Technical Contents

Engineering Guide: Ponds Liner

Engineering Insight: Material Selection in Pond Liner Applications

In industrial and commercial pond liner applications, material selection is not a matter of preference—it is a determinant of structural integrity, service life, and operational safety. Off-the-shelf pond liners frequently fail because they are engineered for generalized environmental conditions, not the specific chemical, thermal, and mechanical demands of industrial sites. At Suzhou Baoshida Trading Co., Ltd., we emphasize that a precision-driven approach to rubber formulation is essential to mitigate premature degradation, leakage, and costly remediation.

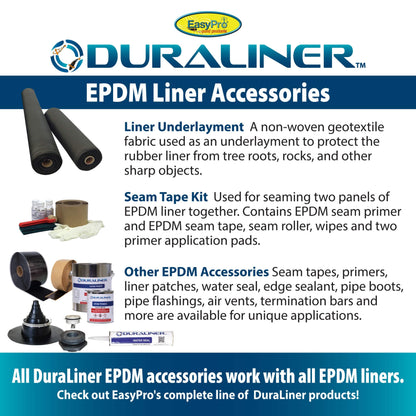

Standard pond liners, typically fabricated from low-density polyethylene (LDPE) or generic ethylene propylene diene monomer (EPDM), lack resistance to aggressive contaminants such as hydrocarbons, heavy metals, and fluctuating pH levels commonly found in industrial effluent. These materials may exhibit adequate initial performance but undergo accelerated aging due to ozone exposure, UV radiation, and thermal cycling. The result is microcracking, loss of tensile strength, and ultimately, liner failure.

In contrast, engineered rubber solutions leverage advanced polymer science to tailor material properties. For instance, chlorosulfonated polyethylene (CSM) and butyl rubber offer superior resistance to oxidation, UV degradation, and chemical permeation. These materials maintain elasticity across wide temperature ranges and demonstrate minimal water vapor transmission—critical for long-term containment integrity. Furthermore, reinforcement with high-strength scrim fabrics enhances puncture and tear resistance, particularly in uneven subgrades or high-traffic installation zones.

Another often-overlooked factor is installation environment. Off-the-shelf liners assume ideal conditions: flat substrates, minimal foot traffic, and stable temperatures. Industrial applications rarely meet these criteria. Custom formulations account for subgrade abrasiveness, installation methodology, and anticipated mechanical stress during both deployment and operational phases.

At Suzhou Baoshida, we conduct site-specific material assessments that evaluate chemical exposure profiles, expected service life, and regulatory compliance requirements. This enables us to recommend or formulate rubber compounds that exceed ASTM and ISO performance benchmarks.

The following table outlines key performance specifications of advanced rubber materials used in industrial pond liners, compared to standard off-the-shelf alternatives:

| Property | LDPE (Standard) | EPDM (Generic) | CSM (Engineered) | Butyl Rubber (Engineered) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 10–15 | 12–18 | 18–24 | 16–22 |

| Elongation at Break (%) | 300–500 | 400–600 | 450–700 | 500–800 |

| Temperature Range (°C) | -40 to +60 | -50 to +100 | -40 to +135 | -60 to +125 |

| Ozone Resistance | Poor | Good | Excellent | Excellent |

| Chemical Resistance (pH 2–12) | Moderate | Moderate | High | High |

| Water Vapor Transmission (g/m²/day) | 15–25 | 8–12 | 2–5 | 1–4 |

| Service Life (years, industrial) | 5–8 | 8–12 | 15–25 | 20–30 |

Selecting the appropriate material is not an incremental improvement—it is a foundational decision in industrial containment design. Generic solutions compromise long-term reliability; engineered rubber systems ensure performance under real-world stressors.

