Technical Contents

Engineering Guide: Non Slip Outdoor Matting For Decking

Material Selection in Non Slip Outdoor Matting for Decking: An Engineering Imperative

The performance and longevity of non slip outdoor matting for decking are fundamentally determined by material selection. In industrial and commercial applications, off-the-shelf rubber matting solutions often fail prematurely due to inadequate resistance to environmental stressors, mechanical degradation, and poor formulation for dynamic load conditions. These failures are not random—they stem from a lack of engineering rigor in polymer selection, filler integration, and cross-linking strategies.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that true durability begins at the molecular level. Standard consumer-grade mats typically utilize reprocessed rubber or low-grade EVA (ethylene-vinyl acetate), which exhibit poor UV resistance, rapid oxidation, and diminished tensile strength under prolonged exposure to moisture and temperature fluctuations. These materials may appear cost-effective initially but lead to increased lifecycle costs due to frequent replacement, safety hazards, and maintenance downtime.

In contrast, engineered industrial rubber compounds—such as EPDM (ethylene propylene diene monomer) and high-density SBR (styrene-butadiene rubber)—offer superior performance in outdoor environments. EPDM, for instance, maintains structural integrity under intense UV radiation and extreme temperatures ranging from -40°C to +130°C. Its saturated polymer backbone resists ozone and weathering, making it ideal for long-term outdoor deployment. SBR, when compounded with reinforcing fillers like carbon black or silica, delivers enhanced abrasion resistance and mechanical strength, critical for high-traffic decking areas.

Moreover, the curing process—specifically sulfur or peroxide vulcanization—directly influences the cross-link density of the rubber matrix. Higher cross-link density translates to improved resistance against compression set, hydrolysis, and chemical exposure. Off-the-shelf mats often under-cure or use inconsistent vulcanization techniques, resulting in surface cracking, delamination, and loss of non-slip functionality.

Another overlooked factor is the role of additives. UV stabilizers, anti-oxidants, and anti-fungal agents must be precisely dosed during compounding to ensure sustained performance. Without these, even premium base polymers degrade prematurely when exposed to real-world conditions.

The following table outlines key material properties essential for high-performance non slip outdoor matting:

| Property | EPDM | High-Density SBR | Low-Grade Recycled Rubber |

|---|---|---|---|

| Tensile Strength (MPa) | 15–20 | 12–18 | 5–8 |

| Elongation at Break (%) | 300–500 | 250–400 | 100–200 |

| Operating Temperature Range (°C) | -40 to +130 | -30 to +100 | -10 to +60 |

| UV Resistance | Excellent | Good | Poor |

| Abrasion Resistance | Good | Excellent | Fair |

| Water Absorption (%) | <1.0 | <1.5 | >3.0 |

| Expected Outdoor Service Life (years) | 8–12 | 6–10 | 1–3 |

In industrial applications, where safety, compliance, and operational continuity are paramount, material selection cannot be compromised. At Baoshida, we engineer our rubber matting systems to exceed OEM specifications, ensuring reliability under the most demanding outdoor conditions. The cost of failure far outweighs the initial savings of generic alternatives—precision in formulation is not optional, it is essential.

Material Specifications

Material Specifications for Non-Slip Outdoor Decking Matting

Selecting the optimal elastomer is paramount for non-slip outdoor matting intended for decking applications. Performance hinges on withstanding continuous UV exposure, temperature extremes, moisture ingress, foot traffic abrasion, and potential chemical contact from pool chemicals, oils, or cleaning agents. Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in industrial rubber formulation to engineer matting solutions meeting these rigorous demands. Three primary elastomer families offer distinct advantages: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Viton excels in environments demanding exceptional resistance to high temperatures, ozone, and aggressive chemicals, including hydrocarbons and chlorinated compounds common near pools. Its dense polymer backbone provides superior durability but commands a higher material cost, making it ideal for premium or highly specialized installations where longevity under extreme stress is non-negotiable. Nitrile rubber presents the optimal balance for most commercial and high-end residential decking. It offers robust resistance to oils, greases, and moderate chemicals alongside excellent abrasion resistance and mechanical strength. NBR formulations can be precisely tuned for enhanced UV stability and cold flexibility, providing a cost-effective solution with proven long-term outdoor service life. Silicone rubber delivers unparalleled flexibility across an extreme temperature range and inherent resistance to UV degradation and oxidation. Its smooth surface can be engineered with aggressive texturing for slip resistance, though its lower abrasion resistance compared to NBR necessitates careful compound design for high-traffic zones. Silicone is preferred where extreme temperature cycling or specific aesthetic requirements are critical.

