Technical Contents

Engineering Guide: Custom Rubber Gaskets

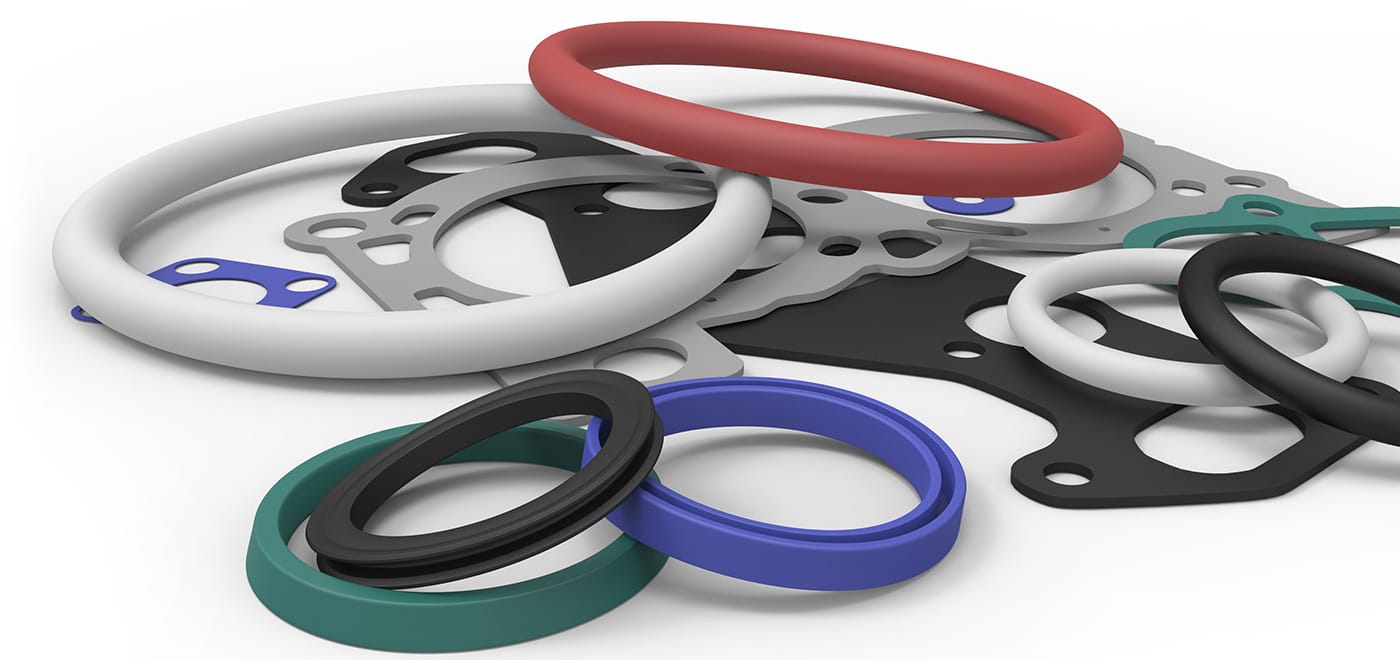

Engineering Insight: The Critical Role of Material Selection in Custom Rubber Gaskets

In precision sealing applications, the performance and longevity of rubber gaskets are fundamentally determined by material selection. While off-the-shelf gaskets may appear to offer a cost-effective and readily available solution, they frequently fail to meet the rigorous demands of industrial environments. These generic components are typically manufactured from standard elastomers designed for broad compatibility rather than specific operational conditions. As a result, they are prone to premature degradation, leakage, and system failure when exposed to extreme temperatures, aggressive chemicals, or dynamic mechanical stresses.

Custom rubber gaskets, by contrast, are engineered to perform under defined parameters. The selection of the appropriate elastomer is not a secondary consideration—it is the cornerstone of reliable sealing performance. Factors such as chemical exposure, temperature range, compression set resistance, and sealing pressure must all be evaluated during the design phase. For example, a gasket exposed to hydraulic fluids in an automotive transmission system will require nitrile rubber (NBR) for its excellent oil resistance, whereas a pharmaceutical processing line may demand fluorocarbon (FKM) for its inertness and high-temperature stability.

Material misselection is one of the leading causes of gasket failure. A common pitfall occurs when standard EPDM gaskets are used in oil-rich environments, despite EPDM’s poor resistance to hydrocarbons. Similarly, silicone gaskets, while effective in high-temperature applications up to 200°C, exhibit low tensile strength and poor abrasion resistance, making them unsuitable for high-wear installations.

