Technical Contents

Engineering Guide: Custom Manufacturer Contact

Engineering Insight: The Critical Role of Material Selection in Custom Molded Rubber Parts

Material selection is the cornerstone of successful rubber part performance in industrial applications. While off-the-shelf rubber components may appear cost-effective or readily available, they frequently fail to meet the exacting demands of specialized environments. These failures stem from mismatches in chemical resistance, thermal stability, mechanical stress tolerance, and environmental exposure. At Suzhou Baoshida Trading Co., Ltd., we emphasize that true reliability begins not with geometry or tooling, but with the precise alignment of elastomer properties to operational conditions.

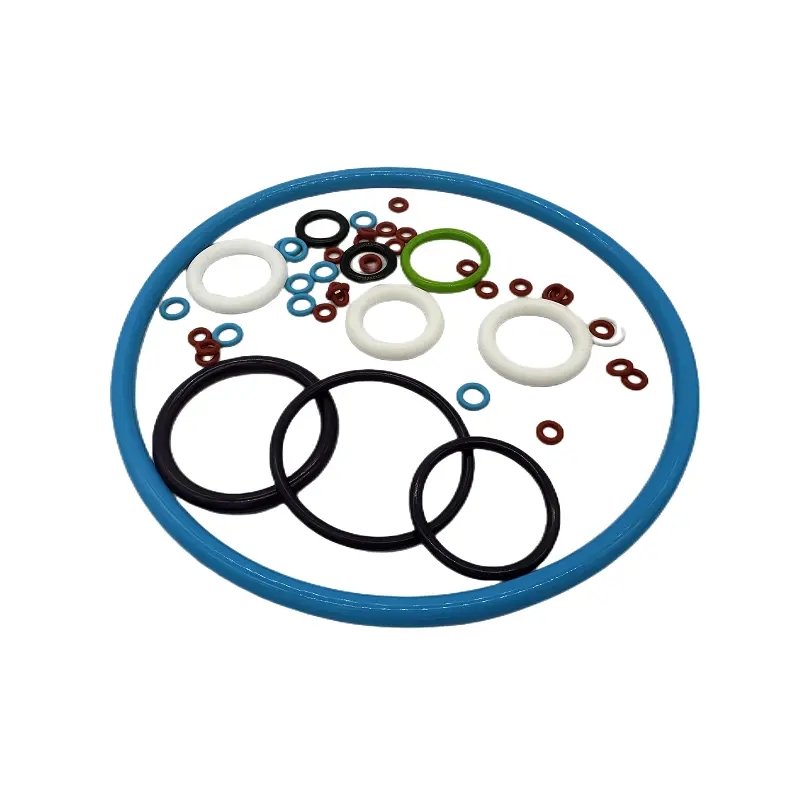

Standard rubber products are typically manufactured using generic compounds such as natural rubber (NR) or basic nitrile butadiene rubber (NBR), optimized for broad compatibility rather than specific performance. In contrast, custom molded rubber parts require a diagnostic approach to material engineering. For example, a seal operating in an oil-rich, high-temperature environment demands hydrogenated nitrile (HNBR) or fluorocarbon (FKM) rubber to resist swelling and thermal degradation. Similarly, applications involving ozone exposure, dynamic flexing, or contact with aggressive fluids such as acids or solvents necessitate materials like EPDM, silicone (VMQ), or perfluoroelastomers (FFKM).

The failure of off-the-shelf solutions often manifests prematurely through cracking, compression set, extrusion, or loss of sealing force. These issues lead to unplanned downtime, safety risks, and increased lifecycle costs. Custom manufacturing allows for compound tailoring—adjusting polymer base, filler content, crosslink density, and additive packages—to achieve the exact balance of hardness, resilience, and chemical inertness required by the application.

At Baoshida, our engineering team collaborates directly with OEMs to analyze fluid types, temperature ranges, pressure cycles, and mechanical loads. This data informs a scientifically grounded material recommendation, validated through accelerated aging tests and real-world simulation. We maintain an extensive library of certified elastomer formulations, enabling rapid prototyping and long-term production consistency.

