Technical Contents

Engineering Guide: 2X2 3/16 Square Tubing

Engineering Insight: Material Selection Criticality for 2×2 3/16 Square Rubber Tubing

The dimensional specification 2×2 3/16 inch square tubing defines only the outer profile and wall thickness. In industrial rubber applications, this geometric parameter is merely the starting point. Material selection dictates functional lifespan, performance under stress, and ultimate cost-effectiveness. Off-the-shelf rubber tubing meeting basic dimensional criteria frequently fails catastrophically in demanding OEM environments because it ignores the compound’s molecular architecture and its interaction with operational stressors. Generic solutions prioritize lowest cost and broad availability over the specific chemical, thermal, and mechanical requirements inherent to complex machinery, fluid handling, or sealing systems. This oversight leads to premature degradation, unplanned downtime, and significant warranty liabilities that far exceed any initial procurement savings.

Industrial failures commonly stem from three core material deficiencies in standard tubing. First, inadequate compound formulation results in poor resistance to specific media such as hydraulic fluids, ozone, or process chemicals, causing swelling, cracking, or loss of physical properties. Second, insufficient resilience under continuous compression or dynamic flexing leads to rapid compression set, permanently deforming the tubing and compromising seal integrity or structural support. Third, thermal limitations are often underestimated; standard compounds may harden or soften outside narrow temperature bands, losing elasticity or dimensional stability during thermal cycling common in machinery. These failures are not random but direct consequences of applying a one-size-fits-all material to applications requiring tailored polymer science. The operational cost of replacing failed tubing—factoring in labor, machine stoppage, and potential secondary damage—typically multiplies the original part cost by orders of magnitude.

Suzhou Baoshida Trading Co., Ltd. addresses this critical gap through precision rubber compounding. We engineer bespoke EPDM, NBR, FKM, and specialty silicone formulations specifically for the 2×2 3/16 square profile, optimizing crosslink density, filler systems, and additive packages to match the client’s exact service environment. This targeted approach ensures performance where generic tubing fails. The table below contrasts key performance parameters:

| Property | Generic Off-the-Shelf Tubing | Baoshida Custom Engineered Solution | Critical Impact of Deficiency |

|---|---|---|---|

| Hardness Range (Shore A) | Fixed (e.g., 70±5) | Precisely Tuned (60-90 selectable) | Affects sealing force, abrasion resistance, flexibility |

| Fluid Resistance (ISO 1817) | Limited Media Coverage | Validated for Specific Fluids | Prevents swelling, hardening, seal failure |

| Compression Set (ASTM D395) | High (e.g., >35% @ 70°C/22h) | Optimized Low (e.g., <15%) | Maintains seal integrity under load, prevents leakage |

| Temp Range (Continuous) | Narrow (-20°C to +100°C) | Extended (-50°C to +230°C possible) | Ensures reliability in thermal extremes |

| Tensile Strength (MPa) | Moderate (e.g., 10-12) | Enhanced (e.g., 15-18) | Resists tearing during installation/operation |

Material selection for 2×2 3/16 square rubber tubing is not a commodity decision but a fundamental engineering requirement. Suzhou Baoshida Trading Co., Ltd. leverages deep compound formulation expertise to transform this standard profile into a reliable, high-performance component. By moving beyond dimensional compliance to address the true chemical and physical demands of the application, we eliminate the hidden costs of failure and deliver tubing engineered for operational continuity. Partnering for material-specific engineering is the only assurance of long-term functional success in critical industrial systems.

Material Specifications

Material Specifications for 2×2 3/16 Square Tubing in Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber square tubing solutions engineered for demanding industrial environments. The 2×2 3/16 inch square tubing profile is designed to deliver structural integrity, consistent sealing performance, and compatibility across a wide range of mechanical and chemical conditions. This tubing format is commonly used in gasketing, sealing, and protective barrier applications where dimensional accuracy and material resilience are critical. The selection of base elastomer significantly influences performance, and three primary materials are recommended: Viton, Nitrile (NBR), and Silicone. Each material offers distinct advantages depending on temperature range, chemical exposure, and mechanical stress requirements.

Viton, a fluorocarbon-based rubber, is the premium choice for extreme environments. It exhibits outstanding resistance to high temperatures, aromatic and chlorinated hydrocarbons, fuels, and acids. With continuous service capability up to 200°C and intermittent peaks exceeding 250°C, Viton is ideal for aerospace, automotive, and chemical processing applications. Its low gas permeability and excellent aging characteristics further enhance reliability in sealed systems.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving petroleum-based oils and fuels. It provides excellent abrasion resistance and tensile strength, making it suitable for hydraulic systems, fuel lines, and industrial machinery seals. While its temperature range is more limited compared to Viton, Nitrile performs reliably between -30°C and 100°C, with short-term exposure up to 125°C. It is less resistant to ozone, UV, and polar solvents, so environmental exposure must be carefully evaluated.

