Technical Contents

Engineering Guide: Air Proof Door Seal

Engineering Insight: Material Selection in Air Proof Door Seals

The performance of an air proof door seal is fundamentally determined by its material composition. In precision environments such as cleanrooms, medical enclosures, and industrial HVAC systems, even minor air leakage can compromise system integrity, energy efficiency, and regulatory compliance. While off-the-shelf rubber seals may appear cost-effective, they frequently fail to meet the stringent demands of specialized applications due to inadequate material properties and inconsistent manufacturing tolerances.

Standard elastomers like generic EPDM or silicone are commonly used in commercial door seals, but these materials often lack the tailored formulation needed for reliable air sealing under variable thermal, mechanical, and environmental conditions. For instance, in high-cycle applications, conventional seals may exhibit compression set, leading to permanent deformation and loss of sealing force. Similarly, exposure to ozone, UV radiation, or chemical agents can accelerate degradation in non-engineered compounds, resulting in cracking, hardening, or swelling.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific material engineering. Our air proof door seals utilize high-purity silicone, fluorosilicone, and specialty EPDM compounds, each selected based on service environment. High-temperature applications demand fluorosilicone for its thermal stability up to 250°C, while EPDM formulations with enhanced ozone resistance are preferred in outdoor or industrial settings. For cleanroom and pharmaceutical applications, platinum-cured silicone ensures low particle shedding and compliance with ISO 14644 standards.

Moreover, material hardness—measured in Shore A—plays a critical role in sealing performance. A seal that is too hard will not conform to surface irregularities, while one that is too soft may extrude under pressure or degrade prematurely. Our engineering team customizes hardness between 40 and 70 Shore A, depending on door weight, closing force, and required compression deflection.

Off-the-shelf solutions often fail because they assume a universal material profile, neglecting the dynamic interplay between mechanical load, environmental exposure, and longevity. In contrast, precision-engineered seals from Baoshida are developed through iterative testing, including accelerated aging, compression set analysis, and air leakage validation under controlled differential pressures.

The following table outlines key material properties for common elastomers used in air proof door seals:

| Material | Temperature Range (°C) | Hardness (Shore A) | Compression Set (% @ 22h, 150°C) | Key Applications |

|---|---|---|---|---|

| Platinum Silicone | -60 to 200 | 40–70 | ≤20 | Cleanrooms, medical, food processing |

| Fluorosilicone | -20 to 250 | 50–70 | ≤25 | Aerospace, high-temp industrial |

| EPDM (High Purity) | -50 to 150 | 45–65 | ≤30 | HVAC, outdoor enclosures |

| Nitrile (NBR) | -30 to 100 | 50–75 | ≤35 | Oil-resistant environments |

In conclusion, the reliability of an air proof door seal is not a function of geometry alone, but of intelligent material science. By rejecting generic solutions and embracing engineered elastomers, manufacturers ensure long-term performance, regulatory compliance, and operational efficiency.

Material Specifications

Material Specifications for Precision Air Proof Door Seals

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions for critical air containment applications. Our air proof door seals undergo rigorous material selection to ensure zero leakage under extreme operational stresses. As an ISO-certified OEM partner, we prioritize chemical composition, thermal stability, and mechanical resilience in all formulations. Below we detail three premium elastomers validated for industrial door sealing: Viton® fluoroelastomer, Nitrile rubber (NBR), and Silicone (VMQ). Each material is compounded to meet ASTM D2000-22 classification standards, with Shore A hardness precision-controlled to ±3 points.

Viton® fluoroelastomer provides unparalleled resistance to aggressive chemicals and sustained high temperatures. Its fluorocarbon backbone maintains integrity in aerospace fuel systems, semiconductor cleanrooms, and chemical processing plants where exposure to oils, acids, and ozone is unavoidable. Operating continuously from -20°C to 230°C, Viton seals exhibit minimal gas permeability—critical for maintaining air pressure differentials. Compression set values remain below 20% after 70 hours at 200°C, ensuring long-term sealing force retention.