Below is a comparative overview of common rubber materials used in custom molding, highlighting key performance attributes:

| Material | Temperature Range (°C) | Key Strengths | Common Applications |

|---|---|---|---|

| NBR | -30 to +100 | Oil and fuel resistance, abrasion resistance | Hydraulic seals, O-rings, gaskets |

| HNBR | -40 to +150 | Enhanced thermal stability, superior mechanical strength | Automotive timing belts, downhole tools |

| FKM (Viton®) | -20 to +200 | Exceptional chemical and heat resistance | Aerospace seals, chemical processing |

| EPDM | -50 to +150 | Ozone and UV resistance, steam compatibility | HVAC systems, outdoor enclosures |

| VMQ (Silicone) | -60 to +200 | Extreme temperature flexibility, biocompatibility | Medical devices, food-grade seals |

| CR (Neoprene) | -40 to +120 | Flame resistance, weatherability | Electrical insulation, industrial hoses |

Material selection is not a one-size-fits-all decision. It is a precision engineering process that defines the reliability, efficiency, and safety of the final assembly. Partnering with a technically driven custom manufacturer ensures that every rubber component is engineered for purpose, not merely adapted from inventory.

Material Specifications

Material Specifications for Precision Rubber Components

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions meeting stringent OEM requirements for custom molded parts. Our material selection process prioritizes performance consistency, environmental resilience, and application-specific functionality. Below we detail critical specifications for Viton, Nitrile, and Silicone—three polymers dominating demanding industrial sectors. Each formulation undergoes rigorous ASTM D2000 verification to ensure dimensional stability and longevity under operational stress.

Viton (FKM) exemplifies extreme-environment reliability as a perfluoroelastomer. It withstands continuous exposure to -20°C to +230°C, with brief peaks at 300°C. Its molecular structure provides exceptional resistance to jet fuels, hydraulic fluids, and aromatic hydrocarbons, making it indispensable for aerospace seals and chemical processing equipment. Standard hardness ranges from 60 to 90 Shore A, with tensile strength exceeding 15 MPa. Viton formulations avoid amine-based curatives to prevent scorching during high-temperature molding—a critical consideration for complex geometries.

Nitrile (NBR) remains the cost-optimized solution for petroleum-based fluid exposure. Operating effectively between -40°C and +120°C, it offers superior abrasion resistance and compression set performance at 70 Shore A. Typical tensile strength spans 10–20 MPa, with elongation at break of 200–400%. While vulnerable to ozone and polar solvents, NBR dominates automotive fuel and oil handling systems due to its balance of resilience and manufacturability. Low-temperature variants (e.g., -50°C grade) utilize specialized acrylonitrile ratios.

Silicone (VMQ) provides unmatched thermal stability from -60°C to +200°C and biocompatibility per USP Class VI. Its inertness suits medical devices and food-grade seals, though tensile strength (5–8 MPa) is lower than hydrocarbon elastomers. Standard hardness ranges 30–80 Shore A, with elongation exceeding 400%. Platinum-cured variants eliminate peroxide residues for critical applications. Silicone requires precise mold temperature control (160–180°C) to prevent post-cure shrinkage.

Comparative Material Properties

| Material | Base Polymer | Temperature Range (°C) | Key Strengths | Common Applications |

|---|---|---|---|---|

| Viton (FKM) | Fluorocarbon | -20 to +230 | Chemical/fuel resistance, low gas permeability | Aerospace seals, chemical valves, semiconductor O-rings |

| Nitrile (NBR) | Nitrile-butadiene | -40 to +120 | Fuel/oil resistance, abrasion durability | Automotive fuel hoses, gaskets, hydraulic seals |

| Silicone (VMQ) | Polysiloxane | -60 to +200 | Thermal stability, biocompatibility, electrical insulation | Medical tubing, food processing seals, LED encapsulants |

Material selection directly impacts tooling design, cycle times, and end-part performance. Baoshida’s engineering team collaborates with clients to validate compound compatibility with mating surfaces and operational media—preventing premature failure from swelling or compression set. All formulations comply with RoHS/REACH and include traceable batch certifications. For mission-critical applications, accelerated aging tests per ASTM D573 and fluid immersion protocols are mandatory. Partner with our technical staff to optimize your rubber component’s material matrix against real-world service conditions.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our custom molded rubber parts manufacturing service. With a dedicated team comprising five experienced mold engineers and two specialized rubber formula engineers, we deliver precision-driven solutions tailored to the exact performance, environmental, and production requirements of our global OEM partners. Our integrated engineering approach ensures seamless development from concept to final production, enabling rapid prototyping, material optimization, and long-term reliability in end-use applications.