At Suzhou Baoshida Trading Co., Ltd., we prioritize material science in every custom gasket solution. Our engineering team conducts a comprehensive application review to match elastomer properties with operational demands. This tailored approach ensures optimal performance, reduced maintenance cycles, and enhanced system safety.

The following table outlines key elastomer properties for common industrial applications:

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Applications |

|---|---|---|---|

| Nitrile (NBR) | -40 to +120 | Oils, fuels, hydraulic fluids | Automotive, hydraulics |

| Fluorocarbon (FKM) | -20 to +200 | Acids, oils, solvents, steam | Aerospace, chemical processing |

| EPDM | -50 to +150 | Water, steam, alkalis, oxygenated solvents | HVAC, water treatment |

| Silicone (VMQ) | -60 to +200 | Ozone, UV, water, moderate chemicals | Medical devices, food processing |

| Neoprene (CR) | -40 to +100 | Refrigerants, mild acids, flame-resistant | Electrical enclosures, refrigeration |

Understanding these material characteristics enables engineers to avoid the pitfalls of generic gasket use. Off-the-shelf solutions may reduce initial procurement costs, but they often lead to unplanned downtime, safety risks, and higher total cost of ownership. Custom rubber gaskets, precisely engineered with the correct elastomer, represent a strategic investment in system integrity and operational efficiency.

Material Specifications

Material Specifications for Precision Rubber Gaskets

Selecting the optimal elastomer is critical for gasket performance in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., our engineering team rigorously evaluates material properties against operational parameters including temperature extremes, chemical exposure, pressure cycles, and regulatory requirements. Viton, Nitrile, and Silicone represent three foundational polymers for custom gasket solutions, each offering distinct advantages under specific conditions. Understanding their inherent characteristics ensures longevity, leak prevention, and compliance with OEM specifications.

Viton (fluoroelastomer, FKM) delivers exceptional resistance to high temperatures, aggressive chemicals, and fuels. It maintains structural integrity from -20°C to +230°C continuous service, with brief excursions up to 300°C. Viton excels in aerospace, automotive fuel systems, and chemical processing due to its low permeability to hydrocarbons and resistance to ozone, acids, and bases. However, its higher cost and reduced flexibility at sub-zero temperatures necessitate careful application assessment. Baoshida formulates Viton compounds meeting ASTM D2000 AA-grade standards for critical sealing interfaces.

Nitrile rubber (NBR) remains the industry standard for cost-effective oil and fuel resistance. Operating effectively between -40°C and +120°C, NBR provides excellent abrasion resistance and tensile strength, making it ideal for hydraulic seals, O-rings in machinery, and automotive transmission systems. Its performance degrades with exposure to ozone, ketones, and chlorinated hydrocarbons. Baoshida optimizes NBR formulations with tailored acrylonitrile content (34%–50%) to balance oil resistance versus low-temperature flexibility, adhering to ISO 3601 flange gasket standards.

Silicone (VMQ) dominates applications requiring extreme temperature resilience and biocompatibility. It functions reliably from -60°C to +200°C, with specialized grades enduring +230°C. Silicone exhibits outstanding resistance to oxidation, UV radiation, and microbial growth, fulfilling FDA 21 CFR 177.2600 and USP Class VI requirements for medical and food-grade gaskets. Limitations include poor tear strength, susceptibility to퀵 fuels, and higher gas permeability. Baoshida employs reinforced silicone compounds for critical aerospace and life science sealing where thermal stability is non-negotiable.

The comparative analysis below summarizes core specifications for informed material selection:

| Material | Temperature Range (°C) | Key Strengths | Key Limitations | Typical Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Superior chemical/fuel resistance | High cost, poor low-temp flexibility | Jet engines, chemical valves |

| Nitrile (NBR) | -40 to +120 | Excellent oil resistance, cost-effective | Weak vs ozone/ketones | Hydraulic systems, fuel hoses |

| Silicone (VMQ) | -60 to +200 | Extreme temp range, biocompatible | Low tear strength, high permeability | Medical devices, oven gaskets |

Material selection directly impacts gasket service life and system reliability. Baoshida’s OEM engineering team collaborates with clients to analyze fluid compatibility, compression set requirements per ASTM D395, and dynamic stress factors. Our custom compounding capabilities allow precise adjustment of hardness (40–90 Shore A), durometer, and filler systems to meet exacting performance criteria. Partner with Baoshida to transform material science into precision sealing solutions that exceed operational demands.

