Technical Contents

Engineering Guide: Anti Slip Composite Decking

Engineering Insight: Material Selection in Anti-Slip Composite Decking

The structural integrity and safety performance of anti-slip composite decking are fundamentally determined by polymer formulation precision. Off-the-shelf solutions frequently fail due to generic material specifications that ignore dynamic environmental stressors. Standard thermoplastic olefin (TPO) or polyvinyl chloride (PVC) composites degrade rapidly under ultraviolet (UV) exposure, thermal cycling, and moisture ingress, leading to surface delamination, loss of traction, and catastrophic adhesion failure between rubberized wear layers and core substrates. These failures manifest within 12–18 months in high-traffic commercial installations, incurring costly remediation and liability risks.

Critical weaknesses in commodity materials stem from inadequate molecular cross-linking and filler dispersion. Standard compounds prioritize initial cost reduction over long-term resilience, omitting essential stabilizers for UV resistance and failing to optimize Shore A hardness for slip resistance across wet/dry conditions. For instance, unmodified TPO decks exhibit Shore A values exceeding 90 under solar loading, reducing coefficient of friction (CoF) to unsafe levels (<0.40 ASTM D2047). Concurrently, poor thermal expansion coefficient matching induces interfacial stress, causing rubber layer separation during temperature fluctuations between -30°C and 70°C. Chemical resistance is equally neglected; standard formulations swell when exposed to pool sanitizers or automotive fluids, accelerating wear.

Suzhou Baoshida Trading Co., Ltd. addresses these failures through engineered rubber compounds co-developed with OEM partners. Our proprietary EPDM/TPV hybrids integrate nano-silica reinforcement and hindered amine light stabilizers (HALS) to maintain Shore A 65–75 stability across 5,000+ hours of QUV accelerated aging. Precision-tuned surface topography—achieved via laser-etched embossing molds—ensures consistent CoF >0.60 under ASTM F2913 protocols, even with oil contamination. Crucially, our formulations match the thermal expansion profile of wood-plastic composite (WPC) cores within ±0.5 ppm/°C, eliminating delamination.

The table below quantifies performance gaps between standard and engineered solutions:

| Property | Standard TPO Composite | Baoshida Engineered EPDM/TPV | Failure Consequence of Standard |

|---|---|---|---|

| UV Resistance (QUV, 2000h) | >35% tensile loss | <8% tensile loss | Surface cracking, color fade |

| Thermal Cycling (-30°C to 70°C) | Delamination at 50 cycles | Zero adhesion loss at 200 cycles | Layer separation, trip hazards |

| CoF (Wet, ASTM F2913) | 0.32–0.38 | 0.62–0.68 | Slip/fall incidents |

| Chemical Resistance (5% NaOCl) | 15% volume swell | <3% volume swell | Texture degradation, staining |

| Shore A Stability (70°C) | 88–92 | 68–72 | Reduced traction in heat |

Generic anti-slip decking treats safety as a surface feature rather than a system-engineered requirement. Baoshida’s OEM-focused approach integrates material science with real-world operational physics, ensuring compliance with ISO 13287 slip resistance standards across the product lifecycle. Collaborative formulation development—adjusting polymer ratios, filler loading, and vulcanization kinetics for specific geographic and usage profiles—eliminates the compromise between cost and reliability. For industrial, marine, or public infrastructure applications, this precision engineering is non-negotiable for risk mitigation and total cost of ownership reduction.