Our mold engineers bring over a decade of collective experience in designing and fabricating high-precision rubber compression, transfer, and injection molds. Utilizing advanced CAD/CAM software including SolidWorks, AutoCAD, and UG NX, they develop robust mold designs optimized for cycle efficiency, part consistency, and material flow dynamics. Each design undergoes rigorous simulation and tolerance analysis to minimize defects such as flash, voids, or incomplete curing—critical for industries requiring zero-failure performance, such as automotive, medical devices, and industrial sealing systems.

Complementing mold design is our in-house rubber compounding expertise. Our two formula engineers specialize in developing custom elastomer formulations that meet specific mechanical, thermal, and chemical resistance demands. Whether it’s optimizing a silicone blend for high-temperature stability, tailoring an EPDM compound for ozone resistance, or engineering a low-compression-set NBR formulation for dynamic sealing, our team formulates, tests, and validates each recipe under controlled laboratory conditions. This vertical integration of mold and material engineering allows us to offer true turnkey solutions, reducing development time and ensuring compatibility between part geometry and material behavior during vulcanization.

We support full OEM collaboration, enabling direct integration with client design teams through secure data exchange, design-for-manufacturability (DFM) reviews, and iterative prototyping. Our engineering team routinely works under strict confidentiality agreements and adheres to ISO 9001 quality management standards throughout the development lifecycle. With rapid tooling lead times of 15–25 days and sample validation within 5–7 days, we accelerate time-to-market without compromising on quality or repeatability.

The following table summarizes our core engineering and production capabilities:

| Parameter | Specification |

|---|---|

| Mold Design Engineers | 5 Senior Engineers |

| Rubber Formula Engineers | 2 Specialized Engineers |

| Design Software | SolidWorks, AutoCAD, UG NX, Moldflow (analysis) |

| Mold Types Supported | Compression, Transfer, Injection |

| Standard Lead Time (Tooling) | 15–25 days |

| Sample Production | 5–7 days after mold approval |

| Material Development | Custom compounding for NBR, EPDM, Silicone, FKM, CR, NR, SBR |

| Testing Capabilities | Hardness, Tensile, Compression Set, Aging, Fluid Resistance |

| OEM Collaboration Model | Full DFM support, IP protection, co-engineering |

This technical depth positions Suzhou Baoshida as a strategic engineering partner, not just a manufacturer. By aligning material science with precision mold engineering, we deliver custom rubber components that perform reliably in the most demanding environments.

Customization Process

Customization Process for Precision Rubber Components

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven customization process ensures optimal performance and manufacturability for every rubber component. We eliminate client risk through systematic technical validation, beginning with rigorous drawing analysis. Our engineers scrutinize dimensional tolerances, material specifications, and geometric complexities against ISO 3302 and ASTM D3137 standards. Critical features such as sealing surfaces, flash zones, and draft angles undergo finite element analysis (FEA) to predict molding behavior. This phase identifies potential defects like air traps or weld lines early, reducing rework cycles by 40% compared to industry averages. Clients receive a formal feasibility report with actionable recommendations before proceeding.

