Technical Contents

Engineering Guide: Rubber O Rings

Engineering Insight: Material Selection Criticality in Rubber O-Ring Performance

The failure of rubber O-rings in industrial applications rarely stems from design flaws in the sealing groove but from inadequate material selection. Off-the-shelf O-rings represent generalized solutions optimized for cost, not performance under specific operational stressors. This oversight leads to premature seal degradation, system contamination, and unplanned downtime costing OEMs thousands per hour. Material properties must align precisely with dynamic variables: temperature extremes, chemical exposure, pressure cycles, and mechanical loads. Generic compounds sacrifice critical polymer characteristics—such as crosslink density, filler dispersion, or antioxidant packages—to achieve broad compatibility, inevitably compromising resilience in targeted environments.

For instance, standard NBR (nitrile) O-rings fail catastrophically in phosphate ester hydraulic fluids due to uncontrolled swelling, while EPDM compounds crack at sub-zero temperatures common in Arctic drilling equipment. Similarly, low-cost FKM (fluorocarbon) variants exhibit poor low-temperature flexibility below -20°C, causing leakage in cryogenic valves. These failures occur because commodity suppliers prioritize shelf availability over application-specific molecular architecture. Precision engineering demands customized polymer formulations where monomer ratios, cure systems, and additive concentrations are tuned to counteract dominant failure modes. At Suzhou Baoshida, we deploy ASTM D2000-compliant compound development, leveraging accelerated aging tests and FTIR spectroscopy to validate resistance to customer-specified media before production.

The table below illustrates how critical material properties diverge across common elastomers, explaining why standardized O-rings fail under non-ideal conditions:

| Material | Temperature Range (°C) | Key Chemical Vulnerabilities | Critical Failure Mode in Off-the-Shelf Applications |

|---|---|---|---|

| Standard NBR | -30 to +100 | Phosphate esters, ozone, brake fluids | Swelling >40% in Skydrol®, leading to extrusion |

| Generic FKM | -20 to +200 | Ketones, low-temperature flexibility | Brittle fracture at -25°C in LNG systems |

| Commercial EPDM | -50 to +150 | Hydrocarbons, steam above 130°C | Compression set >50% after 72h at 120°C |

| Baoshida Custom HNBR | -45 to +150 | Custom-resistant to sour gas (H₂S) | <15% swell in 30% H₂S at 120°C (validated per NORSOK M-710) |

Off-the-shelf O-rings fail because they ignore the synergy between application physics and polymer chemistry. A mining conveyor’s hydraulic cylinder operating at 85°C with biodegradable ester fluid requires different saturation resistance than an aerospace fuel system at -54°C. Generic compounds lack the tailored filler systems to resist ester-induced plasticization or the specialized peroxide cures for ultra-low-temperature elasticity. At Suzhou Baoshida, we reject one-size-fits-all approaches. Our OEM partnerships begin with fluid compatibility mapping and stress-strain profiling to formulate O-rings where compression set, tensile retention, and volume swell remain within 5% tolerance after 1,000 hours of simulated service. This precision prevents the $22,000/hour downtime events that transform a $0.50 O-ring into a six-figure operational crisis. Material selection isn’t procurement—it’s the frontline defense against system failure.

Material Specifications

Material selection is a critical factor in the performance and reliability of rubber O rings in industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the demanding requirements of diverse operating environments. Our expertise includes the formulation and production of O rings using three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct chemical, thermal, and mechanical properties, making them suitable for specific use cases across automotive, aerospace, oil and gas, pharmaceutical, and semiconductor industries.

Viton, a fluorocarbon-based elastomer, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 200°C and intermittent exposure tolerance to 250°C, Viton O rings are ideal for extreme environments where thermal stability and chemical inertness are paramount. Additionally, Viton exhibits low gas permeability and excellent resistance to oxidation and weathering, making it a preferred choice for aerospace and chemical processing applications.

