Technical Contents

Engineering Guide: Foam Sealing Strip

Engineering Insight: The Critical Role of Material Selection in Foam Sealing Strip Performance

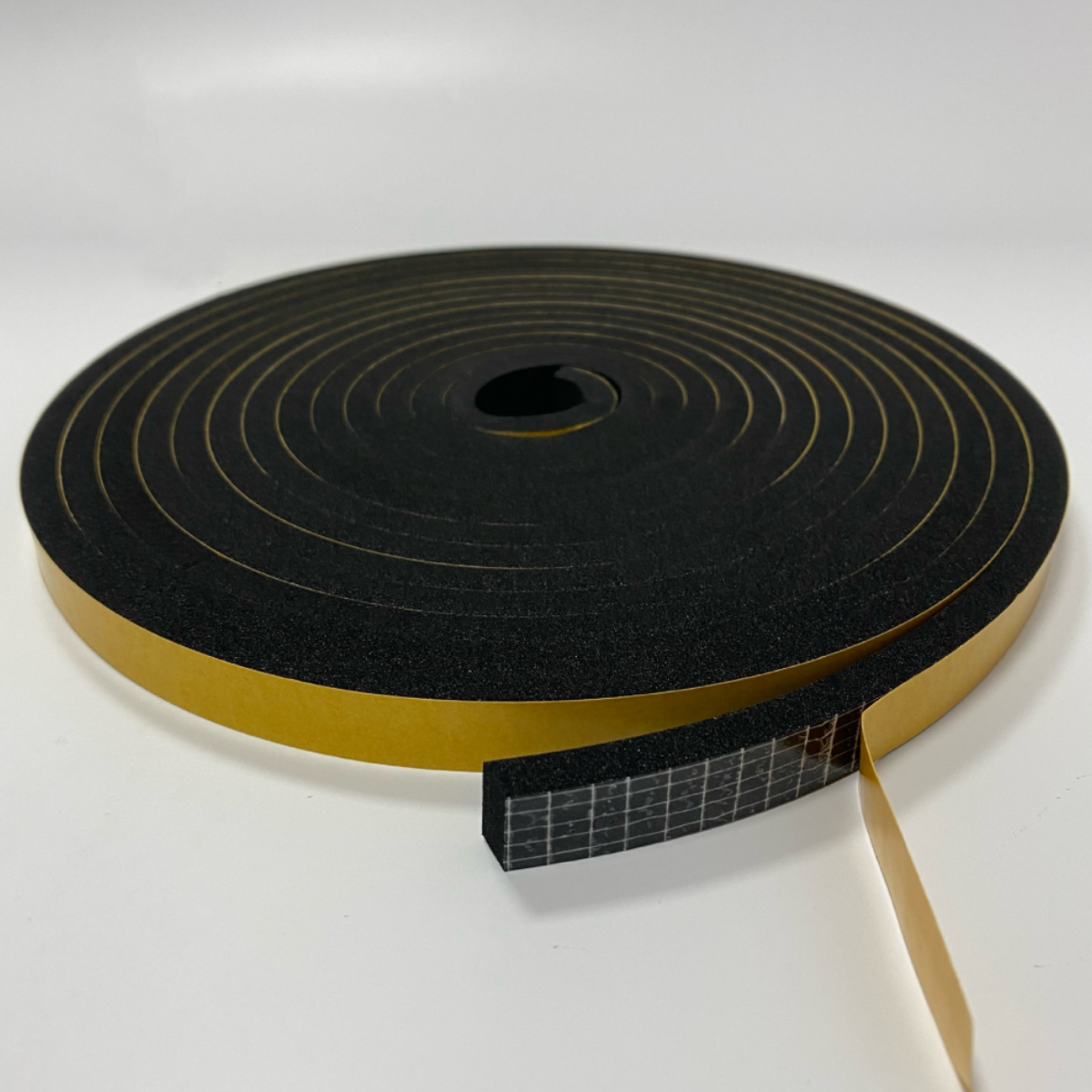

In precision rubber sealing applications, foam sealing strips are often perceived as simple, commodity-grade components. However, this perception leads to a critical oversight—material selection is the determining factor in long-term performance, environmental resilience, and system integrity. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered solutions over off-the-shelf alternatives, particularly because generic foam strips frequently fail under real-world operational stressors such as thermal cycling, chemical exposure, compression set, and UV degradation.

Foam sealing strips function not merely as gap fillers but as dynamic barriers against moisture, dust, vibration, and acoustic transmission. Their cellular structure provides compressibility and recovery, but these properties are highly dependent on base polymer chemistry. Common off-the-shelf products typically utilize low-cost EVA or polyethylene foams, which exhibit poor resistance to elevated temperatures, ozone, and weathering. In industrial or automotive environments, such materials degrade rapidly, leading to premature seal failure, leakage, and increased maintenance costs.