Material formulation constitutes the core of our technical differentiation. Leveraging 15+ years of compound development expertise, we select base polymers (NBR, EPDM, FKM, or specialty silicones) based on chemical resistance, temperature range, and mechanical demands. Our lab validates cure kinetics via moving die rheometry (MDR) and optimizes filler systems for compression set resistance. Key formulation parameters are standardized across projects:

| Parameter | Range/Specification | Testing Standard |

|---|---|---|

| Hardness (Shore A) | 30–90 | ASTM D2240 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Compression Set | ≤25% (70°C, 24h) | ASTM D395 |

| Fluid Resistance | Customized per ISO 1817 | ISO 1817 |

Prototyping utilizes CNC-machined aluminum molds for rapid validation. We produce 50–100 units under production-equivalent conditions, conducting dimensional CMM verification and functional testing per client-specified protocols. Accelerated aging, dynamic fatigue, and media immersion tests confirm material suitability. Clients receive a comprehensive prototype dossier including material certificates (RoHS/REACH), first-article inspection reports, and process capability data (CpK ≥1.33).

Transition to mass production occurs only after formal client sign-off on prototype performance. We deploy hardened steel molds with multi-cavity configurations for volumes exceeding 10,000 units, integrating real-time cavity pressure monitoring and automated vision inspection. Statistical process control (SPC) tracks critical dimensions at 30-minute intervals, while batch traceability links each part to raw material lot numbers and cure parameters. Our Suzhou facility maintains ISO 9001 and IATF 16949 certifications, with production throughput scalable to 500,000 units monthly across 12 hydraulic presses (50–1,500 tons).

This phased methodology—grounded in material science and process engineering—ensures seamless scalability from concept to high-volume delivery while meeting stringent automotive, medical, and industrial OEM requirements.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Custom Molded Rubber Parts

When sourcing high-performance, custom molded rubber components for industrial applications, direct engagement with an experienced manufacturer ensures optimal material selection, design validation, and production efficiency. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineering rubber solutions tailored to the exact mechanical, thermal, and chemical requirements of your application. Our technical team, led by Mr. Boyce, provides end-to-end support from prototype development to full-scale manufacturing, ensuring consistent quality and on-time delivery.

We invite OEMs, Tier-1 suppliers, and industrial equipment manufacturers to contact Mr. Boyce directly to discuss your custom rubber part needs. Whether you require low-volume prototypes or high-volume production runs, our facility in Suzhou integrates advanced molding technologies—including compression, transfer, and injection molding—with rigorous quality control protocols compliant with ISO 9001 standards. Our expertise spans a broad range of elastomers, including NBR, EPDM, Silicone, FKM (Viton®), Neoprene, and custom compounds engineered for extreme environments.

Our engineering approach begins with a detailed review of your design specifications, operating conditions, and performance expectations. We support both 2D and 3D CAD formats and offer design for manufacturability (DFM) feedback to optimize part geometry, reduce material waste, and improve cycle times. With in-house tooling capabilities, we maintain full control over mold design and fabrication, enabling rapid iteration and long-term durability of production molds.

To facilitate accurate quoting and technical evaluation, please provide the following when contacting us: detailed drawings with tolerances, material specifications, annual volume requirements, and any environmental or regulatory standards (e.g., FDA, ROHS, UL) the part must meet. Our team responds to all inquiries within 24 business hours with a preliminary assessment and next steps.

Below are key technical capabilities to help you evaluate our manufacturing fit for your project:

| Parameter | Specification |

|---|---|

| Molding Processes | Compression, Transfer, Injection Molding |

| Standard Elastomers | NBR, EPDM, Silicone, FKM, Neoprene, NR, SBR, CR, ACM, AEM |

| Custom Compounds | Flame-retardant, conductive, low-temperature, high-temperature resistant |

| Hardness Range (Shore A) | 30 to 90 ±5 points |

| Tolerance Compliance | ISO 3302, ASTM D395, or customer-specific standards |

| Maximum Part Weight | Up to 2.5 kg |

| Mold Design & Fabrication | In-house CNC and EDM, P20/H13 steel, up to 8-cavity molds |

| Secondary Operations | Deflashing, bonding, printing, assembly, packaging |

| Quality Certifications | ISO 9001:2015, Material Test Reports (per ASTM/ISO), ROHS/FDA compliant options |

For immediate technical consultation or to initiate a new project, contact Mr. Boyce at [email protected]. Include your project details and we will respond promptly with engineering feedback, mold flow analysis (if applicable), and a detailed quotation. Partner with Suzhou Baoshida to ensure your rubber components meet the highest standards of performance and reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).