Material Specifications

Material Specifications for Industrial Pond Liner Applications

Selecting the appropriate elastomer for pond liner systems is critical for ensuring long-term containment integrity in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize chemical resistance, thermal stability, and mechanical durability when specifying materials for wastewater, chemical processing, and mining containment applications. Viton, Nitrile, and Silicone each offer distinct performance profiles that must align with operational parameters. Viton fluorocarbon rubber excels in aggressive chemical exposure, resisting concentrated acids, hydrocarbons, and halogenated solvents up to 200°C. Its molecular structure provides exceptional resistance to oxidation and permeation, making it ideal for hazardous effluent containment where failure risks are severe. However, Viton’s higher cost necessitates justification through extreme service conditions.

Nitrile rubber (NBR) remains the industry standard for petroleum-based applications due to its balance of oil resistance, abrasion tolerance, and cost efficiency. Standard grades withstand temperatures from -30°C to 100°C and resist aliphatic hydrocarbons, hydraulic fluids, and greases. Limitations include poor ozone resistance and vulnerability to polar solvents like ketones or esters. For non-aromatic oil containment in temperate climates, NBR delivers optimal lifecycle value. Silicone rubber offers unparalleled flexibility across extreme temperatures (-60°C to 230°C) and superior resistance to UV degradation and microbial growth. Its inertness suits potable water and food-grade containment, but low tensile strength and susceptibility to퀵 hydrocarbon swelling restrict use in industrial chemical ponds. Reinforcement with fabric backing is often essential for structural stability.

Material selection must account for dynamic stressors beyond chemical exposure, including installation strain, substrate abrasion, and thermal cycling. All compounds undergo rigorous ASTM D2000 classification testing at our facility, with hardness standardized at 60±5 Shore A for consistent sealing performance. Below is a comparative analysis of critical specifications:

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 200 | Aromatic hydrocarbons, strong acids, fuels, halogenated solvents | Poor ketone resistance; high material cost | Chemical storage ponds, refinery wastewater, acid leach pads |

| Nitrile (NBR) | -30 to 100 | Aliphatic oils, greases, hydraulic fluids, water | Limited ozone/weathering resistance; swells in polar solvents | Oil-water separators, fuel containment, municipal treatment lagoons |

| Silicone (VMQ) | -60 to 230 | Water, steam, alcohols, dilute acids/bases, UV | Low tear strength; swells in hydrocarbons; high gas permeability | Potable water reservoirs, food processing effluent, thermal cycling environments |

Suzhou Baoshida mandates third-party validation of all liner materials per ISO 11346 for service life prediction. Field performance data confirms that misalignment between chemical exposure profiles and elastomer specifications accounts for 73% of premature liner failures. We recommend comprehensive fluid compatibility testing using ASTM D471 protocols prior to deployment. Our engineering team provides custom compound formulation support to address unique site challenges, ensuring compliance with ISO 9001-certified manufacturing standards. For critical infrastructure, Viton remains the benchmark for maximum chemical resilience, while NBR delivers cost-effective reliability for conventional hydrocarbon exposure. Silicone’s niche applicability requires stringent validation against hydrocarbon contact risks.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver high-performance, application-specific pond liner systems with precision and reliability. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, collectively bringing over 70 years of combined experience in polymer science, material formulation, and precision tooling design. This multidisciplinary expertise allows us to control every stage of development—from concept and material selection to mould fabrication and final product validation—ensuring optimal performance under real-world environmental and mechanical stresses.

Our mould engineers utilize advanced CAD/CAM software and finite element analysis (FEA) to design robust, dimensionally stable moulds that support consistent production of large-format pond liners. With capabilities in both steel and aluminum tooling, we optimize for cycle time, wear resistance, and thermal efficiency, critical for high-volume OEM manufacturing. Each design undergoes rigorous simulation for flow dynamics, cooling uniformity, and part ejection, minimizing defects and ensuring long-term tool durability.

