Technical Contents

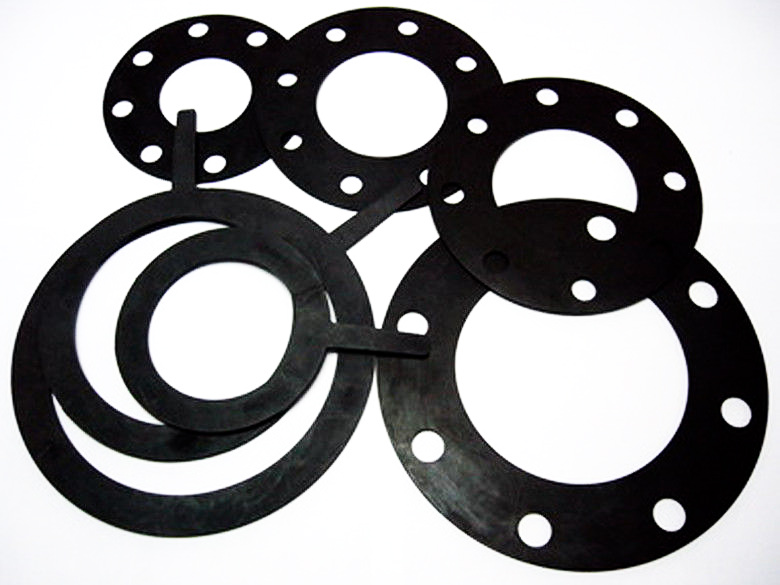

Engineering Guide: Tank Seal

Engineering Insight: The Critical Role of Material Selection in Tank Seal Performance

In precision rubber sealing applications, particularly for tank seals, material selection is not a secondary consideration—it is the foundation of functional reliability. Off-the-shelf sealing solutions are frequently marketed as universal or adaptable, yet they consistently underperform in demanding industrial environments. This failure stems from a fundamental mismatch between generic elastomer properties and the specific chemical, thermal, and mechanical conditions present in tank systems.

Tank seals are exposed to a complex array of stressors: prolonged contact with aggressive media such as fuels, solvents, acids, or hydraulic fluids; fluctuating temperature ranges that can span from sub-zero to over 150°C; and dynamic mechanical loads due to vibration, pressure cycling, and assembly tolerances. Standard elastomers like generic nitrile (NBR) or ethylene propylene diene monomer (EPDM) may appear cost-effective initially, but their limited resistance profiles often lead to premature swelling, cracking, compression set, or extrusion.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection based on application-specific data. For instance, fluorocarbon rubber (FKM) offers exceptional resistance to hydrocarbons and high temperatures, making it ideal for fuel tank applications. However, FKM exhibits poor performance against ketones and steam, necessitating alternative solutions such as perfluoroelastomers (FFKM) or hydrogenated nitrile (HNBR) in mixed-media environments. Similarly, silicone (VMQ) provides excellent low-temperature flexibility but lacks the tensile strength and abrasion resistance required in high-dynamic sealing zones.

The failure of off-the-shelf seals often originates in inadequate chemical compatibility data and oversimplified performance assumptions. A seal that performs adequately during short-term testing may degrade rapidly in continuous service due to synergistic effects—such as heat accelerating fluid absorption—that are not accounted for in generic material guides.

To ensure long-term integrity, material selection must be guided by comprehensive testing under real-world conditions, including immersion aging, compression stress relaxation (CSR), and dynamic sealing performance. At Baoshida, we collaborate with OEMs to analyze fluid composition, operating temperature bands, and expected service life, enabling the formulation of custom compounds that meet exact performance thresholds.

