Technical Contents

Engineering Guide: Air Ventilation Hose

Engineering Insight: The Critical Role of Material Selection in Air Ventilation Hoses

In industrial air ventilation systems, hose performance directly impacts operational efficiency, safety, and lifecycle cost. While off-the-shelf air ventilation hoses may appear cost-effective initially, they frequently fail under real-world conditions due to inadequate material selection. These failures stem from a fundamental mismatch between generic hose construction and the specific chemical, thermal, and mechanical demands of industrial environments.

Material selection is not a secondary consideration—it is the cornerstone of hose reliability. Standard ventilation hoses often utilize low-grade synthetic rubber or thermoplastic elastomers with limited resistance to ozone, UV exposure, or temperature extremes. When deployed in environments involving elevated temperatures, abrasive particulates, or chemically aggressive airstreams, these materials degrade rapidly. Cracking, delamination, and loss of flexibility are common outcomes, leading to unplanned downtime and safety hazards.

At Suzhou Baoshida Trading Co., Ltd., we engineer air ventilation hoses using high-performance elastomers such as EPDM, NBR (nitrile), and silicone, selected based on the operational profile. EPDM offers superior resistance to ozone and weathering, making it ideal for outdoor or high-UV applications. NBR provides excellent oil and fuel resistance, critical in manufacturing or automotive exhaust ventilation. Silicone rubber excels in extreme temperature ranges, maintaining integrity from -60°C to over 200°C, suitable for high-heat industrial processes.

Moreover, reinforcement layers—typically braided or spiral-wound polyester, aramid, or steel—must be matched precisely to the pressure and flexing requirements. A mismatch here can lead to collapse under vacuum, burst under pressure, or premature fatigue. Off-the-shelf hoses often under-specify reinforcement, relying on one-size-fits-all designs that compromise structural integrity.

Custom material formulation also allows for compliance with industry-specific standards such as ISO 1307, DIN 2822, or FDA for food-grade applications. Generic hoses rarely meet these benchmarks, exposing end users to regulatory and liability risks.

The following table outlines key performance characteristics of selected materials used in engineered air ventilation hoses:

| Material | Temperature Range (°C) | Ozone Resistance | Oil/Fuel Resistance | Flexibility | Typical Application |

|---|---|---|---|---|---|

| EPDM | -50 to +150 | Excellent | Poor | High | Outdoor ventilation, HVAC |

| NBR | -30 to +100 | Fair | Excellent | Medium | Automotive, industrial exhaust |

| Silicone | -60 to +220 | Good | Good (limited) | Very High | High-temperature ducting |

| Neoprene | -40 to +120 | Good | Moderate | High | General industrial |

In conclusion, material selection determines the functional lifespan and safety of air ventilation hoses. Off-the-shelf solutions fail because they generalize material properties across diverse applications. At Suzhou Baoshida, we prioritize application-specific engineering to deliver hoses that perform reliably under exact operational demands, reducing total cost of ownership and enhancing system integrity.

Material Specifications

Material Specifications for Industrial Air Ventilation Hoses

Selecting the optimal elastomer for air ventilation hoses is critical for ensuring operational reliability, longevity, and safety in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions where material properties directly correlate with performance under specific thermal, chemical, and mechanical stresses. The three primary elastomers for such applications—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—exhibit distinct molecular structures that dictate their suitability. Viton’s fluorocarbon backbone provides exceptional resistance to high temperatures and aggressive chemicals, making it indispensable for exhaust systems near combustion sources. Nitrile, with its tunable acrylonitrile content, offers superior resistance to oils and fuels while maintaining cost efficiency for general industrial airflow. Silicone delivers unmatched flexibility across extreme temperature ranges and complies with stringent food-grade or medical standards where purity is non-negotiable. Understanding these material nuances prevents premature failure modes such as hardening, swelling, or catastrophic seal degradation under operational duress.

Viton (FKM) formulations withstand continuous exposure to 200–250°C and intermittent peaks up to 300°C. Its resistance to ozone, aromatic hydrocarbons, and acids ensures integrity in chemical processing or automotive turbocharger ducts. However, its high fluorine content increases raw material costs and limits low-temperature flexibility below -20°C. Nitrile (NBR) balances affordability with robust resistance to aliphatic hydrocarbons, hydraulic fluids, and moderate heat (up to 120°C continuous). High-acrylonitrile variants (45%+) excel in oil-rich environments but suffer reduced elasticity below -30°C. Silicone (VMQ) operates from -60°C to 230°C with minimal compression set, ideal for cleanrooms or HVAC systems requiring biocompatibility. Yet, its poor abrasion resistance necessitates protective covers in high-friction installations. Each material must be compounded with precision-engineered additives to meet ASTM D2000 quality standards for tensile strength, elongation, and fluid resistance.

