Technical Contents

Engineering Guide: Metal O-Ring

Material Selection: The Core Determinant in Metal O-Ring Performance

Metal o-rings represent a critical class of precision seals where a metallic core provides structural integrity and spring force, while an elastomeric coating delivers the essential sealing interface. Contrary to common misconception, these are not monolithic metal components but sophisticated composite systems. The performance and longevity of a metal o-ring are fundamentally dictated by the precise engineering synergy between the metal substrate and the specific rubber compound selected for the elastomeric layer. Off-the-shelf solutions frequently fail because they treat metal o-rings as generic parts, neglecting the intricate material science required for demanding industrial applications. Standard catalogs often offer limited elastomer choices paired with generic metal cores, creating inherent vulnerabilities when deployed in environments with specific chemical, thermal, or mechanical challenges.

The criticality of material selection stems from the dual-material interface challenge. The elastomer must exhibit exceptional adhesion to the metal core under operational stresses, maintain its physical properties across the required temperature spectrum, and resist degradation from fluid exposure. Simultaneously, the metal core must possess sufficient yield strength to prevent permanent deformation while maintaining compatibility with the elastomer’s coefficient of thermal expansion. Mismatched materials lead to premature failure modes such as elastomeric delamination, extrusion under pressure, accelerated chemical attack, or loss of sealing force due to thermal cycling. For instance, selecting a standard FKM elastomer for high-temperature aerospace fuel systems might seem adequate, but if the specific peroxide-cured grade lacks resistance to certain biofuels or exhibits poor adhesion to the chosen Inconel core at 300°C, catastrophic seal collapse becomes inevitable. Generic solutions rarely account for these nuanced interactions.

The consequences of inadequate material pairing are severe and costly. Delamination exposes the metal core directly to process media, leading to rapid corrosion and seal breach. Thermal mismatch can cause the elastomer to crack or pull away from the metal during cooldown, creating leak paths. Chemical incompatibility might stiffen the elastomer, preventing it from conforming to surface imperfections under load. These failures result in unplanned downtime, safety hazards, and significant remediation expenses far exceeding the initial cost of a properly engineered seal. True reliability demands a holistic analysis of the application’s pressure, temperature extremes, media composition, cycle frequency, and mating surface finish to formulate both the elastomer compound and specify the optimal metal substrate.

The following table illustrates why standard material combinations often fall short in critical applications:

| Metal Core Material | Typical Elastomer Coating | Standard Temp Range (°C) | Critical Failure Risks in Demanding Applications |

|---|---|---|---|

| 304 Stainless Steel | Standard FKM (60-70 Shore A) | -20 to +200 | Poor adhesion at >220°C; Swelling in ketones; Chloride stress corrosion cracking of core |

| Inconel 718 | Standard VMQ | -60 to +200 | Rapid compression set above 175°C; Inadequate fuel resistance; Weak bond strength under thermal shock |

| Hastelloy C-276 | Standard EPDM | -50 to +150 | Severe degradation in oils/hydrocarbons; Limited high-temp capability; Costly core wasted on incompatible elastomer |

| Custom Alloy | Formulated Perfluoroelastomer | -40 to +325 | Engineered Solution: Optimized CTE match; Tailored fluid resistance; Enhanced adhesion promoters for core |

Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in rubber compounding and metallurgy to overcome these limitations. We do not supply generic metal o-rings; we engineer complete sealing systems. Our process begins with rigorous application analysis, followed by proprietary elastomer formulation designed for specific metal core adhesion and environmental resistance, and concludes with stringent validation testing. This scientific approach ensures the metal core and elastomeric layer function as a single, reliable unit under the most extreme industrial conditions, eliminating the preventable failures inherent in off-the-shelf alternatives. The true cost of a seal is measured in system uptime, not initial purchase price.

Material Specifications

Material selection is a critical engineering decision in the design and application of precision rubber seals, particularly in metal o-rings where performance under extreme conditions is required. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-integrity sealing solutions that combine the structural support of metal carriers with the elastic sealing properties of advanced elastomers. The performance, durability, and chemical compatibility of these composite seals depend heavily on the elastomer material chosen. Among the most widely used materials in industrial applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages based on temperature range, chemical exposure, and mechanical stress.