Material Specifications

Material Specifications for Anti-Slip Composite Decking

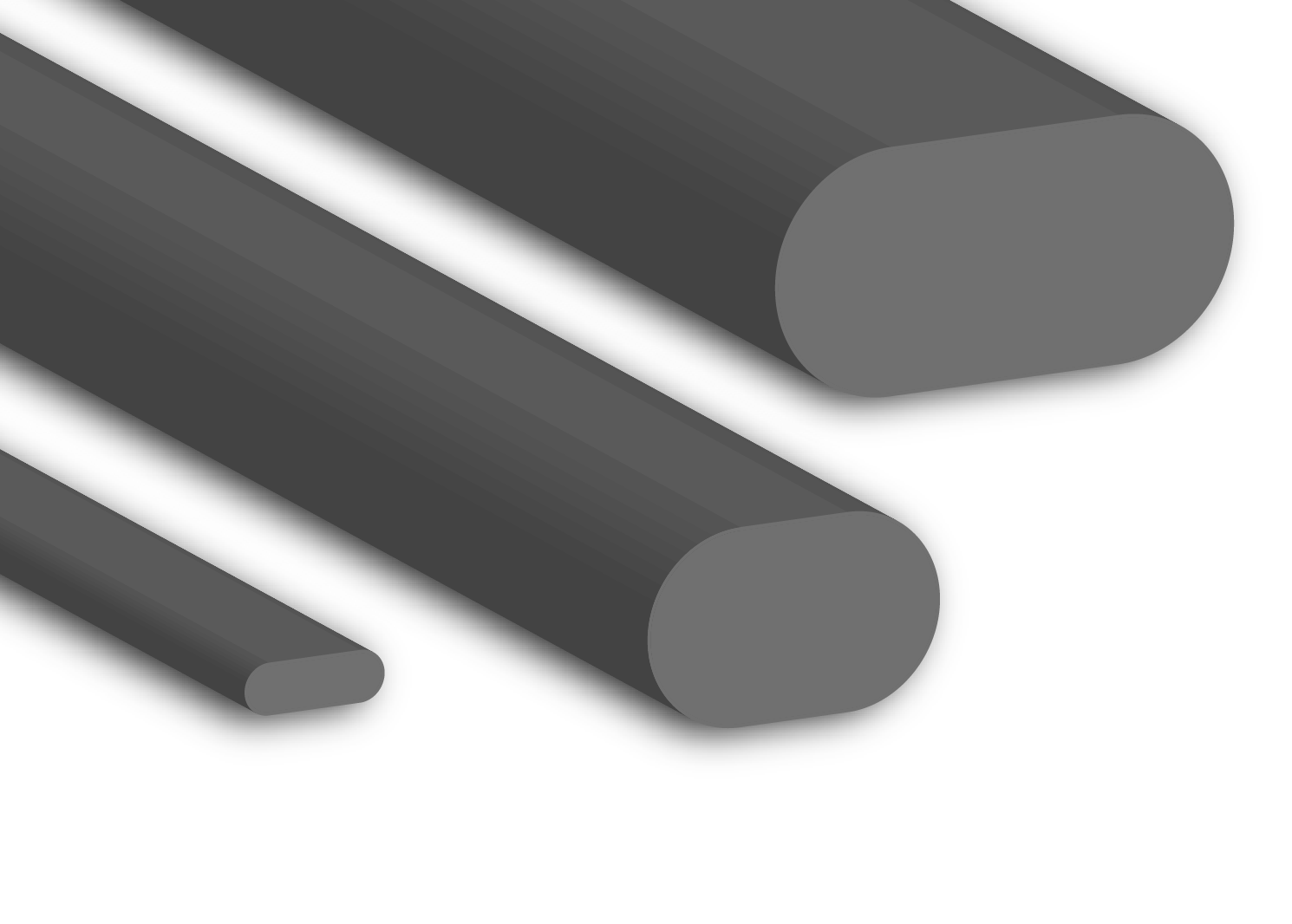

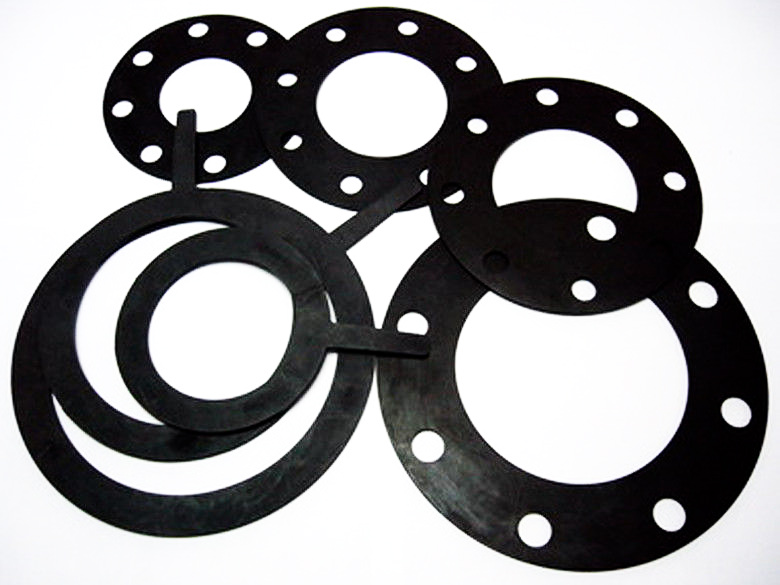

In the development and manufacturing of high-performance anti-slip composite decking, the selection of elastomeric materials is critical to ensuring durability, safety, and resistance to environmental and chemical exposure. Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions, offering precision-engineered anti-slip surfaces utilizing three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material presents distinct mechanical and chemical properties, making them suitable for specific operational environments. Understanding these differences enables OEMs and industrial partners to optimize product performance based on application requirements.

