Technical Contents

Engineering Guide: Orange O-Ring

Engineering Insight: Material Science Imperatives for Orange O-Ring Performance

The designation “orange O-ring” signifies far more than a color code; it represents a precisely engineered elastomeric formulation tailored for aggressive chemical and thermal environments. In precision sealing applications, material selection is the non-negotiable foundation of reliability. Off-the-shelf generic O-rings—often standard NBR or SBR compounds—routinely fail when deployed in critical systems due to fundamental incompatibilities with operational parameters. Empirical evidence from field failures consistently traces premature seal degradation to three critical oversights: inadequate chemical resistance, insufficient thermal stability, and poor compression set recovery under dynamic stress.

Standard commercial O-rings exhibit catastrophic swelling when exposed to phosphate ester hydraulic fluids, polar solvents, or biofuels, leading to extrusion and leakage. Equally problematic is their limited thermal ceiling; conventional NBR compounds degrade rapidly above 120°C, causing hardening, cracking, and loss of sealing force. Crucially, generic formulations lack the specialized additive packages required to maintain elasticity during prolonged compression at elevated temperatures—a failure mode quantified by poor compression set performance. These deficiencies manifest as unplanned downtime, safety hazards, and cascading component damage, with replacement costs often exceeding initial seal expenditure by 20x.

The orange compound designation specifically denotes a high-performance hydrogenated nitrile butadiene rubber (HNBR) or perfluoroelastomer (FFKM) variant engineered for extreme duty cycles. Unlike commodity alternatives, these formulations integrate proprietary saturations and fillers to resist hydrolysis, ozone, and radical attack while sustaining resilience across -30°C to 150°C+ ranges. The table below contrasts critical performance thresholds:

| Property | Standard NBR O-Ring | Orange Specialty Compound | Test Standard |

|---|---|---|---|

| Max Continuous Temp | 120°C | 150°C | ASTM D2000 |

| Compression Set (70h/150°C) | 45% | 18% | ASTM D395 |

| Volume Swell in Skydrol 500 | 35% | <8% | ASTM D471 |

| Tensile Strength Retention | 55% after 168h/150°C | 85% after 168h/150°C | ISO 188 |

| Hardness Range (Shore A) | 70–90 | 75–85 | ASTM D2240 |

These metrics underscore why material substitution compromises system integrity. An orange O-ring’s value lies not in its hue but in its molecular architecture—optimized for low compression set in high-temperature static seals or resilience against jet fuel in aerospace actuators. Suzhou Baoshida Trading Co., Ltd. rigorously validates every orange compound against OEM fluid specifications and dynamic cycling protocols, ensuring compliance with ISO 3601 and SAE AS568C dimensional tolerances. We reject one-size-fits-all solutions; instead, our engineering team collaborates with clients to map material properties to actual service conditions, mitigating failure through chemistry-first design. For mission-critical sealing, the orange designation must correlate with certified performance data—not merely shelf availability. Partner with Baoshida to transform seal reliability from a cost center into a competitive advantage.