In contrast, precision-engineered foam sealing strips leverage advanced elastomeric compounds such as EPDM, silicone (VMQ), or chloroprene (CR). These materials offer superior resilience across extreme conditions. For instance, EPDM foam maintains integrity from -50°C to +150°C and demonstrates excellent resistance to steam, water, and UV radiation—making it ideal for outdoor enclosures and HVAC systems. Silicone foam, while higher in cost, delivers unmatched thermal stability up to 200°C and is essential in aerospace and high-temperature electronics. Chloroprene balances oil resistance and mechanical durability, serving well in transportation and industrial machinery.

The failure of generic solutions often stems from mismatched material properties and application demands. A foam strip selected solely for initial softness or low price may exhibit rapid compression set, losing sealing force within months. Moreover, inadequate cell structure uniformity in commodity foams results in inconsistent sealing pressure and potential leak paths.

At Baoshida, we deploy a materials-first engineering approach, aligning polymer selection, density, hardness, and cross-linking technology with the operational environment. This ensures optimal compression deflection, recovery rate, and service life.

The following table outlines key material properties for common foam sealing strip polymers:

| Material | Temperature Range (°C) | Compression Set (22h, 70°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|---|

| EPDM Foam | -50 to +150 | <30% | UV, ozone, water, steam | Outdoor enclosures, HVAC, solar panels |

| Silicone (VMQ) Foam | -60 to +200 | <25% | Extreme heat, oxidation, weathering | Aerospace, medical devices, high-temp electronics |

| Chloroprene (CR) Foam | -40 to +120 | <35% | Oils, solvents, flame | Industrial machinery, automotive under-hood |

| EVA Foam | -30 to +80 | >50% | Impact, moisture (short-term) | Packaging, consumer goods, temporary seals |

Material selection is not a compromise between cost and performance—it is a precision engineering decision. Off-the-shelf foam strips may satisfy initial fitment, but only purpose-formulated compounds ensure lasting reliability. Baoshida’s expertise lies in transforming application data into optimized sealing solutions, eliminating the guesswork and reducing total cost of ownership.

Material Specifications

Material Specifications for Precision Foam Sealing Strips

Selecting the optimal elastomer for foam sealing strips requires rigorous evaluation of operational parameters including temperature extremes, chemical exposure, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we engineer foam sealing solutions to ASTM D2000 and ISO 3302 standards, ensuring dimensional stability and functional reliability across critical industrial applications. Material choice directly impacts compression set resistance, fluid compatibility, and service life—factors non-negotiable in automotive, aerospace, and energy sectors.

Viton (FKM) foam strips deliver exceptional performance in aggressive chemical environments. With a continuous service temperature range of -20°C to +230°C, Viton maintains integrity against jet fuels, hydraulic fluids, and aromatic hydrocarbons. Its low compression set (≤20% per ASTM D395 at 200°C/70 hours) ensures long-term sealing force retention, critical for dynamic gasketing in turbine engines. However, Viton exhibits limited flexibility below -15°C and higher material costs compared to alternatives.

Nitrile (NBR) foam remains the industry standard for cost-sensitive oil and fuel applications. Operating effectively from -30°C to +120°C (extended to +150°C with peroxide curing), NBR demonstrates excellent resistance to aliphatic hydrocarbons, lubricants, and water-based fluids. Its balanced hardness (40–90 Shore A) facilitates compression sealing in automotive fuel systems and hydraulic assemblies. Key limitations include susceptibility to ozone degradation and swelling in polar solvents like acetone or brake fluid.

Silicone (VMQ) foam excels in extreme temperature scenarios where thermal stability is paramount. Functioning reliably from -60°C to +250°C, silicone retains elasticity in cryogenic conditions and resists thermal aging in HVAC and semiconductor manufacturing. It shows superior resistance to water, steam, and UV exposure but exhibits poor tensile strength and high toluene swell (≥50% per ASTM D471), restricting use in solvent-rich environments.

The comparative analysis below details critical specifications for informed material selection:

| Material | Temperature Range (°C) | Typical Hardness (Shore A) | Key Fluid Resistance | Compression Set (ASTM D395) |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | 50–90 | Jet fuels, acids, hydraulic fluids | ≤20% @ 200°C/70h |

| Nitrile (NBR) | -30 to +120 (+150°C*) | 40–90 | Aliphatic oils, water, lubricants | ≤35% @ 100°C/22h |

| Silicone (VMQ) | -60 to +250 | 30–80 | Water, steam, ozone, UV | ≤30% @ 200°C/70h |

*Peroxide-cured variants only. Toluene swell for NBR: 15–30%; Silicone: ≥50%; Viton: ≤15%. All values represent standard compound ranges; custom formulations available per OEM requirements.

