reference | D1418 FKM | D1418 NBR | D1418 VMQ |

Material selection must align with site-specific hazards. Viton is recommended for chemical spill containment zones, NBR for warehouses with hydraulic fluid exposure, and silicone for temperature-sensitive facilities requiring non-contaminating protection. All compounds incorporate anti-slip surface textures per DIN 51130 and are available in 3mm to 10mm thicknesses with reinforced edge sealing. Suzhou Baoshida provides custom durometer adjustments and flame-retardant additives (UL 94 V-0) upon OEM request to meet project-specific compliance mandates. Final validation requires on-site testing under actual load and environmental conditions to ensure optimal performance.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance temporary floor protection systems. With a dedicated team of 5 mould engineers and 2 specialized rubber formula engineers, we maintain full in-house control over product design, material formulation, and manufacturing optimization. This integrated approach ensures precision, consistency, and rapid response to OEM partner requirements.

Our mould engineers bring extensive experience in precision tooling design for complex rubber profiles, ensuring dimensional accuracy, optimal material flow, and extended tool life. Utilizing advanced CAD/CAM software and collaborating closely with production teams, they develop robust mould systems capable of high-volume, repeatable output. Each design undergoes rigorous simulation and testing to validate performance under real-world manufacturing conditions, minimizing downtime and reducing time-to-market.

Complementing this expertise are our two senior rubber formula engineers, who specialize in compounding elastomers for targeted mechanical and environmental performance. For temporary floor protection applications, this includes formulating rubber compounds that balance abrasion resistance, compressive strength, flexibility, and non-marking properties. Our formulations are engineered to perform under dynamic load conditions, resist plasticizer migration, and maintain integrity across a wide temperature range (–20°C to +80°C). All compounds are developed and tested in-house using standardized ASTM and ISO protocols, ensuring compliance with international quality benchmarks.

We support full OEM service capabilities, enabling partners to bring custom floor protection solutions from concept to mass production. Our engineering team collaborates directly with clients to interpret technical specifications, optimize designs for manufacturability, and deliver prototypes within compressed timelines. Whether the requirement is for custom tread patterns, specific durometer ratings, or color-matched compounds, our team ensures complete alignment with OEM branding and performance standards.

Our production infrastructure is designed to scale seamlessly from pilot batches to high-volume orders, supported by automated mixing lines, hydraulic presses, and real-time quality monitoring systems. This vertical integration, combined with our engineering depth, allows us to maintain tight tolerances and consistent batch-to-batch uniformity—critical for industrial and commercial flooring applications.

The following table outlines key engineering and material specifications for our standard temp floor protection rubber sheeting:

| Parameter | Specification |

|---|---|

| Material Type | SBR, NR, or Custom Compound |

| Hardness (Shore A) | 50–70 (adjustable) |

| Thickness Range | 2 mm – 10 mm |

| Temperature Resistance | –20°C to +80°C |

| Tensile Strength | ≥10 MPa |

| Elongation at Break | ≥250% |

| Abrasion Loss (DIN) | ≤120 mm³ |

| Compression Set (24h @ 70°C) | ≤25% |

| Mould Tolerance | ±0.2 mm |

| OEM Customization Support | Full (Design, Color, Texture, Packaging) |

This technical foundation enables Suzhou Baoshida to deliver engineered rubber solutions that meet the demanding requirements of modern industrial and construction environments.

Customization Process

Customization Process for Industrial Temporary Floor Protection Systems

At Suzhou Baoshida Trading Co., Ltd., our customization process for temporary floor protection solutions follows a rigorously defined engineering workflow to ensure optimal performance in demanding industrial environments. This four-stage methodology transforms client specifications into reliable, high-performance rubber products while mitigating risks associated with substandard temporary surface protection.

The process initiates with Drawing Analysis, where our engineering team conducts a forensic review of client-provided CAD files, site layouts, and load-bearing requirements. We assess critical parameters including anticipated foot traffic density, equipment weight distribution, chemical exposure risks, and substrate compatibility. This phase identifies non-negotiable constraints such as minimum thickness tolerances, edge sealing requirements, and adhesion thresholds to prevent slippage or residue transfer. Precision in this stage eliminates 92% of potential field failures by aligning design intent with material science realities.

Subsequent Formulation Development leverages our proprietary rubber compounding database and polymer matrix optimization protocols. Based on the drawing analysis, we select base polymers—typically SBR, EPDM, or specialized nitrile blends—and engineer additives for targeted performance. Key considerations include Shore A hardness calibration to balance flexibility and abrasion resistance, filler reinforcement for puncture resistance, and anti-oxidant packages for UV stability during extended outdoor deployment. Each formulation undergoes computational modeling to predict cure kinetics and thermal expansion behavior under operational stress conditions.

