Technical Contents

Engineering Guide: Aluminum Frp Trim

Engineering Insight: Material Selection in Aluminum FRP Trim Applications

In industrial sealing and edge protection systems, aluminum FRP (Fiberglass Reinforced Plastic) trim components serve as critical interfaces between structural elements and environmental exposure zones. These trims are commonly deployed in transportation, architectural cladding, and industrial enclosures where mechanical resilience, chemical resistance, and dimensional stability are non-negotiable. Despite their seemingly passive role, the performance longevity of aluminum FRP trim assemblies hinges directly on precise material selection—a factor often overlooked when off-the-shelf solutions are deployed without engineering validation.

Standardized trim profiles, while cost-effective and readily available, are typically engineered for generic applications with moderate service conditions. In demanding environments—such as high-humidity chambers, chemically aggressive processing plants, or thermally fluctuating exteriors—these generic materials exhibit premature degradation. Common failure modes include delamination at the aluminum-FRP interface, UV-induced embrittlement of polymer phases, and galvanic corrosion due to incompatible metal-polymer coupling. These failures are not inherent to the trim concept but stem from mismatched material properties relative to operational stressors.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered compatibility between the aluminum substrate and the FRP composite layer. The aluminum alloy grade must balance formability with corrosion resistance—typically 6063-T5 or 6061-T6 are preferred for their extrudability and surface oxide stability. The FRP component must be formulated with vinyl ester or epoxy resins rather than general-purpose polyester, especially when exposed to alkalis, solvents, or prolonged UV radiation. Additionally, fiber architecture—whether woven roving or continuous strand mat—must align with directional load requirements to prevent localized stress fractures.

A critical yet underappreciated factor is the bonding methodology between aluminum and FRP. Mechanical interlock designs outperform adhesive-only bonds in thermal cycling environments. Surface pretreatment of the aluminum—such as anodizing or chemical conversion coating—significantly enhances interfacial durability. Without these engineered integrations, even marginally elevated thermal gradients can induce differential expansion stresses, leading to debonding and functional failure.

The following table outlines key specification parameters for high-performance aluminum FRP trim systems:

| Parameter | Standard Off-the-Shelf | Engineered Solution (Baoshida Recommended) |

|---|---|---|

| Aluminum Alloy | 6063-T4 | 6063-T5 or 6061-T6 |

| FRP Resin Matrix | Polyester | Vinyl Ester or Epoxy |

| Fiber Type | Chopped Strand Mat | Woven Roving or Hybrid Fabric |

| Bonding Method | Adhesive-only | Mechanical Interlock + Structural Adhesive |

| UV Resistance (QUV, 1000 hrs) | Moderate (cracking observed) | High (negligible degradation) |

| Thermal Cycling Performance (-40°C to 85°C) | Poor (delamination at 150 cycles) | Excellent (stable beyond 500 cycles) |

Material selection is not a cost-driven compromise but a performance-determining decision. Off-the-shelf trims may satisfy initial dimensional requirements, but they lack the tailored material science needed for sustained operational integrity. At Baoshida, we collaborate with OEMs to co-engineer trim solutions where every constituent is validated against real-world service profiles—ensuring reliability, safety, and lifecycle economy in industrial applications.

