Technical Contents

Engineering Guide: Polyamide 6

Engineering Insight: Polyamide 6 in Precision Rubber Composites

Polyamide 6 (PA6) is frequently misapplied in industrial rubber systems due to fundamental misunderstandings of its thermoplastic nature and environmental sensitivity. While PA6 offers high strength and thermal resistance, its role in rubber composites—such as cord reinforcement in tires or seals—demands exacting material specifications. Off-the-shelf PA6 grades fail catastrophically in these applications because they lack the tailored molecular architecture required for rubber adhesion, dynamic fatigue resistance, and dimensional stability under operational stress. Generic formulations prioritize cost over performance, ignoring critical variables like moisture equilibrium, melt viscosity consistency, and interfacial bonding compatibility with elastomer matrices. This results in premature delamination, hydrolytic degradation, and loss of mechanical integrity when exposed to humidity, temperature cycling, or chemical exposure inherent in industrial environments.

The core failure mechanism stems from uncontrolled moisture absorption. PA6 is hygroscopic, and standard commercial grades often exceed 1.5% moisture content as-received. During rubber vulcanization at 150–180°C, this moisture vaporizes, creating microvoids at the rubber-PA6 interface. These voids propagate under cyclic loading, causing catastrophic bond failure. Additionally, inconsistent melt flow rates in commodity PA6 lead to uneven dispersion of adhesion promoters like resorcinol-formaldehyde-latex (RFL) treatments. Without precise viscosity control (±5% deviation), fiber coating uniformity suffers, reducing peel strength by 30–50% versus engineered grades.

Suzhou Baoshida’s OEM validation process identifies three non-negotiable PA6 parameters for rubber integration:

| Critical Parameter | Off-the-Shelf Grade Tolerance | Suzhou Baoshida OEM Specification | Failure Consequence in Rubber Systems |

|---|---|---|---|

| Moisture Content (as-received) | 1.2–2.0% | ≤0.15% | Microvoid formation during cure; interfacial delamination |

| Melt Flow Rate (275°C/2.16kg) | ±15% deviation | ±3% deviation | Inconsistent RFL coating; reduced peel strength |

| Filler Dispersion (max agglomerate) | 100–200 μm | ≤50 μm | Stress concentration points; fatigue crack initiation |

| Thermal Stability (ΔMFR after 10h @ 200°C) | >25% increase | <8% increase | Degraded melt homogeneity; poor adhesion during processing |

Commodity PA6 suppliers rarely certify these parameters batch-to-batch, assuming end-users will adjust processing conditions. However, rubber manufacturing tolerates minimal variation—vulcanization temperature windows are often ±3°C. Attempting to compensate for PA6 inconsistencies by altering cure profiles destabilizes the entire elastomer network, increasing scrap rates by 15–25%. At Suzhou Baoshida, we co-engineer PA6 with specialty polymer producers to lock viscosity profiles within 240–260 mPa·s (ISO 1133) and pre-dry pellets to 0.12% moisture. This ensures RFL-treated cords achieve 8.5–9.2 kN/m peel strength with NR/SBR blends, meeting OEM durability thresholds for 500,000+ fatigue cycles.

Material selection is not a procurement decision—it is a precision engineering prerequisite. When PA6 interfaces with rubber under dynamic loads, molecular-level inconsistencies become macroscopic failures. Partnering with an OEM-focused supplier that validates every polymer attribute against your composite’s stress profile prevents costly field failures and secures supply chain resilience. Our technical team provides full traceability from pellet to performance, ensuring your rubber components operate at design limits without compromise.

Material Specifications

Polyamide 6 in Industrial Rubber Solutions: Material Compatibility and Performance Specifications

Polyamide 6, commonly known as nylon 6, is a semi-crystalline thermoplastic widely utilized in industrial applications due to its excellent mechanical strength, abrasion resistance, and thermal stability. While inherently a polymer distinct from elastomers, polyamide 6 often interfaces with rubber components in dynamic sealing, automotive, and hydraulic systems. Understanding its compatibility and performance in conjunction with elastomeric sealing materials such as Viton, Nitrile, and Silicone is critical for ensuring long-term reliability in demanding environments.

In industrial rubber solutions, the selection of elastomer must account for chemical exposure, temperature extremes, and mechanical stress. Suzhou Baoshida Trading Co., Ltd. provides engineered sealing systems where elastomer performance directly influences the integrity of polyamide 6-based assemblies. Each elastomer exhibits distinct characteristics when exposed to oils, fuels, ozone, and varying thermal cycles—factors that are essential in applications involving polyamide 6 housings, gears, or connectors.