Material Specifications

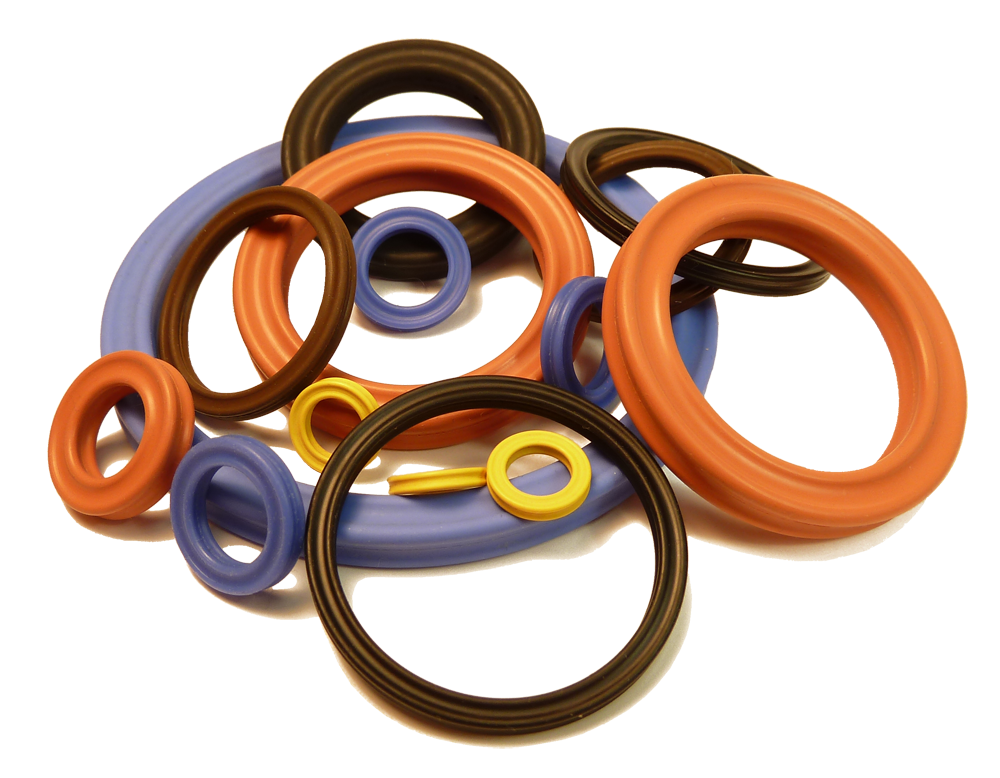

Material selection is a critical determinant in the performance and longevity of precision rubber seals, particularly in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered sealing solutions, with a focus on high-integrity o-rings designed for reliability under extreme temperature, pressure, and chemical exposure. Among the most widely utilized elastomers in our orange o-ring product line are Viton, Nitrile (NBR), and Silicone. Each material offers a distinct set of physical and chemical properties tailored to specific operational conditions.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes Viton ideal for applications in aerospace, automotive fuel systems, and chemical processing equipment. With a continuous service temperature range from -20°C to +230°C, Viton maintains sealing integrity even under prolonged thermal stress. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical high-performance systems.

Nitrile rubber, also known as Buna-N or NBR, is a cost-effective solution for applications involving petroleum-based oils and hydraulic fluids. It exhibits strong abrasion resistance and good tensile strength, making it a preferred choice for dynamic sealing applications such as pumps, compressors, and automotive transmissions. Nitrile operates effectively within a temperature range of -30°C to +100°C, with short-term peaks up to +120°C. While it offers limited resistance to ozone, weathering, and polar solvents, its compatibility with aliphatic hydrocarbons ensures widespread industrial use.

Silicone rubber (VMQ) delivers outstanding thermal stability and flexibility across a wide temperature spectrum, from -60°C to +200°C. It is particularly valued in applications requiring low-temperature flexibility and resistance to UV radiation and ozone. Silicone is commonly used in medical devices, food processing equipment, and electrical insulation due to its inert nature and compliance with high-purity standards. However, it exhibits lower mechanical strength and abrasion resistance compared to Viton and Nitrile, and is less suitable for dynamic or high-pressure applications.

The following table summarizes key performance characteristics of these materials to assist in optimal selection for your sealing requirements.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| FDA Compliance Available | Yes | Limited | Yes |

Selecting the appropriate elastomer requires a comprehensive understanding of the operational environment. Suzhou Baoshida Trading Co., Ltd. ensures that all orange o-rings meet stringent international quality standards, with full traceability and customization options available to meet OEM specifications.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Execution for Orange O-Rings

Suzhou Baoshida Trading Co., Ltd. delivers engineered sealing solutions through integrated material science and precision manufacturing. Our core strength lies in the synergy between dedicated Rubber Formula Engineering and Mold Engineering teams. With 2 specialized Formula Engineers and 5 certified Mold Engineers, we control the entire development lifecycle—from compound design to final tooling validation—ensuring orange o-rings meet exacting industrial performance criteria. This vertical integration eliminates third-party dependencies, accelerating time-to-market while maintaining rigorous quality control.