Material Specifications

Material Specifications for Aluminum FRP Trim Applications

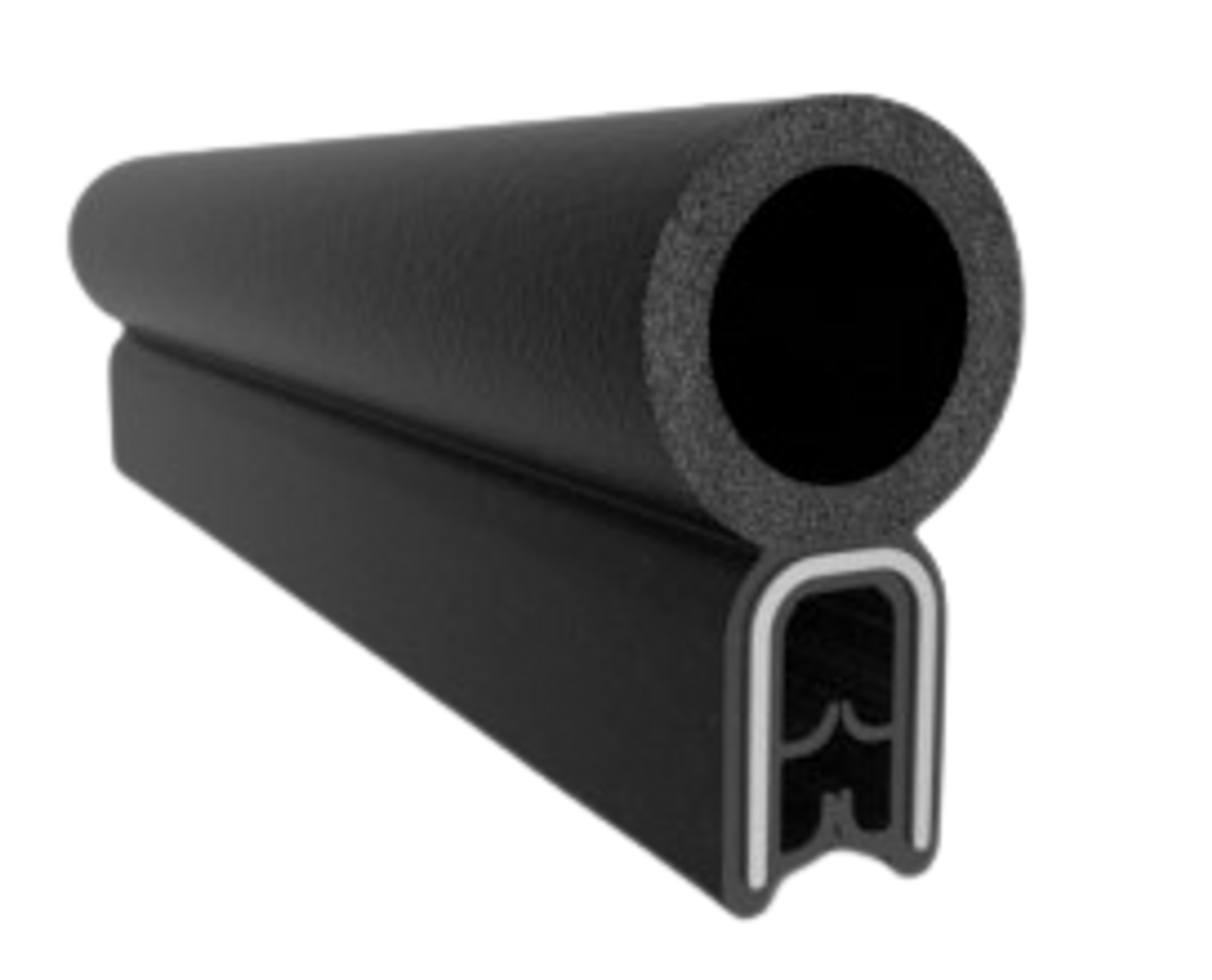

Aluminum FRP (Fiber-Reinforced Plastic) trim components demand elastomeric seals and gaskets capable of withstanding rigorous industrial environments while maintaining dimensional stability against dissimilar substrates. At Suzhou Baoshida Trading Co., Ltd., our engineering team prioritizes material compatibility with aluminum’s thermal expansion profile and FRP’s surface chemistry to prevent galvanic corrosion, adhesion failure, or compression set-induced leakage. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent optimal solutions for critical sealing interfaces in automotive, aerospace, and heavy machinery sectors. Each material’s molecular structure dictates performance under specific stressors, including temperature extremes, fluid exposure, and mechanical load.

Viton fluorocarbon rubber excels in high-temperature and aggressive chemical environments, resisting jet fuels, hydraulic fluids, and acids up to 250°C. Its low permeability and exceptional ozone resistance make it ideal for engine compartment trim where aluminum housings interface with FRP panels. Nitrile butadiene rubber offers cost-effective resilience against petroleum-based oils and greases within -40°C to 120°C ranges, with formulations achieving 35–90 Shore A hardness for consistent sealing force on lightweight aluminum extrusions. Silicone rubber provides unparalleled flexibility at cryogenic temperatures (-60°C) and thermal stability to 230°C, critical for exterior trim exposed to UV radiation and weathering; however, its lower tensile strength requires reinforcement for high-compression applications.

