Technical Contents

Engineering Guide: Brush Type Weather Stripping

Engineering Insight: Material Science as the Foundation of Brush Type Weather Stripping Performance

Material selection constitutes the most critical engineering decision in brush type weather stripping design, directly dictating field longevity and functional reliability. Off-the-shelf solutions frequently fail because they utilize generic elastomer compounds optimized for cost or broad applicability, not the specific, often extreme, operational demands of industrial enclosures, transportation systems, or specialized equipment. These standard formulations lack the tailored resistance to simultaneous environmental stressors encountered in real-world applications, leading to premature degradation and system compromise.

Common failure modes stem directly from material inadequacy. Standard EPDM formulations, while cost-effective for mild environments, exhibit catastrophic compression set under sustained high temperatures (>120°C) common near engines or industrial processes, causing permanent loss of sealing force. Conversely, inadequate low-temperature flexibility in generic compounds results in brittle bristle fracture below -40°C, eliminating wind and particle exclusion. Crucially, resistance to specific chemical exposure—such as hydraulic fluids, brake fluids, or industrial solvents—is rarely addressed in off-the-shelf products. Hydrocarbon exposure induces severe swelling and chain scission in non-resistant compounds, rapidly degrading bristle integrity and mounting adhesion. Furthermore, standard materials often lack sufficient ozone and UV resistance for outdoor exposure, accelerating surface cracking and embrittlement. These failures manifest as air/water infiltration, increased noise transmission, accelerated component corrosion, and ultimately, costly warranty claims or unplanned downtime for the OEM.

Suzhou Baoshida Trading Co., Ltd. emphasizes that effective brush seal engineering requires precise elastomer formulation aligned with the application’s unique stress profile. The following table details key performance differentiators between standard and engineered compounds:

| Property | Standard Off-the-Shelf EPDM | Engineered High-Performance Compound | Critical Impact of Deficiency |

|---|---|---|---|

| Continuous Use Temp | -40°C to +120°C | -60°C to +180°C | Bristle fracture (low temp); permanent set (high temp) |

| Ozone Resistance (50 pphm) | Moderate (Cracking @ 50h) | Excellent (No cracking @ 200h) | Premature surface cracking, loss of flexibility |

| Compression Set (24h/125°C) | >45% | <25% | Permanent loss of sealing force, gap formation |

| Fuel B (ASTM #3) Swell | >80% | <30% | Bristle distortion, mounting failure, seal loss |

| Abrasion Resistance | Standard | Enhanced (Custom filler systems) | Accelerated bristle wear, reduced service life |

Generic solutions ignore the synergistic effect of multiple stressors—simultaneous thermal cycling, chemical mist, vibration, and dynamic compression. Suzhou Baoshida’s approach leverages advanced compounding techniques, incorporating specialized polymers, reinforced filler systems, and custom antioxidant packages to create bristle and carrier compounds that maintain resilience, sealing force, and chemical integrity across the defined operational envelope. This precision engineering mitigates the root causes of field failure inherent in commoditized products. Collaborating with an OEM-focused partner during the specification phase ensures material properties are not merely adequate, but precisely calibrated to deliver the required service life and performance under actual operating conditions, transforming the brush seal from a potential failure point into a reliable, long-term asset. The initial investment in engineered material directly translates to reduced lifecycle costs and enhanced product reputation.

Material Specifications

Material selection is a critical factor in the performance and longevity of brush type weather stripping used in industrial and commercial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions engineered to meet the demanding requirements of sealing systems across diverse environments. For brush type weather stripping—commonly used in doors, enclosures, and transportation systems—the choice of elastomer directly impacts resistance to temperature extremes, chemical exposure, compression set, and abrasion. Our primary materials of selection include Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on the operational conditions.

Viton is a fluorocarbon-based rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for applications in the automotive, aerospace, and petrochemical industries where exposure to harsh substances is routine. Viton brush seals maintain integrity between -20°C and +230°C, offering long-term stability under continuous thermal stress. However, its higher cost and lower flexibility at low temperatures may limit use in general-purpose applications.

Nitrile rubber, or Buna-N, is widely used due to its excellent resistance to petroleum-based oils, fuels, and hydraulic fluids. It offers good abrasion resistance and mechanical strength, making it a cost-effective choice for industrial and automotive sealing applications. Nitrile performs reliably in temperatures ranging from -40°C to +100°C, with some formulations extending to +125°C for short durations. While it lacks the chemical resistance of Viton, Nitrile provides a balanced performance profile for environments involving frequent contact with lubricants and greases.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to +200°C. It demonstrates superior resistance to ozone, UV radiation, and weathering, making it ideal for outdoor or high-exposure installations. Silicone is also highly flexible and maintains seal integrity under repeated compression cycles. However, it has relatively poor resistance to petroleum-based fluids and lower tensile strength compared to Nitrile and Viton. Its use is best suited for non-lubricant environments where thermal stability and aging resistance are paramount.

