Technical Contents

Engineering Guide: Gaskets Packing And Seals

Engineering Insight: Material Selection in Gaskets, Packing, and Seals

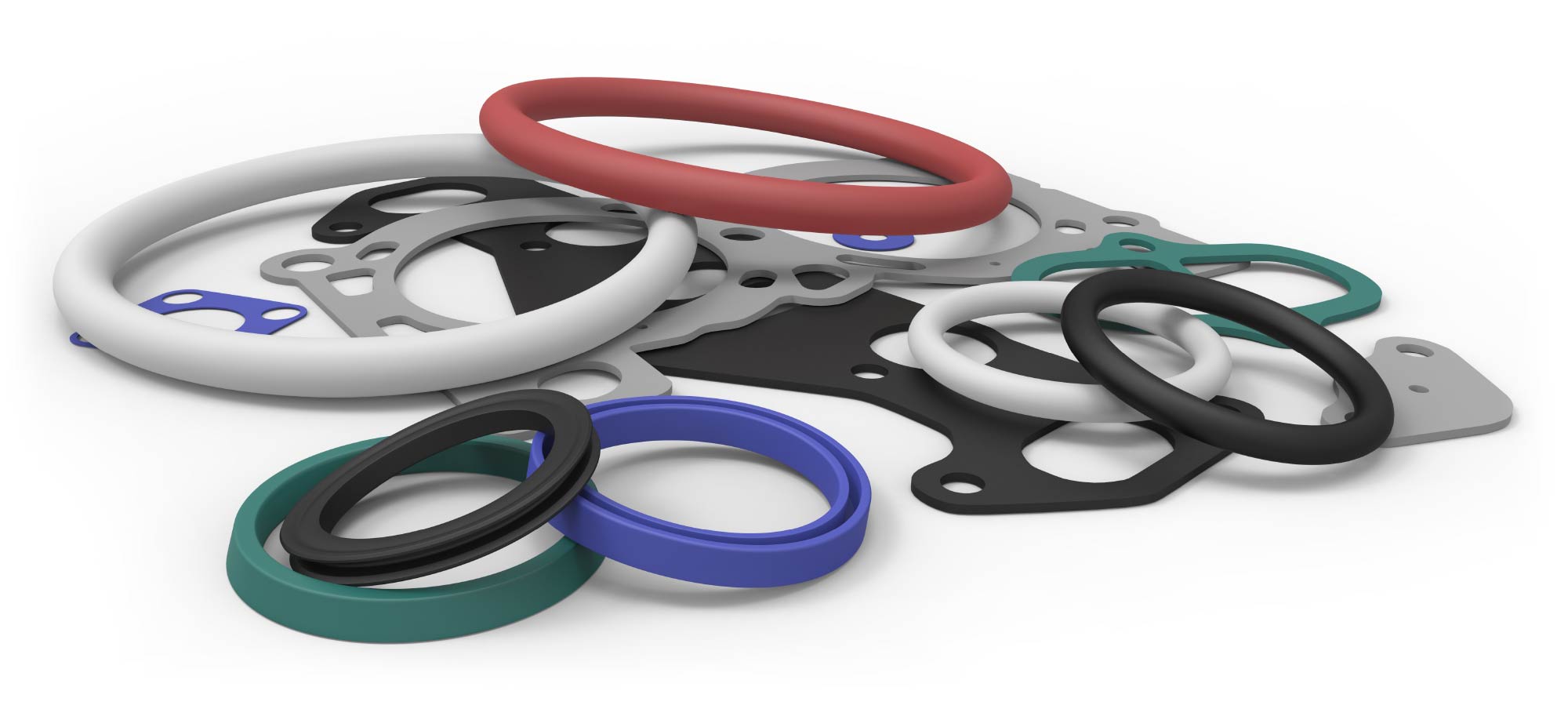

In precision rubber sealing applications, material selection is not merely a design consideration—it is a decisive engineering parameter that governs performance, longevity, and system integrity. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf sealing solutions frequently underperform because they are engineered for generalized conditions, not the specific chemical, thermal, and mechanical environments found in industrial systems. The failure of such generic components often manifests as premature extrusion, chemical degradation, compression set, or loss of sealing force—issues that compromise safety, increase downtime, and elevate total cost of ownership.

The root cause of these failures lies in the mismatch between standard material formulations and application-specific demands. For example, an NBR (nitrile butadiene rubber) gasket may suffice in low-temperature hydraulic systems but will rapidly degrade when exposed to ozone, aromatic hydrocarbons, or continuous operation above 100°C. Similarly, PTFE-based packing may offer excellent chemical resistance but lacks the resilience required for dynamic shaft sealing under fluctuating loads.