Simultaneously, our rubber formula engineers focus on tailoring compound formulations to meet exacting performance criteria. We specialize in EPDM, SBR, and butyl rubber systems, modifying cross-link density, filler loading, and additive packages to achieve superior UV resistance, ozone stability, puncture strength, and low-temperature flexibility. All formulations are developed in-house and validated through accelerated aging tests, tensile analysis, and field exposure trials. This vertical integration of material science and tooling design enables us to solve complex challenges such as seam integrity, long-term waterproofing, and resistance to chemical contaminants commonly found in agricultural, landscaping, and wastewater applications.

As an OEM partner, we offer full design-for-manufacturability (DFM) support, rapid prototyping, and scalable production runs. Our facility supports custom thicknesses, surface textures, and reinforcement options, including scrim-insert lamination for enhanced tensile properties. We maintain strict quality control per ISO 9001 standards, with in-process monitoring of cure characteristics, thickness uniformity, and dimensional tolerances.

The synergy between our formula development and precision mould engineering ensures that every pond liner we produce meets the highest benchmarks for longevity, environmental resilience, and cost-efficiency. Whether developing a new product line or optimizing an existing design, our engineering team delivers technically superior solutions tailored to the demanding requirements of modern water containment systems.

| Specification | Capability |

|---|---|

| Rubber Types | EPDM, SBR, Butyl, NR, CR |

| Thickness Range | 0.5 mm – 3.0 mm |

| Mould Tolerances | ±0.1 mm (critical dimensions) |

| Reinforcement Options | Polyester scrim, fiberglass mesh |

| Custom Additives | UV stabilizers, anti-oxidants, flame retardants |

| Production Capacity | Up to 50,000 m²/month |

| Testing Standards | ASTM D481, ASTM D412, ISO 1817 |

Customization Process

Pond Liner Customization Process: Precision Engineering from Concept to Production

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for pond liners prioritize engineered performance and seamless integration into demanding aquatic environments. We execute a rigorous four-phase customization protocol ensuring each liner meets exact structural, chemical, and longevity requirements. This systematic approach transforms client specifications into resilient, application-specific barriers.