The comparative analysis below details critical performance parameters for informed OEM selection. All data reflects standard commercial grades tested per ISO 37 and ASTM D471 protocols.

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Shore A Hardness | Recommended Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +250 (continuous) | Aromatic fuels, acids, ozone, steam | Poor ketone/alcohol resistance; high cost | 60–90 | Chemical exhaust, turbocharger hoses, semiconductor tooling |

| Nitrile (NBR) | -30 to +120 (continuous) | Aliphatic oils, fuels, water, hydraulic fluids | Swells in esters/aromatics; moderate ozone resistance | 50–90 | General industrial air ducting, compressor lines, machinery coolant |

| Silicone (VMQ) | -60 to +230 (continuous) | Water, oxygen, UV, food-grade compliance | Low tear strength; poor hydrocarbon resistance | 30–80 | Cleanroom ventilation, medical air lines, extreme cold environments |

Material selection must align with fluid media composition, pressure cycles, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. validates all compounds through accelerated aging tests per OEM specifications, ensuring hoses exceed 15,000-hour service life in targeted applications. Consult our engineering team for custom formulations addressing unique operational hazards.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Air Ventilation Hoses

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance air ventilation hoses. With a dedicated team comprising five specialized mould engineers and two advanced rubber formula engineers, we maintain full in-house control over the product development lifecycle. This integrated technical team enables seamless coordination between material science and mechanical design, ensuring that every hose meets stringent performance criteria for flexibility, durability, and resistance to environmental stressors.

Our mould engineers bring extensive experience in precision tooling for complex extrusion and spiral reinforcement configurations. They utilize CAD/CAM systems to develop optimized mould geometries that ensure uniform wall thickness, consistent inner diameter tolerances, and smooth surface finishes—critical parameters in air flow efficiency and long-term reliability. These capabilities support rapid prototyping and low-volume trial runs, accelerating time-to-market for custom OEM projects.

Complementing this mechanical expertise, our two rubber formula engineers specialize in elastomer compounding tailored to industrial ventilation demands. They formulate custom rubber blends using NR, SBR, EPDM, and NBR base polymers, adjusting for specific requirements such as ozone resistance, temperature range, flame retardancy, and low compression set. Each formulation undergoes rigorous laboratory testing for tensile strength, elongation, hardness, and aging performance before validation. This scientific approach ensures that the final hose performs reliably under dynamic operating conditions, including continuous flexing, exposure to UV radiation, and fluctuating temperatures.

Our OEM capabilities are built on this dual foundation of tooling precision and material intelligence. We work directly with industrial partners to co-develop hoses that meet exact dimensional, functional, and regulatory specifications. Whether the application involves high-temperature exhaust systems, mining ventilation, or industrial HVAC networks, we deliver engineered-to-order solutions with full documentation, including material certifications and test reports.

The following table outlines typical technical specifications achievable through our engineering platform:

| Parameter | Standard Range | Custom Capability |

|---|---|---|

| Inner Diameter | 50 – 600 mm | Up to 800 mm |

| Wall Thickness | 2.5 – 8.0 mm | Up to 12.0 mm |

| Operating Temperature | -30°C to +120°C (standard EPDM) | -50°C to +180°C (specialty blends) |

| Reinforcement Type | Steel wire spiral, polyester braid | Hybrid reinforcement options |

| Bend Radius (minimum) | 1.5x ID | 1.2x ID (flex-optimized design) |

| Pressure Rating (working) | 0.3 – 0.8 bar | Up to 1.5 bar (reinforced) |

| Flame Resistance | UL94 HB (standard) | UL94 V-0, MSHA-approved options |

| Surface Finish | Smooth, anti-static optional | Textured, conductive variants |

This technical agility, combined with rigorous quality control and scalable manufacturing, positions Suzhou Baoshida as a trusted engineering partner for mission-critical air ventilation systems across global industries.

Customization Process

Customization Process for Industrial Air Ventilation Hoses

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven customization process ensures air ventilation hoses meet exact operational demands. We begin with rigorous Drawing Analysis, where our engineers dissect client-provided technical schematics using GD&T standards and FEA simulation. This phase identifies critical parameters such as bend radius tolerances, flange alignment, and stress concentration zones. We validate dimensional feasibility against ISO 1307 and SAE J2494-1, ensuring compatibility with existing infrastructure while flagging potential interference or assembly conflicts. Material thickness and reinforcement layer counts are cross-referenced with pressure and vacuum requirements to prevent premature failure.