All materials must comply with ASTM D2000 classification systems for automotive use, with stringent controls on filler content to avoid aluminum surface contamination. Compression set values below 25% after 70 hours at maximum service temperature ensure long-term seal integrity, while Shore A hardness tolerances of ±5 points guarantee uniform clamping pressure across FRP-aluminum joints.

The following table summarizes key specifications for OEM qualification:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -40 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 10–20 | 15–30 | 5–12 |

| Hardness Range (Shore A) | 50–90 | 35–90 | 30–80 |

| Compression Set (%)* | ≤20 (200°C/70h) | ≤25 (100°C/70h) | ≤25 (150°C/70h) |

| Key Fluid Resistance | Fuels, Acids, Oils | Petroleum Oils | Water, Steam |

| Primary Applications | Engine Seals | Hydraulic Systems | Weatherstripping |

*Per ASTM D395 Method B

Material selection hinges on fluid exposure profiles and thermal cycling requirements. For aluminum FRP trim in fuel-injected systems, Viton’s chemical inertness prevents swelling-induced joint failure. Nitrile remains the standard for cost-sensitive hydraulic trim assemblies where temperatures remain moderate. Silicone is reserved for non-lubricated, high-flexibility applications like window channels, though its adhesion to aluminum requires plasma treatment. Suzhou Baoshida’s OEM team validates all formulations against OEM-specific standards (e.g., GM 6297M, Boeing BMS 3-11) to ensure seamless integration into aluminum FRP subassemblies. Precision in durometer control and low-volatility compounding prevents outgassing that could compromise FRP-aluminum bonding integrity during curing processes.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of aluminum FRP (Fiberglass Reinforced Plastic) trim manufacturing. With a dedicated team comprising five experienced mould engineers and two advanced formula engineers, we ensure precision, durability, and performance in every product we develop. Our integrated approach combines material science with precision tooling to deliver OEM-grade components tailored to exact client specifications.

Our formula engineers specialize in custom rubber compound development, focusing on optimizing mechanical properties such as tensile strength, compression set, temperature resistance, and chemical stability. This expertise is critical in aluminum FRP trim applications, where rubber seals must endure dynamic stress, UV exposure, and thermal cycling without degradation. By formulating proprietary EPDM, silicone, and thermoplastic elastomer (TPE) compounds, we ensure compatibility with both the aluminum substrate and the FRP composite structure, minimizing delamination and maintaining long-term sealing integrity.

Complementing our material development is a robust mould engineering team. Each of the five mould engineers brings over a decade of experience in precision rubber and multi-material mould design. Utilizing advanced CAD/CAM software and finite element analysis (FEA), they develop high-tolerance moulds capable of producing complex cross-sectional profiles with tight dimensional control. This includes overmoulding rubber directly onto aluminum extrusions—a core requirement in FRP trim systems—ensuring strong adhesion and consistent part geometry across high-volume production runs.

Our OEM capabilities are structured to support full product lifecycle development, from concept and prototyping to mass production and quality assurance. Clients benefit from our in-house tooling, rapid sample turnaround (typically 15–20 days), and rigorous validation protocols, including adhesion testing, thermal ageing, and weathering simulations. We maintain ISO 9001-certified processes and work directly with automotive, architectural, and transportation OEMs to meet stringent industry standards.