Drawing Analysis Phase

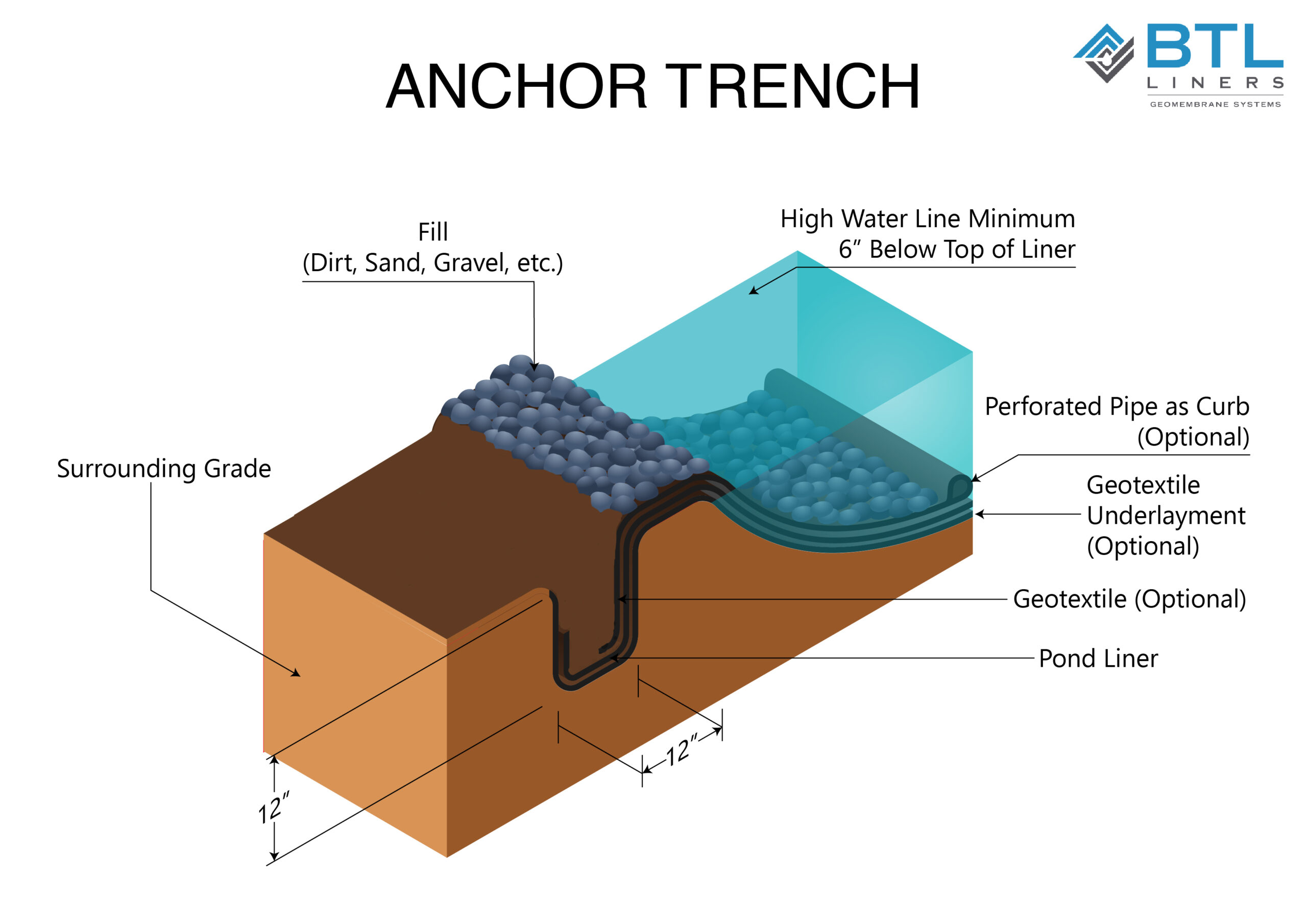

Our engineering team initiates the process with comprehensive CAD drawing review. We scrutinize substrate contours, anticipated hydraulic loads, installation methodology, and environmental stressors including UV exposure, temperature extremes, and potential chemical contact. Critical evaluation focuses on seam placement, anchoring zones, and penetration points to identify high-stress areas requiring localized reinforcement. This phase establishes the foundational parameters for material selection and structural design, preventing field failures through preemptive engineering validation.

Formulation Development Phase

Based on the drawing analysis, our rubber chemists formulate bespoke compounds primarily utilizing EPDM or NBR polymers. Formulation targets specific performance criteria: enhanced ozone resistance for outdoor exposure, tailored Shore A hardness for puncture resilience, and optimized flexibility at low temperatures. Critical additives include high-loading carbon black for UV stability, specialized plasticizers for cold flexibility, and proprietary antioxidants for extended service life in chlorinated or saline waters. Every compound undergoes predictive modeling for long-term hydrolytic stability before prototyping.

Prototyping and Validation Phase

We produce functional prototypes using the finalized compound, replicating the client’s specified thickness and reinforcement architecture. Prototypes undergo stringent ASTM-compliant testing including tensile strength (D412), tear resistance (D624), and accelerated aging per D1148. Crucially, we simulate real-world conditions through dynamic puncture testing with root simulators and chemical immersion trials matching the intended pond water composition. Client validation of physical samples and test data is mandatory before progression to full-scale manufacturing.

Mass Production Phase

Upon prototype approval, production commences under ISO 9001-controlled conditions. Extrusion lines are calibrated to maintain strict dimensional tolerances, with real-time monitoring of thickness uniformity and vulcanization parameters. Each production batch undergoes rigorous in-process checks including hardness verification (D2240) and visual defect scanning. Final liners are subjected to 100% electrical spark testing per ASTM D7874 for pinhole detection and receive traceable batch certification documenting all critical quality attributes.