The following table compares key physical and chemical properties of these materials to aid in material selection for brush type weather stripping:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +230°C | -40°C to +100°C | -60°C to +200°C |

| Oil & Fuel Resistance | Excellent | Very Good | Poor |

| Chemical Resistance | Excellent | Good | Moderate |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Very Good | Good | Very Good |

| Abrasion Resistance | Good | Very Good | Fair |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Typical Applications | Aerospace, Oil & Gas | Automotive, Machinery | Outdoor Enclosures, HVAC |

Selecting the appropriate elastomer ensures optimal performance, durability, and cost-efficiency. Suzhou Baoshida Trading Co., Ltd. provides customized brush type weather stripping solutions with precise material matching to application demands.

Manufacturing Capabilities

Engineering Excellence in Brush Type Weather Stripping Development

Suzhou Baoshida Trading Co., Ltd. leverages deep-rooted expertise in rubber science and precision manufacturing to deliver engineered brush type weather stripping solutions for demanding industrial applications. Our core strength resides in an integrated engineering team comprising five dedicated mold design specialists and two advanced rubber formulation scientists. This dual-discipline approach ensures every component meets exacting performance, durability, and cost-efficiency targets from conceptualization through mass production.

Our rubber formula engineers possess mastery in elastomer chemistry, specializing in custom compound development for brush seal filaments and carrier profiles. We systematically optimize molecular architecture to achieve critical properties: ozone resistance for outdoor exposure, low-temperature flexibility down to -50°C, and precise Shore A hardness control (40–80A) to balance sealing force and brush recovery. Rigorous accelerated aging protocols per ASTM D573 and ISO 188 validate long-term resilience against UV, moisture, and thermal cycling. Material databases spanning 200+ proprietary formulations enable rapid tailoring for chemical resistance, flame retardancy (UL 94 HB/V-0), or low-friction coefficients—eliminating trial-and-error in client-specific scenarios.

Complementing material science, our mold engineering cohort utilizes advanced CAD/CAM (SolidWorks, Moldflow) to design high-cavitation, multi-plate tooling with micron-level tolerances. Focus areas include optimizing filament insertion geometry for consistent bristle density, minimizing flash in critical sealing zones, and ensuring thermal uniformity during vulcanization. Finite element analysis predicts flow dynamics and part warpage, reducing prototyping iterations by 40%. All molds undergo stringent first-article inspection per ASME Y14.5 GD&T standards, guaranteeing dimensional repeatability within ±0.05mm.

Material Performance Comparison

| Property | Standard EPDM Compound | Custom OEM Formulation (Example) | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 55 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 10.0 | ≥ 14.5 | ASTM D412 |

| Compression Set (%) | ≤ 25 (70°C, 22h) | ≤ 18 (70°C, 22h) | ASTM D395 Method B |

| Abrasion Loss (mm³) | ≤ 120 | ≤ 85 | ASTM D5963 |

| Low Temp Flexibility | -40°C | -55°C | ASTM D1329 |

As an OEM partner, we implement a structured co-engineering workflow: initial RFQ analysis within 48 hours, collaborative DFM feedback leveraging our 15-year automotive and appliance sector experience, and rapid prototyping via in-house 3D printing and small-batch molding. Our PPAP-compliant process includes material traceability to batch level, SPC-controlled production, and full validation reporting. This end-to-end capability reduces time-to-market by 30% while ensuring zero non-conformities in high-volume runs exceeding 500k units annually. Clients benefit from reduced NRE costs, IP protection, and seamless scalability—all underpinned by ISO 9001-certified quality systems. Suzhou Baoshida transforms weather stripping from a commodity component into a precision-engineered system advantage.