Precision sealing requires a granular understanding of service conditions. Key variables include fluid media, operating temperature range, pressure differentials, cycle frequency, and surface finish of mating components. A fluorocarbon rubber (FKM) seal may be optimal for high-temperature fuel systems, while EPDM demonstrates superior resistance to steam and polar solvents. In aggressive chemical processing environments, perfluoroelastomers (FFKM) provide unmatched stability, albeit at higher material cost—justifiable when factoring in reduced maintenance intervals and elimination of unplanned shutdowns.

Equally critical is the interaction between material properties and seal geometry. A compound with high tensile strength may still fail under sustained compression if its elastic recovery is insufficient. Likewise, low-friction materials such as silicone or PTFE composites may exhibit poor wear resistance in reciprocating applications without reinforcement.

To illustrate the performance differentiation across materials, consider the following comparative specifications:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|---|

| NBR | -30 to +100 | 15–20 | 60–90 | Aliphatic hydrocarbons, water, oils |

| EPDM | -50 to +150 | 10–18 | 50–80 | Steam, ozone, polar solvents, UV |

| FKM | -20 to +200 | 12–16 | 65–85 | Aromatic fuels, acids, high-temp oils |

| Silicone | -60 to +200 | 5–9 | 40–80 | Extreme temperatures, UV, biocompatibility |

| PTFE | -200 to +260 | 20–35 | 50–65 (Shore D) | Virtually all chemicals, low friction |

| FFKM | -15 to +300 | 8–12 | 70–90 | Aggressive chemicals, high temp, plasma |

Custom material formulation and compound tailoring allow for optimization against these variables. At Suzhou Baoshida, we collaborate with OEMs to analyze operational profiles and develop application-engineered seals that outperform generic alternatives. The cost premium of precision materials is consistently offset by improved reliability, compliance with industry standards (e.g., FDA, ISO 12209, API 6A), and extended service life.

In conclusion, effective sealing is not a commodity function—it is a systems-level engineering solution. Material selection must be treated as a core design variable, not an afterthought.

Material Specifications

Material Specifications for Precision Rubber Seals

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions for critical sealing applications across automotive, aerospace, and industrial systems. Material selection directly impacts seal longevity, chemical compatibility, and operational safety. This section details key specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds, emphasizing performance boundaries under standardized test conditions per ASTM D2000 and ISO 3601.

Viton fluorocarbon rubber excels in extreme chemical and thermal environments. Its molecular structure resists degradation from aggressive media including jet fuels, hydraulic fluids, and aromatic hydrocarbons. Standard grades maintain integrity from -20°C to +230°C continuous service, with specialty formulations extending to +300°C. Tensile strength ranges 10–15 MPa (ASTM D412), elongation at break 150–300%, and compression set (22 hrs/150°C) remains below 25% (ASTM D395). Viton’s low gas permeability makes it ideal for oxygen-rich systems and high-vacuum applications, though it exhibits limited flexibility below -15°C and higher material costs versus hydrocarbon rubbers.

Nitrile butadiene rubber remains the industry standard for cost-sensitive oil and fuel sealing. Optimized for aliphatic hydrocarbons, it operates effectively between -40°C and +120°C, with extended low-temperature grades reaching -55°C. Standard NBR compounds achieve tensile strength of 15–20 MPa, elongation of 300–500%, and compression set (70 hrs/100°C) of 20–40%. Resistance to ozone and weathering is poor without protective additives, and aromatic solvents cause significant swelling. Its balanced abrasion resistance and compression set performance suit hydraulic systems, fuel injectors, and general-purpose O-rings.

Silicone rubber delivers unmatched thermal stability for non-dynamic seals. It functions reliably from -60°C to +200°C, with brief exposure tolerance to +230°C. While tensile strength is moderate (5–8 MPa), its elongation exceeds 400%, and compression set (22 hrs/175°C) stays under 20%. Silicone offers excellent resistance to ozone, UV, and steam but swells in petroleum-based fluids. Limited tear strength necessitates careful design for high-stress applications. Primary uses include medical devices, food processing gaskets, and high-temperature static seals where electrical insulation is critical.