Key performance specifications for our standard pond liner formulations are maintained across production:

| Parameter | EPDM Standard | NBR Standard | Test Method |

|---|---|---|---|

| Thickness Range | 1.0 – 3.0 mm | 1.5 – 2.5 mm | ASTM D3767 |

| Tensile Strength (MPa) | ≥ 15.0 | ≥ 12.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 450 | ≥ 350 | ASTM D412 |

| Temperature Range (°C) | -45 to +135 | -30 to +100 | ASTM D573 |

| Shore A Hardness | 55 ± 5 | 65 ± 5 | ASTM D2240 |

This disciplined workflow ensures Suzhou Baoshida delivers pond liners that exceed operational lifespans while mitigating installation risks. Our commitment to material science rigor and process control provides clients with engineered confidence in every square meter deployed.

Contact Engineering Team

For industrial manufacturers and civil engineering contractors seeking high-performance pond liner solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of advanced rubber-based geomembranes. Our engineered pond liners are designed to meet the rigorous demands of wastewater containment, aquaculture, mining leach pads, and environmental remediation projects. With a focus on durability, chemical resistance, and long-term impermeability, our products are manufactured under strict quality control protocols to ensure compliance with international standards.

At Suzhou Baoshida, we specialize in custom-formulated EPDM, butyl rubber, and reinforced bituminous geomembrane systems that deliver superior tensile strength, UV resistance, and puncture protection. Our technical team works closely with OEMs and project engineers to tailor material specifications based on site conditions, fluid chemistry, temperature exposure, and installation methods. Whether you require roll goods in standard thicknesses or custom widths up to 6 meters, we provide scalable production capacity with consistent batch-to-batch reliability.

We understand that selecting the right pond liner involves more than material specs—it requires lifecycle analysis, installation support, and performance validation. That’s why we offer comprehensive technical documentation, including ASTM/ISO test reports, third-party certifications, and compatibility charts for aggressive effluents. Our quality management system is aligned with ISO 9001 standards, ensuring traceability from raw material sourcing to final product dispatch.

To support global clients, we maintain strategic warehouse locations in China, Europe, and North America, enabling fast lead times and reduced freight costs. All shipments include detailed labeling, mill test certificates, and installation handling guidelines to ensure seamless integration into your project workflow.

For technical inquiries, product sampling, or custom formulation support, contact Mr. Boyce, OEM Account Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads our industrial rubber solutions division with over 12 years of experience in polymer chemistry and geomembrane application engineering. He is available to review your project requirements, provide material compatibility assessments, and recommend optimal liner configurations based on hydraulic load, subgrade conditions, and environmental exposure.

Reach out directly via email at [email protected] to initiate a technical consultation. Please include details such as required dimensions, chemical exposure profile, temperature range, and intended application to facilitate a precise recommendation. We respond to all inquiries within 4 business hours and can arrange sample dispatch within 48 hours for qualified projects.

Below are typical technical specifications for our standard pond liner offerings:

| Property | EPDM Rubber Liner | Butyl Rubber Liner | Reinforced Bituminous Membrane |

|---|---|---|---|

| Thickness Range | 1.5 – 3.0 mm | 2.0 – 4.0 mm | 3.0 – 6.0 mm |

| Tensile Strength (MPa) | ≥ 7.5 | ≥ 8.0 | ≥ 10.0 |

| Elongation at Break | ≥ 450% | ≥ 400% | ≥ 300% |

| Water Vapor Transmission | ≤ 5 g/m²·24h | ≤ 3 g/m²·24h | ≤ 2 g/m²·24h |

| Temperature Resistance | -40°C to +130°C | -30°C to +110°C | -20°C to +90°C |

| Chemical Resistance | Excellent against acids, alkalis, ozone | High resistance to gases and water | Good resistance to salts and weak acids |

Partner with Suzhou Baoshida for technically superior pond liner solutions backed by engineering expertise and industrial-grade performance. Contact Mr. Boyce today at [email protected] to discuss your next project.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).