Viton, a fluorocarbon-based rubber, exhibits exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous service temperature range of -20°C to 250°C, Viton is ideal for extreme environments such as offshore platforms, petrochemical facilities, and high-temperature industrial walkways. Its inherent flame resistance and low outgassing characteristics further enhance safety in critical infrastructure. However, Viton is less flexible at low temperatures and carries a higher material cost, which must be weighed against performance needs.

Nitrile rubber, a copolymer of butadiene and acrylonitrile, offers excellent resistance to aliphatic hydrocarbons, oils, and greases. It is widely used in marine, automotive, and manufacturing environments where exposure to lubricants and hydraulic fluids is common. Nitrile performs reliably within a temperature range of -30°C to 100°C, with higher acrylonitrile content improving oil resistance at the expense of low-temperature flexibility. Its abrasion resistance and cost-effectiveness make NBR a preferred choice for general-purpose anti-slip decking in moderate conditions.

Silicone rubber provides outstanding thermal stability from -60°C to 200°C and maintains flexibility across this broad range. It is highly resistant to UV radiation, ozone, and weathering, making it suitable for outdoor and architectural applications. Silicone also demonstrates good electrical insulation properties, beneficial in environments requiring dielectric safety. While it has lower mechanical strength and abrasion resistance compared to Viton and Nitrile, its non-toxic nature and compliance with food-grade standards expand its utility in clean or sensitive environments.

The following table compares key physical and chemical properties of these materials for informed selection in anti-slip composite decking systems.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Good to Excellent | Poor |

| Resistance to UV/Ozone | Excellent | Fair | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Petrochemical, Offshore | Marine, Manufacturing | Outdoor, Architectural |

Material selection directly influences the service life, safety, and maintenance requirements of anti-slip composite decking. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to align material properties with operational demands, ensuring optimal performance in diverse industrial settings.

Manufacturing Capabilities

Engineering Capability: Precision Development for Anti-Slip Composite Decking

Suzhou Baoshida Trading Co., Ltd. leverages deep industrial rubber expertise to engineer high-performance anti-slip composite decking solutions. Our integrated engineering team—comprising five specialized mould engineers and two dedicated rubber formula engineers—ensures technical excellence from material conception to mass production. This synergy enables rigorous control over both polymer chemistry and manufacturing precision, directly addressing critical performance demands in outdoor architectural applications.

Our formula engineers specialize in advanced thermoplastic elastomer (TPE) and polyurethane (PU) composites, optimizing slip resistance, UV stability, and mechanical durability. Through systematic material science protocols, we develop proprietary blends incorporating engineered silica and ceramic micro-particles. These formulations achieve consistent coefficient of friction (CoF) values exceeding 0.6 under wet conditions per ASTM D2047, while maintaining Shore A hardness between 70–85 for optimal wear resistance and thermal stability. Rigorous accelerated aging tests validate 15+ year service life in harsh climates, with minimal color fade or surface degradation.

Mould engineering excellence underpins manufacturing fidelity. Our five engineers utilize Siemens NX and Moldflow simulation to design precision tooling with micron-level tolerances. Critical features include micro-textured anti-slip patterns, optimized cooling channels for uniform shrinkage control, and hardened H13 steel construction ensuring 500,000+ cycle longevity. This eliminates common defects like warpage or inconsistent surface profiles, guaranteeing dimensional repeatability within ±0.15mm across production runs. Each mould undergoes stringent validation via CMM inspection before deployment, directly translating formula specifications into physical product integrity.

As an OEM partner, we implement a collaborative development framework prioritizing client-specific requirements. Projects commence with joint Design for Manufacturing (DFM) reviews, where our engineers refine decking profiles, slip-pattern geometries, and material formulations to align with structural, aesthetic, and regulatory needs. We manage full-scale prototyping with rapid iteration cycles—typically 15–20 days from CAD to functional sample—using in-house 3D printing and pilot injection lines. Strict IP protection protocols govern all collaborations, with dedicated project managers ensuring seamless transition from validation to high-volume production at our ISO 9001-certified facility.

