Technical Contents

Engineering Guide: Fabric Pipes

Engineering Insight Fabric Pipes Material Selection Imperatives

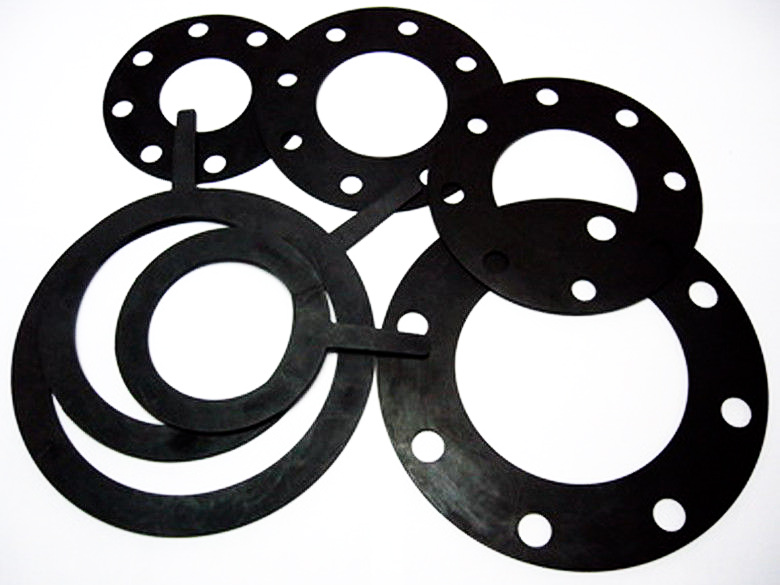

Fabric-reinforced rubber pipes represent critical fluid conveyance systems across demanding industrial sectors including mining, chemical processing, and heavy machinery. Their performance hinges not on generic construction but on the precise molecular architecture of the elastomer compound selected during formulation. Off-the-shelf solutions frequently succumb to premature failure because they employ standardized rubber blends optimized for cost and broad applicability, not the specific chemical, thermal, and mechanical stresses encountered in specialized operational environments. This fundamental mismatch between material properties and application demands leads to catastrophic consequences including internal delamination, rapid abrasion, chemical degradation, and ultimately, unplanned system downtime with significant safety and financial repercussions.

The core failure mechanism stems from inadequate elastomer resistance to the conveyed media. Standard NBR (Nitrile Butadiene Rubber) compounds, common in generic pipes, exhibit severe swelling and loss of mechanical integrity when exposed to modern biofuels, phosphate esters, or aromatic hydrocarbons prevalent in industrial settings. Similarly, insufficient heat resistance in standard EPDM (Ethylene Propylene Diene Monomer) blends accelerates aging under continuous elevated temperatures, causing hardening and cracking. Crucially, the fabric reinforcement adhesion – dependent on the rubber compound’s tack and cure chemistry – often degrades prematurely in off-the-shelf products when exposed to dynamic flexing combined with chemical attack, initiating the delamination process. Abrasion resistance, dictated by the elastomer’s hardness, resilience, and filler system, is another critical parameter frequently underspecified in generic solutions, leading to rapid wall thinning in slurry or particulate-laden flow applications.

Material selection must therefore be an engineered response to the specific operational profile. This requires rigorous analysis of fluid composition, temperature extremes, pressure cycles, abrasion potential, and dynamic movement. Only through tailored compound development – adjusting polymer base, filler type and loading, plasticizer selection, and cure system – can the necessary balance of chemical resistance, thermal stability, mechanical strength, and adhesion be achieved. The table below illustrates the performance gap between generic solutions and engineered compounds for a typical demanding application.