The following comparative table details key performance specifications relevant to outdoor decking matting applications, reflecting standard industrial compound formulations achievable through Suzhou Baoshida’s OEM manufacturing capabilities. All values represent typical achievable ranges under controlled testing per relevant ASTM standards.

| Material Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Service Temp | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Tensile Strength (MPa) | 10 – 18 | 15 – 25 | 5 – 12 |

| Abrasion Resistance (Rank) | Good | Excellent | Fair to Good |

| Oil/Fuel Resistance | Outstanding | Very Good | Poor |

| UV/Ozone Resistance | Excellent | Good (Formulated) | Excellent |

| Slip Coefficient (Wet) | 0.85+ (Textured) | 0.80+ (Textured) | 0.75+ (Textured) |

| Stain Resistance | Excellent | Very Good | Good |

| Relative Material Cost | High | Medium | Medium-High |

| Best Decking Application | Extreme chemical exposure, High heat zones | General commercial/residential, High traffic | Extreme cold/heat cycling, Aesthetic focus |

Suzhou Baoshida Trading Co., Ltd. emphasizes that compound formulation precision is critical. Standard base polymer properties are significantly enhanced through proprietary additive packages developed in our R&D center, optimizing UV stabilizers, fillers for reinforcement, and anti-oxidants specifically for prolonged outdoor exposure. Our OEM management ensures strict adherence to these formulations during manufacturing, guaranteeing consistent material performance batch after batch. Understanding the specific environmental stressors of the deck location allows Baoshida to recommend and produce the most cost-effective, durable matting solution, whether prioritizing chemical resistance with Viton, balanced performance with Nitrile, or thermal flexibility with Silicone. Material selection directly dictates product lifespan and safety compliance in demanding outdoor settings.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our core strength in delivering high-performance non-slip outdoor matting for decking lies in our dedicated engineering team and advanced formulation expertise. We employ five specialized mould engineers and two certified rubber formula engineers, all focused on optimizing product functionality, durability, and manufacturability for industrial and commercial applications. This integrated team ensures that every matting solution is engineered from concept to production with precision and scientific rigor.