Customization Process

Customization Process for Brush Type Weather Stripping

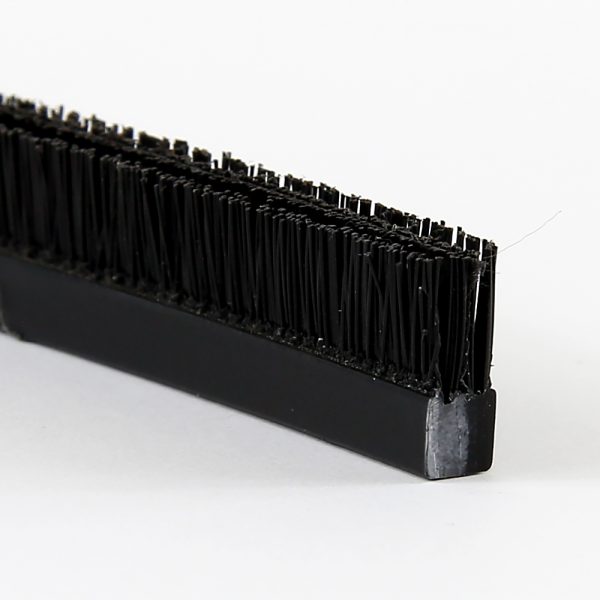

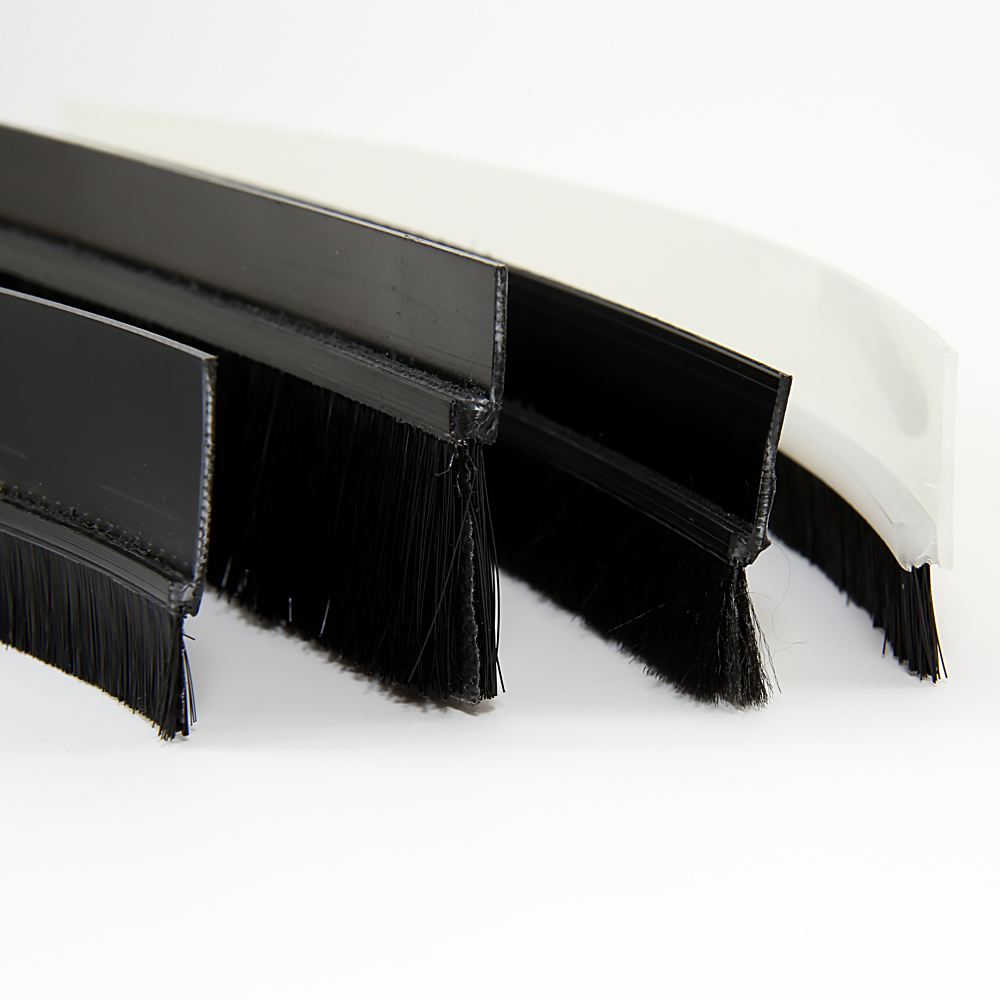

At Suzhou Baoshida Trading Co., Ltd., our approach to customizing brush type weather stripping is rooted in precision engineering and material science. Designed for demanding industrial and automotive applications, our brush seals combine resilient rubber profiles with high-performance filament arrays to deliver superior sealing against dust, moisture, and airflow. The customization process follows four critical stages: Drawing Analysis, Formulation, Prototyping, and Mass Production. Each step ensures the final product meets exact OEM specifications and environmental performance standards.

The process begins with Drawing Analysis, where engineering teams evaluate customer-provided technical drawings or 3D models. Key parameters such as cross-sectional profile dimensions, mounting base geometry, filament density, bristle length, and installation clearance are assessed. Tolerance analysis is conducted to ensure compatibility with mating components under operational stress and thermal cycling. This stage also includes material clearance verification, especially for applications involving tight space constraints or dynamic movement.

Following drawing validation, the Formulation phase determines the optimal rubber compound and filament selection. Our in-house rubber chemists formulate EPDM, silicone, or chloroprene-based compounds tailored to specific resistance requirements—whether UV stability, ozone resistance, low-temperature flexibility, or flame retardancy. Filament options include nylon 6, PET, or polypropylene, selected based on abrasion resistance, stiffness, and chemical exposure. Shore hardness is calibrated between 40 and 80 A to balance sealing force and compression set performance. All materials comply with international standards such as RoHS, REACH, and UL94.

