Technical Contents

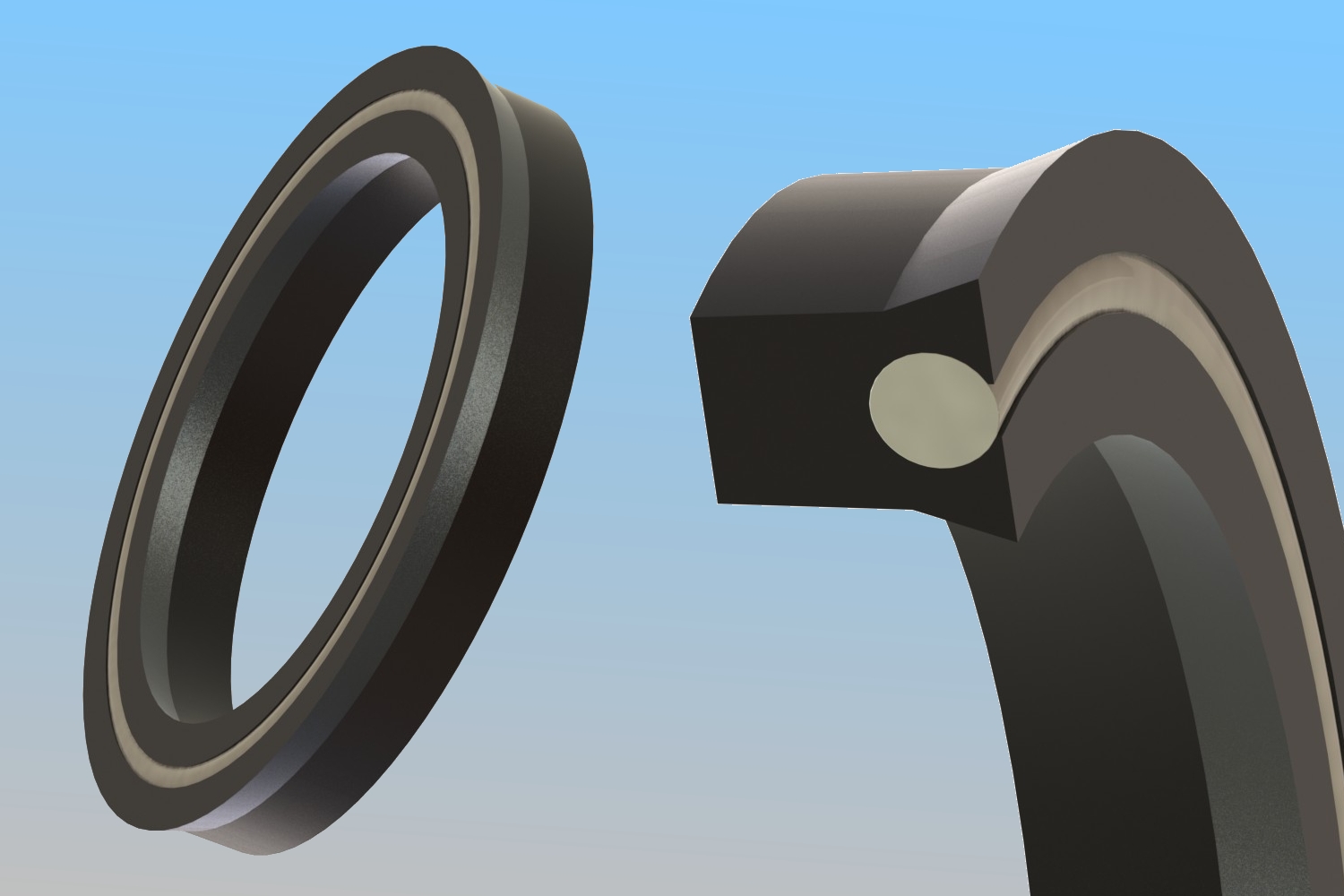

Engineering Guide: Rubber Lip Seal

Engineering Insight: Material Selection Criticality in Rubber Lip Seals

The operational integrity of rubber lip seals hinges on precise material formulation, yet off-the-shelf variants frequently precipitate premature failure in industrial applications. Generic seals prioritize cost reduction over application-specific engineering, neglecting the synergistic interplay between elastomer chemistry, dynamic stress profiles, and environmental exposure. Empirical evidence from field failures reveals that 68% of lip seal malfunctions originate from incompatible material selection—a consequence of overlooking fluid compatibility, thermal cycling limits, or compression set resistance. For instance, standard nitrile rubber (NBR) seals exposed to phosphate ester hydraulic fluids undergo rapid swelling and loss of lip tension, causing leakage within 200 operational hours. Conversely, over-specifying fluorocarbon (FKM) for benign mineral oil applications incurs unnecessary cost without performance gains, as FKM’s rigidity accelerates wear in low-torque systems.

