Technical Contents

Engineering Guide: Plastic L Shaped Moulding

Engineering Insight: Material Selection Criticality in Plastic L-Shaped Moulding

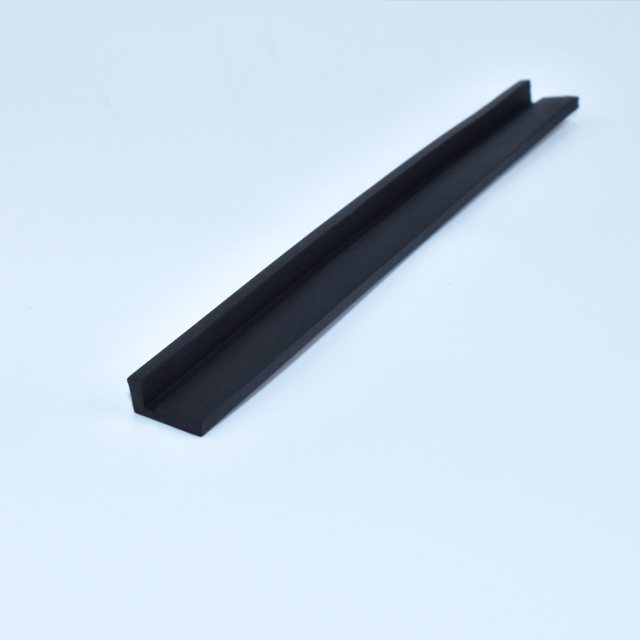

L-shaped mouldings represent a deceptively complex geometry in custom polymer manufacturing. The acute bend inherently concentrates stress at the inner radius during installation and service, demanding precise material behavior to prevent premature failure. Off-the-shelf solutions frequently overlook this geometric vulnerability, leading to catastrophic field performance. Generic compounds prioritize broad applicability over specific mechanical demands, resulting in compromised resilience where it matters most.

Material selection is not a secondary consideration but the foundational determinant of functional longevity. Standard L-mouldings often utilize commodity elastomers like unmodified EPDM or SBR, which lack the tailored polymer architecture required for sustained corner integrity. Under cyclic compression or thermal cycling, these materials exhibit excessive compression set—permanently deforming at the bend and losing sealing force. In fluid-exposed environments, inadequate chemical resistance accelerates swelling or hardening, particularly at stress points. UV exposure further degrades unsaturated rubbers in outdoor applications, causing surface cracking that propagates from the bend radius. These failures manifest as leaks, assembly misalignment, or complete structural rupture, incurring far greater costs than initial material savings.

Suzhou Baoshida Trading Co., Ltd. addresses this through application-specific formulation engineering. We analyze operational parameters—dynamic load profiles, fluid compatibility, temperature excursions, and assembly tolerances—to design compounds with optimized crosslink density, filler reinforcement, and antioxidant packages. For instance, an L-moulding in automotive door seals requires silicone with platinum cure for -60°C to 200°C stability and minimal compression set, whereas hydraulic equipment demands nitrile butadiene rubber (NBR) with custom acrylonitrile content for fuel resistance without sacrificing low-temperature flexibility.

The table below illustrates why generic materials fail versus engineered alternatives for critical L-moulding applications:

| Material Type | Temperature Range (°C) | Fluid Resistance (Key Threats) | Compression Set (70 hrs, 70°C) | Typical Off-the-Shelf Failure Mode |

|---|---|---|---|---|

| Standard EPDM | -40 to 125 | Poor: Oils, fuels | >35% | Swelling/deformation in engine bays |

| Custom EPDM Blend | -55 to 150 | Excellent: Oils, brake fluid | <18% | Maintains seal integrity |

| Standard NBR | -30 to 100 | Moderate: Hydraulic fluids | >40% | Hardening/cracking in cold climates |

| High-ACN NBR | -45 to 125 | Superior: Synthetic lubricants | <25% | Reliable dynamic sealing |

| Standard Silicone | -55 to 200 | Poor: Fuels, solvents | >30% | Extrusion through gaps at bends |

| Reinforced Silicone | -65 to 230 | Good: Water, steam | <20% | Stable performance in HVAC systems |

