Technical Contents

Engineering Guide: Window Ledge

Engineering Insight: Material Selection for Rubber Window Ledges

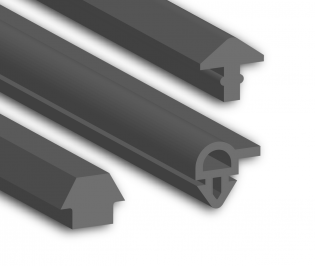

In industrial applications, the window ledge—often overlooked as a passive structural component—plays a critical role in environmental sealing, vibration dampening, and long-term system integrity. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary concern but a foundational engineering decision. Off-the-shelf rubber window ledges frequently fail under real-world conditions due to a mismatch between standardized material properties and the specific demands of the operating environment.

Generic rubber profiles are typically formulated for cost efficiency and broad applicability, relying on commodity-grade EPDM or SBR compounds. While adequate for mild indoor environments, these materials lack the resilience required in industrial settings where exposure to UV radiation, ozone, temperature extremes, and chemical agents is routine. Premature cracking, compression set, and loss of sealing force are common failure modes directly attributable to suboptimal polymer selection.

The performance of a rubber window ledge hinges on its ability to maintain dimensional stability and elastic recovery over extended service cycles. For instance, in transportation or outdoor housing units, ledges must endure thermal cycling from -40°C to +120°C without hardening or softening beyond acceptable limits. Standard formulations often exhibit excessive compression set above 80°C, leading to permanent deformation and seal failure. Similarly, poor ozone resistance in conventional diene-based rubbers results in surface cracking, compromising both aesthetics and functionality.

At Baoshida, we approach material selection through application-specific engineering. Our formulations are tailored using high-performance elastomers such as silicone (VMQ), fluorocarbon (FKM), and hydrogenated nitrile (HNBR), each selected based on environmental exposure and mechanical requirements. Reinforcement with engineered fillers and precision vulcanization protocols further enhance durability and aging resistance.

The following table illustrates key performance characteristics across common elastomer types used in industrial window ledge applications:

| Material | Temperature Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Ozone Resistance | Compression Set (22h @ 100°C) |

|---|---|---|---|---|---|

| EPDM | -50 to +150 | 50–80 | 12–20 | Excellent | 15–25% |

| Silicone (VMQ) | -60 to +200 | 40–80 | 6–9 | Excellent | 20–30% |

| Nitrile (NBR) | -30 to +100 | 50–90 | 10–22 | Poor | 10–20% |

| HNBR | -40 to +150 | 60–90 | 20–30 | Very Good | 10–15% |

| FKM | -20 to +200 | 60–80 | 12–18 | Excellent | 15–25% |

Custom material engineering allows for fine-tuning of durometer, elongation at break, and fluid resistance to meet OEM specifications precisely. This level of control is unattainable with mass-produced alternatives. Furthermore, Baoshida integrates accelerated aging tests and finite element analysis (FEA) in the development phase to predict field performance and optimize cross-sectional geometry alongside material choice.

In conclusion, the failure of off-the-shelf window ledge solutions stems from their inherent compromise between versatility and performance. True reliability in industrial environments demands a scientifically grounded, application-first approach to rubber formulation—one that Suzhou Baoshida Trading Co., Ltd. delivers through precision engineering and deep materials expertise.

Material Specifications

Material Specifications for Industrial Window Ledge Applications

Precision material selection is critical for window ledge seals in demanding industrial environments, where performance under thermal cycling, chemical exposure, and mechanical stress directly impacts product longevity and safety compliance. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber compounds to meet OEM-specific tolerances for automotive, aerospace, and heavy machinery window systems. This section details three core elastomers validated for window ledge applications: Viton fluoroelastomer (FKM), Nitrile rubber (NBR), and Silicone rubber (VMQ). Each material addresses distinct operational hazards while adhering to ASTM D2000 and ISO 37 standards for physical properties.

Viton fluoroelastomer (FKM) delivers superior resistance to extreme temperatures and aggressive chemicals, making it ideal for engine compartment or chemical processing window seals. Its molecular structure withstands continuous exposure to -20°C to +200°C, with intermittent peaks up to 230°C. Viton maintains integrity against oils, fuels, acids, and ozone, exhibiting tensile strength of 15–20 MPa and elongation at break of 150–250%. Compression set remains below 25% after 70 hours at 150°C, ensuring reliable sealing force retention in high-vibration scenarios. However, its higher cost necessitates strategic deployment where NBR or Silicone fall short.

