Technical Contents

Engineering Guide: Custom Cut Gaskets

Engineering Insight: The Critical Role of Material Selection in Custom Cut Gaskets

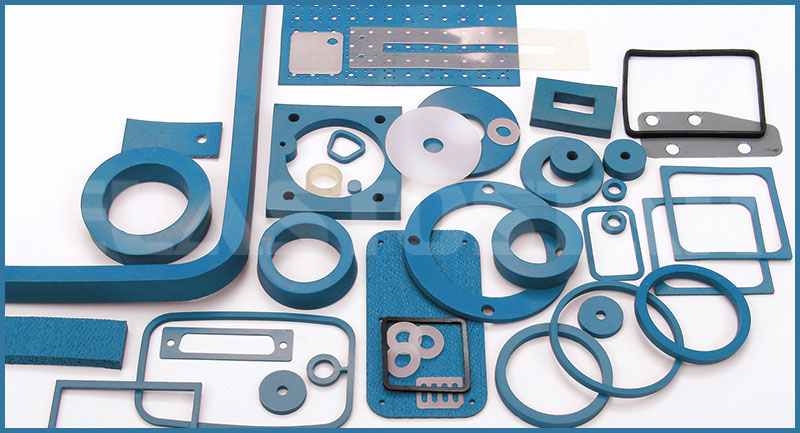

In precision sealing applications, the performance and longevity of a gasket are fundamentally determined by material selection. Off-the-shelf gaskets, while convenient, are engineered for generic conditions and often fail under specific operational demands. The limitations become evident when environmental variables such as temperature extremes, chemical exposure, pressure differentials, and mechanical stress are not uniformly addressed by standard materials. Custom cut gaskets, by contrast, are designed with targeted performance in mind, beginning with the strategic selection of elastomeric compounds tailored to the application.

Material selection is not a secondary consideration—it is the foundation of sealing integrity. For example, an NBR (nitrile butadiene rubber) gasket may perform adequately in oil-resistant applications at moderate temperatures, but it will degrade rapidly in environments involving ozone, strong acids, or continuous exposure above 120°C. Similarly, while silicone offers excellent thermal stability, its poor tensile strength and abrasion resistance make it unsuitable for high-mechanical-load scenarios. These mismatches underscore why universal gasket solutions are inherently flawed.

At Suzhou Baoshida Trading Co., Ltd., we prioritize application-specific engineering. Our custom cut gaskets begin with a thorough analysis of operational parameters, followed by material qualification based on chemical compatibility, thermal range, compression set resistance, and regulatory compliance. This approach ensures that each gasket performs reliably over its intended service life, minimizing downtime and maintenance costs.

The following table outlines common elastomers used in custom gasket manufacturing, along with their key performance characteristics:

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Applications | Compression Set Resistance |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | Oils, fuels, aliphatic hydrocarbons | Automotive, hydraulics | Good |

| EPDM | -50 to +150 | Water, steam, alkalis, oxygenated solvents | HVAC, water treatment | Excellent |

| Silicone (VMQ) | -60 to +200 | Oxidation, UV, ozone | Medical, food processing, electronics | Fair |

| FKM (Viton®) | -20 to +200 | Aromatic hydrocarbons, acids, fuels | Aerospace, chemical processing | Excellent |

| Neoprene (CR) | -40 to +100 | Refrigerants, mild acids, flame | Electrical enclosures, marine | Good |

| Natural Rubber (NR) | -50 to +70 | Water, alcohols, weak acids | General industrial | Poor |

Selecting the wrong material—even with precise dimensional cutting—leads to premature failure modes such as extrusion, hardening, cracking, or swelling. These issues compromise system integrity and can result in costly leaks or safety hazards. Custom cut gaskets eliminate this risk by aligning material properties with real-world conditions.

Ultimately, the value of a custom solution lies in its engineering rigor. At Baoshida, we combine material science expertise with precision fabrication to deliver gaskets that meet exacting industrial standards. When performance cannot be compromised, off-the-shelf is not an option.