Nitrile rubber (NBR) offers optimal cost-performance balance for general industrial environments. With acrylonitrile content tailored between 34–45%, we achieve exceptional resistance to petroleum-based fluids and hydraulic oils. NBR seals function reliably from -40°C to 120°C, making them ideal for warehouse doors, transportation enclosures, and machinery access panels. Tensile strength ranges from 15–25 MPa, with elongation at break exceeding 300%. This material’s abrasion resistance ensures durability against frequent door cycling.

Silicone (VMQ) excels in ultra-high and ultra-low temperature extremes. Its siloxane polymer structure delivers consistent performance from -60°C to 250°C, with short-term peaks to 300°C. Silicone’s inert composition meets FDA and USP Class VI requirements, suiting pharmaceutical and food processing facilities where air purity is non-negotiable. While tensile strength is moderate (6–10 MPa), its exceptional flexibility at cryogenic temperatures prevents seal fracture during cold storage door operations.

The following table compares critical physical properties per ASTM test methods:

| Material | Temp Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Compression Set (% after 70h) | Key Applications | ASTM D2000 Classification |

|---|---|---|---|---|---|---|---|

| Viton® (FKM) | -20 to 230 | 70–90 | 12–18 | 150–250 | <20 @ 200°C | Chemical plants; Semiconductor | FC 745 |

| Nitrile (NBR) | -40 to 120 | 50–90 | 15–25 | 300–500 | <35 @ 100°C | Warehouses; Hydraulic systems | BK 744 |

| Silicone (VMQ) | -60 to 250 | 40–80 | 6–10 | 400–700 | <25 @ 200°C | Pharma; Cold storage | SE 745 |

Material selection must align with environmental exposure, regulatory requirements, and lifecycle cost analysis. All compounds are manufactured under IATF 16949 protocols with traceable lot numbering. Consult our engineering team for custom formulations addressing unique permeation challenges or regulatory mandates. Precision in material science ensures absolute air integrity—non-negotiable in critical containment scenarios.

Manufacturing Capabilities

Engineering Capability: Precision Development for Air Proof Door Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to rubber formulation and mold design. With five dedicated mold engineers and two specialized rubber formula engineers, we maintain full in-house control over the development lifecycle of air proof door seals. This integrated team structure enables seamless collaboration between material science and precision tooling, ensuring that every seal meets the exact performance demands of industrial, transportation, and commercial applications where air leakage cannot be compromised.

Our mold engineers utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to design high-precision molds with tight tolerances, optimized flow channels, and extended service life. Each mold is rigorously tested through simulation tools to predict material behavior during vulcanization, minimizing defects and cycle time. This precision engineering ensures consistent part geometry, critical for achieving uniform compression and long-term sealing integrity under dynamic environmental conditions.

Complementing mold development is our proprietary rubber formulation capability. The two formula engineers on staff specialize in elastomer chemistry, focusing on EPDM, silicone, and neoprene compounds tailored for air tightness, compression set resistance, temperature stability, and aging performance. By controlling the formulation process internally, we eliminate reliance on third-party rubber suppliers and can rapidly iterate material properties to meet specific OEM requirements. Whether the application demands low outgassing in cleanroom environments or resilience in extreme temperature cycles from -40°C to +150°C, our formulations are engineered for functional reliability.

We operate as a full-service OEM partner, supporting customers from concept to mass production. Our engineering team engages early in the design phase, providing DFM (Design for Manufacturability) feedback, prototype validation, and performance testing under simulated operational conditions. This proactive collaboration reduces time-to-market and ensures manufacturability without sacrificing performance.

All air proof door seals are validated against key performance metrics, including compression deflection force, air leakage rate, and cyclic durability. Our facility is equipped with environmental chambers, tensile testers, and leak detection systems to verify compliance with international standards such as ISO 10243 and DIN 7865.