Material selection must align with fluid compatibility charts and dynamic stress testing protocols specific to the application. Suzhou Baoshida Trading Co., Ltd. provides full material traceability and application-specific validation data sheets compliant with IATF 16949. Consult our engineering team to optimize foam cell structure density and cross-section geometry for your sealing challenge—precision begins with polymer science.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in precision rubber seals is anchored in a dedicated team of highly trained specialists, including five experienced mould engineers and two advanced rubber formula engineers. This technical backbone enables us to deliver high-performance foam sealing strips tailored to the exacting demands of industrial OEMs across automotive, electronics, construction, and appliance sectors. Our integrated approach ensures that both material formulation and mould design are optimized in parallel, reducing development time and enhancing product consistency.

Our two rubber formula engineers possess deep expertise in polymer chemistry and elastomer compounding. They specialize in developing proprietary foam rubber formulations based on EPDM, silicone, neoprene, and NBR/PVC blends, engineered for specific performance criteria such as compression set resistance, thermal stability, UV and ozone resistance, and low outgassing. Each formulation is rigorously tested under simulated application conditions to ensure long-term reliability. This in-house formulation capability allows us to customize density, hardness (ranging from 20 to 80 Shore A), cell structure, and adhesive properties—critical parameters for achieving optimal sealing performance in dynamic environments.

Complementing our material science expertise, our five mould engineers focus on precision tooling design and process optimization. They utilize advanced CAD/CAM software and finite element analysis (FEA) to develop high-tolerance moulds that support complex cross-sectional profiles, tight dimensional control, and consistent cellular structure in the final foam product. Our engineers work closely with clients during the prototyping phase to refine geometry, draft angles, and parting lines, ensuring manufacturability and minimizing waste during high-volume production.

We operate a fully integrated OEM service platform, supporting customers from concept to mass production. Our engineering team conducts Design for Manufacturability (DFM) reviews, tolerance stack-up analysis, and rapid prototyping using in-house extrusion and continuous vulcanization (CV) lines. This allows us to deliver functional samples within 7–10 days, accelerating time-to-market for our partners. All developments are documented under strict IP protection protocols, ensuring confidentiality and traceability.

Our production processes adhere to ISO 9001 standards, with real-time monitoring of critical parameters such as temperature profile, line speed, and cure time to maintain consistency across batches. We also perform in-line and final quality checks using calibrated instruments for dimensional accuracy, adhesion strength, and compression deflection.

The combination of advanced material formulation, precision mould engineering, and scalable OEM manufacturing makes Suzhou Baoshida a trusted partner for technically demanding foam sealing applications.

Typical Foam Sealing Strip Specifications

| Parameter | Range/Value |

|---|---|

| Material Options | EPDM, Silicone, Neoprene, NBR/PVC |

| Hardness (Shore A) | 20 – 80 |

| Density (kg/m³) | 300 – 800 |

| Operating Temperature | -40°C to +150°C (up to +300°C for silicone) |

| Linear Length Tolerance | ±1.5 mm/m |

| Cross-Section Tolerance | ±0.1 mm (precision), ±0.3 mm (standard) |

| Adhesion Strength | 15 – 40 N/25mm (peel test, 180°) |

| Compression Set (22h, 70°C) | ≤25% |

| Production Length | Up to 100 m per roll |

Customization Process

Customization Process for Precision Foam Sealing Strips

Suzhou Baoshida Trading Co., Ltd. implements a rigorously controlled customization workflow for foam sealing strips, ensuring dimensional accuracy, material resilience, and functional reliability under demanding industrial conditions. Our four-phase methodology begins with Drawing Analysis, where engineering teams dissect client CAD files and technical specifications. Critical parameters such as cross-sectional geometry, tolerance bands per ISO 2768-mK, and surface finish requirements are validated against material behavior models. We assess compatibility with mating components, environmental exposure (e.g., fluid immersion, UV radiation), and assembly forces to preempt design flaws. Non-conformities trigger collaborative redesign sessions with the client, leveraging GD&T expertise to optimize manufacturability without compromising sealing integrity.

Subsequent Formulation leverages Suzhou Baoshida’s proprietary rubber compound database, aligning base polymers (EPDM, silicone, or NBR) with performance mandates. Key variables include closed-cell microstructure density, compression set resistance, and thermal stability. For instance, automotive under-hood seals demand formulations with -40°C to +150°C operational ranges and <30% compression set at 70°C/24h per ASTM D395. Our lab synthesizes trial batches, adjusting vulcanizing agents, foaming agents, and fillers to achieve target hardness (Shore A 15–60), density gradients, and chemical resistance. Each compound undergoes accelerated aging and fluid compatibility testing against OEM-specified media (e.g., brake fluid, coolant).