Viton (FKM) is a fluorocarbon-based elastomer known for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range up to 230°C, Viton is ideal for aerospace, automotive, and chemical processing environments where long-term stability in harsh media is essential. Its low gas permeability and excellent aging characteristics further enhance reliability in dynamic sealing applications. However, Viton exhibits lower flexibility at low temperatures and higher material cost compared to alternatives.

Nitrile (NBR) remains one of the most commonly used elastomers due to its excellent resistance to petroleum-based oils and fuels, coupled with good abrasion resistance and mechanical strength. It performs reliably in temperature ranges from -30°C to 120°C, making it suitable for hydraulic systems, fuel handling, and general industrial machinery. While NBR offers cost-effective performance in oil-rich environments, its resistance to ozone, weathering, and polar solvents is limited, which may restrict use in outdoor or chemically aggressive settings.

Silicone (VMQ) excels in extreme temperature applications, with a service range from -60°C to 200°C, and demonstrates outstanding resistance to UV radiation, ozone, and weathering. It is frequently selected for medical, food-grade, and high-purity applications due to its inert nature and compliance with regulatory standards. However, silicone has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure or oil-exposed mechanical systems.

The following table summarizes key physical and chemical properties of these materials to support informed material selection for metal o-ring applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Chemical Resistance | Very Good | Good (limited) | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Common Applications | Aerospace, Chemical | Automotive, Hydraulics | Medical, Food, Outdoor |

Selection of the appropriate elastomer must consider not only environmental exposure but also mechanical loading, sealing pressure, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. provides customized material certification and testing data to ensure optimal performance in your specific application.

Manufacturing Capabilities

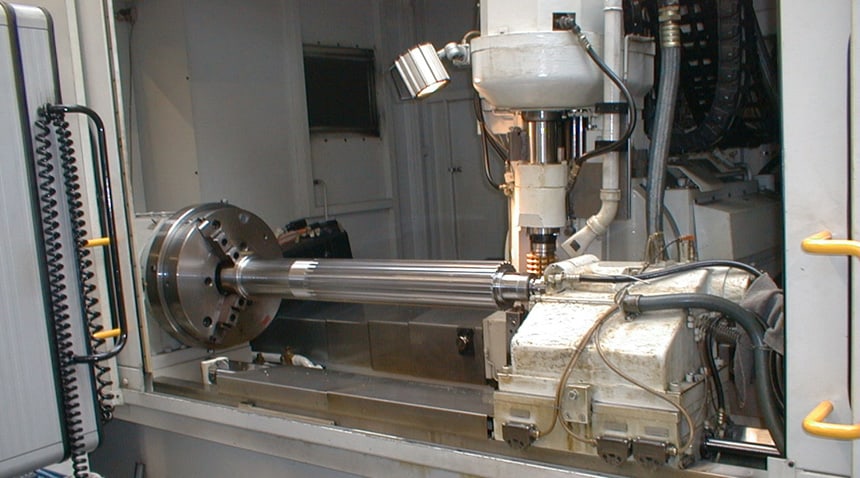

Engineering Capability: Precision Metal O-Ring Development at Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. maintains a dedicated engineering core specifically focused on the complex demands of precision metal-reinforced o-ring manufacturing. Our capability transcends standard sealing solutions through the integrated expertise of five specialized mould engineers and two advanced rubber formula engineers. This dual-discipline team operates synergistically from initial concept through to volume production, ensuring every metal o-ring assembly meets the stringent performance and reliability requirements of critical industrial applications. The inherent challenge of metal o-rings lies in achieving perfect interfacial adhesion integrity between the elastomer and the metal core under extreme thermal cycling, pressure differentials, and chemical exposure. Our engineers systematically address these challenges through co-developed material science and precision tooling strategies.