Material performance is quantified through standardized testing, as summarized below:

| Parameter | Standard Composite Decking | Baoshida Enhanced Anti-Slip Composite | Test Standard |

|---|---|---|---|

| Coefficient of Friction (Wet) | 0.35–0.45 | 0.62–0.75 | ASTM D2047 |

| Abrasion Loss (mm³) | ≤ 120 | ≤ 65 | ISO 4649 |

| Shore A Hardness | 60–75 | 70–85 | ASTM D2240 |

| UV Resistance (ΔE after 2000h) | > 5.0 | < 2.5 | ISO 4892-2 |

| Thermal Expansion (10⁻⁶/°C) | 85–110 | 60–75 | ASTM E831 |

This engineering rigor ensures our anti-slip decking delivers measurable safety advantages without compromising longevity or aesthetics. By unifying formula science with precision tooling, Suzhou Baoshida provides OEM clients with technically differentiated products that meet stringent global building codes and end-user expectations for performance-critical outdoor infrastructure.

Customization Process

Customization Process for Anti Slip Composite Decking

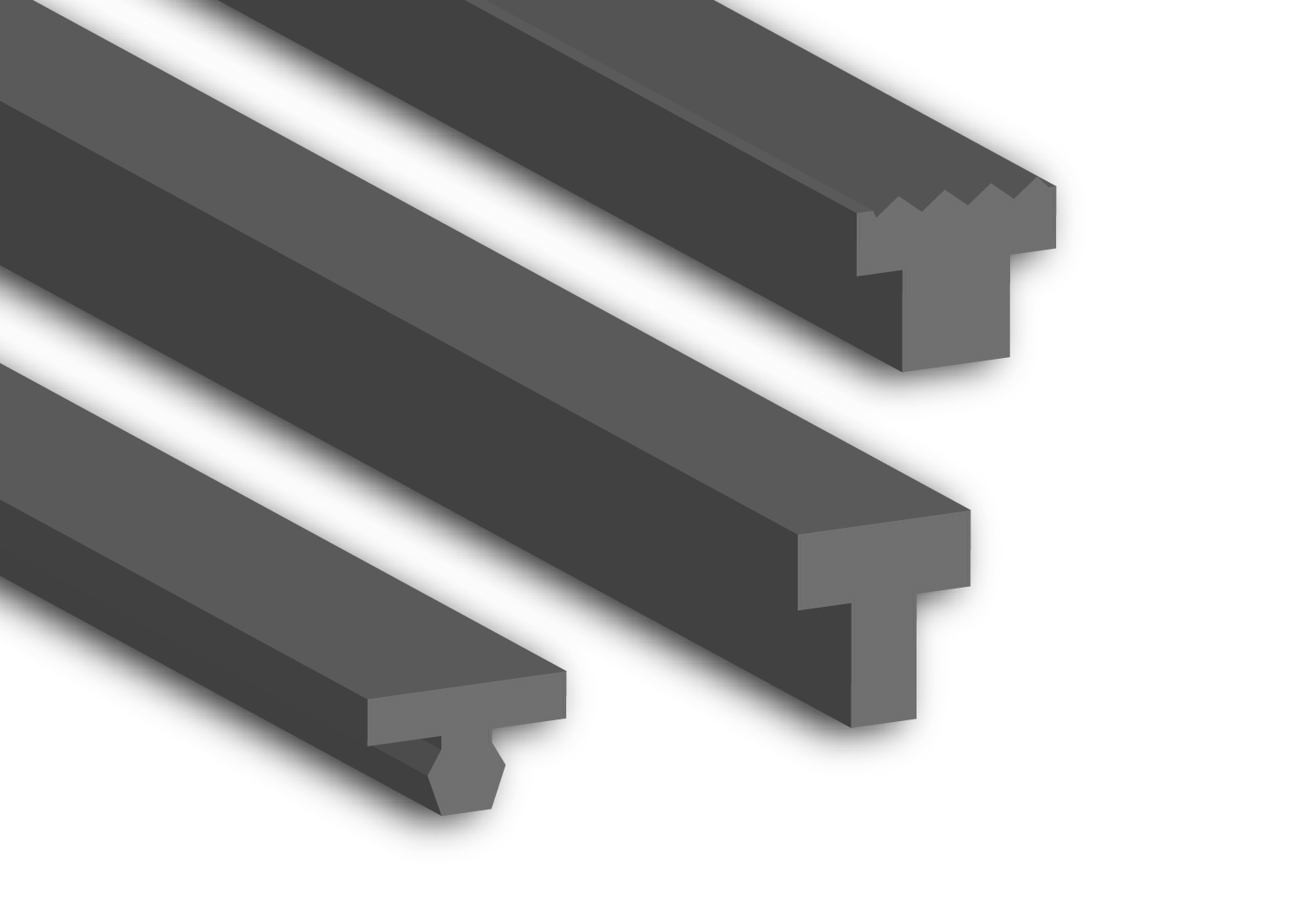

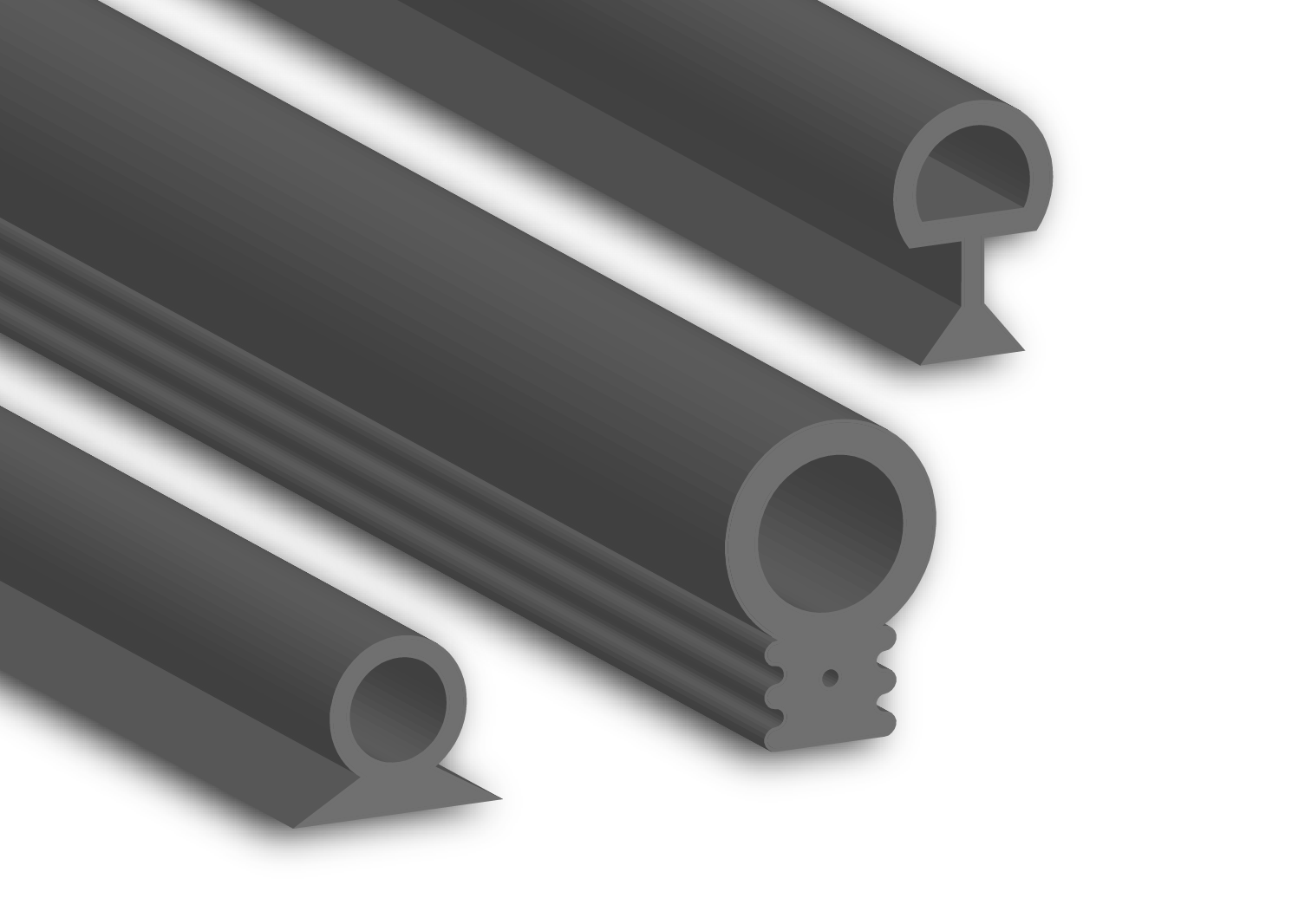

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exact performance demands in demanding environments. The customization process for anti slip composite decking follows a rigorous four-stage methodology: Drawing Analysis, Formulation, Prototyping, and Mass Production. This systematic approach ensures dimensional accuracy, material integrity, and functional reliability tailored to client specifications.

