Technical Contents

Engineering Guide: Rubber Coin Floor

Engineering Insight: Material Selection in Rubber Coin Floor Systems

The performance and longevity of rubber coin flooring systems are fundamentally determined by the precision of material selection. In industrial environments, where mechanical stress, chemical exposure, and thermal fluctuations are routine, generic or off-the-shelf rubber flooring solutions frequently fail to meet operational demands. These pre-formulated products are typically designed for aesthetic appeal or light-duty applications, lacking the engineered resilience required in high-intensity manufacturing, logistics, or maintenance facilities. As a result, premature degradation—manifesting as cracking, delamination, or loss of traction—compromises both safety and productivity.

At Suzhou Baoshida Trading Co., Ltd., our approach to rubber coin flooring begins with a rigorous assessment of the end-use environment. Key parameters include load frequency, dynamic impact levels, exposure to oils, solvents, or cleaning agents, and ambient temperature ranges. Standard rubber compounds, often based on reclaimed or mixed-content SBR (Styrene-Butadiene Rubber), exhibit inconsistent cross-link density and filler distribution. This variability leads to poor compression recovery and accelerated wear under cyclic loading. In contrast, purpose-formulated compounds utilizing virgin EPDM (Ethylene Propylene Diene Monomer) or high-abrasion NR (Natural Rubber) with controlled carbon black reinforcement provide superior elasticity, UV resistance, and tensile strength.

Another critical failure point in off-the-shelf systems is inadequate vulcanization control. Mass-produced rubber coins may undergo inconsistent curing cycles, resulting in under-cured zones that soften under heat or over-cured regions that become brittle. Our engineered solutions employ precision-controlled continuous vulcanization (CV) lines, ensuring uniform cross-link formation and dimensional stability across every unit.

Furthermore, the geometry and bonding interface of the coin design must align with substrate characteristics. Non-customized systems often use generic adhesive profiles that fail under shear stress, especially on uneven or marginally prepared concrete. We integrate substrate analysis with tailored bonding primers and interlocking coin profiles to maximize adhesion and load distribution.

The following table outlines key material and performance specifications differentiating standard versus engineered rubber coin flooring:

| Property | Off-the-Shelf Solution | Engineered Solution (Baoshida) |

|---|---|---|

| Base Polymer | Recycled SBR blend | Virgin EPDM or high-purity NR |

| Tensile Strength | 7–10 MPa | 15–18 MPa |

| Elongation at Break | 200–250% | 350–400% |

| Hardness (Shore A) | 55–65 | 60–70 (adjustable) |

| Abrasion Loss (DIN) | ≤ 250 mm³ | ≤ 120 mm³ |

| Oil Resistance (IRHD change) | > 25 points | < 10 points |

| Operating Temp Range | -10°C to +60°C | -40°C to +100°C |

| Vulcanization Process | Batch, variable control | Continuous, PID-controlled |

Material selection is not a secondary consideration—it is the cornerstone of functional durability. By rejecting one-size-fits-all formulations and focusing on application-specific engineering, Suzhou Baoshida ensures rubber coin flooring systems deliver sustained performance under real-world industrial conditions.

Material Specifications

Material Specifications for Industrial Rubber Coin Flooring Systems

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber coin flooring solutions for demanding industrial environments. While Viton, Nitrile, and Silicone are critical elastomers in specialized sealing applications, they are not technically or economically viable for coin flooring due to excessive cost, processing complexity, and over-engineering for typical floor load requirements. Industrial rubber flooring instead relies on high-abrasion-resistant compounds optimized for impact absorption, slip resistance, and longevity under heavy foot/vehicle traffic. The primary materials used in coin flooring—SBR (Styrene-Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), and TPE (Thermoplastic Elastomer)—deliver the ideal balance of durability, chemical resistance, and cost efficiency. These compounds are formulated with recycled tire-derived rubber (80–90% content) to meet sustainability targets without compromising performance. Key specifications include Shore A hardness of 65–85 for optimal shock absorption, ASTM D2240-compliant abrasion resistance (≤120 mg loss per DIN 53516), and temperature stability from -40°C to +70°C. All materials undergo rigorous compression set testing (ASTM D395) to ensure dimensional stability under constant load, critical for forklift-operated warehouses.