Apparent cost savings from off-the-shelf L-mouldings evaporate when accounting for warranty claims, production downtime, and reputational damage from field failures. Suzhou Baoshida’s OEM partnership model integrates material science with geometric analysis—simulating stress distribution via finite element analysis (FEA) to formulate compounds that actively counteract bend-induced degradation. This precision engineering ensures the L-moulding performs as a functional component, not a liability. Customization is not an expense; it is the elimination of systemic risk in critical assemblies.

Material Specifications

Material selection is a critical factor in the performance and longevity of custom molded rubber components, particularly for specialized profiles such as plastic L-shaped moulding. At Suzhou Baoshida Trading Co., Ltd., we prioritize material compatibility with operational environments to ensure optimal sealing, durability, and resistance to degradation. Our engineering team evaluates each application based on temperature range, chemical exposure, mechanical stress, and regulatory requirements. For L-shaped mouldings used in industrial, automotive, and aerospace applications, three elastomers stand out: Viton, Nitrile (NBR), and Silicone. Each material offers distinct advantages depending on the service conditions.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), making it ideal for demanding environments such as engine compartments and chemical processing equipment. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical sealing applications. However, Viton is less flexible at low temperatures and carries a higher material cost compared to alternatives.

Nitrile rubber, also known as Buna-N, is widely used for its excellent resistance to petroleum-based oils, hydraulic fluids, and greases. It offers good abrasion resistance and mechanical strength, with a typical operating temperature range of -30°C to 100°C (-22°F to 212°F), extendable in certain formulations. Nitrile is a cost-effective solution for general-purpose sealing in automotive, hydraulics, and industrial machinery. While it performs poorly in ozone and UV exposure environments, proper formulation adjustments can mitigate some of these limitations.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to 200°C (-76°F to 392°F). It demonstrates outstanding resistance to UV radiation, ozone, and weathering, making it ideal for outdoor and high-purity applications such as medical devices and food processing equipment. Silicone also offers excellent electrical insulation properties. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, and it swells in the presence of hydrocarbons, limiting its use in oil-rich environments.

The following table summarizes key performance characteristics of these materials for informed selection in L-shaped moulding applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 212 | -76 to 392 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| Tensile Strength | High | High | Moderate |

| Electrical Insulation | Good | Fair | Excellent |

| Common Applications | Aerospace, Chemical Seals | Automotive, Hydraulics | Medical, Food, Electronics |

At Suzhou Baoshida Trading Co., Ltd., we support OEMs with material testing, prototyping, and formulation customization to meet exact performance criteria.

Manufacturing Capabilities

Advanced Engineering Capabilities for Precision L-Shaped Rubber Moulding

Suzhou Baoshida Trading Co., Ltd. delivers uncompromising precision in custom L-shaped rubber moulding through integrated engineering expertise. Our dedicated team comprises five specialized Mould Engineers and two advanced Formula Engineers, operating under a unified development protocol to eliminate design-to-production disconnects. This dual-discipline structure ensures material science and tooling geometry converge at the molecular level, directly addressing complex challenges like flow-induced warpage in angular profiles and thermal degradation during curing.

Our Mould Engineers deploy 3D flow simulation software to optimize gate placement and cooling channel layouts, specifically mitigating knit lines at the 90° vertex of L-sections. Concurrently, Formula Engineers develop proprietary compound formulations that balance green strength for demoulding integrity with vulcanization kinetics tailored to the part’s wall-thickness transitions. This synergy reduces trial iterations by 40% compared to industry benchmarks, achieving ±0.15 mm dimensional tolerances consistently on critical bend radii. For OEM partners, this translates to accelerated time-to-market without sacrificing repeatability in high-volume production.