Silicone rubber excels in extreme temperature applications, offering serviceability from -60°C to 230°C. It maintains flexibility at low temperatures and stability at high heat, making it ideal for thermal insulation, food-grade environments, and electrical insulation. While it has lower mechanical strength and poor resistance to petroleum fuels, its biocompatibility, low toxicity, and resistance to ozone and UV radiation make it a preferred choice in medical, pharmaceutical, and outdoor applications.

The following table summarizes key physical and chemical properties of each material in the context of 2×2 3/16 square tubing:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 100 (125 intermittent) | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel/Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliance Availability | Limited | No | Yes |

Selection of the appropriate material must consider operational temperature, media exposure, mechanical loading, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with material testing, custom compounding, and precision extrusion to ensure optimal performance of 2×2 3/16 square tubing in mission-critical applications.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Tubing Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers uncompromising precision in industrial rubber solutions, specifically engineered for demanding applications like 2×2 3/16 square tubing. Our core strength lies in the seamless integration of material science and advanced tooling expertise, driven by a dedicated team of 5 specialized Mould Engineers and 2 certified Rubber Formula Engineers. This dual-engineering framework ensures every component meets exacting dimensional, chemical, and performance criteria while optimizing production efficiency.

Our Mould Engineers focus on geometric integrity and process stability for square tubing profiles. They utilize 3D CAD/CAM simulations to eliminate flow imbalances, weld lines, and dimensional drift inherent in complex extrusion dies. Concurrently, our Rubber Formula Engineers develop proprietary compound formulations tailored to the tubing’s end-use environment—whether requiring ozone resistance for outdoor infrastructure, fuel tolerance for automotive systems, or low-compression set for sealing applications. This collaborative approach prevents costly iterations by aligning material behavior with tooling dynamics from the initial design phase.

As a certified OEM partner, we provide end-to-end manufacturing control. Clients supply specifications or CAD models, and our team executes rapid prototyping, material validation, and volume production under ISO 9001 protocols. We maintain full traceability of raw materials (including FDA/USP Class VI options) and in-process testing for durometer, tensile strength, and extrusion consistency. Critical to our OEM value is the ability to modify compounds in-house—adjusting hardness, filler content, or cure systems without third-party dependencies—accelerating time-to-market for custom solutions.

The following table details standard specifications for our 2×2 3/16 square tubing, reflecting baseline capabilities. All parameters are fully adjustable per client requirements:

| Parameter | Standard Specification | Tolerance | Test Method |

|---|---|---|---|

| Outer Dimensions | 2.000″ x 2.000″ | ±0.015″ | ASTM D375 |

| Wall Thickness | 0.1875″ (3/16″) | ±0.008″ | ASTM D375 |

| Material Options | EPDM, NBR, Silicone | Custom blends | ASTM D2000 |

| Durometer Range | 50A to 90A | ±5 points | ASTM D2240 |

| Tensile Strength | ≥1,500 psi | Min. value | ASTM D412 |

| Elongation | ≥250% | Min. value | ASTM D412 |

| Compression Set | ≤25% (70°C, 22h) | Max. value | ASTM D395 |

This technical rigor extends to secondary operations: we offer precision cutting, splicing, and surface treatments (e.g., plasma activation for adhesion) under controlled cleanroom conditions. By embedding formula and mould engineering into every project lifecycle—from feasibility analysis to post-production support—we eliminate performance gaps between design intent and physical output. For OEMs requiring mission-critical rubber components, Suzhou Baoshida provides not just manufacturing, but engineered reliability backed by material science authority and industrial-scale execution. Partner with us to transform complex tubing specifications into validated, high-yield production realities.

Customization Process

Customization Process for Rubber-Integrated 2×2 3/16 Square Tubing Solutions

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber-integrated 2×2 3/16 square tubing begins with a rigorous drawing analysis. This foundational step ensures dimensional accuracy, material compatibility, and functional alignment with the client’s application. Our engineering team conducts a detailed review of technical blueprints, focusing on critical tolerances, load-bearing requirements, and environmental exposure conditions. We assess joint configurations, surface finish specifications, and any integration points where rubber components will be bonded or overmolded onto the steel tubing substrate. This phase also includes finite element analysis (FEA) when dynamic stress or thermal cycling is anticipated in service.