The following table outlines key elastomer properties relevant to tank seal applications:

| Material | Temperature Range (°C) | Fuel/Oil Resistance | Acid/Base Resistance | Compression Set Resistance | Typical Use Case |

|---|---|---|---|---|---|

| NBR | -30 to +100 | Good | Poor | Moderate | Low-cost hydraulic tanks |

| HNBR | -40 to +150 | Excellent | Good | Excellent | High-performance fuel systems |

| FKM | -20 to +200 | Excellent | Excellent | Excellent | Aviation and chemical tanks |

| EPDM | -50 to +150 | Poor | Excellent | Good | Water/glycol systems |

| VMQ | -60 to +180 | Poor | Moderate | Poor | Low-stress environmental seals |

Precision sealing is not a commodity function. It is an engineered solution where molecular structure determines mission success. Relying on generic seals risks system failure, downtime, and safety hazards. At Baoshida, we deliver material intelligence—ensuring every tank seal is as resilient as the system it protects.

Material Specifications

Material Specifications for Precision Tank Seals

Selecting the optimal elastomer for tank sealing applications requires rigorous evaluation of operational parameters including chemical exposure, temperature extremes, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., our engineered rubber compounds undergo stringent ASTM and ISO validation to ensure dimensional stability and leak-free performance in critical fluid containment systems. Material choice directly impacts seal longevity, safety compliance, and total cost of ownership. Below we detail three industry-standard polymers validated for industrial tank sealing: Viton, Nitrile, and Silicone.

Viton fluoroelastomers (FKM) deliver exceptional resistance to aggressive chemicals, fuels, and high temperatures. With a continuous service range of -20°C to +230°C and intermittent tolerance up to 300°C, Viton seals maintain integrity in aerospace hydraulic reservoirs, chemical processing tanks, and semiconductor manufacturing equipment. Its low permeability to hydrocarbons and aromatic solvents prevents swelling-induced failure, while compression set values below 25% after 70 hours at 200°C ensure long-term sealing force retention. Viton formulations meet ASTM D2000 AA734 and ISO 3601 standards for critical fluid systems.

Nitrile rubber (NBR) provides a cost-optimized solution for petroleum-based fluid containment where extreme temperatures are not primary concerns. Operating effectively between -40°C and +120°C, NBR exhibits superior resistance to mineral oils, greases, and aliphatic hydrocarbons. Its abrasion resistance and tensile strength (15-25 MPa) make it ideal for industrial hydraulic tanks, automotive fuel systems, and lubrication reservoirs. Standard NBR compounds achieve compression sets of 15-30% at 100°C after 70 hours, with formulations adjustable to 90 Shore A hardness for dynamic applications per ASTM D2000 BA510.

Silicone rubber (VMQ) excels in applications demanding extreme temperature flexibility and biocompatibility. With an operational range spanning -60°C to +200°C and cryogenic resilience to -100°C, silicone seals perform reliably in pharmaceutical storage tanks, food-grade processing vessels, and cryogenic liquid containment. Its inert composition meets USP Class VI and FDA 21 CFR 177.2600 requirements, while low compression set (20-35% at 200°C) ensures recovery in static sealing interfaces. Silicone’s inherent resistance to ozone and UV degradation supports outdoor tank installations.

Comparative Material Performance Specifications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Shore A Hardness Range | 60-90 | 50-90 | 30-80 |

| Tensile Strength (MPa) | 10-20 | 15-25 | 5-12 |

| Compression Set (%)* | ≤25 | 15-30 | 20-35 |

| Key Chemical Resistance | Fuels, Acids, Aromatics | Oils, Greases, Aliphatics | Water, Oxygen, Ozone |

| Primary ASTM Standard | D2000 AA734 | D2000 BA510 | D2000 CA220 |

*Tested per ASTM D395 Method B at specified temperature for 70 hours.

Material selection must align with fluid compatibility charts and dynamic/static load requirements. Suzhou Baoshida Trading Co., Ltd. provides OEM-specific compound customization including peroxide-cured Viton for low-temperature flexibility or hydrogenated NBR (HNBR) for enhanced thermal stability. All formulations undergo batch traceability per IATF 16949 protocols to guarantee consistent sealing performance across production runs. Consult our engineering team for application-specific validation testing.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in manufacturing high-performance tank seals for demanding industrial applications. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced sealing solutions tailored to the exacting requirements of OEM partners across automotive, industrial equipment, and fluid handling sectors.