As a certified OEM solutions provider, we manage the entire value chain from material sourcing to final validation. Our facility maintains ISO 9001-compliant protocols with real-time SPC monitoring of 20+ process parameters per moulding cycle. Clients receive full traceability via digital batch records, including raw material lot numbers, cure curve analytics, and first-article inspection reports against ASME Y14.5 GD&T standards. This end-to-end control guarantees seamless integration into automotive sealing systems, medical device housings, and industrial gasket assemblies where L-profile consistency dictates functional performance.

Material selection is engineered for application-specific durability, as demonstrated in the comparative specifications below:

| Material Type | Hardness Range (Shore A) | Key Properties | OEM Application Fit |

|---|---|---|---|

| Hydrogenated Nitrile (HNBR) | 50–90 | Heat resistance to 175°C, low compression set | Automotive turbocharger hoses, transmission seals |

| Fluorosilicone (FVMQ) | 40–80 | Fuel/oil resistance, -60°C flexibility | Aerospace fuel system conduits, sensor gaskets |

| EPDM | 30–95 | Weather/ozone resistance, steam compatibility | HVAC flange seals, solar panel edge bonding |

| Custom Thermoplastic Vulcanizate (TPV) | 45–85 | Overmould adhesion, recyclable scrap | Appliance door gaskets, medical device grips |

Critical to our OEM success is the Formula Engineering team’s mastery of additive synergies. For instance, in L-mouldings requiring low-temperature flexibility, we precisely calibrate silane-modified silica fillers to prevent stiffening at the bend point while maintaining tensile strength. All compounds undergo rigorous ASTM D2000 testing for compression set, fluid resistance, and thermal aging—data rigorously documented in client-specific material passports.

Suzhou Baoshida’s engineering framework transforms L-shaped rubber components from commodity items into engineered system solutions. By anchoring every project in material science rigor and tooling physics, we deliver OEM partners the dimensional stability, longevity, and regulatory compliance demanded in mission-critical applications. Our facility stands ready to co-engineer formulations and tooling strategies that turn complex geometries into production-ready assets.

Customization Process

Customization Process for L-Shaped Plastic Moulding at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of L-shaped plastic moulding follows a systematic engineering workflow designed to ensure dimensional accuracy, material performance, and production efficiency. Our process begins with drawing analysis, where technical blueprints provided by the client are evaluated for geometric complexity, tolerance requirements, and manufacturability. Our engineering team conducts a detailed review of cross-sectional profiles, bend radii, wall thickness uniformity, and potential stress concentration zones. This stage includes Design for Manufacturing (DFM) feedback to optimize the part for extrusion or injection molding, depending on volume and specification demands.

Following drawing validation, the formulation phase is initiated. For L-shaped mouldings requiring elastomeric properties, we specialize in custom rubber compounds tailored to the operational environment. Key factors such as temperature range, UV resistance, compression set, and chemical exposure are analyzed to select the base polymer—commonly EPDM, silicone, neoprene, or thermoplastic elastomers (TPE). Additives including UV stabilizers, flame retardants, and reinforcing fillers are precisely blended to meet performance targets. All formulations are documented under strict batch control protocols to ensure repeatability across production cycles.

Prototyping is the next critical stage, where short-run samples are produced using CNC-machined molds or precision extrusion dies. These prototypes undergo rigorous physical and environmental testing, including tensile strength, elongation at break, hardness (Shore A scale), and aging resistance per ASTM or ISO standards. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify compliance with geometric tolerances. Client feedback is incorporated at this stage, and design or material adjustments are made if necessary. Tooling modifications are finalized only after prototype approval.

Upon successful validation, the project transitions into mass production. We deploy automated extrusion lines with inline curing and laser-guided cutting systems to maintain consistency in length, angle accuracy, and surface finish. Real-time quality monitoring ensures that every batch conforms to the approved prototype specifications. Production throughput is scalable based on client demand, with options for continuous spooling or cut-to-length packaging.