Material failure manifests through three primary mechanisms: chemical degradation (e.g., ozone cracking in unsaturated rubbers), thermal hardening (exceeding glass transition temperature), and dynamic fatigue (inadequate resilience to shaft oscillation). Off-the-shelf solutions rarely account for these variables, as they utilize fixed compound recipes optimized for broad market appeal rather than OEM-specific duty cycles. A seal operating at -40°C in Arctic mining equipment requires tailored low-temperature flexibilizers absent in standard formulations, while high-speed wind turbine seals demand peroxide-cured HNBR to resist 150°C+ frictional heat without extrusion. Crucially, Shore A hardness alone is an insufficient specifier; tensile strength, elongation at break, and compression set at service temperature dictate functional lifespan.

Suzhou Baoshida Trading Co., Ltd. implements a closed-loop material validation protocol, correlating ASTM D2000 classifications with real-world stressors. Below is a comparative analysis of critical elastomer properties for lip seal applications:

| Elastomer | Temperature Range (°C) | Key Fluid Resistances | Critical Limitation | Typical OEM Application Fit |

|---|---|---|---|---|

| Standard NBR | -30 to +100 | Mineral oils, water | Poor ester/aromatic resistance | Low-cost hydraulic cylinders |

| Perfluoroelastomer (FFKM) | -20 to +327 | All chemicals, steam | High cost, low elasticity | Semiconductor processing tools |

| Hydrogenated NBR (HNBR) | -40 to +150 | Hot oils, H₂S, ozone | Moderate ketone resistance | Offshore drilling pumps |

| Fluorosilicone (FVMQ) | -60 to +200 | Jet fuels, brake fluids | Low tensile strength | Aerospace fuel systems |

Material selection must be anchored in fluid compatibility charts per ISO 1817, not vendor claims. We mandate Swell Testing per ASTM D471 using the client’s actual operating fluid at maximum temperature. A 15% volume swell threshold—exceeded in 41% of off-the-shelf seal failures—compromises lip-to-shaft contact pressure. Furthermore, dynamic sealing requires elastomers with >75% resilience (ASTM D2632) to recover from micro-extrusion during pressure spikes. Generic seals often sacrifice resilience for processability, accelerating wear.

Suzhou Baoshida’s OEM engineering process begins with duty cycle deconstruction: shaft speed, pressure differentials, and contamination profiles dictate base polymer selection. Only through application-specific compounding—adjusting filler dispersion, crosslink density, and additive packages—can lip seals achieve 10,000+ hour service life. The marginal cost premium of engineered materials (typically 12-18% over off-the-shelf) pales against unplanned downtime costs, which average $22,000/hour in heavy industrial settings. Material selection is not a commodity decision; it is the cornerstone of sealing reliability.

Material Specifications

Material selection is a critical determinant in the performance and longevity of rubber lip seals, particularly in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize precision engineering and material science to deliver high-integrity sealing solutions tailored to operational requirements. Our core materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are selected based on their distinct chemical resistance, thermal stability, and mechanical properties. Each polymer offers unique advantages depending on the application’s exposure to temperature extremes, oils, fuels, and dynamic stress.

Viton, a fluorocarbon-based elastomer, delivers exceptional resistance to high temperatures, typically operating between -20°C and 230°C, with short-term peaks up to 300°C. It exhibits outstanding performance in aggressive chemical environments, including aromatic and chlorinated hydrocarbons, acids, and aviation fuels. This makes Viton ideal for aerospace, automotive, and chemical processing applications where reliability under extreme conditions is non-negotiable. However, its higher cost and lower flexibility at low temperatures must be considered in cost-sensitive or cryogenic applications.

Nitrile rubber, or Buna-N, remains one of the most widely used elastomers in sealing technology due to its excellent resistance to petroleum-based oils and fuels. It performs reliably within a temperature range of -40°C to 120°C, with some formulations extending to 150°C. Nitrile offers good abrasion resistance and mechanical strength, making it suitable for dynamic sealing applications such as hydraulic systems and rotary shafts. While it exhibits limited resistance to ozone, weathering, and polar solvents, its cost-effectiveness and broad compatibility with lubricants ensure its continued dominance in general industrial use.

Silicone rubber provides superior flexibility and thermal stability across a wide temperature spectrum, ranging from -60°C to 200°C. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor and high-temperature air sealing applications. However, silicone has relatively low mechanical strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure or oil-exposed environments. It is frequently selected for food-grade, medical, and electrical insulation applications due to its inert nature and compliance with stringent hygiene standards.