Formulation Development follows, translating mechanical needs into precise polymer chemistry. Our lab tailors compound recipes using EPDM or NBR base polymers, selecting curatives, fillers, and antioxidants based on fluid exposure, temperature extremes, and ozone resistance. For instance, a chemical plant ventilation hose requiring -40°C flexibility and 150°C continuous operation would incorporate high-saturation NBR with specialized plasticizers and peroxide curing. Shore A hardness is calibrated between 55–75 to balance kink resistance and airflow efficiency, while carbon black loading optimizes UV stability without compromising elongation. Every formulation undergoes accelerated aging tests per ASTM D573 to confirm 10,000+ hour service life.

Prototyping validates theoretical designs through physical iteration. We produce 3–5 sample hoses using precision extrusion and vulcanization tooling, then subject them to destructive and non-destructive testing. Hydrostatic burst pressure must exceed 3x operational maxima per ISO 1402, while pulse fatigue testing simulates 500,000 cycles at 2 Hz. Dimensional accuracy is verified via CMM, and airflow efficiency is measured in our wind tunnel against target CFM curves. Client feedback on handling and installation informs final tweaks before sign-off.

Mass Production leverages our ISO 9001-certified facility with real-time SPC monitoring. Each hose batch undergoes 100% visual inspection for surface defects, coupled with statistical sampling for tensile strength (ASTM D412), adhesion (ASTM D429), and electrical continuity. Traceability is maintained via laser-etched batch codes, and final packaging includes material certificates compliant with REACH and RoHS. Our OEM partnership model ensures scalability from 500 to 50,000 units with ≤0.5% defect rates.

Key performance specifications for standard ventilation hoses are summarized below. All parameters are adjustable per client requirements.

| Spec Parameter | Standard Range | Customization Capability |

|---|---|---|

| Operating Pressure | -0.8 to 15 bar | Up to 20 bar with braided reinforcement |

| Temperature Range | -40°C to +150°C | -55°C to +180°C via specialty polymers |

| Material Types | EPDM, NBR, Silicone | Hybrid compounds (e.g., EPDM/NBR blends) |

| Bend Radius | 1.5x ID (min) | 1.2x ID with helical wire core |

| Conductivity | 10⁶–10⁹ Ω (standard) | 10⁴–10⁵ Ω for static dissipation |

This systematic approach—grounded in material science and process control—guarantees hoses that optimize airflow integrity, longevity, and safety in demanding industrial environments. Suzhou Baoshida delivers not just components, but engineered airflow solutions.

Contact Engineering Team

Contact Suzhou Baoshida for High-Performance Air Ventilation Hoses

At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered industrial rubber solutions designed to meet the rigorous demands of modern manufacturing, HVAC systems, pneumatic transport, and heavy-duty ventilation applications. Our air ventilation hoses are precision-manufactured to deliver optimal airflow, durability under extreme conditions, and long service life across diverse industrial environments. Whether you require flexible ducting for dust extraction, high-temperature exhaust, or corrosion-resistant air transfer systems, our team ensures tailored solutions backed by material science expertise and strict quality control.

We invite technical buyers, OEM partners, and engineering project managers to initiate direct collaboration with our lead engineer and OEM account manager, Mr. Boyce. With over 15 years of experience in rubber compounding and industrial hose development, Mr. Boyce leads technical consultations, product customization, and volume supply coordination for global clients. His role ensures that every hose specification aligns precisely with operational requirements—whether it’s resistance to abrasion, ozone, UV exposure, or fluctuating temperatures.

To support your procurement and integration process, we provide comprehensive technical documentation, including pressure ratings, bend radius data, chemical compatibility charts, and compliance certifications (REACH, RoHS, ISO 9001:2015). Our production facility integrates automated extrusion and vulcanization systems, enabling consistent dimensional accuracy and batch-to-batch repeatability. We also offer OEM labeling, custom length spooling, and just-in-time delivery scheduling to streamline your supply chain.

For new product development or replacement part sourcing, early engagement with our engineering team allows for optimized material selection—such as EPDM for ozone resistance, NBR for oil tolerance, or silicone for extreme temperature stability. Our air ventilation hoses are available with embedded steel helix wires for full vacuum support, textile braiding for burst strength, or smooth bore linings to minimize turbulence and pressure drop.