Material Specifications

Material Specifications for Precision Custom Cut Gaskets

Selecting the optimal elastomer for custom cut gaskets is critical for ensuring long-term sealing integrity under specific operational demands. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science rigor to match gasket performance with application requirements. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three foundational polymers, each engineered for distinct environmental challenges. Viton, a fluorocarbon elastomer, delivers exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and high-temperature oils. Its molecular stability supports continuous service up to 230°C, making it indispensable for aerospace fuel systems and chemical processing equipment where hydrocarbon degradation must be mitigated. Nitrile rubber excels in petroleum-based fluid environments due to its high acrylonitrile content, providing robust resistance to oils, greases, and aliphatic hydrocarbons. Standard formulations maintain functionality between -40°C and 120°C, with specialized grades extending to 150°C, positioning NBR as the dominant choice for automotive engine gaskets and hydraulic seals. Silicone rubber offers unparalleled flexibility across extreme temperatures, functioning reliably from -60°C to 200°C, while exhibiting excellent resistance to ozone, UV radiation, and steam. Its biocompatibility and low compression set suit medical devices and food-grade applications, though it demonstrates limited resilience against concentrated acids and hydrocarbons.

Material selection must account for fluid compatibility, thermal cycling, pressure dynamics, and regulatory constraints. Viton’s superior chemical inertness comes with higher material costs, while Nitrile provides cost-effective durability in oil-exposed industrial settings. Silicone’s thermal versatility is offset by lower mechanical strength compared to hydrocarbon rubbers. Below is a comparative analysis of key technical parameters:

| Material | Temperature Range (°C) | Key Fluid Resistance | Tensile Strength (MPa) | Compression Set (22h, 150°C) | Primary Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Fuels, oils, acids, solvents | 10–20 | ≤25% | Aerospace, chemical processing, semiconductor |

| Nitrile (NBR) | -40 to 120 (up to 150) | Petroleum oils, greases, water | 15–25 | ≤30% | Automotive, hydraulics, industrial machinery |

| Silicone (VMQ) | -60 to 200 | Water, steam, alcohols, ozone | 5–10 | ≤20% | Medical, food processing, electronics, HVAC |

Critical limitations require careful evaluation: Viton exhibits poor resistance to ketones and brake fluids; Nitrile swells in polar solvents like acetone; Silicone shows vulnerability to concentrated acids and hydrocarbon fuels. Suzhou Baoshida Trading Co., Ltd. leverages ASTM D2000 standards to validate all formulations, ensuring dimensional stability and sealing force retention under operational stress. Our OEM partnerships integrate material testing protocols—such as fluid immersion per ISO 1817 and thermal aging per ASTM D573—to preempt field failures. Precision cutting techniques further optimize gasket performance by minimizing material deformation during fabrication. Ultimately, the synergy between elastomer chemistry and application physics dictates sealing efficacy, underscoring why Baoshida’s engineering team collaborates closely with clients to specify materials meeting exact functional and compliance mandates.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Design and Material Science for Custom Cut Gaskets

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a dual-specialty technical team comprising five dedicated mould engineers and two advanced rubber formula engineers. This integrated expertise enables us to deliver custom cut gaskets that meet exacting performance, environmental, and dimensional requirements across industrial, automotive, and electronics sectors. Our approach combines precision tooling design with advanced elastomer formulation to ensure every gasket performs reliably under real-world operational stress.

Our mould engineers specialize in the development of high-tolerance cutting dies and compression moulds tailored to complex geometries and tight tolerance specifications. Utilizing CAD/CAM systems and precision CNC machining, they design and validate tooling that ensures consistent part repeatability and edge definition. Each custom gasket profile undergoes rigorous simulation and prototype testing to optimize flow, compression set, and sealing integrity before full-scale production. This proactive engineering process minimizes material waste, reduces time-to-market, and enhances long-term reliability.