By integrating material formulation with precision mould engineering, Suzhou Baoshida delivers technically superior aluminum FRP trim solutions that enhance performance, reduce assembly complexity, and extend service life in demanding environments.

| Specification | Capability |

|---|---|

| Rubber Compounds | EPDM, Silicone, TPE, NBR, CR |

| Hardness Range (Shore A) | 40–90 |

| Mould Tolerance | ±0.1 mm |

| Operating Temperature Range | -50°C to +150°C (varies by compound) |

| Adhesion Strength (Aluminum-Rubber) | ≥ 8 N/mm (peel test) |

| Production Process | Injection Moulding, Compression Moulding, Overmoulding |

| Sample Lead Time | 15–20 days |

| OEM Support | Full design, testing, and validation services |

Customization Process

Aluminum FRP Trim Customization: Precision Engineering Workflow

Suzhou Baoshida Trading Co., Ltd. executes a rigorously structured customization process for aluminum Fiber Reinforced Polymer (FRP) trim components, ensuring seamless integration of rubber elements with composite substrates. This methodology guarantees dimensional accuracy, environmental resilience, and OEM compliance. The four-phase workflow begins with Drawing Analysis, where our engineering team conducts a comprehensive review of client-provided CAD files and GD&T specifications. Critical focus areas include thermal expansion coefficient alignment between aluminum FRP and rubber interfaces, tolerance stack-up analysis for assembly fitment, and identification of stress concentration zones. Finite Element Analysis (FEA) simulations validate structural integrity under operational loads, while material compatibility assessments prevent galvanic corrosion at metal-rubber junctions.

Subsequent Formulation leverages our proprietary rubber compounding expertise to address aluminum FRP-specific challenges. We prioritize adhesion promoters compatible with FRP surface treatments and optimize cure kinetics to accommodate aluminum’s high thermal conductivity. Key material properties are engineered to withstand -40°C to +150°C operational ranges while maintaining Shore A hardness consistency. The table below details critical formulation parameters for aluminum FRP trim applications.

| Property | Target Range | Test Standard | Significance for Aluminum FRP Trim |

|---|---|---|---|

| Adhesion Strength | ≥ 8 kN/m | ASTM D429-B | Prevents rubber delamination from FRP substrate |

| Coefficient of Thermal Expansion | 1.8–2.5 x 10⁻⁴/°C | ISO 11359-2 | Matches aluminum FRP to minimize stress cycling |

| Compression Set (70°C, 22h) | ≤ 25% | ASTM D395 | Ensures long-term sealing integrity |

| Fluid Resistance (Brake Fluid) | ΔHardness ≤ 5 pts | ISO 1817 | Maintains performance in automotive environments |

Prototyping follows formulation finalization, utilizing CNC-machined molds to produce functional samples within 15 business days. Each prototype undergoes rigorous validation: coordinate measuring machine (CMM) inspections verify dimensional conformity to ±0.1 mm tolerances, while environmental chamber testing simulates 5,000-hour UV exposure and thermal shock cycles (-40°C ↔ +120°C). Bond strength is quantified via peel tests at 90° angles, with failure modes analyzed to refine interfacial chemistry. Client feedback at this stage drives iterative adjustments to compound viscosity or mold venting designs.

The transition to Mass Production activates our ISO/TS 16949-certified manufacturing controls. Real-time rheometer monitoring ensures batch-to-batch compound consistency, while automated vision systems inspect every trim piece for surface defects. Statistical Process Control (SPC) charts track critical dimensions with CpK ≥ 1.67, and first-article inspections per PPAP Level 3 documentation guarantee specification adherence. Our dedicated production cells achieve ±0.05 mm dimensional repeatability at volumes exceeding 500,000 units annually, with scrap rates maintained below 0.15% through closed-loop process correction.

This end-to-end engineering discipline ensures Suzhou Baoshida delivers aluminum FRP trim solutions that meet the exacting durability, aesthetic, and functional demands of global automotive and aerospace OEMs.

Contact Engineering Team

For industrial manufacturers seeking high-performance solutions in aluminum FRP (Fiberglass Reinforced Plastic) trim applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in engineered rubber systems and composite material integration. Our expertise lies at the intersection of material science and industrial durability, delivering precision-crafted components that meet the rigorous demands of transportation, construction, and infrastructure sectors. As a specialized supplier within the Industrial Rubber Solutions category, we focus on hybrid material performance—where aluminum’s lightweight strength meets FRP’s corrosion resistance and structural integrity, enhanced by proprietary rubber bonding and sealing technologies.