Our Formula Engineers optimize NBR, HNBR, and FKM compounds specifically for orange o-rings, balancing critical properties: heat resistance (up to 150°C for HNBR), fluid compatibility (fuels, hydraulic oils), and compression set (<20% per ASTM D395). The orange pigment is meticulously dispersed to avoid compromising mechanical integrity, ensuring consistent color visibility for assembly verification without sacrificing seal longevity. Each formulation undergoes accelerated aging tests and FTIR spectroscopy to validate stability under operational stress.

The Mold Engineering team executes precision tooling using CAD/CAM-driven processes, achieving tolerances to ISO 3601-1 Class S (±0.05mm cross-section). We perform mold flow analysis to eliminate knit lines and optimize cure kinetics, directly enhancing o-ring dimensional stability. Critical to OEM success, we implement tolerance stack-up analysis across multi-cavity molds, guaranteeing uniformity in high-volume production. All tooling is maintained in-house with real-time cavity pressure monitoring to detect wear before part quality drifts.

OEM Manufacturing Specifications

| Parameter | Standard Capability | Precision Tier (OEM) | Testing Standard |

|————————–|—————————|————————–|————————|

| Material Hardness | 50–90 Shore A | ±3 Shore A tolerance | ASTM D2240 |

| ID Range | 3–500 mm | Custom beyond 500 mm | ISO 3601-3 |

| Cross-Section Tolerance | ±0.10 mm | ±0.03 mm | ISO 3302-E2 |

| Batch Traceability | Lot-level | Cavity-specific | IATF 16949 compliant |

| Production Volume | 1k–500k units | 500k+ units | Automated packing |

OEM partnerships benefit from our closed-loop production system. Dedicated production lines isolate customer-specific compounds, preventing cross-contamination. Every orange o-ring batch includes full material certification (3.1/3.2 EN 10204), with optional real-time SPC data sharing via secure cloud portals. For regulated industries—automotive, aerospace, or medical—we provide PPAP Level 3 documentation and support rapid design iterations through digital twin mold simulations.

Our engineering-led approach transforms material constraints into competitive advantages. By embedding formula science into mold design, we resolve challenges like extrusion gaps in high-pressure systems or low-temperature flexibility down to -40°C. Suzhou Baoshida does not merely manufacture o-rings; we engineer failure-resistant sealing interfaces where color-coded identification meets uncompromised performance. Partner with us for OEM solutions where every micron of tolerance and every compound additive is a deliberate engineering outcome.

Customization Process

Drawing Analysis

The customization process for an orange o-ring begins with rigorous drawing analysis, where engineering specifications are evaluated for dimensional accuracy, tolerance compliance, and application context. At Suzhou Baoshida Trading Co., Ltd., we assess customer-provided technical drawings or CAD models to verify critical parameters such as inner diameter, cross-sectional diameter, tolerance class per ISO 3601 or AS568 standards, and any special surface or chamfer requirements. Our engineering team cross-references the design with intended operating conditions, including pressure range, dynamic or static sealing application, and mating hardware configuration. This step ensures that the proposed geometry is manufacturable and functionally reliable under real-world service conditions.

Formulation Development

Following drawing validation, the rubber compound is formulated to meet the specific chemical, thermal, and mechanical demands of the application. The orange color of the o-ring is not merely aesthetic; it often signifies a specialized formulation, such as hydrogenated nitrile (HNBR) or fluorocarbon (FKM) with enhanced heat and oil resistance. Our Rubber Formula Engineers tailor the polymer base, filler system, plasticizers, and curatives to achieve target properties including compression set resistance, tensile strength, and fluid compatibility. For example, in high-temperature automotive or industrial hydraulic systems, an orange FKM compound may be selected for its stability at 200°C and resistance to aggressive media such as synthetic lubricants or sour gas environments. Each formulation is documented and archived for full traceability, meeting ISO 9001 and IATF 16949 quality system requirements.

Prototyping and Validation

Once the compound is finalized, precision molding techniques are employed to produce prototype o-rings. These samples are manufactured using CNC-machined steel molds that replicate production tooling, ensuring dimensional fidelity. Prototypes undergo a full suite of quality checks, including dimensional inspection via optical comparators, hardness testing (Shore A), and application-specific performance testing such as thermal aging, fluid immersion, and leak rate evaluation under simulated service conditions. Customer feedback is integrated at this stage, and design or material adjustments are made if necessary. Only after successful validation do we proceed to full-scale production.