Following drawing validation, we proceed to rubber formulation design. Leveraging our expertise in polymer science, we select elastomer compounds tailored to the operational demands—be it resistance to ozone, oil, extreme temperatures, or abrasion. Common base materials include EPDM for outdoor durability, NBR for oil resistance, and silicone for high-temperature stability. The hardness (Shore A), elongation at break, and compression set values are precisely tuned. Additives such as reinforcing fillers, antioxidants, and adhesion promoters are incorporated to ensure robust bonding between the rubber and the steel surface. This formulation is documented and archived for batch consistency and traceability.

Prototyping is the next critical stage. Using precision extrusion and vulcanization techniques, we produce sample runs of the rubber-coated or rubber-inserted 2×2 3/16 square tubing. These prototypes undergo comprehensive testing, including adhesion strength (per ASTM D429), dimensional verification, and environmental aging (e.g., 70°C for 72 hours). Clients receive physical samples along with material test reports (MTRs) and are invited to conduct field trials. Feedback is systematically integrated into final design adjustments before release for mass production.

Mass production is executed under strict ISO 9001-compliant protocols. Continuous in-line monitoring ensures uniform rubber thickness, consistent cure profiles, and defect-free surface quality. Each batch is subjected to random sampling and third-party verification when required. Our facility supports monthly output volumes scalable from 5,000 to 200,000 linear feet, depending on complexity and logistics.

The following table outlines key technical specifications for standard 2×2 3/16 square tubing with rubber integration:

| Parameter | Value | Standard/Test Method |

|---|---|---|

| Outer Dimension | 2 in x 2 in | ASTM A500 |

| Wall Thickness | 3/16 in (0.1875 in) | ASTM A500 |

| Typical Steel Grade | ASTM A500 Grade B | ASTM A500 |

| Rubber Hardness Range | 50–80 Shore A | ASTM D2240 |

| Adhesion Strength | ≥ 15 kN/m | ASTM D429, Method B |

| Operating Temperature Range | -40°C to +150°C (varies by compound) | ASTM D573 |

| Linear Tolerance | ±0.005 in per foot | ISO 2768 |

Our end-to-end customization ensures that every 2×2 3/16 square tubing solution meets the exact mechanical, chemical, and environmental demands of industrial applications.

Contact Engineering Team

Technical Collaboration for Precision Rubber Manufacturing Applications

Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber solutions where dimensional accuracy directly impacts performance in demanding industrial environments. Our expertise extends to supporting critical components like 2×2 3/16 square tubing, a structural element frequently integrated into rubber extrusion tooling, conveyor frameworks, and custom machinery housings. Precise tubing specifications ensure optimal alignment, pressure distribution, and longevity when interfacing with elastomeric compounds under thermal and mechanical stress. As your OEM partner, we validate material compatibility and tolerances to prevent premature seal failure or assembly deviations in high-cycle production systems.

The following table details the critical dimensional and material specifications for 2×2 3/16 square tubing, reflecting industry standards essential for rubber manufacturing integration. These parameters are rigorously controlled during production to maintain consistency across batches, directly influencing the repeatability of rubber molding and extrusion processes.

| Parameter | Specification | Tolerance | Relevance to Rubber Applications |

|---|---|---|---|

| Outer Dimension | 2.000 in x 2.000 in | ±0.005 in | Ensures precise die plate alignment in extrusion tooling |

| Wall Thickness | 0.1875 in (3/16) | ±0.003 in | Maintains structural integrity under hydraulic pressure |

| Material Grade | ASTM A500 Gr. B | – | Resists corrosion from rubber accelerators and oils |

| Straightness | ≤ 0.093 in/ft | Per ASTM A500 | Prevents uneven clamping forces on rubber molds |

| Surface Finish | Mill Scale | Consistent | Facilitates secure bonding with rubber adhesion promoters |

Deviations beyond these tolerances introduce micro-misalignments that propagate into rubber product defects—such as flash, incomplete curing, or dimensional drift in molded profiles. Our engineering team proactively addresses these risks through pre-production validation, leveraging Suzhou Baoshida’s ISO 9001-certified supply chain and material traceability protocols. We collaborate with clients to adjust tubing specifications based on elastomer durometer, cure temperature profiles, and operational load requirements, ensuring the metallic substrate complements the rubber component’s functional lifecycle.