Prototyping employs precision extrusion and continuous vulcanization lines to produce functional samples within 10–15 business days. Samples undergo dimensional verification via CMM (Coordinate Measuring Machine) against original drawings, with tolerances held to ±0.1mm for critical features. Physical validation includes compression force-deflection (CFD) profiling, leak testing per SAE J1773, and dynamic fatigue cycling. Client feedback on fit, function, and installation ergonomics drives iterative refinements until all KPIs are met, with full material traceability maintained via batch-coded documentation.

Mass Production commences only after formal client sign-off on prototypes. Suzhou Baoshida’s ISO/TS 16949-certified facility deploys statistical process control (SPC) on extrusion speed, die temperature, and curing profiles to ensure batch consistency. Every production run includes in-process checks for density uniformity, cell structure homogeneity (via microscopy), and adhesion strength. Final inspection packages comprise material certificates, CMM reports, and compression set data. Full traceability—from raw material lot numbers to operator IDs—is embedded in our ERP system, enabling rapid root-cause analysis if required.

Critical Foam Sealing Strip Specifications

| Parameter | Unit | Typical Range | Application Impact |

|---|---|---|---|

| Density | g/cm³ | 0.4–0.8 | Determines weight, compressibility, and cost |

| Hardness (Shore A) | Points | 15–60 | Affects sealing force and recovery speed |

| Compression Set (70°C/24h) | % | <25–35 | Critical for long-term sealing retention |

| Temperature Range | °C | -55 to +200 | Defines operational envelope |

| Tensile Strength | MPa | 0.8–2.5 | Influences tear resistance during installation |

This structured approach guarantees that Suzhou Baoshida’s foam sealing strips meet exacting OEM standards while minimizing time-to-market. Our commitment to material science precision and process control ensures zero-defect delivery across automotive, aerospace, and industrial equipment applications.

Contact Engineering Team

For manufacturers and engineering teams seeking high-performance foam sealing strip solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision rubber components. Specializing in custom-engineered sealing systems, we deliver advanced material science and manufacturing expertise to meet the demanding requirements of automotive, electronics, construction, and industrial equipment sectors. Our foam sealing strips are designed to provide consistent compression set resistance, superior weatherability, and long-term durability under dynamic environmental conditions.

At the core of our offering is a deep understanding of elastomer behavior and application-specific performance. Whether you require EPDM, silicone, neoprene, or custom-blended compounds, our formulations are optimized for density, cell structure, and sealing force to ensure reliable performance across temperature extremes and mechanical stress. Every foam sealing strip is manufactured under strict quality control protocols, adhering to international standards including ISO 9001 and IATF 16949, ensuring traceability, consistency, and compliance.

Our engineering team collaborates directly with OEMs and Tier suppliers to develop sealing solutions that address real-world challenges—such as vibration damping, moisture ingress, thermal insulation, and acoustic attenuation. From prototype development to full-scale production, we support rapid turnaround and scalable manufacturing through advanced die-cutting, splicing, and automated extrusion technologies.

To ensure optimal integration into your assembly process, we provide comprehensive technical documentation, material certifications, and on-site support when required. Our global supply chain infrastructure enables just-in-time delivery to manufacturing hubs across Asia, Europe, and North America, minimizing lead times and inventory overhead.

For immediate technical consultation or custom quotation, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in rubber formulation and industrial sealing applications, Mr. Boyce serves as the primary technical liaison for engineering teams requiring precision foam sealing solutions. He will assist in material selection, design validation, and production planning to ensure your project meets performance, timeline, and cost targets.

Below are key technical specifications commonly requested for our standard and custom foam sealing strips:

| Property | EPDM Foam | Silicone Foam | Neoprene Foam | Units |

|---|---|---|---|---|

| Density | 0.45 – 0.65 | 0.35 – 0.50 | 0.50 – 0.70 | g/cm³ |

| Hardness (Shore A) | 15 – 30 | 20 – 40 | 25 – 35 | Shore A |

| Tensile Strength | ≥0.8 | ≥0.6 | ≥0.7 | MPa |

| Elongation at Break | ≥150% | ≥120% | ≥130% | % |

| Compression Set (22h, 70°C) | ≤30% | ≤25% | ≤35% | % |

| Temperature Range | -40°C to +130°C | -60°C to +200°C | -30°C to +100°C | °C |

| Closed Cell Content | ≥90% | ≥85% | ≥88% | % |

Reach out to Mr. Boyce directly at [email protected] to initiate a technical review of your sealing application. Include detailed requirements such as cross-sectional profile, operating environment, mating surfaces, and performance criteria for a tailored solution proposal.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).