Complementing our tooling expertise, our two in-house rubber formula engineers bring deep knowledge of polymer chemistry and material behavior under dynamic conditions. They formulate custom elastomer compounds based on NBR, EPDM, silicone, FKM, and CR to meet specific requirements for temperature resistance, chemical exposure, compression set, and aging performance. This internal formulation capability allows us to fine-tune material properties beyond off-the-shelf rubber sheets, delivering gaskets that perform in extreme environments—such as high-temperature engine compartments or aggressive chemical processing units.

As an OEM manufacturing partner, Suzhou Baoshida provides full technical ownership from concept to delivery. We support clients through material selection, 2D/3D design validation, prototype sampling, and serial production. Our facility is equipped for die-cutting, water jet cutting, and flat moulding processes, enabling flexible production of low-volume custom runs and high-volume OEM supply with equal precision.

The integration of material science and precision engineering ensures that every custom cut gasket we produce is not only dimensionally accurate but also functionally optimized for its intended application. This holistic approach differentiates our OEM service, offering clients a single-source solution for technically demanding sealing challenges.

Typical Material Properties and Performance Range for Custom Cut Gaskets

| Material | Hardness (Shore A) | Temperature Range (°C) | Key Resistance Properties | Common Applications |

|---|---|---|---|---|

| NBR (Nitrile) | 50–90 | -30 to +120 | Oil, fuel, water, abrasion | Automotive seals, hydraulic systems |

| EPDM | 50–80 | -50 to +150 | Ozone, UV, steam, weathering | HVAC, outdoor enclosures, water systems |

| Silicone | 40–80 | -60 to +230 | Extreme temperatures, oxidation | Medical devices, electronics, food-grade |

| FKM (Viton®) | 60–90 | -20 to +250 | Chemicals, oils, high heat | Aerospace, chemical processing |

| CR (Neoprene) | 50–70 | -40 to +120 | Flame, sunlight, moderate oils | Electrical enclosures, marine seals |

Customization Process

Custom Cut Gasket Manufacturing Process: Precision Engineering Pathway

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven methodology for custom cut gasket production, ensuring absolute alignment with client engineering specifications and operational demands. Our process transcends simple fabrication, integrating deep material science expertise with precision manufacturing protocols. The journey begins with comprehensive Drawing Analysis. Our engineering team meticulously dissects client-provided CAD files or technical drawings, scrutinizing critical dimensions, tolerances (ISO 3301/3302 standards applied), surface finish requirements, and application context. This phase involves cross-functional validation with the client to resolve ambiguities, confirm material compatibility assumptions, and identify potential design optimizations for manufacturability without compromising seal integrity. Precise interpretation of groove geometry, flange type, and anticipated service stresses is paramount at this stage.

Following drawing validation, our Rubber Formula Engineering team initiates Material Formulation. Leveraging an extensive database of polymer compounds and decades of OEM application experience, we select or develop the optimal elastomer matrix. This decision is scientifically grounded in the gasket’s required resistance to specific media (oils, chemicals, steam), operating temperature extremes, compression set performance, and physical property targets. Formulation adjustments to polymer base, filler type/loading, curative systems, and additives are precisely calculated to achieve the exact balance of resilience, sealing force, and longevity demanded by the application. Material selection is never generic; it is a tailored chemical engineering solution.

The validated design and formulated compound proceed to Prototyping & Validation. Utilizing advanced CNC waterjet or laser cutting systems within controlled cleanroom environments, we produce initial gasket samples from the specified sheet stock. These prototypes undergo stringent in-house performance testing, including compression deflection analysis, fluid immersion resistance checks per ASTM D471, and dimensional verification against the original drawing using calibrated CMM equipment. Client feedback on prototype fit and function within their assembly is actively solicited and integrated. Only upon successful validation of all performance criteria do we authorize progression to full-scale production.