Viton (FKM) demonstrates superior resistance to high temperatures and aggressive chemicals, making it ideal for use in fuel systems and high-temperature seals where polyamide 6 components are exposed to engine oils or aromatic hydrocarbons. Its continuous service temperature range extends up to 200°C, aligning well with the thermal capabilities of reinforced polyamide 6. However, Viton exhibits higher compression set and lower elasticity compared to other elastomers, which must be considered in dynamic sealing applications.

Nitrile rubber (NBR) offers excellent resistance to aliphatic hydrocarbons, water, and hydraulic fluids, presenting a cost-effective solution for general-purpose sealing. It maintains flexibility at lower temperatures and adheres well to polyamide 6 in composite components. However, its upper temperature limit is restricted to approximately 120°C, and it degrades rapidly when exposed to ozone, UV radiation, or polar solvents. This limits its use in outdoor or high-heat environments.

Silicone rubber (VMQ) provides exceptional thermal stability across a wide range, from -60°C to 180°C, and outstanding resistance to UV and ozone. It is frequently selected for electrical insulation and medical applications where polyamide 6 is used as a structural component. However, silicone has relatively poor mechanical strength and abrasion resistance, and it swells significantly in hydrocarbon oils, limiting its use in oil-exposed mechanical systems.

The following table summarizes key performance characteristics of these elastomers in relation to polyamide 6 integration:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -40 to 120 | -60 to 180 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 300–700 |

| Hardness (Shore A) | 70–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Very Good | Good | Fair |

| Common Applications | Automotive seals, aerospace, chemical processing | Hydraulic systems, fuel hoses, gaskets | Electrical insulation, medical devices, weather seals |

Selection of the appropriate elastomer in conjunction with polyamide 6 must be based on a comprehensive evaluation of operational parameters. Suzhou Baoshida Trading Co., Ltd. supports OEMs with material compatibility testing and engineering consultation to ensure optimal performance in industrial rubber solutions.

Manufacturing Capabilities

Engineering Capabilities for Polyamide 6 Solutions

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered polyamide 6 (PA6) compounds specifically optimized for demanding industrial rubber applications. Our technical team integrates deep polymer science expertise with advanced manufacturing rigor to overcome the inherent limitations of standard PA6, transforming it into high-performance elastomeric solutions. This capability stems from a dedicated engineering unit comprising five specialized mould engineers and two senior rubber formula engineers, all focused exclusively on PA6-based system development and production.

Our formula engineers possess mastery in modifying PA6’s molecular structure through strategic additive integration, cross-linking techniques, and filler dispersion protocols. We address critical challenges such as moisture sensitivity, impact resistance at low temperatures, and long-term thermal stability—essential for automotive seals, hydraulic components, and industrial conveyor systems. This is achieved without compromising PA6’s core advantages: exceptional mechanical strength, abrasion resistance, and chemical resilience. Concurrently, our mould engineering team leverages advanced simulation software (Moldflow®) to optimize tool design, gate placement, and cooling channels. This ensures dimensional accuracy, minimizes internal stresses, and eliminates knit lines in complex geometries—directly translating material potential into flawless physical parts.

As a certified OEM partner, we implement a closed-loop development process. Client specifications undergo rigorous feasibility analysis, followed by iterative compound formulation and mould validation. We manage full project lifecycles from CAD data review through PPAP documentation, maintaining strict IP confidentiality via signed NDAs. Our facility supports low-volume prototyping and high-volume production (500–50,000 units/month), with real-time process monitoring ensuring batch-to-batch consistency. Every compound is traceable to raw material lot numbers, and final parts undergo ASTM D2000-compliant testing before shipment.

Critical performance enhancements in our PA6 formulations are quantifiable against industry baselines, as demonstrated below:

| Property | Standard PA6 (Unmodified) | Baoshida Engineered PA6 Compound | Test Standard |

|---|---|---|---|

| Tensile Strength | 80 MPa | 95 MPa | ISO 527 |

| Elongation at Break | 150% | 220% | ISO 527 |

| Heat Deflection Temp (1.8 MPa) | 70°C | 110°C | ISO 75 |

| Shore A Hardness | N/A | 75–85 | ISO 868 |

| Compression Set (70°C, 22h) | N/A | 18% | ISO 815 |

This data reflects our ability to tailor PA6 for elastomeric functionality while exceeding standard thermoplastic performance metrics. Our OEM clients benefit from reduced time-to-market through concurrent engineering support and rapid design-for-manufacturability feedback. All solutions undergo accelerated aging and dynamic fatigue validation specific to the application environment, ensuring reliability under operational stress. Suzhou Baoshida’s engineering framework transforms polyamide 6 from a commodity resin into a mission-critical component—proven in global supply chains where failure is not an option.