Nitrile rubber, also known as Buna-N, is one of the most widely used materials for O rings due to its excellent resistance to petroleum-based oils and fuels. It performs reliably in temperatures ranging from -30°C to 120°C, offering good abrasion resistance and compressive strength. Nitrile is cost-effective and well-suited for hydraulic systems, fuel delivery components, and general industrial machinery. However, its performance degrades in the presence of ozone, UV radiation, and polar solvents, limiting its use in outdoor or highly oxidative environments.

Silicone rubber is valued for its outstanding thermal stability across a wide temperature range, typically from -60°C to 200°C, with certain formulations extending to 230°C. It demonstrates excellent resistance to UV light, ozone, and weathering, along with low toxicity and high biocompatibility. These traits make silicone ideal for medical devices, food and beverage processing, and electronic insulation. While it offers poor resistance to petroleum oils and lower mechanical strength compared to Nitrile or Viton, its flexibility at low temperatures and inert nature are unmatched.

The following table provides a comparative overview of key physical and chemical properties for these materials to assist in optimal material selection.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 120 | -60 to 200 (up to 230 intermittent) |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair to Poor | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Biocompatibility | Moderate | Poor | Excellent |

Selecting the appropriate elastomer requires a comprehensive understanding of the operational environment, including media exposure, temperature fluctuations, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial partners with material consultation, custom formulation, and precision manufacturing to ensure optimal sealing performance and longevity.

Manufacturing Capabilities

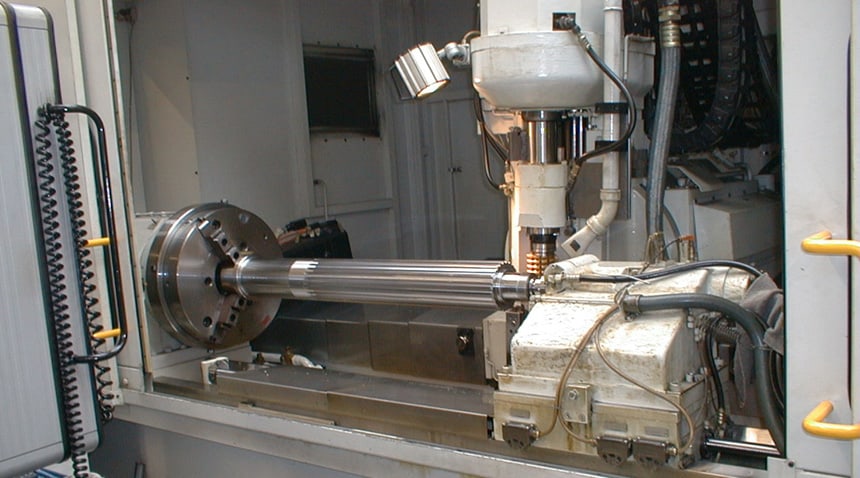

Engineering Capability: Precision Rubber O-Ring Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering infrastructure forms the technical backbone of precision rubber O-ring production. We deploy a dedicated team of five specialized mold engineers and two advanced formula engineers, ensuring end-to-end control from material science to finished component. This integrated approach eliminates external dependencies, accelerates development cycles, and guarantees strict adherence to OEM specifications for critical sealing applications across aerospace, automotive, and industrial hydraulics.

Our formula engineering team focuses on polymer matrix optimization and compound customization. Leveraging extensive databases of elastomer behavior under extreme conditions, we develop proprietary formulations that exceed standard material grades. This includes precise control over crosslink density, filler dispersion, and additive synergies to achieve target properties such as low-temperature flexibility down to -55°C, resistance to aggressive chemicals like Skydrol or biodiesel, and minimal compression set after 1,000 hours at 100°C. Every compound undergoes rigorous validation per ASTM D2000 and ISO 3601 standards, with full traceability from raw material lot to final test report.

Complementing this, our five mold engineers utilize 3D simulation tools to perfect cavity design, runner systems, and venting geometry before steel cutting. They resolve challenges like flash control in micron-tolerance dimensions (±0.05mm), weld line mitigation in complex profiles, and thermal uniformity for consistent vulcanization. This expertise enables rapid prototyping of custom O-rings with geometries up to 500mm ID while maintaining concentricity within 0.1mm TIR. All molds are manufactured in-house using hardened P20 or H13 tool steel, ensuring 500,000+ shot longevity with zero dimensional drift.

