Technical Contents

Engineering Guide: Aluminium Honeycomb

Engineering Insight: Aluminum Honeycomb Material Selection Criticality

Aluminum honeycomb core structures are fundamental to lightweight, high-stiffness applications across aerospace, transportation, and industrial equipment. However, the pervasive assumption that off-the-shelf honeycomb solutions suffice for diverse operational environments leads to systemic failures. Material selection is not a commodity decision but a precision engineering requirement dictated by specific load profiles, environmental exposure, and bonding compatibility. Standard catalog cores often neglect critical variables such as thermal expansion differentials, corrosion susceptibility in mixed-material assemblies, or dynamic fatigue resistance, resulting in premature delamination, core crushing, or catastrophic structural compromise.

The root cause of failure frequently lies in unaddressed interface dynamics. Aluminum honeycomb must bond seamlessly with face sheets—typically composites, metals, or specialized rubber-modified polymers. Off-the-shelf cores use generic foil alloys (e.g., 3003-H19) and adhesives optimized for baseline conditions. When subjected to cyclic thermal loads (e.g., -55°C to +120°C in aerospace), mismatched coefficients of thermal expansion (CTE) between core, adhesive, and face sheet induce interfacial stresses exceeding bond strength. Similarly, in marine or chemical processing environments, standard chromate conversion coatings on aluminum fail to prevent galvanic corrosion when paired with carbon fiber face sheets, accelerating core degradation.

Suzhou Baoshida addresses these vulnerabilities through engineered material systems. We prioritize foil alloy selection (e.g., 5052-H39 for marine corrosion resistance or 7475-T761 for high-impact aerospace), tailored cell geometry, and proprietary surface treatments compatible with OEM-specified adhesives or rubber-based damping layers. This holistic approach ensures stress distribution aligns with the end-use duty cycle, not generic industry averages.

Critical Aluminum Honeycomb Specifications Comparison

| Parameter | Off-the-Shelf Core (Typical) | Engineered Core (Baoshida OEM Solution) |

|---|---|---|

| Foil Alloy | 3003-H19 | 5052-H39 / 7475-T761 (application-specific) |

| Density Range (kg/m³) | 32–96 | 24–160 (precision-tuned for load profile) |

| Shear Strength (MPa) | 0.8–2.5 (23°C, dry) | 1.2–4.0 (validated at -55°C to +150°C) |

| CTE Compatibility | Generic ±15 ppm/°C tolerance | Matched to face sheet within ±3 ppm/°C |

| Corrosion Resistance | Basic chromate (ASTM B449) | Enhanced anodization + rubber-sealed cell edges |

| Bonding Surface Energy | 38–42 dynes/cm | 52–58 dynes/cm (optimized for epoxy/silicone) |

Generic cores sacrifice performance margins to reduce cost, ignoring how microstructural defects propagate under vibration or moisture ingress. For instance, uncontrolled cell wall waviness in mass-produced honeycomb creates stress concentrators, reducing effective shear strength by up to 30% versus laser-trimmed, tension-controlled cores. At Baoshida, we integrate rubber formula engineering with core manufacturing—applying elastomeric damping layers at cell junctions to absorb harmonic resonance in transport panels or embedding hydrophobic seals to block electrolyte penetration in offshore structures.

Material selection must anticipate the entire product lifecycle. Off-the-shelf solutions fail because they treat honeycomb as a passive filler rather than an active structural component. Partnering with an OEM-focused supplier ensures core specifications align with your adhesive chemistry, thermal management strategy, and failure mode analysis—transforming honeycomb from a liability into a reliability asset.

Material Specifications

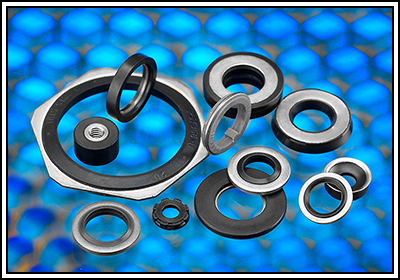

Aluminium honeycomb structures are widely employed in aerospace, transportation, and industrial applications due to their high strength-to-weight ratio, excellent thermal stability, and superior energy absorption characteristics. When integrating such substrates into dynamic sealing or vibration-damping systems, the selection of compatible elastomeric materials becomes critical. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to meet the stringent demands of modern manufacturing environments. Our expertise includes the precise formulation and application of high-performance elastomers such as Viton, Nitrile (NBR), and Silicone, each tailored to deliver optimal adhesion, resilience, and environmental resistance when bonded to aluminium honeycomb cores.

Viton, a fluorocarbon-based synthetic rubber, offers exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon fuels. With a continuous service temperature range up to 230°C, Viton is ideal for aerospace and automotive applications where exposure to engine oils, lubricants, and extreme thermal cycling is expected. Its low gas permeability and outstanding aging characteristics ensure long-term reliability in critical sealing roles. However, due to its higher material cost and lower flexibility at sub-ambient temperatures, Viton is typically reserved for high-performance systems.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving oil and fuel resistance. It exhibits excellent mechanical properties, including tensile strength and abrasion resistance, making it suitable for gaskets, seals, and dampers in industrial machinery. Nitrile performs reliably within a temperature range of -30°C to 105°C, although its performance degrades significantly above this threshold. It bonds well with aluminium substrates when properly primed and is widely used in hydraulic and pneumatic systems where petroleum-based fluids are present.