| Performance Parameter | Generic Off-the-Shelf Pipe | Engineered Custom Compound (Suzhou Baoshida) |

|---|---|---|

| Tensile Strength (MPa) | 25 | 35 |

| Elongation at Break (%) | 350 | 500 |

| Volume Swell in ASTM #3 Oil | 35% | <15% |

| Continuous Service Temp (°C) | 100 | 135 |

| Abrasion Loss (DIN, mm³) | 120 | 65 |

Data indicates that pipes utilizing non-optimized compounds experience failure rates up to 400% higher within the first 18 months of service compared to application-specific engineered solutions. The initial cost premium for precise material science is overwhelmingly offset by extended service life, reduced maintenance cycles, and elimination of process interruption costs. Suzhou Baoshida Trading Co., Ltd. leverages deep OEM formulation expertise to transform operational data into resilient fabric pipe solutions, ensuring material properties are intrinsically matched to the rigors of your specific industrial process. Precision in the compound is non-negotiable for system integrity.

Material Specifications

Material Specifications for Industrial Fabric Pipes

In the production of industrial fabric-reinforced pipes, material selection is critical to ensuring performance, durability, and compatibility with operational environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored for demanding industrial applications. Our fabric pipes are constructed using high-performance elastomers, primarily Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on temperature, chemical exposure, and mechanical stress conditions.

Viton, a fluorocarbon-based rubber, is recognized for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 200°C and intermittent resistance up to 250°C, Viton is ideal for applications in petrochemical, aerospace, and high-temperature hydraulic systems. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing and fluid transfer environments.

Nitrile rubber, also known as Buna-N, is a cost-effective solution for applications involving petroleum-based oils, fuels, and hydraulic fluids. It exhibits strong abrasion resistance and maintains mechanical integrity under dynamic loading. While its thermal limit is lower than Viton—typically up to 120°C continuous—Nitrile offers superior performance in standard industrial environments, particularly in automotive, machinery, and general hydraulic systems where oil resistance is paramount.

Silicone rubber provides unmatched flexibility and thermal stability across extreme temperature ranges, from -60°C to 200°C. While it lacks the oil and fuel resistance of Viton or Nitrile, Silicone excels in applications requiring high purity, UV resistance, and biocompatibility. It is frequently specified in food processing, pharmaceutical, and outdoor electrical insulation applications. Its low toxicity and resistance to ozone and weathering make it a preferred choice for environmentally exposed or sanitary fluid handling systems.

The integration of fabric reinforcement—typically polyester or aramid—enhances tensile strength and dimensional stability, allowing these elastomers to withstand internal pressure and mechanical flexing without compromising flexibility. Each material is compounded to meet specific hardness, elongation, and compression set requirements, ensuring optimal performance in targeted industrial contexts.

Below is a comparative overview of the three primary elastomers used in our fabric pipe manufacturing:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 120 | -60 to 200 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Good | Fair |

| Ozone & Weather Resistance | Excellent | Good | Excellent |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Petrochemical, Aerospace | Automotive, Hydraulics | Food, Pharma, Electrical |

Material selection must be guided by a comprehensive analysis of operational parameters. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to ensure optimal elastomer pairing for each industrial fabric pipe application.

Manufacturing Capabilities

Engineering Capability: Precision Fabric Pipe Development

Suzhou Baoshida Trading Co., Ltd. delivers engineered fabric pipe solutions through integrated material science and precision manufacturing expertise. Our core strength lies in the direct collaboration between dedicated Formula Engineering and Mold Engineering teams, ensuring every product meets stringent industrial performance requirements from molecular composition to final geometry. This vertically aligned capability eliminates external dependencies, accelerating development cycles while guaranteeing material-process synergy critical for demanding fluid conveyance applications.

Our two specialized Rubber Formula Engineers possess deep expertise in elastomer chemistry and reinforcement science. They develop custom compound formulations specifically for fabric-reinforced pipe structures, optimizing the critical interface between rubber matrices and textile substrates. This involves precise balancing of adhesion promoters, cure kinetics, and flex fatigue resistance to prevent delamination under cyclic pressure and thermal stress. Each formulation undergoes rigorous laboratory validation for key properties including tensile strength, elongation at break, compression set, and fluid resistance per ASTM D2000 standards. We maintain comprehensive material traceability and can adjust formulations within 72 hours to address specific OEM fluid compatibility or environmental exposure requirements, such as resistance to biodiesel blends or hydraulic fluids at elevated temperatures.