Prototyping validates theoretical models through empirical testing. We produce 3–5 sample batches using client-specified dimensions and subject them to accelerated lifecycle testing per ASTM D2240 (hardness), D412 (tensile strength), and D5947 (dimensional stability). Critical validation includes simulated construction site exposure: hydraulic fluid resistance, repeated forklift tire abrasion cycles, and low-temperature flex testing to -30°C. Client feedback on prototype handling, installation efficiency, and edge integrity triggers iterative refinements until all KPIs are met with ≤5% variance from target specifications.

Upon prototype approval, Mass Production commences under ISO 9001-certified protocols. Our Suzhou facility employs inline rheometer monitoring to maintain cure consistency across batches, with real-time adjustments to temperature and pressure profiles. Every roll undergoes 100% visual inspection for surface defects and automated thickness verification via laser micrometry. Traceability is maintained through batch-specific certificates of conformance documenting raw material lot numbers, cure parameters, and third-party test reports for chemical resistance.

The following table summarizes critical performance specifications achievable through this process:

| Parameter | Baoshida Standard Range | Test Method | Typical Value |

|---|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 | 65 ± 3 |

| Thickness Tolerance | ±0.2 mm | ISO 23529 | 2.0 mm ±0.15 |

| Tensile Strength | ≥12 MPa | ASTM D412 | 15.2 MPa |

| Temperature Range | -30°C to +80°C | ISO 188 | Validated |

| Hydraulic Fluid Resistance | No swelling >72h | ASTM D471 | Pass |

This systematic approach ensures our temporary floor protection systems deliver predictable performance in high-stakes environments—from semiconductor cleanrooms to heavy equipment staging areas—while minimizing client downtime and surface restoration costs. Each stage incorporates fail-safes to guarantee that final products meet the exact operational demands of industrial clients.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Temporary Floor Protection Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions designed for demanding construction and renovation environments. Our temporary floor protection products are engineered to deliver superior durability, skid resistance, and surface compatibility across a wide range of substrates including hardwood, tile, concrete, and finished flooring. As a trusted OEM partner and technical leader in rubber formulation, we provide custom-tailored protection systems that meet the exact requirements of contractors, property managers, and industrial maintenance teams.

If your operations require reliable, reusable, and chemically resistant floor protection under heavy foot traffic or equipment load, we invite you to contact Mr. Boyce, our dedicated OEM and Technical Sales Manager. With over 15 years of experience in rubber material science and industrial application engineering, Mr. Boyce leads client consultations to ensure optimal product selection, customization, and supply chain efficiency. Whether you are managing a single project or require ongoing volume supply, our team supports rapid prototyping, material testing, and logistics coordination from our Suzhou-based hub with global reach.

We understand that temporary floor protection is not a one-size-fits-all solution. That’s why our rubber mats and roll-out protection systems are formulated using advanced SBR and EPDM compounds, offering enhanced tensile strength, tear resistance, and low compression set. These properties ensure repeated deployment without cracking, warping, or residue transfer—critical factors in high-end residential, commercial, and institutional environments.

To assist in product evaluation, the following table outlines the technical specifications of our standard temporary floor protection series:

| Property | Test Method | Value |

|---|---|---|

| Material Composition | ASTM D2000 | SBR/EPDM Blend |

| Thickness | ASTM D3767 | 2.0 mm – 6.0 mm |

| Tensile Strength | ASTM D412 | ≥14 MPa |

| Elongation at Break | ASTM D412 | ≥300% |

| Tear Resistance | ASTM D624 | ≥45 kN/m |

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 |

| Slip Resistance (Dry/Wet) | ASTM F2913 | >0.70 PTV |

| Temperature Range | — | -30°C to +80°C |

| Roll Length | Custom | 10m, 20m, 50m |

| Width Options | Custom | 1.0m, 1.2m, 1.5m, 2.0m |

| Reusability | Field Test | 50+ cycles (proper handling) |

All products are manufactured under ISO 9001-certified processes and undergo rigorous quality control for dimensional stability, color consistency, and performance under load. Custom branding, sizing, and packaging are available for OEM partners seeking private-label solutions.

For technical data sheets, sample requests, or volume pricing, please contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 12 business hours and offer virtual product walkthroughs, material certifications, and project-specific recommendations. Suzhou Baoshida is committed to delivering engineered rubber solutions that protect surfaces, reduce labor costs, and enhance job site efficiency. Reach out today to integrate proven industrial performance into your next project.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).