Technical Contents

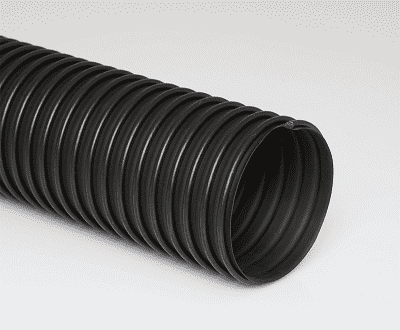

Engineering Guide: 6 Flexible Air Duct Hose

Engineering Insight: Material Selection Imperatives for 6 Flexible Air Duct Hose

The operational integrity of 6-inch flexible air duct hose in demanding industrial environments is fundamentally dictated by precise material science. Generic, off-the-shelf solutions frequently fail catastrophically under real-world OEM conditions due to inadequate compound formulation. These failures manifest as premature cracking, chemical degradation, excessive elongation, or catastrophic joint separation, leading to costly downtime, safety hazards, and compromised system efficiency. The root cause lies in the inability of standard formulations to address the specific synergistic stresses encountered: extreme thermal cycling, aggressive chemical exposure, continuous flexing, and high-pressure pulsation. A rubber compound optimized for one parameter—such as basic flexibility—often sacrifices critical resistance to ozone, heat aging, or abrasion, creating a single point of failure.

Suzhou Baoshida Trading Co., Ltd. engineers custom EPDM and specialty NBR-based compounds specifically for 6-inch air duct applications. Standard commercial hoses typically utilize generic EPDM with insufficient peroxide curing systems, resulting in poor low-temperature flexibility below -30°C and vulnerability to thermal oxidation above 135°C. Similarly, basic NBR formulations lack adequate acrylonitrile content or supplemental stabilizers, causing rapid swelling when exposed to trace hydrocarbons or lubricants common in compressed air systems. Off-the-shelf products also frequently under-specify reinforcement ply adhesion promoters, leading to delamination under dynamic flexing. Our proprietary compounds integrate high-purity, solution-polymerized EPDM with tailored co-agents for superior thermal stability, coupled with nano-dispersed reinforcing fillers that maintain tensile strength after 10,000+ flex cycles. Critical ozone resistance is achieved through synergistic antioxidant packages validated per ASTM D1149, not merely minimum industry thresholds.

Material selection must align with the exact operational profile. A hose handling ambient air in a warehouse requires vastly different chemistry than one conveying 150°C exhaust gases laden with sulfur compounds in a power generation turbine. Generic hoses apply a one-size-fits-all approach, ignoring these critical variables. Suzhou Baoshida conducts rigorous application-specific testing, including dynamic flex fatigue under load, accelerated aging in simulated chemical environments, and burst pressure validation per SAE J224. This ensures the rubber matrix, reinforcement interface, and cover compound function as a unified system. The consequence of improper selection extends beyond immediate failure; suboptimal compounds increase energy loss through excessive hose wall deformation and generate particulate contamination from abrasion.

The following table contrasts critical performance parameters between standard commercial hose and Suzhou Baoshida’s engineered solution for 6-inch flexible air duct applications:

| Performance Parameter | Standard Commercial Hose | Suzhou Baoshida Engineered Hose |

|---|---|---|

| Continuous Operating Temp | -30°C to +120°C | -50°C to +150°C |

| Ozone Resistance (100 pphm, 40°C) | Moderate Cracking (24h) | No Cracking (168h) |

| Flex Life (Mandrel Bend, 10k cycles) | Visible Cracking | Full Integrity Maintained |

| Tensile Retention after Aging (150°C/72h) | < 50% | > 85% |

| Abrasion Loss (DIN 53516) | 120 mm³ | 45 mm³ |

| Chemical Resistance (Synthetic Oil) | Severe Swelling (>25%) | Minimal Swelling (<5%) |

Investing in scientifically engineered rubber compounds is not a cost but a strategic mitigation of total operational risk. Suzhou Baoshida’s OEM-focused methodology ensures the 6-inch flexible air duct hose performs reliably within the precise chemical, thermal, and mechanical envelope of your application, eliminating the hidden costs of premature failure inherent in commoditized solutions. Material science is the cornerstone of durability.