Mass Production and Quality Assurance

Mass production leverages automated rubber molding and curing systems to ensure consistency and efficiency. Every production batch is subject to in-process and final quality inspections, with material certificates and test reports provided upon request. Our manufacturing workflow supports scalability from low-volume specialized batches to high-volume OEM supply.

The table below outlines typical specifications for a custom orange o-ring:

| Parameter | Typical Value / Range |

|---|---|

| Material | FKM, HNBR, or EPDM |

| Color | Orange (Pantone 158C or customer-specific) |

| Hardness (Shore A) | 70 ±5 |

| Temperature Range | -20°C to +200°C (FKM) |

| Tolerance Standard | ISO 3601-1 or AS568 |

| Fluid Resistance | Oil, fuel, hydraulic fluid, steam |

| Compression Set (24h, 150°C) | ≤20% (FKM-based compound) |

| Production Lead Time | 15–25 days (after prototype approval) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Orange O-Ring Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber sealing technology, specializing in mission-critical o-rings for demanding industrial applications. Our orange o-rings are not merely colored components but precision-engineered solutions designed for traceability, chemical resistance, and operational reliability in sectors such as semiconductor manufacturing, aerospace hydraulics, and pharmaceutical processing. The distinctive orange hue—formulated to Pantone 158 C specifications—serves as a critical visual identifier for fluid compatibility and safety protocols, ensuring zero cross-contamination in multi-system environments. As your dedicated Rubber Formula Engineer and OEM Manager, we validate every compound against ASTM D2000 and ISO 3601 standards, guaranteeing extrusion tolerances within ±0.05 mm and consistent Shore A hardness across production batches.

Material science drives our differentiation. Our proprietary orange nitrile (NBR) and fluorocarbon (FKM) compounds undergo rigorous thermal aging tests at 150°C for 72 hours, maintaining >80% tensile strength retention. This stability is non-negotiable for clients operating in high-temperature vacuum systems or aggressive solvent exposure. Below are key technical specifications for our standard orange o-ring formulations, reflecting our commitment to dimensional and chemical precision.

| Parameter | NBR Compound Value | FKM Compound Value | Testing Standard |

|---|---|---|---|

| Color | Pantone 158 C | Pantone 158 C | Visual Match (D629) |

| Hardness (Shore A) | 70 ± 5 | 75 ± 5 | ASTM D2240 |

| Temp Range (°C) | -30 to +120 | -20 to +230 | ISO 3601-1 |

| Tensile Strength | ≥15 MPa | ≥12 MPa | ASTM D412 |

| Compression Set | ≤25% (70h, 100°C) | ≤20% (70h, 200°C) | ASTM D395 |

Footnote: Color stability verified per ISO 188 after 24h aging at max continuous service temperature.

OEM integration requires more than off-the-shelf parts. We collaborate directly with your engineering teams to optimize compound selection, curing profiles, and tooling geometry—reducing leakage risks in dynamic sealing applications by up to 40% versus generic alternatives. Our Suzhou facility operates under IATF 16949-certified processes, with real-time SPC monitoring of durometer, volume swell, and extrusion consistency. For custom formulations, we provide full material traceability from polymer batch to finished part, including 3D surface roughness analysis for critical sealing surfaces.

Initiate your technical consultation today to resolve sealing challenges that impact yield, safety, or maintenance cycles. Contact Mr. Boyce, our OEM Manager and lead Rubber Formula Engineer, for immediate support on material compatibility assessments, rapid prototyping, or volume production scaling. Email [email protected] with your application parameters, including fluid media, pressure range, and dynamic/static requirements. Specify “Orange O-Ring Technical Query” in the subject line to expedite engineering review. We respond within 4 business hours with actionable data—not generic sales pitches. Partner with Suzhou Baoshida to transform sealing performance from a cost center into a competitive advantage. Your systems demand uncompromised integrity; our science delivers it.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).