The following table details the technical specifications of standard coin flooring materials used in industrial applications. These values represent minimum performance thresholds for Suzhou Baoshida’s OEM-certified products:

| Material | Hardness (Shore A) | Temperature Range | Abrasion Resistance (DIN 53516) | Compression Set (ASTM D395, 22h/70°C) | Recycled Content | Key Applications |

|---|---|---|---|---|---|---|

| SBR | 70 ± 5 | -40°C to +70°C | ≤ 110 mg | ≤ 25% | 85–90% | Loading docks, workshops with moderate chemical exposure |

| EPDM | 75 ± 5 | -50°C to +80°C | ≤ 100 mg | ≤ 20% | 80–85% | Outdoor facilities, food processing (FDA-compliant grades) |

| TPE | 65 ± 5 | -30°C to +60°C | ≤ 130 mg | ≤ 15% | 75–80% | Cleanrooms, pharmaceutical facilities requiring non-marking surfaces |

Critical formulation parameters include carbon black reinforcement for UV stability (essential for outdoor EPDM variants), zinc oxide activation for vulcanization control, and proprietary anti-oxidant packages extending service life beyond 15 years in covered installations. All compounds comply with ISO 14001 environmental standards and exhibit ≤0.01 mg/m³ VOC emissions (ISO 16000-9). SBR dominates high-traffic logistics centers due to its superior resistance to hydraulic fluid and mild acids, while EPDM’s ozone resistance makes it ideal for perimeter zones exposed to weathering. TPE formulations prioritize low extractables for sterile environments, though with slightly reduced abrasion resistance versus SBR/EPDM.

Suzhou Baoshida’s coin flooring undergoes batch-specific validation per ASTM F1913 for slip resistance (static coefficient ≥0.5 wet, ≥0.7 dry) and EN 14041 for impact sound reduction. Material selection must align with site-specific factors: oil exposure mandates SBR with nitrile-modified grades (not pure NBR), while thermal cycling demands EPDM’s wider operational envelope. We advise against substituting high-cost fluoroelastomers like Viton, which offer no functional benefit for flooring yet increase costs by 300–400%. Partner with our engineering team to validate compound selection against your facility’s mechanical, chemical, and regulatory requirements. Our OEM program guarantees traceability from raw material sourcing to finished tile, with full material disclosure reports available upon request.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber manufacturing expertise, particularly in specialized applications such as rubber coin flooring. With a dedicated team comprising five experienced mould engineers and two advanced formula development specialists, we deliver precision-engineered rubber solutions tailored to the rigorous demands of commercial and industrial environments.

Our mould engineering team brings over a decade of cumulative experience in designing high-tolerance, durable steel and aluminum moulds optimized for rubber coin flooring production. Each mould is engineered to ensure uniform embossing, consistent coin pattern replication, and long-term resistance to wear under high-volume manufacturing cycles. Utilizing CAD/CAM simulation tools and finite element analysis (FEA), our engineers validate thermal distribution, flow dynamics, and demoulding efficiency prior to production, minimizing defects and maximizing output stability.

Complementing our mould design expertise, our two senior rubber formulation engineers specialize in elastomer chemistry for performance-driven flooring applications. They develop custom compound formulations using SBR, EPDM, and recycled rubber blends, engineered to meet specific requirements for slip resistance, UV stability, compression set, and abrasion resistance. These formulations are rigorously tested under simulated environmental conditions to ensure long-term durability in both indoor and outdoor installations.

Our integrated approach enables seamless coordination between material science and tooling design, ensuring that each rubber coin floor product achieves optimal mechanical performance and aesthetic consistency. This synergy is critical in OEM manufacturing, where clients demand precise alignment with technical specifications, branding standards, and performance benchmarks.

Suzhou Baoshida Trading Co., Ltd. offers full OEM services, from concept development and prototyping to mass production and packaging customization. Our clients benefit from end-to-end control over design, material selection, and quality assurance, supported by in-house testing facilities compliant with ISO 9001 standards. Whether scaling a proprietary pattern or co-developing a new performance compound, our engineering team ensures technical feasibility, cost efficiency, and on-time delivery.

The following table outlines key technical specifications achievable through our engineering and manufacturing platform:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–85 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Abrasion Loss (Taber, 1000 rev) | ≤120 mg | ASTM D1044 |

| Compression Set (70°C, 22h) | ≤20% | ASTM D395 |

| Slip Resistance (DIN 51130) | R9–R13 | DIN 51130 |

| Temperature Range | -40°C to +80°C | Internal Simulation |

Through advanced engineering integration and dedicated OEM support, Suzhou Baoshida delivers industrial rubber flooring solutions that combine durability, safety, and design precision for global commercial infrastructure needs.

Customization Process

Rubber Coin Floor Customization Process

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber coin floor solutions through a rigorously controlled four-stage customization workflow. This process ensures optimal performance alignment with client specifications while maintaining industrial-grade durability and safety compliance.