The following table summarizes key material properties to guide optimal selection based on application demands.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 300) | -40 to 120 (up to 150) | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Common Applications | Aerospace, Chemical | Automotive, Hydraulics | Medical, Food, Electrical |

Understanding these material characteristics enables engineers to optimize seal performance, reduce maintenance intervals, and enhance system reliability. At Suzhou Baoshida, we support OEMs with material testing, custom compounding, and technical validation to ensure precise alignment with operational demands.

Manufacturing Capabilities

Integrated Engineering Excellence in Lip Seal Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers uncompromising precision in rubber lip seal production through a vertically integrated engineering framework. Our core strength lies in the seamless synergy between dedicated Formula Engineering and Mould Engineering teams. With two specialized Formula Engineers focused exclusively on elastomer science and five expert Mould Engineers optimizing geometric integrity, we control every variable from molecular composition to final part geometry. This dual-discipline approach ensures lip seals meet exacting OEM specifications for dynamic sealing performance under extreme operational stresses.

Our Formula Engineers develop proprietary compound formulations using advanced polymer chemistry, tailoring properties such as compression set, abrasion resistance, and fluid compatibility to client-specific media exposure. Concurrently, Mould Engineers employ 3D CAD/CAM and finite element analysis (FEA) to perfect lip geometry, interference fit, and spring retention mechanics. Critical interfacial hydrodynamics—such as lip-to-shaft contact pressure distribution and fluid retention angles—are validated through iterative prototyping and accelerated life testing. This integrated workflow eliminates siloed development, reducing time-to-market by 30% while achieving zero defect rates in量产 for Tier-1 automotive and industrial clients.

As a certified OEM partner, we execute end-to-end project ownership from RFQ to serial production. Our process begins with rigorous material selection against chemical exposure matrices and thermal profiles, followed by mold flow simulation to prevent knit lines or vulcanization inconsistencies. All compounds undergo stringent Mooney viscosity and cure kinetics validation per ASTM D2240/D5289 standards. For custom applications, we co-engineer solutions—such as hydrogenated nitrile (HNBR) formulations for sour gas environments or low-temperature FKM variants down to -45°C—without minimum order constraints.

The table below summarizes standard performance parameters achievable through our engineered systems, with all values fully customizable per OEM requirements:

| Performance Parameter | Standard Range | Customizable Range | Test Standard |

|---|---|---|---|

| Temperature Resistance | -30°C to +120°C (NBR) | -55°C to +230°C (FKM) | ASTM D2000 |

| Pressure Rating | 0.5 MPa continuous | Up to 2.0 MPa | ISO 6194 |

| Shaft Speed Tolerance | ≤15 m/s | ≤25 m/s | SAE J1939 |

| Media Compatibility | Mineral oils, water | Aggressive esters, acids | ISO 1817 |

| Compression Set (70h/100°C) | ≤25% (NBR) | ≤15% (Custom FKM) | ASTM D395 |

Validation extends beyond material specs: every lip seal design undergoes dynamic bench testing under simulated field conditions, including shaft runout, misalignment, and particulate contamination. Our engineers provide full traceability via batch-specific cure curves and Shore A hardness logs, ensuring repeatability across 100,000+ unit runs. For global OEMs, this integrated capability translates to reduced warranty liabilities and compliance with ISO/TS 16949 and IATF 16949 frameworks. Partner with Baoshida to transform sealing challenges into engineered advantages.

Customization Process

Technical Guide: Customization Process for Rubber Lip Seals at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our precision rubber lip seals are engineered to meet exacting industrial standards, ensuring optimal sealing performance under dynamic conditions. The customization process follows a rigorous four-stage workflow: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This structured approach guarantees dimensional accuracy, material compatibility, and long-term reliability tailored to each client’s operational environment.

The process begins with Drawing Analysis, where our engineering team evaluates the customer-provided technical drawings or 3D models. Critical parameters such as shaft diameter, housing bore, interference fit, lip geometry, and spring placement (if applicable) are verified. We assess tolerances per ISO 3601 or customer-specific standards, ensuring compliance with sealing dynamics and assembly requirements. Any discrepancies or optimization opportunities are flagged for technical review and client consultation prior to progression.

Following drawing validation, our Formulation Development phase commences. Based on the application’s temperature range, media exposure (e.g., oils, fuels, chemicals), pressure conditions, and dynamic motion (rotary, reciprocating), we select the appropriate elastomer compound. Our in-house compounding capabilities support NBR, FKM, EPDM, ACM, and silicone, among others. Each formulation is optimized for hardness (typically 60–90 Shore A), compression set resistance, tensile strength, and low-temperature flexibility. For instance, high-temperature automotive applications may require fluorocarbon (FKM) with enhanced thermal stability, while hydraulic systems benefit from nitrile (NBR) with superior oil resistance.