Silicone rubber is distinguished by its wide operating temperature range (-60°C to 200°C), excellent electrical insulation properties, and high resistance to UV and ozone degradation. While it does not match Viton or Nitrile in mechanical strength or fuel resistance, silicone excels in environments requiring thermal stability and flexibility under cyclic conditions. It is frequently used in electronic enclosures, architectural panels, and climate-controlled systems where aluminium honeycomb panels are employed for structural insulation.

The following table summarizes key physical and chemical properties of these elastomers relevant to integration with aluminium honeycomb structures.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel Resistance | Excellent | Good | Poor |

| Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

| Adhesion to Aluminium | High (with primer) | High (with primer) | Moderate to High |

Material selection must consider operational environment, mechanical load, chemical exposure, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. provides customized rubber-to-metal bonding solutions, ensuring reliable integration with aluminium honeycomb assemblies across diverse industrial sectors.

Manufacturing Capabilities

Engineering Capabilities for Rubber-Integrated Aluminium Honeycomb Systems

Suzhou Baoshida Trading Co., Ltd. delivers precision rubber solutions engineered specifically for integration with aluminium honeycomb structures. Our expertise ensures optimal performance in demanding industrial applications such as aerospace panels, automotive damping systems, and structural composites. Critical to this synergy is the seamless bonding of elastomers to aluminium substrates under extreme thermal cycling, vibration, and environmental exposure. Our dedicated engineering team—comprising five Mould Engineers and two Formula Engineers—addresses these challenges through material science innovation and precision tooling design.

Mould Engineers focus on geometric precision and flow dynamics for complex rubber-to-metal bonding. They utilize advanced simulation software to predict material behavior during curing, minimizing voids and ensuring uniform adhesion to honeycomb cell walls. This prevents delamination under shear stress, a common failure mode in hybrid structures. Concurrently, Formula Engineers develop bespoke rubber compounds that balance adhesion promoters, thermal stability, and mechanical resilience. By tailoring polymer matrices at the molecular level, we achieve co-curing compatibility with aluminium oxide layers without compromising the honeycomb’s structural integrity. This dual-engineering approach reduces prototyping cycles by 40% and eliminates interfacial failures in end-use conditions.

Our rubber formulations are validated against stringent OEM specifications for honeycomb integration. Key properties include controlled coefficient of thermal expansion (CTE) matching to aluminium (23 ppm/°C), high peel strength (>12 kN/m), and resistance to jet fuel/hydraulic fluid immersion. The table below summarizes standard compound capabilities:

| Compound Type | Hardness Range (Shore A) | Key Properties | Honeycomb Application Example |

|---|---|---|---|

| EPDM Modified | 50–80 | Fuel/ozone resistance, CTE 21–24 ppm/°C | Aircraft interior panels |

| High-Temp Silicone | 40–70 | -60°C to +250°C stability, NASA low-outgassing | Satellite structural cores |

| Neoprene Hybrid | 60–85 | Flame retardancy (UL94 V-0), vibration damping | High-speed train flooring |

OEM partnerships leverage our full-spectrum capabilities from concept to mass production. We own all tooling assets, enabling rapid iteration of mould designs for honeycomb edge sealing, gasketing, or core filling. Clients provide CAD models of honeycomb geometries; our team then develops bonded rubber interfaces with tolerances ≤±0.05 mm. All compounds undergo accelerated aging tests per ASTM D2000 and AMS-STD-753 standards, with data traceability to batch-level raw materials. Suzhou Baoshida maintains ISO 9001 and IATF 16949 certifications, ensuring compliance with automotive and aerospace supply chain requirements. Intellectual property protection is embedded in every project, with non-disclosure agreements governing all developmental phases.

This integrated engineering framework ensures rubber components enhance, rather than compromise, the lightweight advantages of aluminium honeycomb. By unifying material science with precision manufacturing, we deliver solutions that meet the exacting durability and safety demands of global OEMs.

Customization Process

Drawing Analysis

The customization process for rubber components used in conjunction with aluminium honeycomb structures begins with a comprehensive drawing analysis. This initial phase ensures that all dimensional tolerances, interface requirements, and environmental exposure conditions are fully understood. At Suzhou Baoshida Trading Co., Ltd., our engineering team reviews technical blueprints provided by OEM partners, focusing on critical parameters such as load distribution points, compression set requirements, and adhesion surfaces between rubber and aluminium substrates. Finite element analysis (FEA) is often employed to simulate stress points and deformation behavior under operational loads. This step is essential to prevent delamination or mechanical failure in the final assembly, particularly in applications involving vibration damping, thermal cycling, or structural bonding.