Customization Process

Drawing Analysis

The customization process for polyamide 6 (PA6) components begins with a comprehensive drawing analysis to ensure dimensional accuracy, functional performance, and compatibility with the intended application. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a detailed review of technical drawings provided by the client, focusing on critical tolerances, wall thickness, gate locations, and stress concentration zones. We assess both 2D blueprints and 3D CAD models to identify potential molding challenges such as warpage, sink marks, or flow imbalances. This phase also includes material suitability verification, confirming that PA6—known for its high mechanical strength, abrasion resistance, and thermal stability up to 80–120°C—meets the operational demands of the end-use environment. Feedback is provided promptly to optimize geometry for manufacturability without compromising performance.

Formulation Development

Following drawing validation, we proceed to formulation design, tailoring the PA6 compound to meet specific mechanical, thermal, and chemical resistance requirements. Standard unfilled PA6 offers excellent toughness and low friction, but many industrial applications demand enhanced properties. Our in-house compounding laboratory integrates additives such as glass fiber, impact modifiers, heat stabilizers, and lubricants to achieve desired characteristics. For instance, 30% glass fiber-reinforced PA6 increases tensile strength from 80 MPa to over 170 MPa and improves heat deflection temperature by up to 90°C. All formulations are developed in accordance with ISO 1873-1 and ASTM D6103 standards, ensuring consistency and traceability. Clients receive a full material data sheet outlining physical and rheological properties prior to prototyping.

Prototyping and Validation

Once the formulation is finalized, we produce functional prototypes using precision injection molding under production-intent conditions. These prototypes undergo rigorous testing, including dimensional inspection, mechanical load testing, and environmental exposure (e.g., humidity, oil, or elevated temperatures). We utilize coordinate measuring machines (CMM) and tensile testers to verify conformance to specifications. This stage allows for design or process adjustments before committing to full-scale tooling. Clients are provided with test reports and physical samples for field evaluation, ensuring confidence in performance prior to launch.

Mass Production and Quality Assurance

Upon approval, we transition to mass production using high-speed, automated injection molding lines equipped with real-time process monitoring. Each batch is subject to strict quality control protocols in compliance with IATF 16949 standards. Raw materials are batch-tracked, and in-process checks ensure consistency in color, weight, and dimensions. Final inspection includes 100% visual checks and statistical sampling for dimensional and mechanical verification.

Below is a representative specification comparison of common PA6 formulations offered:

| Property | Unfilled PA6 | 30% Glass Fiber PA6 | Impact-Modified PA6 |

|---|---|---|---|

| Tensile Strength (MPa) | 80 | 175 | 65 |

| Flexural Modulus (MPa) | 2800 | 8500 | 2200 |

| Heat Deflection Temp (°C, 1.8 MPa) | 70 | 210 | 65 |

| Notched Impact Strength (kJ/m²) | 8 | 10 | 35 |

| Application Examples | Gears, bushings | Structural brackets, connectors | Housings, clips |

Contact Engineering Team

Technical Engagement for Polyamide 6 Integration in Industrial Rubber Systems

Suzhou Baoshida Trading Co., Ltd. operates at the convergence of advanced polymer science and precision rubber manufacturing. While polyamide 6 (PA6) itself is a semi-crystalline thermoplastic distinct from elastomeric materials, its strategic integration into rubber composite systems—particularly in reinforced seals, timing belts, and dynamic gaskets—demands specialized formulation expertise. PA6’s high tensile strength, thermal stability, and chemical resistance complement rubber matrices when engineered for interfacial adhesion and stress distribution. Our OEM team excels in developing hybrid solutions where PA6 fibers or fillers enhance the performance of EPDM, NBR, or HNBR compounds under extreme operational conditions.