Manufacturing Capabilities

Engineering Capabilities in Custom Rubber Gasket Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering division forms the backbone of our precision rubber seal manufacturing services. With a dedicated team of five certified mold engineers and two specialized rubber formulation engineers, we deliver fully integrated OEM solutions tailored to the exact performance, environmental, and dimensional requirements of our industrial clients. Our engineering synergy ensures that every custom rubber gasket is conceived, designed, and produced with scientific rigor and technical precision.

Our mold engineers possess extensive experience in precision tooling for compression, transfer, and injection molding processes. They utilize advanced CAD/CAM software—SolidWorks, AutoCAD, and UG NX—to develop optimized mold designs that ensure tight tolerances, uniform material flow, and minimal flash. Finite element analysis (FEA) is routinely applied during the design phase to simulate stress distribution and deformation under operational loads, significantly reducing prototyping cycles and accelerating time-to-market. All molds are fabricated in-house or through vetted partners using high-grade tool steels, with surface finishes and venting systems engineered to match the specific polymer’s flow characteristics.

Complementing our mold expertise is our proprietary rubber compounding capability. Our two formulation engineers hold advanced degrees in polymer science and have over 15 years of combined experience in elastomer development. They specialize in tailoring rubber compounds for extreme environments—resistance to high temperatures, aggressive chemicals, ozone, and dynamic compression. Whether the application demands EPDM for weather resistance, FKM for fuel exposure, NBR for oil resistance, or specialty materials like ACM or AEM, our team designs formulations that meet or exceed ASTM D2000 specifications. Each compound is validated through rigorous lab testing for tensile strength, elongation, hardness, compression set, and volume swell.

Our OEM capabilities extend beyond design and formulation to full project lifecycle management. We engage with clients from initial concept through to mass production, providing DFM (Design for Manufacturability) feedback, material selection guidance, and first-article inspection reports. All processes adhere to ISO 9001 standards, with full traceability maintained for molds, raw materials, and production batches.

The integration of mold and material engineering allows us to solve complex sealing challenges—such as multi-material bonding, low-temperature flexibility, or long-term compression recovery—that off-the-shelf gaskets cannot address. This vertical expertise positions Suzhou Baoshida as a strategic partner in high-reliability industries including automotive, energy, industrial automation, and medical devices.

| Parameter | Capability Range |

|---|---|

| Mold Tolerance | ±0.05 mm |

| Hardness Range (Shore A) | 30–90 |

| Operating Temperature Range | -60°C to +300°C (material-dependent) |

| Standard Elastomers | NBR, EPDM, FKM, NR, SIL, CR, ACM, AEM, IIR |

| Secondary Operations | Bonding, Insert Molding, Printing, Cryogenic Deflashing |

| Sample Lead Time | 7–14 days (based on complexity) |

| Production Volume Flexibility | Prototypes to 500,000+ units/month |

Our engineering-first approach ensures that every rubber gasket we produce is not just a component—but a precision-engineered sealing solution.

Customization Process

Custom Rubber Gasket Manufacturing Process: Precision Engineering Pathway

At Suzhou Baoshida Trading Co., Ltd., our custom rubber gasket production adheres to a rigorously defined engineering sequence, ensuring dimensional accuracy, material performance, and functional reliability for demanding industrial applications. This structured pathway mitigates risk and optimizes time-to-market for OEM clients.

Drawing Analysis initiates the process. Our engineering team conducts a comprehensive review of client-provided technical specifications, focusing on geometric dimensioning and tolerancing (GD&T), critical sealing surfaces, and interface requirements. We assess environmental factors including operating temperature extremes, fluid exposure, pressure differentials, and dynamic/static loading conditions. This phase identifies potential manufacturability challenges early, such as excessive thin sections, complex undercuts, or tolerance stacks incompatible with rubber flow characteristics. Client collaboration at this stage is essential to validate application intent and refine specifications where necessary, preventing costly iterations later.

Formulation leverages our material science expertise to translate application demands into a precise compound recipe. Based on the environmental analysis from Drawing Review, we select the optimal base polymer (e.g., NBR, EPDM, FKM, Silicone) and engineer the additive package. This includes curatives (sulfur or peroxide systems), fillers (reinforcing carbon black, silica), plasticizers, antioxidants, and specialized additives for flame resistance or low-temperature flexibility. Each component ratio is calculated to achieve target properties like compression set resistance, tensile strength, and fluid compatibility. Material selection directly dictates long-term gasket integrity under operational stress.

Prototyping validates both design and formulation. Using precision tooling (often CNC-machined for initial runs), we produce physical gaskets from the engineered compound. These prototypes undergo stringent in-house testing per ASTM/ISO standards: compression set analysis, fluid immersion resistance checks, hardness verification, and dimensional metrology against the original drawing. Client-side functional testing in the actual assembly environment is strongly encouraged. Feedback from this phase drives minor compound adjustments or drawing refinements, ensuring the final design meets all performance criteria before committing to production tooling.