The combination of advanced tooling, scientific material development, and OEM-centric engineering makes Suzhou Baoshida a trusted partner for mission-critical sealing solutions.

| Property | Standard Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Temperature Range | -40°C to +150°C | ISO 1817 |

| Air Leakage Rate | ≤0.1 L/min·m at 1 kPa | Internal Test Protocol |

| Cyclic Durability | 100,000 cycles (no cracking) | Custom Fixture Test |

Customization Process

Customization Process for Precision Airproof Door Seals

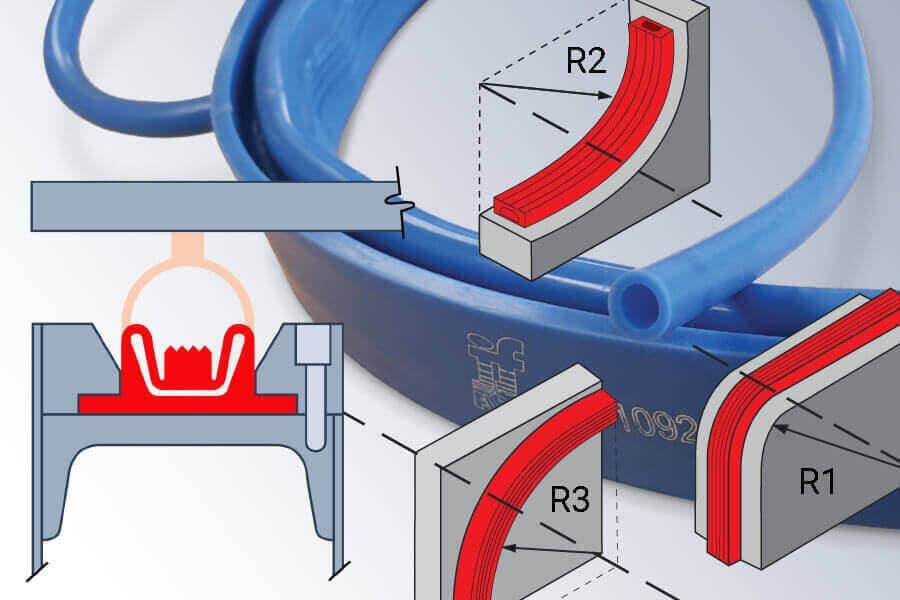

At Suzhou Baoshida Trading Co., Ltd., our airproof door seal customization follows a rigorously controlled sequence to ensure zero leakage under extreme operational conditions. This process begins with comprehensive drawing analysis, where engineering teams dissect client-provided CAD files and technical specifications. Critical dimensions, geometric tolerances per ASME Y14.5, and interface requirements are validated against ISO 3302-1 material deformation limits. We identify potential stress concentration zones and verify compliance with OEM sealing force parameters, typically 15–25 N/mm for aerospace and rail applications. Non-conformities trigger immediate cross-functional feedback loops with the client to resolve ambiguities before material selection.

Material formulation constitutes the scientific core of our workflow. Based on environmental exposure data from the drawing analysis phase, our rubber chemists develop bespoke compounds targeting specific performance thresholds. For instance, doors operating in Arctic conditions demand silicone formulations with glass transition temperatures below -60°C, while chemical-resistant EPDM variants are prioritized for industrial cleanrooms. Key variables include polymer backbone selection, filler reinforcement ratios, and peroxide vs. sulfur curing systems to optimize compression set resistance. All formulations undergo predictive aging simulations via ASTM D2240 and D395 protocols prior to prototyping.

Prototyping leverages CNC-machined aluminum molds to produce 5–10 validation units per iteration. Each prototype undergoes multi-axis pressure testing in our climate-controlled chamber, simulating -40°C to +150°C cycles with 0.5 MPa differential pressure. Leakage rates are quantified using helium mass spectrometry per ISO 10648-2, with acceptance thresholds set at ≤1.0 × 10⁻⁶ mbar·L/s. Dimensional audits via CMM verify conformity to ±0.05 mm tolerances. Only prototypes passing 10,000-cycle durability tests advance to client validation.

Mass production deployment activates our ISO 9001-certified manufacturing cell. Real-time process monitoring tracks injection molding parameters including cavity pressure, cure time deviation (±3 seconds), and post-cure oven profiles. Every batch undergoes 100% visual inspection via automated optical systems and statistical sampling for hardness (Shore A), tensile strength, and compression set. Full traceability is maintained through laser-etched batch codes linked to raw material certificates and process data logs. Production output sustains CpK ≥1.67 for critical dimensions, ensuring consistent airtight performance across 50,000+ units.