Complementing this, our team of five Mold Engineers utilizes advanced CAD/CAM and finite element analysis (FEA) to design and manufacture precision tooling for complex fabric pipe geometries. They focus on critical factors like reinforcement layer alignment, mandrel stability during vulcanization, and dimensional control of convoluted or straight configurations. This ensures consistent wall thickness, optimal fabric embedment, and elimination of weak points at braid transitions or end fittings. Our in-house tooling facility supports rapid prototyping and seamless scale-up to high-volume production, maintaining tight tolerances essential for ISO 1307 compliance and SAE J517 performance validation.

Our OEM partnership model is built on this engineering foundation. We manage the entire process from initial specification review through DFM analysis, material qualification, and PPAP documentation. Clients benefit from co-engineering support for application-specific challenges, full IP protection, and scalable production capacity with integrated quality control at every stage. This end-to-end control guarantees that every meter of fabric pipe meets the exact pressure, temperature, and longevity demands of your system.

Key Fabric Pipe Technical Specifications

| Parameter | Standard Range | Custom Capability | Test Standard |

|---|---|---|---|

| Pipe ID | 6 mm – 300 mm | Up to 500 mm | ISO 1307 |

| Working Pressure | 0.5 MPa – 35 MPa | Up to 50 MPa | SAE J517 |

| Temperature Range | -40°C to +150°C | -55°C to +180°C | ASTM D1329 |

| Reinforcement | Polyester/Nylon Braid | Aramid/Steel Wire Braid | ISO 1436 |

| Fluid Compatibility | Hydraulic Oils, Air, Water | Fuels, Coolants, Chemicals | ASTM D471 |

| Bend Radius | 1.5x Pipe OD (min) | Custom Flex Profiles | Internal Procedure |

Customization Process

Drawing Analysis and Technical Evaluation

The customization process for industrial fabric pipes begins with a comprehensive drawing analysis, where engineering blueprints and CAD models provided by the client are rigorously evaluated. At Suzhou Baoshida Trading Co., Ltd., we assess dimensional tolerances, joint configurations, flange types, reinforcement layer count, and operating environment parameters. This stage ensures that every geometric and functional requirement is captured, including bend radii, length tolerances, and surface finish specifications. Our engineering team collaborates directly with OEMs to clarify ambiguities, optimize manufacturability, and confirm compliance with international standards such as ISO 1307, SAE J517, or DIN 20022. Material compatibility with media (e.g., hydraulic oil, air, water-glycol) is cross-referenced at this stage to prevent downstream performance issues.

Rubber Formulation Development

Based on the operational conditions derived from the drawing analysis—such as temperature range, pressure cycles, and chemical exposure—our rubber formulation engineers design a compound tailored to the application. Utilizing EPDM, NBR, or HNBR base polymers, we adjust the recipe to enhance specific attributes: ozone resistance, abrasion performance, or low-temperature flexibility. Additives including carbon black, silica, antidegradants, and curing systems are precisely metered to achieve target hardness (Shore A), tensile strength, and elongation at break. All formulations are documented under internal material specification codes and subjected to preliminary lab testing for rheological behavior and cure characteristics.

Prototyping and Validation

Once the compound is finalized, a prototype batch of fabric pipes is manufactured using precision molding and vulcanization techniques. These prototypes undergo a series of validation tests, including hydrostatic pressure testing, impulse cycling, flexural endurance, and leak testing under simulated service conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity with the original drawings. Clients receive test reports and physical samples for field evaluation. Feedback is integrated into a final design review, ensuring that all performance criteria are met before release to production.