For mission-critical applications where tubing integrity affects rubber part quality, direct technical consultation is non-negotiable. Mr. Boyce, our dedicated OEM Relationship Manager, possesses 14 years of experience resolving complex interface challenges between structural metals and polymer systems. He will coordinate dimensional validation, material certification review, and rapid prototyping support to align tubing performance with your rubber manufacturing objectives. Do not rely on generic supplier data sheets when micron-level precision determines production yield. Contact Mr. Boyce immediately to initiate a technical assessment of your 2×2 3/16 square tubing requirements. His engineering-focused approach eliminates procurement guesswork and accelerates time-to-press for rubber component manufacturers.

Reach Mr. Boyce directly via email at [email protected] to schedule a confidential technical review. Include your application’s operational parameters, elastomer type, and current pain points for a targeted solution analysis. Suzhou Baoshida commits to responding within 4 business hours with actionable engineering insights—not generic sales templates. Partner with us to transform structural tubing from a commodity component into a validated element of your rubber manufacturing excellence.

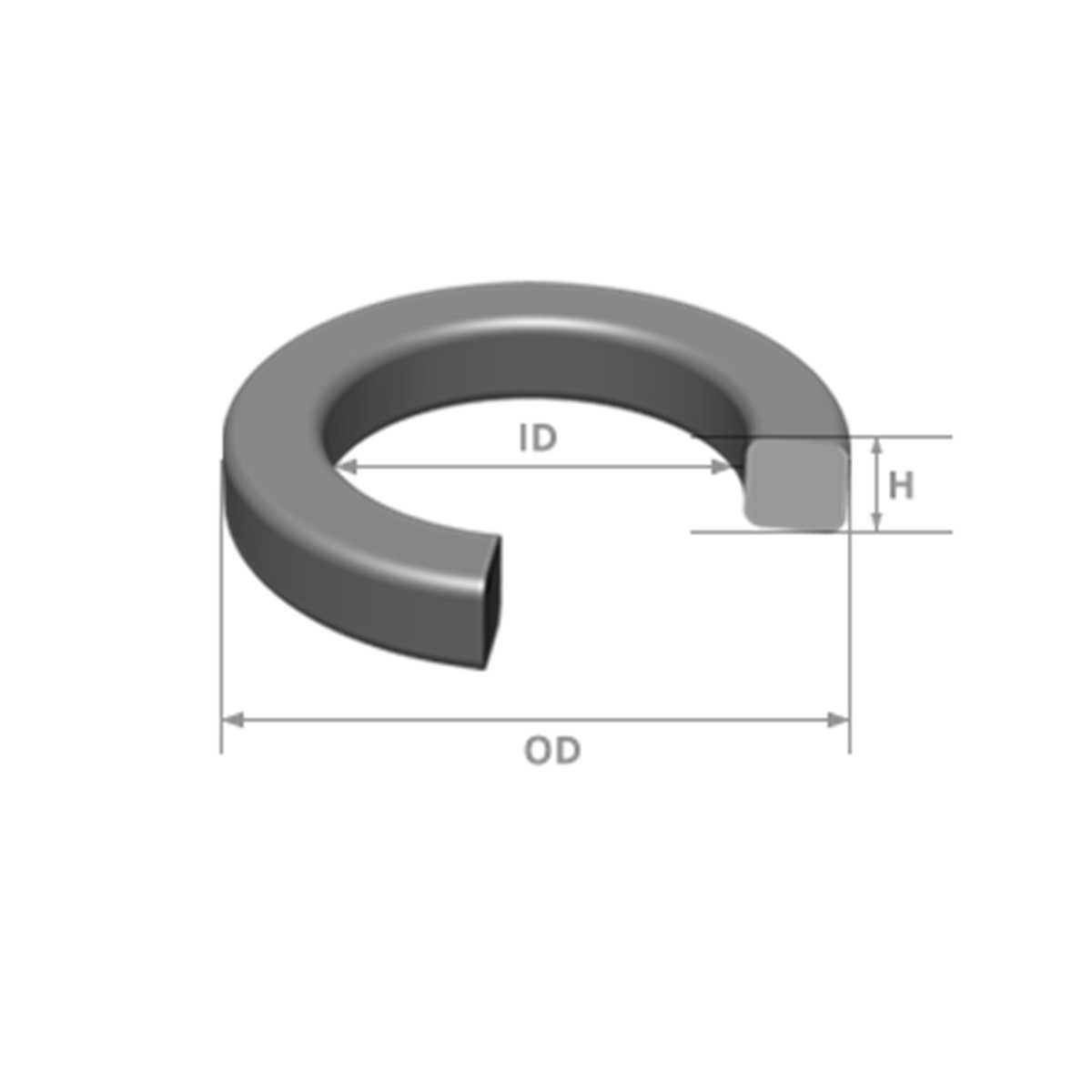

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).