Our OEM process is engineered for seamless integration with client workflows. We initiate projects with joint DFMEA sessions to de-risk application-specific failure modes. Clients receive digital twin models for virtual fit-checks and accelerated life-test data against their operational parameters. Crucially, all formulations and tooling remain under strict IP protection, with dedicated production cells isolating sensitive programs. This capability has reduced time-to-market by 30% for Tier-1 automotive clients requiring AS9100-compliant seals.

Material performance is quantifiable through standardized testing. Below is a comparison of typical standard versus custom compound capabilities:

| Property | Standard Nitrile (NBR) | Custom Compound Range | Test Method |

|---|---|---|---|

| Tensile Strength (MPa) | 15–20 | 18–32 | ASTM D412 |

| Elongation at Break (%) | 250–350 | 200–450 | ASTM D412 |

| Hardness (Shore A) | 70 ±5 | 50–90 (±3) | ASTM D2240 |

| Compression Set (70h/100°C) | 25–35% | 10–20% | ASTM D395 |

| Volume Swell in IRM 903 | 15–25% | <8% | ASTM D471 |

This technical synergy between formula science and precision molding ensures Suzhou Baoshida delivers O-rings that consistently meet the most demanding functional and regulatory requirements. We partner with clients to transform sealing challenges into engineered solutions, backed by full documentation and process validation.

Customization Process

Drawing Analysis: The Foundation of Precision Engineering

At Suzhou Baoshida Trading Co., Ltd., every successful rubber o ring customization begins with rigorous drawing analysis. This initial phase ensures that all dimensional tolerances, groove specifications, and application parameters are fully understood. Our engineering team evaluates customer-provided technical drawings or assists in generating precise CAD models when required. Critical parameters such as inner diameter (ID), outer diameter (OD), cross-sectional diameter (CS), and tolerance grades per ISO 3601 or AS568 standards are verified. We also assess environmental factors including mating hardware, dynamic or static sealing conditions, and installation stresses. This comprehensive review prevents misinterpretation and ensures design integrity before any material is compounded.

Formulation: Tailoring Material Performance

Once the dimensional and mechanical requirements are confirmed, our rubber formula engineers develop a compound optimized for the intended service environment. The selection of polymer base—such as Nitrile (NBR), Fluorocarbon (FKM), Silicone (VMQ), Ethylene Propylene (EPDM), or specialty blends—is determined by exposure to temperature extremes, chemical media, pressure cycles, and regulatory compliance (e.g., FDA, ROHS, or UL). Hardness is precisely adjusted within the range of 40 to 90 Shore A, depending on sealing force and extrusion resistance needs. Additives are incorporated to enhance wear resistance, compression set performance, and thermal stability. Every formulation is documented and archived for full traceability, ensuring consistency across production batches.

Prototyping: Validating Design and Material

Before initiating mass production, we fabricate prototype o rings using precision molding techniques such as compression, transfer, or injection molding. Prototypes are subjected to dimensional inspection via optical comparators and coordinate measuring machines (CMM), ensuring conformity to print specifications. Functional testing may include compression set analysis, thermal aging, fluid immersion, and leak rate evaluation under simulated operating conditions. Feedback from this phase is used to refine either the tooling, compound, or design, guaranteeing optimal performance prior to scale-up.

Mass Production: Consistency at Scale

Upon customer approval of prototypes, we transition to high-volume manufacturing. Our production lines operate under strict process controls, with real-time monitoring of cure time, temperature, and pressure. Each batch undergoes statistical process control (SPC) checks, and final products are inspected for visual defects, dimensional accuracy, and material consistency. Packaging is customized to prevent deformation and contamination during shipping.