Once material specifications are confirmed, we proceed to Prototyping. Using precision extrusion and automated tufting equipment, functional prototypes are produced within 7–10 days. These samples undergo rigorous testing, including compression deflection analysis, air leakage assessment, and cycle durability testing (up to 100,000 operations). Prototypes are shipped to the client for fitment and function validation, with detailed test reports provided for review.

Upon approval, the project transitions into Mass Production. Our facility supports high-volume output with strict in-line quality control, including automated vision inspection and batch traceability. Production runs are managed under ISO 9001 protocols, ensuring consistency across millions of linear meters. Packaging and labeling are customized per client logistics requirements, with JIT delivery options available for global supply chains.

Below is a summary of typical performance specifications for custom brush type weather stripping:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Base Material | EPDM, CR, Silicone | ASTM D2000 |

| Filament Material | Nylon 6, PET, Polypropylene | ISO 5076 |

| Shore Hardness (Base) | 40–80 A | ASTM D2240 |

| Operating Temperature | -40°C to +150°C (varies by compound) | ISO 188 |

| Filament Density | 8–20 tufts per inch | Internal Specification |

| Compression Force | 1.5–5.0 N/cm | GB/T 20627 |

| Flame Resistance | UL94 V-0, V-1 (optional) | UL 94 |

This systematic customization process ensures that every brush type weather strip we manufacture delivers engineered reliability, long-term durability, and seamless integration into the client’s assembly line.

Contact Engineering Team

Precision Brush Type Weather Stripping Solutions: Technical Engagement Pathway

Suzhou Baoshida Trading Co., Ltd. delivers engineered brush type weather stripping for critical industrial sealing applications where standard elastomeric profiles fail. Our formulations address dynamic gap sealing challenges in aerospace, rail transit, heavy machinery, and cleanroom environments—resisting abrasion, extreme temperatures, and chemical exposure while maintaining consistent compression recovery. Unlike generic alternatives, our brush seals integrate precisely calibrated filament density, frame rigidity, and substrate adhesion to eliminate airflow leakage, particulate ingress, and acoustic transmission in high-vibration operational cycles. Material science drives our design: proprietary thermoplastic polyurethane (TPU) and silicone filaments are compounded for 300% elongation at break (ASTM D412) and 85 Shore A hardness, ensuring resilience against repeated deflection without permanent set.

For OEM integration, we prioritize dimensional accuracy and process compatibility. All profiles undergo laser micrometry verification per ISO 2768-mK tolerances, with custom cross-sections developed within 15 business days using our in-house CAD/CAM prototyping suite. Our technical team collaborates directly with your engineering department to validate sealing performance under simulated service conditions—including wind tunnel testing at 250 Pa differential pressure and thermal cycling from -60°C to +150°C. This eliminates field failure risks during equipment commissioning. The table below summarizes core specifications for our standard industrial brush seal series:

| Parameter | Suzhou Baoshida Standard | Industrial Significance |

|---|---|---|

| Filament Material | TPU or Silicone | Chemical resistance to oils, UV, ozone |

| Temperature Range | -60°C to +150°C | Stable performance in Arctic to desert ops |

| Frame Material | Anodized Aluminum 6063 | Lightweight corrosion resistance |

| Compression Deflection | 1.2 N/mm at 50% strain | Balanced sealing force without binding |

| Adhesion Strength | ≥6 kN/m (ASTM D3167) | Prevents delamination in high-humidity env |

| Filament Density | 18 filaments/cm² | Optimized barrier against fine particulates |

As your dedicated OEM partner, we manage end-to-end production from raw material sourcing to final inspection. Our ISO 9001-certified supply chain guarantees batch-to-batch consistency through FTIR spectroscopy and Mooney viscosity tracking. For custom projects, our rubber formula engineers adjust polymer blends to meet MIL-STD-810G or EN 45545-2 flame requirements without compromising flexibility. Lead times remain predictable at 25–35 days for 5,000-meter production runs due to our strategic buffer stock of base polymers.

Initiate technical validation with Mr. Boyce, our OEM Account Manager, who holds dual expertise in rubber compounding and industrial procurement logistics. He will coordinate material samples, DFM reviews, and PPAP documentation within 48 hours of engagement. Specify your application’s pressure differentials, cycle life expectations, and regulatory constraints to receive a data-driven proposal. Contact Mr. Boyce directly at [email protected] with subject line “Brush Seal Technical Query – [Your Company Name]” for immediate engineering support. Suzhou Baoshida ensures your sealing solution performs as rigorously as your machinery demands—no compromises, only certified precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).