Mass Production commences only after prototype approval. We deploy optimized, hardened steel molds for high-volume molding (compression, transfer, or injection). Our ISO-certified production lines implement Statistical Process Control (SPC) at critical stages: raw material batch verification, preform weighing, cure cycle monitoring, and 100% visual inspection. Dimensional sampling using calibrated CMMs ensures continued conformance to tolerances. Final gaskets receive comprehensive lot testing for key physical properties, with full traceability from raw material batch to finished part. This disciplined transition guarantees consistent, high-yield output meeting OEM quality expectations.

Material selection is foundational to gasket performance. The following table outlines key properties of common elastomers we formulate for custom applications:

| Material | Typical Hardness (Shore A) | Temp Range (°C) | Compression Set (70h, 70°C) | Key Fluid Resistance | Primary Applications |

|---|---|---|---|---|---|

| NBR (Nitrile) | 50-90 | -40 to +120 | ≤ 25% | Oils, Fuels, Hydraulic Fluids | Automotive Seals, Fuel Systems |

| EPDM | 40-90 | -50 to +150 | ≤ 20% | Water, Steam, Brake Fluid, Alkalis | HVAC, Water Systems, Radiators |

| FKM (Viton®) | 60-80 | -20 to +230 | ≤ 15% | Aggressive Chemicals, Jet Fuels, High-Temp Oils | Aerospace, Chemical Processing |

| Silicone | 30-80 | -60 to +200 | ≤ 25% | Extreme Temp Stability, Ozone | Medical Devices, Food Processing, High-Temp Seals |

This systematic approach, from initial drawing scrutiny through validated mass production, embodies Suzhou Baoshida’s commitment to engineering excellence in precision rubber seals. We partner with OEMs to transform conceptual sealing requirements into robust, manufacturable solutions.

Contact Engineering Team

For mission-critical sealing applications across aerospace, automotive, industrial machinery, and medical device manufacturing, precision-engineered rubber gaskets are not just components—they are performance determinants. At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and production of custom rubber gaskets tailored to exact OEM specifications, ensuring optimal fit, longevity, and environmental resistance. Our expertise spans material selection, compression set performance, and dimensional accuracy down to ±0.05 mm, enabling us to meet the most stringent industrial requirements.

We understand that every application presents unique challenges—whether it’s exposure to extreme temperatures, aggressive chemicals, or dynamic mechanical stress. That’s why our engineering team works directly with clients to analyze operating conditions, define performance parameters, and select the optimal elastomer compound. From standard NBR and EPDM to specialty materials like FKM, silicone, and hydrogenated nitrile (HNBR), we provide comprehensive material certification and batch traceability. Our in-house tooling facility supports rapid prototyping and low-to-high volume production, ensuring fast turnaround without compromising quality.

To illustrate our technical capabilities, the following table outlines key performance specifications for common elastomers used in custom gasket manufacturing:

| Material | Hardness Range (Shore A) | Temperature Range (°C) | Key Resistance Properties |

|---|---|---|---|

| NBR (Nitrile) | 40–90 | -30 to +100 | Oil, fuel, water, abrasion |

| EPDM | 45–85 | -50 to +150 | Ozone, UV, steam, weathering |

| FKM (Viton®) | 50–90 | -20 to +200 | High-temp oils, acids, hydrocarbons |

| Silicone | 30–80 | -60 to +200 | Extreme cold/heat, biocompatibility |

| HNBR | 50–90 | -40 to +150 | High pressure, dynamic stress, oil |

All gaskets are manufactured under ISO 9001-certified processes, with full documentation including First Article Inspection (FAI) reports, material test data, and dimensional validation. We support multiple molding techniques—compression, transfer, and injection—to accommodate complex geometries and tight tolerances.

If your operation demands gaskets that deliver consistent sealing integrity under real-world conditions, it’s time to partner with an engineering-focused supplier. Contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd., to discuss your next custom sealing solution. With decades of experience in rubber formulation and precision molding, we are equipped to solve even the most demanding sealing challenges.

Reach out today via email at [email protected] to initiate a technical consultation. Include your application details, performance requirements, and any existing drawings or samples for rapid evaluation. Our team responds to all inquiries within 12 business hours and can provide material recommendations, prototype timelines, and competitive pricing within 48 hours. For time-sensitive projects, expedited development and testing services are available.

Partner with Suzhou Baoshida for precision rubber gaskets engineered to perform—where reliability meets exacting standards.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).