Below are typical customizable specifications managed throughout this workflow:

| Parameter | Range / Options | Standard Compliance |

|---|---|---|

| Inner Diameter (ID) | 3 mm – 500 mm | ISO 3601, AS568 |

| Cross Section (CS) | 1.0 mm – 12.0 mm | ISO 3601, AS568 |

| Hardness | 40 – 90 ±5 Shore A | ASTM D2240 |

| Material Types | NBR, FKM, EPDM, VMQ, ACM, AEM, HNBR | ASTM D1418 |

| Tolerances | Class M (Standard), Class S (Precision) | ISO 3302, RMA AA |

| Temperature Range | -40°C to +250°C (material-dependent) | ASTM D573, D865 |

| Certifications | FDA, ROHS, UL, NSF (upon request) | Customer-specific |

This structured, science-driven approach ensures that every custom o ring produced by Suzhou Baoshida meets the highest standards of reliability and performance in demanding industrial applications.

Contact Engineering Team

Technical Engagement for Precision Rubber O-Ring Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial sealing performance. Our engineering team specializes in formulating and manufacturing custom rubber O-rings for mission-critical applications where failure is not an option. With ISO 9001-certified processes and in-house material development capabilities, we address complex sealing challenges across aerospace hydraulics, semiconductor manufacturing, and high-pressure fluid systems. Our formulations transcend standard commercial grades, incorporating proprietary fillers and cross-linking technologies to achieve unparalleled resilience against thermal degradation, chemical exposure, and extrusion. When standard catalog offerings cannot resolve your leakage risks or service life limitations, our OEM partnership model delivers engineered solutions validated through ASTM D2000 and ISO 3601 protocols.

Below represents our core material specifications for industrial O-rings, reflecting the precision achievable through our compounding expertise:

| Material Type | Hardness Range (Shore A) | Temperature Range (°C) | Key Fluid Resistance | ASTM D2000 Classification |

|---|---|---|---|---|

| Hydrogenated Nitrile (HNBR) | 60–90 | -40 to +150 | Oils, Fuels, HFC Hydraulic Fluids | BC, BK, BM |

| Perfluoroelastomer (FFKM) | 70–85 | -25 to +325 | Aggressive Chemicals, Plasma | FE, FK |

| Ethylene Propylene (EPDM) | 50–80 | -50 to +150 | Water, Steam, Brake Fluids | EA, EF |

| Silicone (VMQ) | 40–80 | -60 to +230 | Ozone, UV, Biomedical Fluids | GE, GF |

This table illustrates baseline capabilities; our formulation laboratory routinely develops bespoke compounds exceeding these parameters for specialized OEM requirements. Recent projects include FFKM variants with 350°C intermittent exposure tolerance for semiconductor chamber seals and HNBR formulations with 50% reduced compression set for downhole drilling equipment. Our technical review process begins with your operational parameters—pressure cycles, media compatibility, and dynamic movement profiles—to model seal behavior before prototype production.

Partnering with Suzhou Baoshida eliminates the compromise between standard product limitations and custom development costs. We manage full lifecycle support from material selection and GD&T-compliant molding to accelerated aging validation and production scaling. Our OEM clients report 40% extended service life in corrosive environments through our tailored additive packages and post-cure optimization techniques. For applications demanding zero permeation or sub-micron dimensional stability, our engineering team implements real-time process monitoring with ±0.05mm tolerance control.

Initiate your precision sealing solution by contacting Mr. Boyce, our dedicated OEM Technical Manager. Provide your application’s critical parameters—including media type, pressure differentials, temperature extremes, and failure modes—and receive a data-driven proposal within 72 hours. Mr. Boyce coordinates direct engagement with our formulation chemists and tooling engineers to ensure technical alignment from inquiry to serial production. Do not settle for generic sealing components when your system integrity depends on molecular-level material science.

Contact Mr. Boyce immediately at [email protected] with your project specifications. Include required dimensions, material specifications, and operational environment details to expedite engineering analysis. Suzhou Baoshida commits to resolving your most demanding sealing challenges through scientifically validated rubber compounding and precision manufacturing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).