Our rubber formula engineers possess deep expertise in compounding elastomers specifically engineered for robust bonding to stainless steel, titanium, and other metal substrates. They formulate proprietary rubber compounds that optimize adhesion promoters, cure kinetics, and thermal expansion coefficients to minimize stress at the rubber-metal interface. This prevents common failure modes such as delamination or compression set under dynamic service conditions. Concurrently, our five mould engineers utilize advanced CAD/CAM systems and finite element analysis (FEA) to design and manufacture precision moulds that ensure exact geometric conformity of the elastomer to the metal core. Critical attention is paid to gate location, venting, and temperature control profiles to eliminate voids, ensure complete encapsulation, and maintain micron-level dimensional tolerances on the final bonded assembly.

This integrated engineering approach is fundamental to our OEM capability. We partner directly with clients during the design phase, providing material selection guidance, manufacturability feedback, and prototype validation. Our facility supports full-scale OEM production with rigorous in-process quality control, including adhesion peel testing per ASTM D429 Method B, dimensional verification via CMM, and comprehensive material certification. Suzhou Baoshida delivers not just components, but engineered sealing systems validated for the specific operational environment.

The following table summarizes key technical specifications achievable through our engineered metal o-ring process:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Material System | FKM, EPDM, VMQ, FVMQ, ACM | ASTM D2000, ISO 3601 |

| Temperature Range | -55°C to +325°C (dependent on compound) | Client Specification |

| Hardness (Shore A) | 60 ± 5 to 80 ± 5 | ASTM D2240 |

| Tolerance Class | ISO 3601 Class M or tighter | ISO 3601-1 |

| Metal Core Options | 304SS, 316SS, Titanium, Inconel | ASTM A276, AMS 5645 |

| Adhesion Strength | ≥ 8 kN/m (peel strength, minimum) | ASTM D429 Method B |

Suzhou Baoshida’s engineering strength provides clients with a decisive advantage in applications demanding absolute sealing integrity where failure is not an option. Our commitment to scientific formulation and precision moulding ensures metal o-rings deliver consistent, long-term performance in aerospace, semiconductor manufacturing, and high-pressure fluid systems. Partner with us for engineered sealing solutions backed by demonstrable technical expertise and robust OEM execution.

Customization Process

Customization Process for Metal O-Rings at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of metal o-rings follows a rigorous, science-driven methodology designed to meet the exacting demands of high-performance industrial applications. Our process ensures dimensional precision, material compatibility, and long-term sealing integrity under extreme conditions such as high pressure, temperature fluctuations, and corrosive environments. The workflow progresses systematically through four critical stages: Drawing Analysis, Formulation, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a comprehensive review of the customer-provided technical specifications. Our engineering team evaluates critical parameters including inner diameter, cross-sectional thickness, groove dimensions, surface finish requirements, and metallurgical grade. We assess compliance with international standards such as ISO 3601, AS568, or custom OEM blueprints. Tolerance analysis is performed using GD&T principles to ensure fit and function within the target assembly. Any discrepancies or optimization opportunities are communicated directly to the client for alignment before proceeding.

Following drawing validation, the Formulation stage determines the optimal elastomer or composite material system to be bonded to the metal core. For metal o-rings, this typically involves fluorocarbon rubber (FKM), perfluoroelastomer (FFKM), silicone (VMQ), or ethylene propylene diene monomer (EPDM), selected based on chemical exposure, thermal range, and mechanical stress. Our rubber formulation laboratory tailors compound recipes with precise filler loading, cure systems, and adhesion promoters to ensure robust bonding between the metallic substrate—usually stainless steel (304, 316) or Inconel—and the elastomeric seal.

Prototyping is executed using precision molding techniques, including injection or transfer molding, under controlled vulcanization conditions. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and bond strength testing through peel and shear evaluations. Functional performance is validated through pressure decay testing, thermal cycling, and exposure to simulated service media. Prototype data is compiled into a detailed test report for customer review and approval.

Upon successful validation, the project transitions to Mass Production. Our automated production lines operate under strict ISO 9001:2015 and IATF 16949 quality management systems. In-process statistical process control (SPC) monitors key variables such as cure time, mold temperature, and clamp pressure. Final inspection includes 100% visual checks and batch sampling for physical property verification. All production lots are traceable through serialized batch records.