Drawing Analysis

Initial engagement begins with comprehensive technical drawing review. Our engineering team dissects client-provided CAD files or sketches to validate dimensional tolerances, coin pattern geometry, and substrate interface requirements. Critical parameters include coin diameter (typically 15–30 mm), height (3–10 mm), spacing density, and edge profiles. We cross-reference these against ISO 10289 surface finish standards and ASTM D2240 durometer compatibility for the intended application environment. Any geometric conflicts or material stress points are resolved via collaborative redesign prior to formulation.

Formulation Development

Based on validated drawings, our rubber chemists formulate compound recipes targeting specific mechanical and environmental performance. Key considerations include Shore A hardness (50–85), oil/fuel resistance (ASTM D471), and operating temperature range (-40°C to +120°C). Natural rubber (NR) dominates high-resilience applications, while nitrile butadiene rubber (NBR) is selected for oil-exposed zones. Reinforcing agents like silica or carbon black adjust abrasion resistance, and proprietary additives enhance UV stability per ISO 4892-2. All formulations undergo computational simulation for vulcanization kinetics before lab-scale mixing.

Prototyping & Validation

A physical prototype is manufactured using client-approved tooling. We conduct accelerated lifecycle testing per ISO 4649 (abrasion), ISO 188 (heat aging), and ASTM F2913 (slip resistance). Critical metrics include tensile strength (≥12 MPa), elongation at break (≥250%), and compression set (≤25% after 70 hrs at 70°C). Clients receive a detailed test report alongside the prototype for functional verification. Iterations occur within 7–10 days if adjustments are required, ensuring zero deviations from operational requirements.

Mass Production

Upon prototype sign-off, production commences under IATF 16949-certified protocols. Automated calendaring presses maintain ±0.3 mm thickness tolerance, while inline spectrophotometers ensure color consistency (ΔE ≤1.5). Every batch undergoes real-time rheometry checks (MH-ML variance <5%) and post-cure hardness validation. Final inspection includes 100% visual screening for surface defects and random sampling for physical property verification. Lead time from order to shipment averages 25–35 days for 20,000 m² volumes.

Key Performance Specifications

| Parameter | Test Standard | Target Range | Measurement Method |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 55–85 | 3-sec dwell, 5 samples |

| Abrasion Loss | ISO 4649 | ≤120 mm³/1.61 km | Rotary drum, 1000 cycles |

| Tensile Strength | ISO 37 | ≥12 MPa | Type 2 dumbbell |

| Oil Swell (IRM 903) | ASTM D471 | ≤25% | 70°C, 70 hrs immersion |

| Slip Resistance (DC) | ASTM F2913 | ≥0.60 | Wet ceramic tile, 12° incline |

This systematic approach guarantees rubber coin floors that exceed industrial safety mandates while delivering 15+ years of service life in demanding settings like automotive plants, marine decks, and logistics hubs. Suzhou Baoshida’s engineering oversight eliminates performance ambiguity from concept to container loading.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Rubber Coin Floor Solutions