Nitrile rubber (NBR) serves as the cost-optimized solution for standard automotive and industrial window ledges exposed to petroleum-based fluids. Operating effectively from -30°C to +100°C (with low-temperature variants to -50°C), NBR provides excellent resistance to mineral oils, greases, and hydraulic fluids. Typical formulations achieve 10–18 MPa tensile strength and 200–400% elongation, balancing flexibility with durability. Its abrasion resistance outperforms Silicone, though ozone and weathering resistance is moderate without protective additives. NBR’s 30–40% compression set at 100°C suits applications with infrequent thermal extremes.

Silicone rubber (VMQ) excels in wide-temperature window ledge applications requiring extreme flexibility and biocompatibility. It functions reliably from -60°C to +200°C, with specialty grades enduring +230°C. VMQ’s inert composition resists UV, ozone, and water ingress, making it optimal for exterior-facing seals in construction equipment or medical devices. Tensile strength ranges from 6–10 MPa, with elongation exceeding 400%, though tear strength is lower than NBR. Critical for cleanroom environments, it complies with USP Class VI and FDA 21 CFR 177.2600 standards. Compression set is moderate (25–35% at 150°C), but its elastic recovery suits static sealing roles.

Comparative Material Properties

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -50 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Elongation at Break (%) | 150–250 | 200–400 | 400–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Chemical Resistance | Fuels, Acids, Ozone | Oils, Greases | Water, UV, Ozone |

| Compression Set (100h/150°C) | ≤25% | 30–40% | 25–35% |

Material selection must align with fluid exposure, thermal profiles, and lifecycle cost targets. Viton is non-negotiable for high-temperature chemical resistance, NBR dominates cost-sensitive oil-exposed systems, and Silicone prevails in extreme cold or medical-grade applications. Suzhou Baoshida Trading Co., Ltd. provides customized compounding support to optimize these base materials for your window ledge specifications, ensuring seamless OEM integration and regulatory adherence. Consult our engineering team for application-specific validation testing protocols.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber manufacturing expertise, particularly in the development and production of precision components such as window ledge seals. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development cycle—from concept and material formulation to tooling design and final validation. This integrated approach ensures technical consistency, accelerated time-to-market, and superior product performance tailored to OEM requirements.

Our mould engineers bring over a decade of experience in precision rubber and silicone mould design, utilizing advanced CAD/CAM software including SolidWorks, UG NX, and AutoCAD. They specialize in multi-cavity, cold-runner, and transfer moulding systems optimized for high-volume production and tight-tolerance applications. Each mould is rigorously evaluated for flow dynamics, parting line integrity, and ejection efficiency to minimize flash, reduce cycle times, and enhance dimensional repeatability. Finite element analysis (FEA) is routinely applied to simulate moulding conditions and preemptively resolve potential defects such as air traps or non-uniform curing.

Complementing our tooling expertise, our two rubber formula engineers focus on material science innovation to meet exacting performance demands. They develop custom elastomer compounds based on EPDM, silicone (VMQ), NBR, and ACM, engineered for specific thermal stability, compression set resistance, UV and ozone endurance, and sealing force characteristics. These formulations are especially critical in window ledge applications exposed to outdoor weathering, temperature extremes, and mechanical stress. All compounds undergo accelerated aging, Shore hardness tracking, and dynamic compression testing to ensure long-term reliability.

Our OEM capabilities are built on a foundation of technical collaboration. We work directly with automotive, construction, and transportation clients to co-develop window ledge profiles that integrate seamlessly into final assemblies. This includes tolerance matching to mating components, adhesion optimization for co-extrusion or bonding, and compliance with industry standards such as ISO 1817, ASTM D2000, and GB/T 531.1.

Through our vertically integrated engineering model, Suzhou Baoshida ensures that every window ledge product is not only dimensionally precise but also chemically and mechanically optimized for its operational environment.

| Parameter | Specification |

|---|---|

| Mould Design Software | SolidWorks, UG NX, AutoCAD |

| Mould Types Supported | Multi-cavity, Cold-runner, Transfer, Compression |

| Rubber Compounds | EPDM, NBR, VMQ, ACM, Custom Blends |

| Hardness Range (Shore A) | 40–90 ±5 |

| Tolerance Compliance | ISO 3302, ISO 2768-m |

| Testing Standards | ASTM D2000, ISO 1817, GB/T 531.1 |

| OEM Development Lead Time | 6–8 weeks (from concept to prototype) |

Customization Process

Customization Process for Industrial Rubber Window Ledge Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for extruded rubber seals in window ledge applications begins with rigorous drawing analysis. We dissect OEM technical schematics to verify dimensional conformance against ISO 1302 surface finish standards and GD&T callouts. Critical parameters include cross-sectional tolerances (±0.1 mm), curvature radii, and adhesion zones for co-extrusion. Our engineering team identifies potential failure modes such as compression set under sustained load or UV degradation in exposed ledges, ensuring material selection aligns with environmental stressors like temperature cycling (-40°C to +100°C) and ozone exposure. This phase concludes with a joint review session to resolve ambiguities and confirm feasibility before formulation.