Industrial clients face critical challenges in balancing PA6’s moisture sensitivity against rubber’s viscoelastic behavior, especially in automotive and hydraulic applications requiring long-term dimensional stability. Suzhou Baoshida addresses this through proprietary coupling agents and dynamic vulcanization techniques, ensuring optimal phase compatibility without compromising the rubber’s fatigue resistance. Our in-house R&D facility conducts rigorous ASTM D412 tensile testing, ISO 188 heat aging, and fluid immersion analysis to validate PA6-rubber synergies under real-world stressors.

Below are key PA6 properties relevant to rubber system integration, emphasizing parameters critical for co-molded or laminated components:

| Property | Typical Value for PA6 | Relevance to Rubber Composite Design |

|---|---|---|

| Tensile Strength | 80–85 MPa | Reinforcement backbone for high-load seals |

| Melting Point | 215–220°C | Defines upper processing limit for co-curing |

| Water Absorption (23°C) | 2.5–3.5% | Critical for dimensional stability in wet environments |

| Continuous Use Temp | -40°C to +120°C | Compatibility window with standard rubber grades |

| Flexural Modulus | 2,500–3,000 MPa | Stiffness contribution to composite rigidity |

Suzhou Baoshida’s OEM management framework prioritizes collaborative engineering from prototype to量产 (mass production). We provide full traceability via ISO 9001-certified workflows, including DOE-driven compound optimization and finite element analysis (FEA) validation for complex geometries. Our clients leverage reduced NRE costs through shared tooling investments and accelerated qualification cycles using our regional supply chain network across the Yangtze River Delta.

For polyamide 6-rubber hybrid systems, marginal formulation adjustments yield exponential performance gains. Suzhou Baoshida invites technical teams to submit application-specific requirements—such as dynamic compression set targets in oil-exposed environments or cryogenic flexibility thresholds—to initiate a precision engineering dialogue. Mr. Boyce, our dedicated OEM Solutions Manager, possesses 14 years of cross-material formulation experience spanning European automotive and Chinese industrial machinery sectors. He will coordinate material sampling, failure mode analysis, and co-development roadmaps tailored to your production timeline.

Contact Mr. Boyce directly at [email protected] to schedule a technical consultation. Include your target application, performance metrics, and current material pain points to receive a preliminary feasibility assessment within 72 hours. Suzhou Baoshida commits to transforming polyamide 6 integration challenges into competitive advantages through science-led partnership.

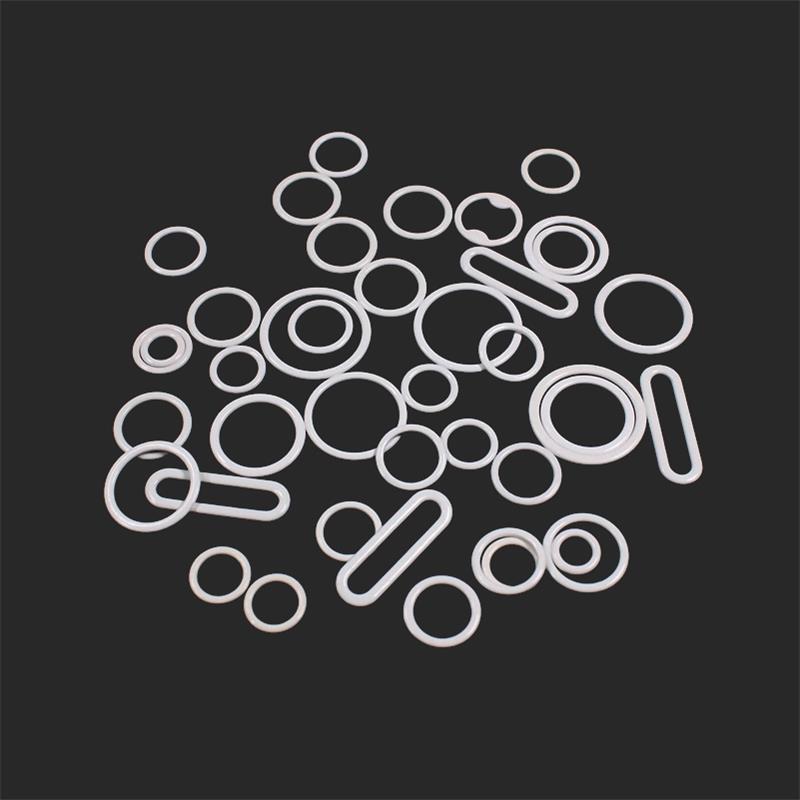

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).