Material Performance Specifications for Critical Applications

| Material Type | Key Properties | Typical Applications | Performance Limits |

|---|---|---|---|

| High-Purity Silicone | 60–80 Shore A hardness, -60°C to +230°C range | Aerospace cabin doors, medical isolation rooms | Compression set ≤20% after 72h at 150°C |

| Peroxide-Cured EPDM | 50–70 Shore A, ozone resistance >100 pphm | Train vestibule doors, cleanroom entrances | Water absorption <5%, tensile strength >10 MPa |

| Fluorosilicone | Chemical resistance to jet fuels, -45°C to +200°C | Military aircraft access panels | Helium permeability <1.5 × 10⁻¹⁰ m³·m/m²·s·Pa |

This end-to-end methodology guarantees airproof integrity while minimizing time-to-market. Suzhou Baoshida’s integration of material science rigor with industrial-scale precision ensures seals meet the most stringent OEM airtightness mandates.

Contact Engineering Team

For industrial manufacturers and OEMs requiring high-performance sealing solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision rubber engineering. Specializing in custom-engineered air proof door seals, we deliver uncompromising reliability for applications in cleanrooms, medical enclosures, transportation systems, and high-pressure environments. Our seals are formulated to meet exacting standards for airtight integrity, compression set resistance, and long-term durability under dynamic and static conditions.