Material formulation leverages our proprietary compound database, targeting precise Shore A hardness (60–75), low compression set (<25% per ASTM D395), and ozone resistance (ASTM D1149). We optimize polymer bases—typically EPDM for weatherability or silicone for extreme temperatures—with fillers, curatives, and stabilizers. For window ledge seals requiring paint adhesion, we integrate surface-modifying additives to achieve 4B–5B rating per ASTM D3359. Each formulation undergoes computational modeling to predict cure kinetics and flow behavior during extrusion, minimizing scrap rates in production.

Prototyping employs precision aluminum tooling to produce 50–100-meter test batches within 15 working days. Seals undergo accelerated aging (1,000 hours QUV per ASTM G154), tensile testing (ASTM D412), and dynamic compression analysis simulating 50,000 opening/closing cycles. Adhesion strength to common window substrates (aluminum, uPVC) is validated per ASTM D429. We deliver comprehensive test reports with deviation analysis, iterating compounds until all OEM specifications are met.

Mass production initiates only after formal sign-off on prototype validation. Our ISO 9001-certified facility implements SPC-controlled extrusion lines with real-time monitoring of barrel temperatures (±2°C), die swell, and cure state via on-line rheometers. Every 500-meter batch undergoes destructive testing for hardness, tensile properties, and compression set. Full traceability is maintained via laser-etched batch codes linked to raw material certificates. Final inspection uses automated vision systems to detect surface defects below 0.05 mm resolution, ensuring zero non-conformities reach OEM assembly lines.

Key Performance Specifications Comparison

| Parameter | OEM Requirement | Prototype Result | Production Tolerance |

|---|---|---|---|

| Shore A Hardness | 70 ± 5 | 72 | ±3 |

| Compression Set (70°C/22h) | ≤25% | 21% | ≤23% |

| Tensile Strength (MPa) | ≥10.0 | 12.3 | ≥10.5 |

| Adhesion to uPVC | 4B min (ASTM D3359) | 5B | 4B–5B |

This phased approach guarantees seamless transition from concept to high-volume supply, with Suzhou Baoshida maintaining ≤0.1% defect rates across 500,000+ meters of annual window seal production.

Contact Engineering Team

For manufacturers and OEMs seeking precision-engineered rubber components for industrial applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced elastomer solutions. Specializing in custom rubber formulations and high-performance sealing systems, we deliver tailored products that meet the rigorous demands of modern industrial environments. Our expertise extends to the development of rubber window ledge components—critical elements in automotive, construction, and transportation sectors—where durability, weather resistance, and dimensional accuracy are paramount.

At Suzhou Baoshida, we understand that the performance of a window ledge is not solely defined by its shape, but by the material science behind it. Our rubber compounds are formulated to withstand prolonged UV exposure, extreme temperature fluctuations, moisture ingress, and mechanical stress. Whether the application requires EPDM, silicone, neoprene, or custom blends, our engineering team works closely with clients to optimize material properties such as compression set resistance, tensile strength, and Shore hardness. This ensures long-term sealing integrity and structural resilience under dynamic operating conditions.

We support global supply chains with ISO-compliant manufacturing processes, strict quality control protocols, and scalable production capabilities. Our facility integrates advanced mixing, extrusion, vulcanization, and CNC trimming technologies to produce window ledge profiles with tight tolerances and consistent surface finish. All formulations are developed in-house, allowing full traceability and customization to meet specific OEM specifications and international standards.

To facilitate seamless integration into your production workflow, we offer comprehensive technical documentation, material test reports, and sample prototyping services. Our team provides end-to-end support—from initial concept review and CAD-assisted design to tooling development and batch validation.

For immediate technical consultation or to initiate a project collaboration, please contact Mr. Boyce, OEM Account Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. He is available to discuss material selection, performance requirements, and custom formulation strategies tailored to your application needs. Reach out directly via email at [email protected] to request technical data sheets, initiate a quotation, or schedule a virtual engineering review.

Below are representative specifications for our standard rubber window ledge profiles. Custom parameters can be developed based on project-specific demands.

| Property | Test Method | EPDM Typical Value | Silicone Typical Value | Neoprene Typical Value |

|---|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–80 | 50–70 | 65–75 |

| Tensile Strength | ASTM D412 | ≥10 MPa | ≥8 MPa | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% | ≥200% | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% | ≤20% | ≤30% |

| Temperature Range | — | -40°C to +130°C | -60°C to +200°C | -40°C to +100°C |

| UV/Ozone Resistance | ASTM D1149 | Excellent | Good | Good |

Partner with Suzhou Baoshida to ensure your window ledge components are engineered for performance, longevity, and compliance. Contact Mr. Boyce today at [email protected] to advance your next industrial rubber solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).