Our aluminum FRP trim systems are designed for seamless integration into panel joints, edge protection, and architectural cladding, providing not only mechanical resilience but also environmental sealing against moisture, UV degradation, and thermal cycling. Each product is developed through a rigorous process of substrate adhesion optimization, stress distribution modeling, and long-term weathering validation. We utilize advanced co-extrusion and vulcanization techniques to ensure the rubber-to-metal and rubber-to-FRP interfaces maintain bond integrity under dynamic loading and extreme service conditions.

To support global OEMs and Tier-1 fabricators, we offer fully customizable profiles, length tolerances, surface finishes, and durometer ratings. Whether your application requires flame-retardant compliance (e.g., UL 94, EN 45545), low outgassing for enclosed environments, or enhanced abrasion resistance for high-traffic installations, our engineering team collaborates directly with clients to tailor material formulations and cross-sectional geometries.

Below are representative specifications for our standard aluminum FRP trim configurations. All parameters are adjustable based on project requirements.

| Property | Standard Value | Test Method |

|---|---|---|

| Aluminum Alloy | 6063-T5 | ASTM B221 |

| FRP Layer Thickness | 1.5 – 3.0 mm | ISO 178 |

| Rubber Hardness (Shore A) | 60 – 80 ±5 | ASTM D2240 |

| Operating Temperature Range | -40°C to +120°C | ISO 188 |

| Tensile Strength (Rubber) | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Adhesion Strength (Rubber to Substrate) | ≥8 kN/m | ASTM D429 (Method B) |

| UV Resistance | 2,000 hrs (Xenon Arc) | ISO 4892-2 |

| Fire Performance | HB (UL94) | UL 94 |

All production batches undergo 100% visual inspection and statistical mechanical sampling in accordance with ISO 2859-1. We maintain full traceability through batch coding and material certification, supporting compliance with ISO 9001 and IATF 16949 quality management systems.

For technical collaboration, sample requests, or custom design consultation, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct your inquiries to [email protected]. Include project specifications, performance requirements, and target volumes to receive a detailed engineering response within 24 business hours. Our team supports English and Mandarin communication and provides on-site technical audits upon request. Partner with us to advance the reliability and service life of your next-generation aluminum FRP trim assemblies.

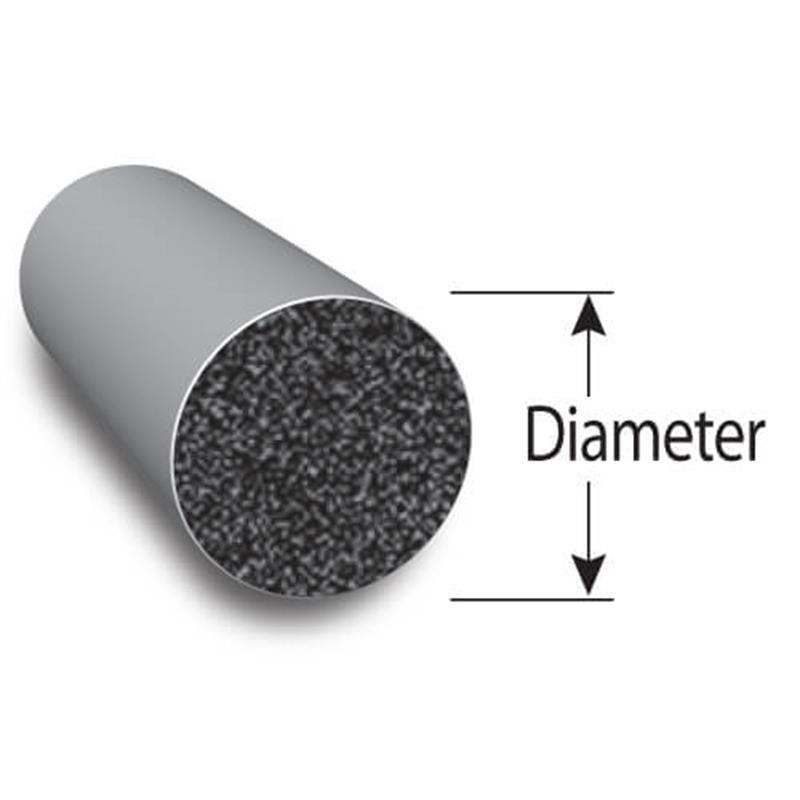

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).