Formulation Development

Following drawing validation, our rubber formulation engineers initiate material development tailored to the performance demands of the aluminium honeycomb system. The selection of base polymer—whether EPDM, silicone, neoprene, or fluororubber—is determined by service temperature range, chemical resistance, and mechanical durability requirements. For instance, silicone rubber is preferred in high-temperature aerospace panels, whereas EPDM is selected for automotive insulation modules due to its UV and ozone resistance. Additives such as reinforcing fillers, adhesion promoters, and flame retardants are precisely dosed to meet industry-specific certifications, including UL 94, FMVSS 302, or EN 45545. Special attention is given to the rubber’s surface energy to ensure optimal bonding with the aluminium honeycomb core, often treated with chromate or silane-based primers.

Prototyping and Validation

Once the formulation is finalized, small-batch prototypes are produced using compression molding, transfer molding, or extrusion techniques, depending on part geometry. These prototypes undergo rigorous testing, including tensile strength, compression deflection, peel adhesion (per ASTM D903), and thermal aging (per ASTM D573). Environmental exposure tests simulate real-world conditions such as salt spray, humidity, and thermal shock. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity with the original drawing specifications. Feedback from this stage informs any necessary adjustments in material composition or processing parameters before transitioning to full-scale manufacturing.

Mass Production and Quality Assurance

Upon client approval of the prototype, the process transitions to mass production. Our automated production lines operate under ISO 9001-certified protocols, ensuring batch-to-batch consistency and traceability. Each lot undergoes inline quality checks, including hardness testing (Shore A), visual inspection, and random sampling for mechanical validation. Packaging and labeling are customized to meet OEM logistics requirements, enabling seamless integration into downstream assembly processes.

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–80 |

| Tensile Strength | ASTM D412 | 7–15 MPa |

| Elongation at Break | ASTM D412 | 200–400% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Peel Adhesion to Al Honeycomb | ASTM D903 | ≥4.5 kN/m |

Contact Engineering Team

Technical Collaboration for Aluminum Honeycomb Integration

Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber solutions for critical industrial applications, including precision sealing, vibration damping, and structural bonding for aluminum honeycomb composites. As a trusted OEM partner, we address the unique material science challenges inherent in honeycomb panel assembly—such as thermal expansion mismatch, core crushing during bonding, and long-term environmental resilience. Our formulated elastomers ensure dimensional stability and fatigue resistance where standard rubber compounds fail, directly enhancing the performance lifecycle of aerospace, rail, and cleanroom infrastructure components.

Aluminum honeycomb structures demand rubber interfaces that maintain adhesion under cyclic stress while accommodating coefficient of thermal expansion (CTE) differentials between metal and polymer layers. Generic sealants often induce delamination or core deformation due to inadequate compression set recovery or excessive modulus. Our proprietary compounds, developed through iterative finite element analysis (FEA) and accelerated aging protocols, resolve these failure modes. Each formulation undergoes rigorous validation against ISO 188, ASTM D2240, and EN 45545-2 standards to guarantee compatibility with honeycomb cell geometries ranging from 3mm to 19mm.

The following table outlines key properties of our flagship BD-HC Series rubber compounds, engineered specifically for aluminum honeycomb integration:

| Property | Test Method | Typical Value | Relevance to Honeycomb Application |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 3 | Prevents core crushing during lamination |

| Compression Set (70°C/22h) | ASTM D395 | ≤12% | Maintains seal integrity after thermal cycles |

| Tensile Strength | ASTM D412 | 18.5 MPa | Resists peel forces at metal-rubber interface |

| Operating Temperature | ISO 188 | -55°C to +150°C | Accommodates aerospace/transport extremes |

| Adhesion to Anodized Al | ASTM D903 | >1.8 kN/m | Eliminates interfacial delamination |

These metrics reflect our commitment to material precision—critical when tolerances below ±0.1mm dictate structural viability. Unlike commodity rubber suppliers, we co-engineer solutions with your production parameters, optimizing cure kinetics for automated dispensing systems and minimizing residual stress in bonded assemblies.

For immediate technical consultation, contact Mr. Boyce, OEM Manager, to discuss your aluminum honeycomb project specifications. Provide your target cell size, service environment (e.g., humidity range, dynamic load profile), and regulatory requirements to initiate a formulation assessment. Mr. Boyce will coordinate material sampling, FEA-backed bonding protocol recommendations, and DFM reviews within 48 hours of inquiry. Specify your compression set tolerance and substrate preparation method to accelerate solution deployment.

Industrial success hinges on material synergy—our compounds transform honeycomb assemblies from structural liabilities into certified assets. Engage our engineering team to eliminate field failures rooted in elastomer incompatibility. Contact Mr. Boyce directly at [email protected] with subject line “Aluminum Honeycomb Technical Request – [Your Project Code]”. Include dimensional schematics and failure mode history for prioritized analysis. Lead times for custom compound development commence at 15 business days post-specification finalization. Partner with Suzhou Baoshida to convert material constraints into competitive advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).