Material Specifications

Material Specifications for 6 Inch Flexible Air Duct Hoses

Suzhou Baoshida Trading Co., Ltd. provides high-performance flexible air duct hoses engineered for demanding industrial environments. These 6-inch diameter hoses are manufactured using advanced elastomeric compounds to ensure durability, chemical resistance, and thermal stability. The primary materials used in production are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected based on operational requirements such as temperature range, fluid compatibility, and mechanical stress.

Viton is a fluorocarbon-based rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), making it ideal for aerospace, petrochemical, and high-temperature industrial air transfer applications. Its low permeability to gases and superior aging characteristics ensure long-term integrity in critical systems.

Nitrile rubber, or Buna-N, offers excellent resistance to petroleum-based oils, hydraulic fluids, and fuels. It is a cost-effective solution for general-purpose industrial air ducting where exposure to greases and hydrocarbons is common. Nitrile hoses maintain flexibility and mechanical strength across a wide temperature range, typically from -30°C to +100°C (-22°F to +212°F), with short-term excursions up to 125°C. This material is widely used in automotive, manufacturing, and pneumatic systems.

Silicone rubber provides outstanding thermal stability and flexibility across extreme temperature ranges, from -60°C to +200°C (-76°F to +392°F). It is inherently resistant to ozone, UV radiation, and weathering, making it suitable for outdoor and cleanroom environments. While it exhibits lower resistance to petroleum-based fluids compared to Viton or Nitrile, silicone excels in applications requiring high flexibility, low compression set, and non-toxic performance, such as food processing, pharmaceuticals, and HVAC systems.

Each material is reinforced with high-tensile polyester or stainless steel wire helixes to maintain hose shape under vacuum conditions and resist kinking. The inner tube is precision-extruded for smooth airflow, while the cover is formulated to resist abrasion, tearing, and environmental degradation.

The following table compares key material properties for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 (+125 short) | -60 to +200 |

| Temperature Range (°F) | -4 to +446 | -22 to +212 (+257 short) | -76 to +392 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Good (oils, greases, water) | Poor (oils), Good (water, steam) |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Flexibility | Moderate | Good | Excellent |

| Abrasion Resistance | Good | Excellent | Moderate |

| Common Applications | Petrochemical, aerospace, high-temp air transfer | Industrial machinery, automotive, hydraulics | HVAC, food processing, cleanrooms |

Selection of the appropriate material depends on the specific operational parameters of the system. Suzhou Baoshida Trading Co., Ltd. supports OEM customization and technical consultation to ensure optimal hose performance in critical industrial applications.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Execution for Flexible Air Duct Hose

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions grounded in deep material science and precision manufacturing control. Our core strength for the 6 flexible air duct hose product line resides in the integrated expertise of our dedicated in-house engineering team, specifically structured to ensure optimal performance and seamless OEM collaboration. This team comprises five specialized Mould Engineers and two advanced Rubber Formula Engineers, working in concert to translate client specifications into reliable, high-volume production.

Our Rubber Formula Engineers possess extensive expertise in polymer chemistry and compounding for demanding pneumatic applications. They meticulously develop and refine elastomer formulations targeting the critical balance required for flexible air ducts: exceptional low-temperature flexibility down to -40°C, sustained high-temperature resistance up to 120°C, robust ozone and weathering resistance, and minimal permanent set after repeated flexing. This involves precise control over polymer selection (primarily specialized NBR/PVC blends and EPDM variants), reinforcing fillers, plasticizers, and vulcanizing systems to achieve the exact durometer (Shore A 60±5), tensile strength, and elongation properties demanded by industrial air handling systems. Every compound undergoes rigorous empirical validation for flow characteristics, curing kinetics, and final physical properties before release, ensuring batch-to-batch consistency critical for OEM supply chains.