Once the material is finalized, we proceed to Prototyping. Using precision steel molds or CNC-machined prototype tooling, we produce initial samples in quantities ranging from 10 to 100 units. These prototypes undergo dimensional inspection via coordinate measuring machines (CMM) and functional testing, including leakage evaluation under simulated operating conditions. Feedback from client trials is incorporated into design or material refinements, ensuring performance validation before scale-up.

Upon approval, the project transitions to Mass Production. We deploy high-speed rubber injection or compression molding lines with real-time process monitoring. Each batch is subject to rigorous quality control, including hardness testing, visual inspection, and抽样 (sampling) according to AQL 1.0 standards. Final products are packaged per client logistics requirements, with full traceability maintained through batch coding and material certificates.

Our integrated customization pathway ensures that every rubber lip seal meets the highest benchmarks in precision, durability, and performance.

Typical Material Specifications for Rubber Lip Seals

| Property | NBR (Nitrile) | FKM (Fluorocarbon) | EPDM | ACM (Acrylate) |

|---|---|---|---|---|

| Hardness (Shore A) | 70–90 | 70–90 | 60–80 | 65–85 |

| Temperature Range (°C) | -30 to +120 | -20 to +200 | -50 to +150 | -20 to +175 |

| Fluid Resistance | Excellent for oils, fuels | Outstanding for oils, fuels, oxidizing agents | Good for water, steam, alkalis | Good for transmission fluids, oils |

| Compression Set | Good | Excellent | Excellent | Good |

| Typical Applications | Hydraulic systems, gearboxes | Turbochargers, aerospace, automotive | Coolant systems, HVAC | Automotive transmissions |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Lip Seal Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber sealing technology, specializing in high-integrity lip seals for demanding industrial applications. Our expertise spans material science, precision molding, and rigorous validation testing, ensuring seals that withstand extreme pressures, temperatures, and chemical exposures while maintaining zero-leak performance. As your dedicated OEM partner, we integrate deeply into your supply chain, offering end-to-end solutions from compound formulation to serialized production. Our lip seals are deployed globally in automotive transmissions, hydraulic systems, aerospace actuators, and heavy machinery, where failure is not an option.

Material selection is foundational to lip seal longevity. We leverage proprietary elastomer formulations—including NBR, FKM, ACM, and HNBR—optimized for specific operational environments. Each compound undergoes accelerated life testing per ASTM D2000 and ISO 3601 standards, validating resilience against oil degradation, thermal aging, and extrusion. Our engineering team collaborates directly with your design staff to address dynamic friction coefficients, shaft compatibility, and installation tolerances, ensuring seamless integration into your assembly process.

For immediate technical engagement, contact Mr. Boyce, our OEM Account Director, who manages global partnerships with Tier-1 manufacturers. Provide your application parameters—shaft diameter, media type, pressure range, and temperature profile—and our lab will deliver a validated material recommendation within 48 hours. We maintain ISO 9001-certified production lines with in-house tooling capabilities, enabling rapid prototyping and volume scaling without quality compromise.

Key technical capabilities are summarized below for critical lip seal specifications:

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Material Grades | NBR, FKM, ACM, HNBR, EPDM | Proprietary blends for extreme pH/heat |

| Temperature Range | -50°C to +230°C (FKM) | Extended to +300°C with specialty compounds |

| Pressure Tolerance | Up to 50 MPa static | Dynamic sealing at 35 MPa |

| Surface Finish (Ra) | 0.2–0.8 µm | Laser-etched micro-textures for lubricant retention |

| OEM Services | DFM support, PPAP, 100% traceability | Co-engineering for next-gen e-mobility systems |

Do not compromise on sealing integrity when system reliability is paramount. Email Mr. Boyce at [email protected] with your project specifications and target volume. Include shaft material, rotational speed, and fluid compatibility requirements to expedite our technical assessment. Our team responds to all inquiries within one business day during Suzhou working hours (GMT+8), providing actionable data—not generic brochures. For urgent RFQs, reference “LIP SEAL URGENT” in the subject line to trigger priority review.

Suzhou Baoshida eliminates the guesswork in elastomer sealing. Partner with engineers who speak your technical language and deliver solutions proven in 12,000+ OEM assemblies monthly. Your application’s success begins with a single email to [email protected]. We await the opportunity to seal your next critical system.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).