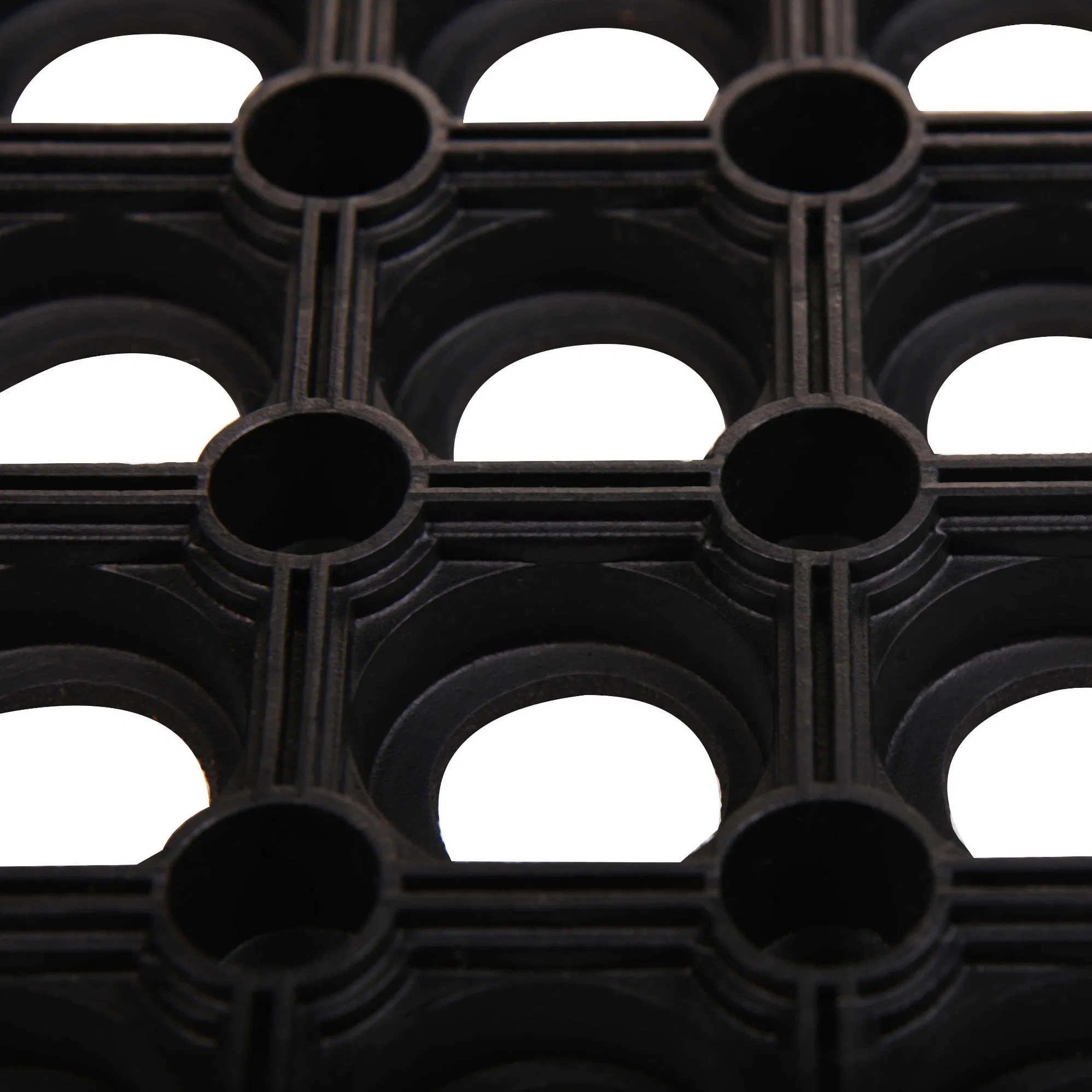

Our mould engineers utilize state-of-the-art CAD/CAM software and CNC prototyping systems to design and refine tooling for complex tread patterns, edge profiles, and interlocking geometries. These capabilities allow us to produce highly effective anti-slip surfaces tailored to specific environmental conditions, including wet, oily, or high-traffic outdoor environments. Each mould is stress-analyzed and cycle-tested to ensure dimensional stability and long service life under continuous production.

Complementing this is our rubber formulation division, where our two formula engineers develop proprietary elastomer blends that meet the demanding requirements of outdoor decking applications. Using a base of high-resilience SBR, EPDM, or NBR compounds, we customize hardness, UV resistance, ozone stability, and low-temperature flexibility. Our formulations are engineered to resist algae growth, hydrolysis, and thermal degradation—common failure points in outdoor rubber matting. Through iterative lab testing and field validation, we ensure that each compound delivers optimal slip resistance (measured by DIN 51130 and BS 7976 standards), tensile strength, and abrasion resistance.

We operate as a full-service OEM partner, capable of managing end-to-end development from technical drawings to mass production. Clients provide performance specifications or application requirements, and our engineering team responds with material recommendations, 3D mould designs, and functional prototypes within 10–15 working days. Our production lines support custom branding, color integration, and size configurations, including roll-form and tile-based systems.

The following table outlines the standard technical specifications achievable through our engineering and formulation capabilities:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Resistance (Taber Wheel) | ASTM D1044 | ≤120 mg loss |

| Slip Resistance (R9–R13) | DIN 51130 | R10 minimum |

| UV and Ozone Resistance | ASTM D1149 | Pass (48h, 50pphm, 40°C) |

| Operating Temperature Range | — | -40°C to +80°C |

With a foundation in material science and precision engineering, Suzhou Baoshida ensures that every non-slip outdoor matting solution is not only compliant with international safety standards but also optimized for real-world performance and longevity in challenging outdoor environments.

Customization Process

Customization Process for Non-Slip Outdoor Matting

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for non-slip outdoor decking matting follow a rigorously defined customization pathway. This ensures optimal performance under demanding environmental conditions while meeting precise client specifications. The process begins with Drawing Analysis, where engineering teams dissect client-provided CAD files or technical sketches. Critical parameters such as surface texture geometry, drainage channel dimensions, edge profiles, and tolerance allowances are validated against ASTM F1637 standards for slip resistance and structural integrity. We assess load-bearing requirements per square meter and verify compatibility with common decking substrates like composite lumber or pressure-treated wood. Any dimensional conflicts or material stress points are resolved collaboratively with the client before progression.

Subsequent Formulation leverages our proprietary rubber compound database and accelerated aging protocols. Base polymers—typically EPDM or SBR—are selected for UV resistance and thermal stability between -40°C to +120°C. Silica reinforcement replaces carbon black to maintain color fidelity in pigmented mats, while specialized anti-slip additives (e.g., aluminum oxide or ceramic grit) are calibrated to achieve a COF (Coefficient of Friction) >0.6 when wet. Each formulation undergoes computational fluid dynamics modeling to predict drainage efficiency and wear patterns. Critical properties are validated via ISO 48-4 hardness testing, ISO 37 tensile strength analysis, and ISO 4649 abrasion resistance cycles.