Complementing this material mastery, our five Mould Engineers focus on the precision tooling essential for dimensional accuracy, surface finish, and structural integrity of the convoluted hose profile. They utilize advanced CAD/CAM software and apply deep knowledge of rubber flow dynamics and thermal management during the curing process. This expertise guarantees strict adherence to critical tolerances for inner diameter (ID 6.00″ ±0.05″), wall thickness (0.08″ ±0.01″), and convolution geometry, directly impacting flow efficiency, pressure handling, and hose longevity. Their proactive approach to mould design and maintenance minimizes production variability and maximizes tool life, a significant factor in cost-effective, high-volume OEM manufacturing.

Our OEM capability is engineered for partnership and reliability. We implement structured joint development protocols from initial RFQ through to serial production. Clients benefit from transparent communication channels, shared technical documentation (including full material traceability and ISO 9001-certified process control records), and robust IP protection frameworks. We excel at integrating client-specific performance requirements, branding, and packaging specifications into our validated manufacturing processes without compromising on quality or delivery timelines. Suzhou Baoshida functions not merely as a supplier, but as an extension of your engineering team, providing the technical depth and manufacturing discipline required for mission-critical air duct components.

The following table details the core engineering specifications achievable for our standard 6 flexible air duct hose, reflecting the output of our integrated formula and mould engineering capabilities:

| Parameter | Standard Specification | Test Standard | Significance for Application |

|---|---|---|---|

| Inner Diameter (ID) | 6.00 inches ±0.05″ | ASTM D380 | Ensures correct airflow volume & fit |

| Wall Thickness | 0.08 inches ±0.01″ | ASTM D377 | Critical for pressure rating & crush resistance |

| Material Hardness | 60 Shore A ±5 | ASTM D2240 | Balances flexibility & structural integrity |

| Tensile Strength | ≥ 12.0 MPa | ASTM D412 | Resistance to mechanical stress |

| Elongation at Break | ≥ 250% | ASTM D412 | Flexibility & resilience under strain |

| Temperature Range | -40°C to +120°C | ASTM D573 | Performance in extreme environments |

| Ozone Resistance | No cracks (50 pphm, 40°C, 96h) | ASTM D1149 | Long-term durability outdoors |

| Minimum Bend Radius | 12 inches | Internal Method | Installation flexibility in tight spaces |

| Operating Pressure | 15 PSI (continuous) | ASTM D138 | Safe performance for standard air systems |

Customization Process

Customization Process for 6 Flexible Air Duct Hose – Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., the customization of 6 flexible air duct hose follows a rigorous, science-driven engineering workflow designed to meet precise industrial performance standards. Each stage—from initial drawing analysis to mass production—is executed with technical discipline to ensure dimensional accuracy, material integrity, and long-term operational reliability in demanding environments.

The process begins with Drawing Analysis, where engineering teams evaluate client-provided technical schematics or develop new CAD models based on application requirements. Critical parameters such as inner diameter (ID), outer diameter (OD), wall thickness, bend radius, and end-fitting compatibility are verified. Environmental exposure factors—including operating temperature range, airflow velocity, chemical contact, and mechanical stress—are documented to inform downstream material decisions. This phase ensures full compliance with ISO 1307 and SAE J2492 dimensional and performance benchmarks.

Following drawing validation, the Formulation phase initiates. Our rubber formula engineers develop a compound tailored to the operational profile of the 6 flexible air duct hose. Base polymers such as EPDM, NBR, or silicone are selected based on thermal stability and chemical resistance needs. Reinforcement agents, plasticizers, and anti-aging additives are precisely dosed to achieve optimal flexibility, abrasion resistance, and UV/ozone stability. Every formulation undergoes Durometer testing (Shore A scale), tensile strength analysis per ASTM D412, and elongation verification to guarantee consistency. The compound is also tested for flame retardancy (UL 94) if required by application.

Once the formulation is approved, we proceed to Prototyping. Using precision extrusion and vulcanization techniques, short-run samples are produced under controlled conditions. Each prototype undergoes dimensional inspection, pressure cycling, and flex endurance testing (up to 100,000 cycles at rated bend radius). Airflow efficiency is evaluated via differential pressure testing at multiple flow rates. Clients receive test reports and physical samples for field evaluation. Feedback is integrated into final design adjustments, ensuring performance alignment with real-world use.