The following table outlines typical technical specifications for custom metal o-rings manufactured at Suzhou Baoshida:

| Parameter | Standard Range | Notes |

|---|---|---|

| Metal Core Material | SS304, SS316, Inconel 625, Hastelloy C-276 | Custom alloys available |

| Elastomer Options | FKM, FFKM, EPDM, VMQ, NBR | Chemically tailored compounds |

| Inner Diameter | 10 mm – 500 mm | Tolerance ±0.05 mm |

| Cross Section | 1.5 mm – 5.0 mm | Custom profiles supported |

| Operating Temperature | -40°C to +327°C (FKM) up to +350°C (FFKM) | Depends on elastomer |

| Bond Strength | ≥ 8 kN/m | Peel resistance per ASTM D429 |

| Surface Finish (Metal) | Ra ≤ 0.8 µm | Electropolished option available |

This structured approach ensures that every metal o-ring delivered by Suzhou Baoshida meets the highest standards of engineering fidelity and operational reliability.

Contact Engineering Team

Technical Partnership for Precision Metal O-Ring Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced rubber compounding and precision metal forming, delivering engineered metal o-rings for extreme industrial environments. Our technical team specializes in solving sealing challenges where conventional elastomers fail—addressing ultra-high pressure, cryogenic temperatures, and corrosive media in aerospace, semiconductor, and oilfield applications. Unlike standard suppliers, we integrate material science with OEM-driven design validation, ensuring every component meets AS9100 and ISO 13485 compliance frameworks.

Our metal o-rings combine laser-welded 316L stainless steel or Inconel 718 cores with proprietary fluorocarbon or FFKM overmolding, achieving hermetic seals under 15,000 psi and -269°C to +327°C conditions. The table below summarizes critical performance parameters for common configurations:

| Material Grade | Core Material | Plating | Temperature Range | Pressure Rating | Hardness (Shore A) | Applications |

|---|---|---|---|---|---|---|

| BD-MO-718FFKM | Inconel 718 | Gold | -269°C to +327°C | 15,000 psi | 75±5 | Semiconductor CMP, Cryogenic Valves |

| BD-MO-316LVMQ | 316L SS | Silver | -196°C to +230°C | 10,000 psi | 80±5 | LNG Systems, Aerospace Hydraulics |

| BD-MO-316LFFKM | 316L SS | Nickel | -40°C to +288°C | 12,000 psi | 70±5 | Downhole Tools, Chemical Reactors |

These specifications reflect our baseline formulations. Actual performance is validated through client-specific finite element analysis (FEA) and dynamic testing in our Suzhou R&D facility, which houses pressurized thermal cycling chambers and helium mass spectrometry leak detection systems. We prioritize material traceability—each batch includes certified mill test reports and lot-specific compression set data per ASTM D395.

Collaboration begins with technical due diligence. When you engage our engineering team, we conduct a joint application review to assess media compatibility, surface finish requirements (Ra ≤ 0.4 µm), and installation tolerances. This prevents field failures caused by overlooked factors like galvanic corrosion between the metal core and mating hardware. Our OEM clients reduce prototyping cycles by 40% through our digital twin modeling service, which simulates seal deformation under operational loads.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Manager, to advance your critical sealing project. Provide your application’s pressure-temperature profile, media composition, and dimensional constraints via email to [email protected]. Mr. Boyce will coordinate a 72-hour feasibility assessment, including material compatibility matrices and GD&T-compliant CAD models. All communications are protected under our standard NDA framework, ensuring your IP remains confidential during evaluation.

For time-sensitive projects requiring rapid iteration, we maintain strategic inventory of 316L SS cores in ISO standard sizes (AS568A). Submit your drawing for immediate review—we respond to engineering inquiries within one business day. Suzhou Baoshida transforms sealing challenges into validated solutions through material science rigor and responsive engineering partnership. Contact Mr. Boyce to commence technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).