Prototyping utilizes CNC-machined molds to produce 3–5 sample batches. These undergo accelerated weathering in QUV chambers (500+ hours per ASTM G154), slip testing on inclinable wet surfaces (ASTM F2913), and freeze-thaw cycling. Client feedback on texture, flexibility, and aesthetic integration with decking systems is incorporated within 72 hours. Only after third-party laboratory certification of all safety and durability metrics does the design advance.

Mass Production commences with mold qualification and raw material batch traceability via blockchain-enabled logs. Continuous inline monitoring tracks vulcanization temperature profiles (±1.5°C tolerance), compound viscosity (Mooney ML 1+4 @ 100°C), and dimensional consistency via laser scanners. Every 500th unit undergoes destructive testing to validate aging resistance. Final inspection includes 100% visual checks for surface defects and random COF verification. Production scalability ranges from 5,000 to 500,000 units monthly with lead times of 25–35 days post-approval.

Key performance specifications are adjustable within scientific limits as shown below.

| Property | Standard Range | Test Method | Adjustability |

|---|---|---|---|

| Shore A Hardness | 55–75 | ISO 48-4 | ±5 units |

| Tensile Strength (MPa) | 8.0–15.0 | ISO 37 | ±1.5 MPa |

| Abrasion Loss (mm³) | ≤120 | ISO 4649 | Target-based |

| Wet COF (ASTM F2913) | ≥0.60 | ASTM F2913 | Fixed minimum |

| UV Resistance (ΔE) | ≤3.0 after 1,000h | ASTM G154 | Material-dependent |

This closed-loop engineering approach guarantees mats that resist algae adhesion, thermal cracking, and surface wear for 8+ years in marine-grade environments. Suzhou Baoshida’s integration of material science with industrial manufacturing discipline delivers decking solutions where safety and longevity are non-negotiable.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Non-Slip Outdoor Matting Solutions

When it comes to high-performance non-slip outdoor matting for decking applications, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation. As a trusted OEM manager and rubber formulation engineer, we specialize in delivering durable, weather-resistant, and safety-compliant matting systems tailored to commercial, industrial, and residential outdoor environments. Our engineered rubber solutions are designed to meet the rigorous demands of outdoor exposure, including UV resistance, thermal stability, and long-term slip resistance under wet and high-traffic conditions.

We understand that every decking project presents unique challenges—whether it’s a rooftop terrace, marine dock, or public walkway. That’s why we prioritize material science and precision manufacturing in every product we deliver. Our non-slip outdoor mats are formulated using advanced EPDM and SBR rubber compounds, ensuring optimal grip, resilience, and dimensional stability across diverse climates and substrates. From custom thicknesses to specific color matching and texture profiles, our team works closely with clients to develop solutions that align with both functional requirements and aesthetic expectations.

Our commitment to quality is reflected in every stage of production, from raw material selection to final inspection. All mats undergo rigorous testing for slip resistance (measured via DIN 51130 and ASTM D2047 standards), abrasion resistance, and elongation at break to guarantee performance under real-world conditions. Additionally, our products are engineered for easy installation and minimal maintenance, offering long-term cost efficiency and enhanced safety.

For technical inquiries, custom project consultation, or sample requests, we invite you to contact Mr. Boyce, your dedicated point of contact at Suzhou Baoshida Trading Co., Ltd. With extensive experience in industrial rubber applications and global supply chain coordination, Mr. Boyce provides expert guidance on material selection, compliance, and scalable manufacturing solutions. Whether you are sourcing for a single project or establishing a long-term supply agreement, we are equipped to support your needs with precision and reliability.

Reach out today via email at [email protected] to discuss your non-slip matting specifications. Our team responds promptly to all inquiries and is prepared to provide technical data sheets, test reports, and product samples upon request.

Below are key technical specifications representative of our standard non-slip outdoor matting for decking:

| Property | Test Method | Typical Value |

|---|---|---|

| Material Composition | Visual/IR Analysis | EPDM/SBR Blend |

| Thickness Tolerance | ASTM D3767 | ±0.5 mm |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥9.0 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Slip Resistance (Wet) | DIN 51130 (R11) | R11 Classification |

| UV Resistance | ASTM G154 | 1500 hrs no cracking |

| Operating Temperature Range | N/A | -40°C to +80°C |

| Fire Rating (Optional) | ASTM E84 | Class B (Flame Spread ≤75) |

Partner with Suzhou Baoshida for technically superior, industrially proven non-slip outdoor matting. Contact Mr. Boyce directly at [email protected] to begin your custom solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).