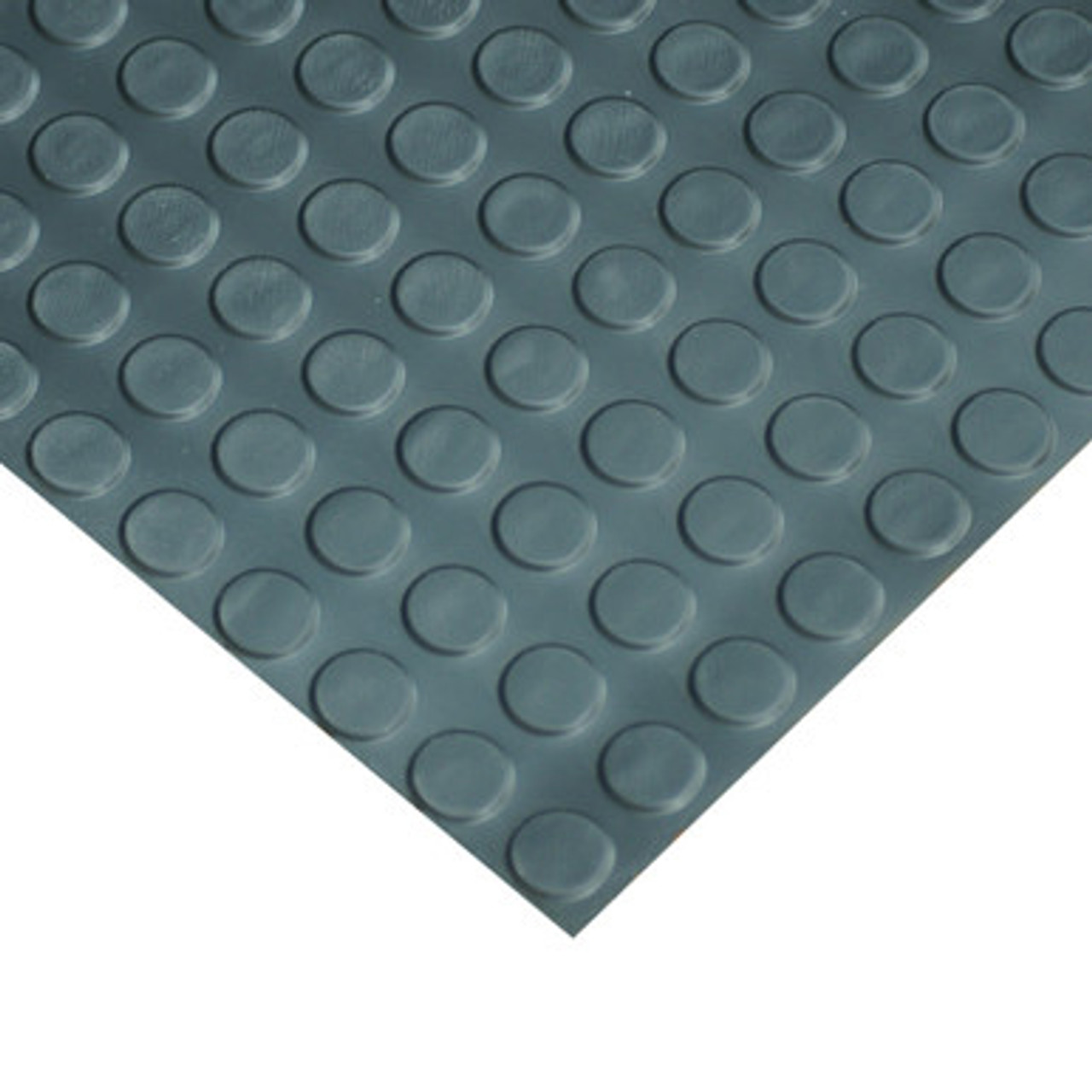

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, delivering high-performance rubber coin flooring systems tailored to the rigorous demands of commercial and industrial environments. As a trusted OEM manager and rubber formulation engineer, we specialize in engineered resilience, slip resistance, and long-term durability—critical factors in facilities where safety, hygiene, and operational continuity are paramount. Our rubber coin floor products are designed for applications in gyms, fitness centers, logistics hubs, automotive workshops, and food processing facilities, where impact absorption, noise reduction, and chemical resistance are non-negotiable.

Each rubber coin floor solution is developed using precision-compounded SBR and EPDM rubber granules, ensuring optimal density, elasticity, and UV stability. Our in-house R&D team formulates materials to meet specific load-bearing requirements and environmental conditions, whether indoor or outdoor, high-traffic or chemically aggressive. We maintain strict quality control throughout the production process, from raw material sourcing to final packaging, ensuring consistency and compliance with international safety and performance standards.

For project-specific inquiries, technical consultations, or custom formulation support, we invite you to contact Mr. Boyce, our dedicated OEM and technical liaison. With extensive experience in industrial rubber applications, Mr. Boyce provides expert guidance on product selection, installation protocols, and performance optimization. Reach him directly via email at [email protected] to discuss your flooring requirements, request samples, or obtain a detailed quotation. Our team supports global clients with end-to-end service, including logistics coordination, technical documentation, and after-sales support.

We understand that every industrial space presents unique challenges. That’s why we offer scalable production capabilities and flexible customization options—including color matching, thickness variation, and anti-microbial additives—to meet your exact specifications. As a direct manufacturer partner, Suzhou Baoshida ensures competitive pricing without compromising material integrity or performance.

Below are the standard technical specifications for our most widely deployed rubber coin floor system:

| Property | Specification |

|---|---|

| Material Composition | 80% Recycled SBR, 20% Virgin EPDM |

| Thickness Options | 10 mm, 15 mm, 20 mm |

| Density | 1.15–1.25 g/cm³ |

| Tensile Strength | ≥7.5 MPa (ASTM D412) |

| Elongation at Break | ≥150% |

| Shore A Hardness | 65–75 |

| Slip Resistance (R-value) | R10–R12 (DIN 51130) |

| Impact Sound Reduction | Up to 19 dB |

| Temperature Range | -30°C to +80°C |

| Fire Rating | Class Bfl-s1 (EN 13501-1) |

| Installation Method | Polyurethane adhesive bonding |

Partner with Suzhou Baoshida Trading Co., Ltd. to integrate advanced rubber flooring technology into your next industrial or commercial project. Contact Mr. Boyce today at [email protected] to initiate a technical discussion or request application-specific data sheets and compliance certificates.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).