Below is a representative specification table for our standard industrial air ventilation hose series:

| Parameter | Value |

|---|---|

| Inner Diameter Range | 50 mm – 600 mm |

| Wall Thickness | 2.5 mm – 6.0 mm |

| Operating Temperature | -40°C to +150°C (up to +250°C intermittent) |

| Pressure Rating | Up to 12 bar (positive), Full Vacuum |

| Bend Radius | 1.5x Outer Diameter (minimum) |

| Reinforcement Layer | Steel helix + Polyester braid |

| Cover Resistance | Abrasion, UV, Ozone, Weathering |

| Liner Material Options | Smooth NBR, EPDM, Silicone |

| Standards Compliance | ISO 1307, ISO 9001, REACH, RoHS |

Partnering with Suzhou Baoshida means gaining access to a responsive technical team, scalable manufacturing capacity, and a commitment to solving complex fluid handling challenges. For immediate technical consultation or to request samples and quotes, contact Mr. Boyce directly at [email protected]. Include your application details, required quantities, and performance criteria to receive a targeted solution proposal within 24 business hours.

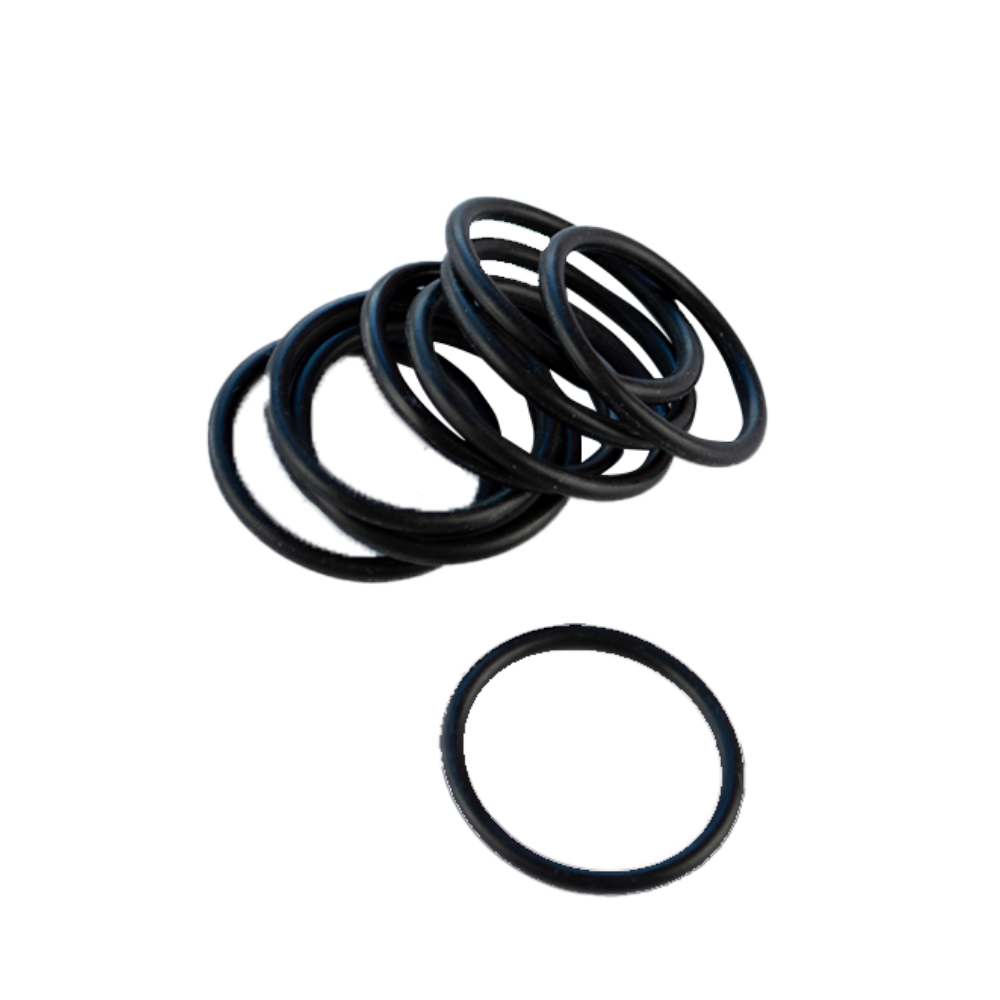

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).