Our mould engineering team brings over 60 combined years of experience in precision tool design, finite element analysis (FEA), and rapid prototyping. Each engineer is proficient in advanced CAD/CAM platforms, including SolidWorks, UG NX, and AutoCAD, enabling precise 3D modeling and tolerance optimization down to ±0.05 mm. This level of dimensional accuracy ensures consistent part replication and seamless integration into complex tank assembly lines. We utilize in-house CNC machining and EDM processing to produce high-cavity, multi-material moulds capable of supporting high-volume production runs with minimal cycle time variance.

Complementing our mould design expertise, our two rubber formulation specialists focus on material science innovation to meet specific performance criteria such as chemical resistance, thermal stability, and compression set. With access to a fully equipped polymer laboratory, they develop custom EPDM, NBR, FKM, and silicone compounds engineered for prolonged service life under extreme pressure and temperature conditions. Each formulation undergoes rigorous testing for tensile strength, elongation, hardness (Shore A), and fluid immersion resistance to ensure compliance with ISO 3601, SAE J514, and ASTM D2000 standards.

Our integrated engineering workflow enables concurrent development of moulds and rubber compounds, reducing time-to-market by up to 30% compared to conventional sequential processes. This synergy is critical in OEM environments where design validation, durability testing, and production scalability must align seamlessly.

Suzhou Baoshida supports full turnkey OEM services, including design for manufacturability (DFM) reviews, IP-protected tooling, batch traceability, and PPAP documentation. We maintain long-term partnerships with Tier 1 suppliers by consistently delivering high-reliability seals that minimize leakage risk and extend maintenance intervals.

Material and Performance Specifications

| Property | EPDM | NBR | FKM | Silicone |

|---|---|---|---|---|

| Temperature Range (°C) | -50 to +150 | -30 to +120 | -20 to +200 | -60 to +200 |

| Hardness Range (Shore A) | 50–90 | 55–95 | 60–85 | 40–80 |

| Tensile Strength (MPa) | ≥12 | ≥15 | ≥10 | ≥7 |

| Fluid Resistance | Excellent (water, steam, alkalis) | Excellent (oils, fuels) | Outstanding (acids, oils, solvents) | Good (water, ozone) |

| Compression Set (24h, 100°C) | ≤25% | ≤30% | ≤20% | ≤25% |

Through a fusion of advanced tooling, scientific material development, and OEM-centric collaboration, Suzhou Baoshida ensures every tank seal meets the highest benchmarks in reliability and performance.

Customization Process

Precision Tank Seal Customization Process

Precision tank seal customization begins with rigorous drawing analysis to translate client specifications into manufacturable designs. Our engineering team evaluates dimensional tolerances per ISO 3302-1, surface finish requirements, and geometric constraints against fluid dynamics and pressure differentials inherent to tank applications. Critical parameters such as groove dimensions, compression ratios, and potential extrusion gaps are validated using CAD cross-section simulation. This phase identifies feasibility risks early, ensuring the design accommodates thermal expansion, chemical swelling, and dynamic movement without compromising sealing integrity.

Material formulation follows strict performance criteria derived from the operating environment. We select base polymers and additives to achieve target resistance against specific chemicals, temperatures, and pressures. For instance, fuel storage tanks demand FKM compounds with fluorine content >66% for hydrocarbon resistance, while water treatment applications may require EPDM with high ozone stability. Our lab adjusts cure systems, filler ratios, and plasticizers to optimize compression set (per ASTM D395), tensile strength, and low-temperature flexibility. All formulations comply with FDA 21 CFR 177.2600 or NSF/ANSI 61 where applicable.

Prototyping validates both material performance and manufacturability. We produce 5–10 samples via precision molding under controlled conditions matching mass production parameters. Each prototype undergoes accelerated life testing: 72-hour immersion in target media at maximum operating temperature, compression set measurement after 24 hours at 100°C, and burst pressure verification. Dimensional conformity is confirmed via CMM inspection against the original drawing. Client feedback on prototype performance triggers iterative refinements until all KPIs are met.