Material Performance Comparison

| Parameter | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 10–15 | 15–20 | 5–8 |

| Elongation at Break (%) | 150–300 | 300–500 | 400–600 |

| Compression Set (ASTM) | <25% (150°C/22h) | 20–40% (100°C/70h) | <20% (175°C/22h) |

| Key Chemical Resistance | Fuels, Acids, Ozone | Aliphatic Oils | Steam, Ozone, UV |

| Key Limitation | Poor low-temp flex | Swells in aromatics | Low tear strength |

Material selection requires balancing chemical exposure, temperature extremes, mechanical stress, and regulatory compliance. Suzhou Baoshida’s OEM team collaborates with clients to customize compound formulations—such as carboxylated NBR for enhanced abrasion resistance or peroxide-cured silicone for medical purity—ensuring optimal seal performance against ISO 3601 dimensional standards. Always validate material suitability through application-specific testing under actual service conditions.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Seal Development at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a dedicated team of technical specialists focused exclusively on the science and performance of rubber seals, gaskets, and packing solutions. Our team comprises five experienced mould engineers and two in-house rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to production. This dual expertise ensures that every component we manufacture meets exacting performance, durability, and dimensional accuracy standards required in demanding industrial applications.

Our mould engineers specialize in precision tooling design for complex rubber sealing profiles. Utilizing advanced CAD/CAM systems and finite element analysis (FEA), they develop moulds that ensure consistent part geometry, optimal material flow, and minimal flash—critical factors in high-integrity sealing environments. Each design undergoes rigorous simulation and validation to anticipate compression set, deformation under load, and thermal expansion characteristics, ensuring reliability across temperature extremes and dynamic operating conditions.

Complementing our tooling expertise is our proprietary rubber compounding capability. Our two formula engineers possess deep knowledge in polymer chemistry, filler systems, and cure kinetics, allowing us to tailor elastomer formulations for specific resistance profiles—whether to oils, acids, steam, or extreme temperatures. We routinely develop custom compounds based on NBR, EPDM, FKM, silicone, and specialty fluorosilicone polymers, optimized for hardness, elongation, compression set, and chemical compatibility. This in-house formulation control eliminates reliance on third-party material suppliers and ensures batch-to-batch consistency critical for long-term OEM partnerships.

Our OEM capabilities are structured to support clients from initial design input through prototyping, testing, and full-scale production. We collaborate closely with engineering teams to interpret application requirements, conduct material selection reviews, and perform seal performance simulations. Rapid prototyping using CNC-machined mould bases and lab-scale mixing enables quick turnaround for sample validation. Once qualified, seamless transition to mass production is achieved through synchronized process validation and statistical process control (SPC) monitoring.

The integration of material science and precision engineering allows us to deliver sealing solutions that exceed industry benchmarks. Whether addressing leakage in hydraulic systems, thermal degradation in automotive underhood environments, or chemical attack in industrial processing equipment, our engineering team ensures every seal performs as intended.

Typical Material Performance Specifications

| Material | Hardness (Shore A) | Temperature Range (°C) | Key Resistance Properties |

|---|---|---|---|

| NBR | 50–90 | -30 to +120 | Oil, fuel, water, aliphatic hydrocarbons |

| EPDM | 50–80 | -50 to +150 | Steam, water, ozone, weathering |

| FKM | 60–90 | -20 to +230 | Aromatic fuels, acids, high-temperature oils |

| Silicone | 40–80 | -60 to +200 | Extreme cold, UV, biocompatibility |

| Fluorosilicone | 50–80 | -55 to +175 | Jet fuels, oxygenated solvents, low-temperature flexibility |

Customization Process

Customization Process for Precision Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for gaskets, packing, and seals integrates rigorous engineering protocols to transform client specifications into high-performance sealing solutions. This four-phase methodology ensures dimensional accuracy, material resilience, and operational reliability under demanding industrial conditions.

Drawing Analysis

Initial engagement begins with comprehensive GD&T (Geometric Dimensioning and Tolerancing) validation of client-provided technical drawings. Our engineering team scrutinizes critical features including cross-sectional tolerances (ISO 3302-1:2015 compliant), surface finish requirements, and assembly interface geometries. We conduct feasibility assessments for complex profiles such as spiral-wound gaskets or唇形密封 (lip seals), identifying potential molding challenges like flash formation or material flow inconsistencies. This phase includes collaborative review sessions to resolve ambiguities and optimize designs for manufacturability, reducing time-to-prototype by up to 30%.

Formulation

Material selection is driven by application-specific performance criteria. Our rubber compounding laboratory develops proprietary elastomer formulations tailored to chemical exposure, temperature range (-60°C to +300°C), and pressure dynamics. Key properties are validated against ASTM D2000 standards, with formulations adjusted for compression set resistance, tensile strength, and fluid compatibility. The table below summarizes common elastomer options and their industrial applications.

| Elastomer Type | Temperature Range (°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|

| FKM (Viton®) | -20 to +250 | Fuels, oils, acids | Aerospace hydraulic systems |

| EPDM | -50 to +150 | Steam, ozone, water | HVAC and automotive coolant |

| Silicone | -60 to +230 | Extreme temps, UV | Medical devices, food processing |

| NBR | -30 to +120 | Hydrocarbons, abrasion | Oilfield equipment, fuel lines |

Prototyping

Precision prototypes are manufactured using CNC-machined molds or 3D-printed tooling for low-volume validation. Each sample undergoes accelerated life testing per SAE AS568 standards, including compression set analysis (ASTM D395), leakage rate measurement, and thermal cycling. Clients receive detailed test reports with dimensional conformance data (±0.05mm tolerance) and material property certificates. Iterative adjustments are implemented within 72 hours based on feedback, ensuring final geometry and material behavior align with operational demands before tooling release.