Critical Material Selection Parameters for Common Gasket Applications

| Material Type | Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Fluid Resistance Strengths |

|---|---|---|---|

| NBR (Nitrile) | 50 – 90 | -30 to +120 | Oils, Fuels, Aliphatic Hydrocarbons |

| EPDM | 50 – 80 | -50 to +150 | Steam, Hot Water, Alkalis, Oxygenated Solvents |

| FKM (Viton®) | 60 – 90 | -20 to +230 | Aggressive Chemicals, High-Temp Oils, Fuels |

| Silicone | 30 – 80 | -60 to +200 | Extreme Temp Variations, Ozone, UV Light |

| CR (Neoprene) | 40 – 70 | -40 to +100 | Weathering, Ozone, Moderate Oils |

Mass Production commences only after all prior stages are conclusively approved. Our ISO-certified production lines implement strict process controls: raw material traceability (lot/batch coding), real-time monitoring of cutting parameters (pressure, speed, kerf width), 100% automated visual inspection for edge integrity and dimensional compliance, and final lot sampling against critical quality attributes. Statistical process control (SPC) data is maintained, ensuring every gasket batch consistently meets the engineered specifications defined during the initial analysis phase. Suzhou Baoshida delivers not just gaskets, but validated sealing solutions engineered for predictable, long-term performance in your critical applications.

Contact Engineering Team

Contact Suzhou Baoshida for Custom Cut Gaskets – Precision Engineering for Demanding Applications

At Suzhou Baoshida Trading Co., Ltd., we specialize in the design, formulation, and production of high-performance custom cut gaskets tailored to the exacting standards of industrial, automotive, aerospace, and fluid control systems. As a trusted OEM partner, we combine advanced rubber compounding expertise with precision die-cutting and CNC water-jet technologies to deliver seals that perform under extreme pressure, temperature, and chemical exposure.

Our engineering team works directly with clients to analyze application requirements, environmental conditions, and regulatory compliance needs. Whether you require low-volume prototyping or high-volume series production, we offer rapid turnaround, rigorous quality control, and full traceability across every batch. Our facility in Suzhou is equipped with state-of-the-art testing equipment, including tensile testers, hardness gauges, aging ovens, and compression set analyzers, ensuring every gasket meets or exceeds international standards such as ASTM, ISO, and SAE.

We understand that sealing performance is not just about shape and size—it’s about material integrity. That’s why we formulate proprietary rubber compounds using EPDM, Nitrile (NBR), Silicone, Viton® (FKM), Neoprene, and other specialty elastomers, each optimized for resistance to oils, ozone, steam, or extreme temperatures. Our technical team supports clients in material selection, hardness tuning (Shore A 30 to 90), and dimensional tolerancing down to ±0.1 mm.

For complex sealing challenges, we provide full technical documentation, including material data sheets, test reports, and 2D/3D drawings. We also support custom packaging, barcoding, and JIT delivery logistics for seamless integration into your assembly line.

Below are typical technical specifications we support for custom cut gaskets:

| Parameter | Range / Capability |

|---|---|

| Material Types | NBR, EPDM, Silicone, FKM, Neoprene, CR, SBR, HNBR, AEM |

| Hardness (Shore A) | 30 to 90 ±5 |

| Thickness | 0.5 mm to 10.0 mm |

| Tolerance | ±0.1 mm (standard), ±0.05 mm (precision) |

| Die-Cutting Size | Up to 1200 mm × 800 mm |

| Water-Jet Cutting Accuracy | ±0.2 mm |

| Temperature Resistance | -60°C to +300°C (material-dependent) |

| Certifications | ISO 9001:2015, RoHS, REACH compliant |

| Production Lead Time | 7–15 days (prototype), 15–30 days (mass production) |

Partnering with Suzhou Baoshida means gaining access to a responsive, technically driven team committed to solving sealing challenges with precision and reliability. If your application demands a custom gasket solution backed by engineering rigor and manufacturing excellence, contact Mr. Boyce today.

Email Mr. Boyce at [email protected] to initiate a technical consultation. Include your gasket drawings, material requirements, operating conditions, and volume expectations to receive a detailed proposal and sample timeline. We respond to all inquiries within 24 hours on business days. Let us help you achieve leak-free performance—engineered to specification, built to last.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).