Mass production commences only after formal client sign-off on prototypes. We implement SPC monitoring for critical dimensions (e.g., cross-section diameter ±0.05mm) and material consistency using real-time rheometer data. Every production batch undergoes 100% visual inspection and抽样 testing per AQL 1.0 for hardness, tensile properties, and fluid resistance. Traceability is maintained via laser-etched batch codes linked to raw material certificates and process logs. This structured workflow ensures seamless transition from prototype to volume manufacturing with zero compromise on reliability.

Material Selection Guide for Tank Seals

| Material Grade | Temperature Range | Key Fluid Resistance | Compression Set (22h/100°C) |

|---|---|---|---|

| NBR 70 Shore A | -30°C to +120°C | Oils, water, alcohols | ≤25% |

| FKM 75 Shore A | -20°C to +230°C | Fuels, acids, solvents | ≤18% |

| EPDM 60 Shore A | -50°C to +150°C | Steam, alkalis, brake fluid | ≤22% |

| FFKM 80 Shore A | -15°C to +327°C | Aggressive chemicals, plasma | ≤15% |

This process eliminates guesswork through data-driven engineering, delivering tank seals that prevent costly leaks and downtime in critical fluid containment systems.

Contact Engineering Team

For mission-critical applications in industrial systems, the performance of a tank seal is not merely a matter of containment—it directly influences system reliability, safety, and operational longevity. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber seals designed to meet the stringent demands of modern manufacturing, chemical processing, automotive, and marine industries. Our expertise lies in formulating elastomeric compounds that deliver optimal resistance to pressure, temperature extremes, and aggressive media such as oils, fuels, and solvents.

When selecting a tank seal, material compatibility, dimensional accuracy, and long-term resilience under dynamic or static conditions are paramount. Off-the-shelf solutions often fail to address the unique sealing challenges presented by custom tanks, high-pressure vessels, or corrosive environments. This is where Suzhou Baoshida’s engineering-led approach makes the critical difference. We do not manufacture generic seals—we develop tailored sealing solutions grounded in material science, application analysis, and rigorous quality control.

Our team works directly with OEMs and industrial clients to evaluate operational parameters, including fluid type, operating temperature range, compression set requirements, and expected service life. Based on this data, we recommend or develop custom formulations using materials such as Nitrile (NBR), Fluorocarbon (FKM/Viton®), Ethylene Propylene Diene Monomer (EPDM), Silicone (VMQ), or specialty blends engineered for extreme environments. Each seal is manufactured to exacting tolerances, ensuring repeatable performance across batches and compliance with international standards.

The following table outlines typical material properties for common elastomers used in tank sealing applications:

| Material | Temperature Range (°C) | Hardness (Shore A) | Fluid Resistance | Key Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (+120 short-term) | 50–90 | Excellent for oils, fuels, aliphatic hydrocarbons | Hydraulic tanks, fuel systems |

| FKM (Viton®) | -20 to +200 (+250 short-term) | 60–90 | Outstanding for oils, fuels, aromatics, acids | Chemical tanks, aerospace |

| EPDM | -50 to +150 | 50–80 | Excellent for water, steam, alkalis, ketones | Water treatment, steam vessels |

| Silicone (VMQ) | -60 to +200 | 40–80 | Good for water, oxygen, ozone; poor in oils | Sanitary tanks, medical equipment |

All compounds are subject to in-house testing for compression set, tensile strength, elongation, and volume swell in target media. We support low-volume prototyping and high-volume production with full traceability and documentation.

For technical consultation or custom seal development, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. He leads client engineering engagement and ensures seamless integration of our sealing solutions into your manufacturing or assembly process. Reach out directly via email at [email protected] to discuss material selection, sample requests, or application-specific testing protocols. Our team responds to all inquiries within 24 business hours and supports English and Chinese communication. Partner with Suzhou Baoshida for sealing performance you can engineer with confidence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).