Mass Production

Full-scale manufacturing leverages automated injection molding and hydraulic press systems with real-time process monitoring. Every batch undergoes 100% visual inspection and statistical dimensional sampling per AQL 1.0. Critical parameters like cure time, temperature profiles, and post-vulcanization are logged for full traceability. Finished seals are packaged in ESD-safe containers with lot-specific CoC (Certificate of Conformance) documenting hardness, density, and fluid immersion results. Our ISO 9001-certified production floor maintains ±0.5°C temperature control to eliminate batch variability, supporting OEM volumes from 1,000 to 500,000 units monthly.

This structured workflow minimizes client risk through data-driven validation at each stage, delivering seals that meet exacting performance requirements while adhering to global quality frameworks. Suzhou Baoshida’s engineering oversight ensures seamless transition from concept to certified production.

Contact Engineering Team

For industrial manufacturers requiring high-performance gaskets, packing, and seals, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber sealing solutions tailored to the most demanding environments. As a trusted OEM partner in the precision rubber components sector, we specialize in material formulation, custom molding, and performance validation to ensure leak-free, long-term reliability across automotive, aerospace, energy, and heavy industrial applications.

Our expertise lies in the scientific design of elastomeric compounds—balancing compression set, tensile strength, temperature resistance, and chemical compatibility to meet exact OEM specifications. Whether you require static or dynamic seals, custom gaskets for high-pressure flanges, or packing solutions for rotary and reciprocating equipment, our engineering team applies rigorous material science principles to deliver consistent, repeatable performance.

To initiate a technical collaboration or request a custom quote, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in industrial sealing applications and serves as the primary technical liaison between our R&D team and global manufacturing partners. He is equipped to review your application requirements, recommend optimal elastomer grades (including NBR, EPDM, FKM, silicone, and specialty compounds), and coordinate sample production or full-scale manufacturing with precise tolerance control.

Reach Mr. Boyce directly at [email protected]. Include detailed specifications such as operating temperature range, media exposure, pressure conditions, dimensional tolerances (per ASTM D3183 or ISO 3601), and any relevant industry certifications (e.g., FDA, NSF, UL, or ATEX). Our team responds to technical inquiries within 4 business hours and can provide material test reports, 2D/3D drawings, and prototype timelines upon request.

For rapid evaluation, refer to the typical performance specifications of our standard elastomer families below:

| Material | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|---|

| NBR (Nitrile) | 50–90 | -30 to +120 | ≥15 | ≥250 | Oil, fuel, hydraulic fluids |

| EPDM | 50–80 | -50 to +150 | ≥12 | ≥300 | Steam, water, ozone, UV |

| FKM (Viton®) | 60–90 | -20 to +200 | ≥10 | ≥200 | High-temp oils, acids, aromatics |

| Silicone | 40–80 | -60 to +200 | ≥6 | ≥200 | Extreme temps, biocompatibility |

| ACM (Acrylate) | 60–80 | -10 to +170 | ≥10 | ≥200 | Heat, oxidation, synthetic lubricants |

All materials are subject to custom formulation adjustments based on application demands. Suzhou Baoshida maintains ISO 9001-certified quality systems and supports full traceability, batch testing, and on-site audits for strategic OEM partners.

Contact Mr. Boyce today to engineer a sealing solution that meets your performance, durability, and compliance requirements.

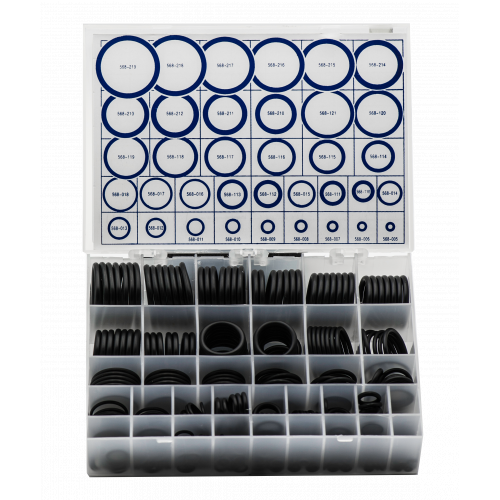

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).