Upon client approval, the project transitions to Mass Production. Our ISO 9001-certified manufacturing line implements strict process control, including real-time extrusion monitoring, batch traceability, and 100% visual inspection. Finished hoses are packaged per client logistics requirements, with optional barcoding and documentation packages.

Below are standard technical specifications for the 6 flexible air duct hose, customizable per project:

| Parameter | Standard Value | Customizable Range |

|---|---|---|

| Inner Diameter (ID) | 152 mm (6 inch) | 100–200 mm |

| Wall Thickness | 4.0 ± 0.3 mm | 3.0–6.0 mm |

| Operating Temperature | -40°C to +150°C (EPDM) | -60°C to +250°C (Silicone) |

| Bend Radius (Minimum) | 300 mm | 200–500 mm |

| Pressure Rating (Max) | 15 psi (continuous) | Up to 30 psi (reinforced) |

| Material Options | EPDM, NBR, Silicone, CR | Client-specified compounds |

| Reinforcement Layer | High-tensile polyester braid | Stainless steel spiral optional |

| Flame Resistance | UL 94 HB standard | UL 94 V-0 available |

This systematic approach ensures that every 6 flexible air duct hose delivers engineered performance, durability, and compliance across industrial ventilation, pneumatic transport, and exhaust systems.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Industrial Air Duct Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber solutions for demanding industrial environments. Our 6-layer flexible air duct hoses are rigorously developed to address critical challenges in airflow management, including thermal cycling, pressure fluctuations, and spatial constraints inherent in modern manufacturing, HVAC, and material handling systems. These hoses are not merely components but integrated system enhancers, designed to minimize downtime and maximize operational longevity through advanced elastomer compounding and structural reinforcement. As your dedicated OEM partner, we prioritize technical alignment with your specific application parameters, ensuring seamless integration into complex machinery or facility infrastructure.

The performance specifications below reflect our commitment to quantifiable engineering excellence. Each parameter is validated through ISO 188 accelerated aging tests, DIN 2822 pressure cycling protocols, and ASTM D2240 durometer stability assessments under continuous operational loads.

| Specification Parameter | Performance Value | Industry Standard Reference |

|---|---|---|

| Temperature Range | -40°C to +150°C continuous | ISO 188 |

| Maximum Working Pressure | 1.8 bar (26 PSI) | DIN 2822 |

| Minimum Bend Radius | 3x nominal hose diameter | ISO 10619 |

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Flame Resistance | UL 94 V-0 compliant | UL 94 |

| Abrasion Loss (DIN) | ≤80 mm³ | DIN 53516 |

Initiate a technical dialogue with Mr. Boyce, our Rubber Formula Engineer and OEM Manager, to resolve your most complex airflow challenges. His expertise spans custom elastomer formulation for chemical resistance, dynamic flex fatigue mitigation, and dimensional tolerance optimization for high-vibration installations. Direct engineering collaboration ensures your duct hose solution transcends generic market offerings—whether adapting our core 6-layer architecture for specialized media conveyance or developing fully proprietary compounds meeting OEM certification requirements. Contact Mr. Boyce via email at [email protected] to submit detailed application criteria, including pressure profiles, media composition, and environmental exposure conditions.

We operate on an engineer-to-engineer engagement model, requiring no preliminary sales formalities. Expect a substantive technical response within 12 business hours, including preliminary material compatibility analysis and feasibility assessment. For time-sensitive projects, reference your target production timeline and volume requirements in the initial inquiry to prioritize resource allocation. Suzhou Baoshida’s manufacturing ecosystem—integrating Suzhou-based compounding facilities with certified partner extrusion lines—delivers scalable production from prototype batches to annual volumes exceeding 500,000 meters, all under IATF 16949 quality management protocols. Partner with us to transform airflow reliability from a maintenance concern into a competitive operational advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).