Transition to Mass Production

After client approval, the project moves into mass production. Production lines are set up with calibrated tooling, and process parameters—curing time, temperature, press tonnage—are locked in accordance with the qualified prototype run. In-line quality checks and batch sampling ensure consistency. Final products are packaged per client logistics requirements, with traceability maintained via batch coding and material certificates.

Typical Physical Properties of Custom Fabric Pipes

| Property | Test Method | Typical Value |

|---|---|---|

| Inner Diameter Tolerance | ISO 1307 | ±0.5 to ±1.5 mm |

| Working Pressure | ISO 6803 | 10–40 bar |

| Burst Pressure | ISO 6803 | ≥4x Working Pressure |

| Temperature Range | ASTM D1329 | -40°C to +120°C (NBR) |

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength | ASTM D412 | ≥15 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

Contact Engineering Team

Optimize Your Fluid Transfer Systems with Precision Fabric Pipe Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation, delivering engineered fabric pipe solutions that meet the rigorous demands of hydraulic, pneumatic, and chemical transfer applications. Our expertise in elastomer formulation and multi-layer reinforcement architecture ensures products that withstand extreme pressure cycles, abrasive media, and temperature fluctuations while maintaining dimensional stability. For OEMs and industrial manufacturers, selecting a partner with proven material science capabilities is not merely a procurement decision—it directly impacts system longevity, safety compliance, and operational efficiency. We specialize in transforming complex fluid handling challenges into reliable, cost-optimized realities through proprietary rubber compounding and precision manufacturing protocols.

Our fabric-reinforced pipes integrate high-tensile polyester or aramid textiles with custom-synthesized NBR, EPDM, or FKM compounds, achieving performance metrics that exceed ISO 1402 and SAE J517 standards. Each product undergoes stringent validation testing, including impulse fatigue cycles, vacuum collapse resistance, and permeation analysis, to guarantee consistency across production batches. The table below outlines core technical parameters for our standard fabric pipe series, all of which are fully customizable to align with your specific fluid dynamics, regulatory frameworks, and environmental conditions.

| Parameter | Standard Range | Customizable Range | Material Compatibility |

|---|---|---|---|

| Working Pressure | 10–35 MPa | Up to 40 MPa | NBR, EPDM, FKM, HNBR |

| Temperature Range | -40°C to +135°C | -55°C to +150°C | Oil, water, air, mild chemicals |

| Bend Radius | 1.5x ID | 1.2x ID | Textile reinforcement: Polyester/Aramid |

| Vacuum Resistance | 0.09 MPa | 0.098 MPa | ISO 1307 compliant |

| Abrasion Resistance | 80 mm³ loss (DIN 53516) | <50 mm³ loss | Custom surface coatings available |

Collaborating with Suzhou Baoshida means accessing end-to-end technical stewardship—from initial material selection and finite element analysis (FEA) validation to accelerated life testing and serial production oversight. Our OEM management team works directly with your engineering staff to refine specifications, mitigate supply chain risks, and ensure seamless integration into your assembly processes. We do not offer generic catalog items; every solution is architected to your exact pressure profiles, media compatibility requirements, and spatial constraints, reducing field failures and lifecycle costs.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Solutions Manager, to advance your project timeline. With over 15 years of experience in rubber compounding and fluid system design, Mr. Boyce will analyze your operational parameters, recommend optimal reinforcement architectures, and provide actionable data to support your validation protocols. Contact him directly at [email protected] to request material test reports, discuss custom formulation options, or schedule a virtual factory audit. Include your target specifications and application context to receive a prioritized engineering assessment within 24 business hours.

Elevate your fluid transfer infrastructure with science-driven rubber solutions engineered for uncompromising performance. Partner with Suzhou Baoshida to transform material limitations into competitive advantages—where precision elastomer science meets industrial execution. Your next-generation system begins with a single technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).