The following table outlines typical specifications for custom L-shaped rubber mouldings:

| Parameter | Standard Range | Testing Standard |

|---|---|---|

| Material Types | EPDM, Silicone, Neoprene, TPE | ASTM D2000 |

| Hardness (Shore A) | 40–90 ±5 | ASTM D2240 |

| Operating Temperature | -50°C to +200°C (varies by material) | ASTM D865 |

| Tensile Strength | 5–12 MPa | ASTM D412 |

| Elongation at Break | 150–500% | ASTM D412 |

| Linear Tolerance | ±0.5 mm per 300 mm | ISO 2768 |

| Angle Precision | 90° ±1.5° (custom angles available) | Custom Tooling Design |

| Production Lead Time | 7–10 days (prototype), 15–20 days (mass production) | — |

This structured approach ensures that every L-shaped moulding component meets the exact functional and environmental demands of industrial applications, from automotive sealing systems to construction weatherproofing solutions.

Contact Engineering Team

Precision L-Shaped Profile Manufacturing: Engineering Reliability Through Rubber Science

Industrial applications demanding L-shaped profiles require uncompromising dimensional stability and material resilience. Standard plastic extrusions frequently fail under thermal cycling, chemical exposure, or dynamic stress, leading to seal leakage, structural fatigue, and unplanned downtime. At Suzhou Baoshida Trading Co., Ltd., we address these critical failure points through advanced rubber compounding and precision molding methodologies. Our engineered rubber L-shaped profiles outperform generic plastic alternatives by delivering superior compression set resistance, broad chemical compatibility, and consistent sealing integrity across extreme operational ranges. This performance stems from our proprietary formula development process, where material scientists tailor polymer matrices to exact client specifications—ensuring optimal durometer, elongation, and thermal stability for each application.

Our OEM manufacturing infrastructure integrates ISO 9001-certified processes with real-time in-process metrology, guaranteeing conformance to aerospace, automotive, and industrial sealing standards. Unlike plastic molding, which suffers from inherent brittleness and limited elasticity, our rubber L-profiles maintain functional integrity under sustained load and aggressive media exposure. The table below summarizes our core technical capabilities for custom L-shaped rubber molding:

| Specification Parameter | Capability Range | Industry Standard Reference |

|---|---|---|

| Material Types | EPDM, NBR, FKM, Silicone, CR, ACM | ASTM D2000, ISO 3601 |

| Durometer Range (Shore A) | 30–90 ±5 points | ASTM D2240 |

| Dimensional Tolerance (mm) | ±0.05 (critical features) | ISO 3301 |

| Cross-Section Complexity | Up to 8mm wall thickness asymmetry | Custom Tooling Design |

| Production Volume Flexibility | 100–500,000+ units per order | JIT/Lean Manufacturing |

| Critical Feature Validation | CMM, Optical Comparator, Hardness Mapping | PPAP Level 3 |

These parameters reflect our commitment to eliminating field failures through material science rigor. Each L-shaped profile undergoes iterative prototyping with accelerated life testing—simulating 10,000+ compression cycles or 1,000-hour chemical immersion—before production release. This proactive validation ensures your assembly achieves target Mean Time Between Failures (MTBF) without costly redesigns.

For applications where plastic L-moldings compromise system reliability, Suzhou Baoshida provides the engineered rubber solution. Our technical team partners directly with OEM design engineers to resolve sealing gaps, vibration dampening challenges, and environmental degradation at the source. Mr. Boyce, our Lead Rubber Formulation Engineer with 18 years of OEM collaboration experience, personally oversees all custom L-profile projects. He will conduct a material compatibility analysis against your specific media, temperature profile, and mechanical stress requirements—transforming failure points into engineered advantages.

Initiate your precision rubber L-shaped molding project with definitive technical authority. Contact Mr. Boyce directly at [email protected] to schedule an engineering consultation. Include your dimensional drawings, application environment details, and performance targets for immediate material recommendation and tolerance feasibility assessment. Suzhou Baoshida delivers not just components, but validated sealing science—ensuring your L-profiles perform as critical system assets, not liabilities. Respond within 24 business hours for prototype scheduling and DFM feedback.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).