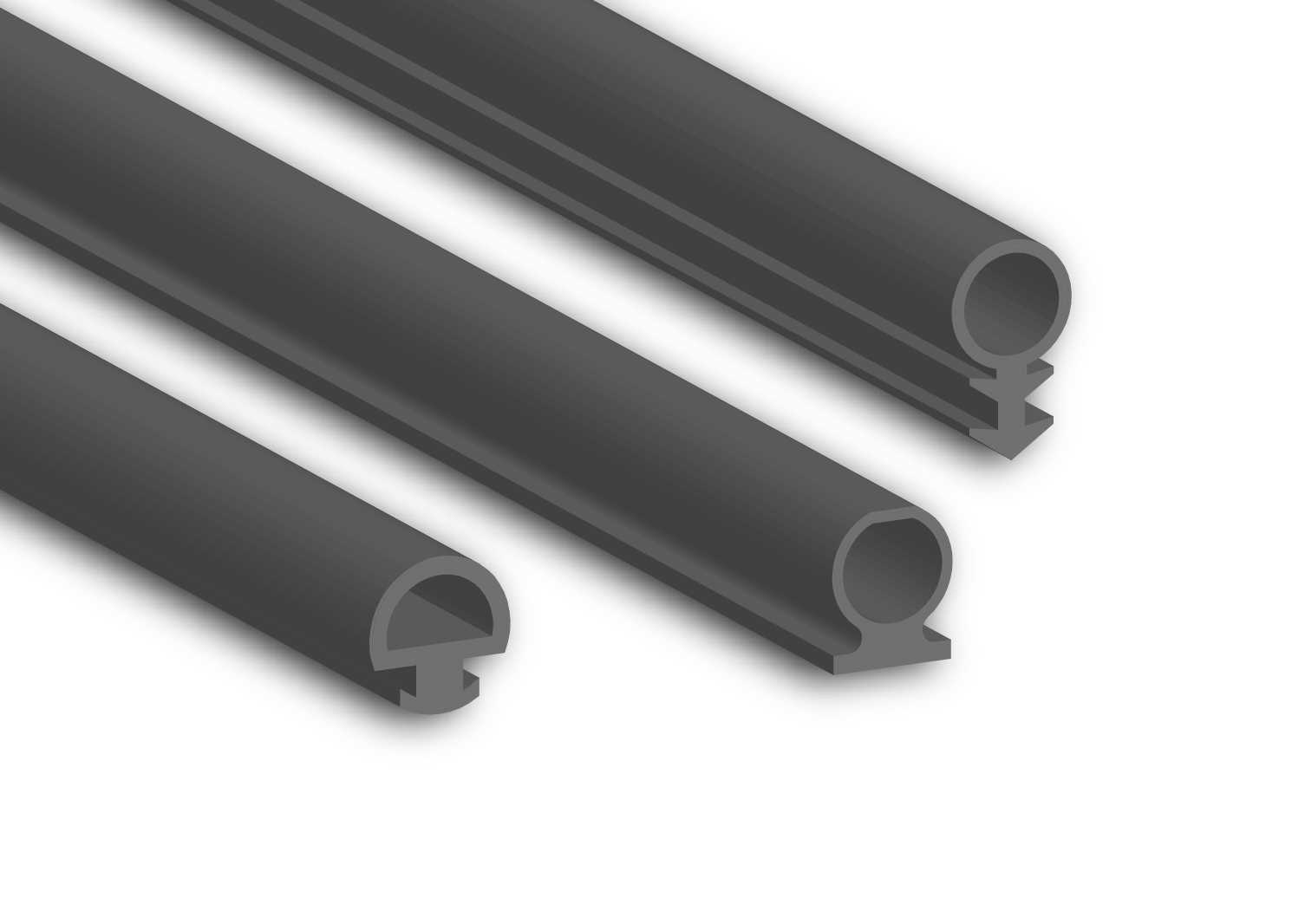

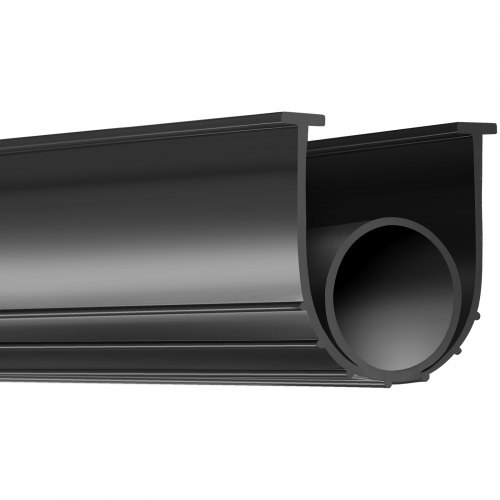

Each air proof door seal produced by Suzhou Baoshida is developed through a rigorous process of material selection, mold design, and performance validation. We utilize advanced elastomers such as EPDM, silicone (VMQ), fluorosilicone (FVMQ), and chloroprene (CR), chosen for their exceptional sealing characteristics, temperature resilience, and chemical stability. Our engineering team works directly with clients to analyze sealing interface geometry, deflection requirements, environmental exposure, and lifecycle expectations—ensuring the final product performs flawlessly in real-world conditions.

We understand that in precision manufacturing, tolerances matter. Our production capabilities support tight dimensional control down to ±0.1 mm, with customizable durometer ratings from 40 to 80 Shore A. Whether you require sponge rubber profiles for compression sealing or solid extrusions for structural integrity, our formulations are optimized for consistent density, uniform cell structure, and minimal outgassing—critical for sensitive environments.

The following table outlines standard technical specifications for our most commonly requested air proof door seal configurations:

| Property | Material | Value / Range | Test Method |

|---|---|---|---|

| Hardness (Shore A) | EPDM, Silicone, CR | 40–80 ±5 | ASTM D2240 |

| Tensile Strength | EPDM | ≥9.0 MPa | ASTM D412 |

| Elongation at Break | Silicone | ≥250% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | EPDM | ≤20% | ASTM D395B |

| Operating Temperature Range | Silicone | -60°C to +230°C | Internal |

| Linear Dimensional Tolerance | Extruded Profiles | ±0.1 mm to ±0.5 mm | ISO 3302-1 |

| Flame Resistance | CR | Self-extinguishing | UL 94 HF-1 |

All materials are compliant with RoHS, REACH, and FDA (where applicable), and can be customized for low outgassing (per ASTM E595) for aerospace and semiconductor applications.

To initiate a technical consultation or request a quotation for custom air proof door seals, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in rubber formulation and industrial sealing solutions, Mr. Boyce provides direct engineering support to global clients, ensuring seamless integration of our seals into your assembly process. He is available to review CAD drawings, material specifications, volume requirements, and delivery timelines.

Reach out via email at [email protected] to discuss your project requirements. We support low-volume prototyping through high-volume production runs, with rapid tooling and sample turnaround. Partner with Suzhou Baoshida for engineered rubber solutions where performance, precision, and reliability are non-negotiable.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).