The process begins with Drawing Analysis, where technical blueprints and CAD models are evaluated for structural feasibility, load-bearing requirements, and environmental exposure conditions. Our engineering team scrutinizes tolerances, surface profile geometry, and integration points with substructures. This phase ensures compliance with international standards such as ISO 9001 and ASTM D4065, while identifying critical zones requiring enhanced slip resistance or abrasion protection.

Following drawing validation, we proceed to Formulation Development. Based on application parameters—such as exposure to UV radiation, moisture, oils, or thermal cycling—we design proprietary rubber compounds using EPDM, SBR, or TPE matrices. The anti-slip functionality is achieved through controlled filler dispersion, cross-link density optimization, and incorporation of functional additives like silica or ceramic microspheres. Hardness, tensile strength, and coefficient of friction are precisely tuned to deliver optimal grip without compromising durability. All formulations undergo accelerated aging and dynamic mechanical analysis (DMA) to verify long-term performance.

Once the compound is finalized, Prototyping commences. Using precision molds and calibrated extrusion or compression molding equipment, we produce sample decking segments for client evaluation. These prototypes are subjected to standardized slip resistance testing per DIN 51130 (R-value) and BS 7976, alongside real-world validation under simulated service conditions. Feedback is integrated iteratively, ensuring the final design meets both aesthetic and functional expectations.

Upon client approval, we transition to Mass Production. Our facility operates under strict process control protocols, with real-time monitoring of cure time, temperature profiles, and dimensional consistency. Each batch undergoes quality assurance screening, including hardness testing, visual inspection, and adhesion verification between rubber and composite substrate. Production scalability supports volumes from 5,000 to over 100,000 linear meters annually, with lead times optimized through lean manufacturing principles.

The table below outlines key performance specifications achievable through our customization process.

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–85 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Coefficient of Friction (wet) | ASTM C1028 | ≥0.65 |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤80 mg |

| Operating Temperature Range | — | -40°C to +120°C |

| Slip Resistance (R-value) | DIN 51130 | R10–R13 |

This structured customization pathway ensures that every anti slip composite decking solution delivered by Suzhou Baoshida Trading Co., Ltd. meets the highest benchmarks in safety, longevity, and industrial performance.

Contact Engineering Team

Optimize Your Anti-Slip Composite Decking Performance Through Precision Rubber Engineering

Suzhou Baoshida Trading Co., Ltd. stands as your definitive industrial partner for advanced rubber solutions within the demanding composite decking sector. Our core competency lies in the scientific formulation and precise manufacturing of high-performance rubber compounds specifically engineered to deliver superior, long-lasting anti-slip properties. We understand that safety, durability, and aesthetic integration are non-negotiable requirements for decking products exposed to diverse environmental stresses and user traffic. Our dedicated team of Rubber Formula Engineers leverages deep material science expertise to develop proprietary polymer matrices that achieve the critical balance between aggressive surface traction and resistance to wear, UV degradation, moisture ingress, and thermal cycling. This ensures your composite decking maintains optimal slip resistance throughout its entire lifecycle, significantly reducing liability risks and enhancing end-user confidence.

Partnering with Suzhou Baoshida provides access to our integrated OEM capabilities, transforming your technical specifications into robust, production-ready rubber components. We move beyond standard material supply, offering collaborative engineering support from initial concept through to mass production. Our stringent quality control protocols, aligned with ISO 9001 standards, guarantee batch-to-batch consistency and adherence to the most exacting performance criteria. The table below outlines key technical specifications representative of our advanced anti-slip rubber formulations, demonstrating the measurable performance attributes critical for decking applications.

| Technical Property | Typical Value Range | Measurement Standard | Significance for Decking |

|---|---|---|---|

| Shore A Hardness | 60 – 75 | ASTM D2240 | Optimal balance: Sufficient firmness for structural support yet compliant enough for effective grip underfoot |

| Abrasion Resistance (Loss) | ≤ 80 mm³ | ASTM D5963 | Exceptional resistance to wear from foot traffic and cleaning, ensuring long-term slip performance |

| Operating Temperature Range | -40°C to +100°C | Internal Protocol | Maintains integrity and friction properties across extreme global climates |

| Tensile Strength | ≥ 12 MPa | ASTM D412 | Resists tearing and deformation during installation and service |

| Elongation at Break | ≥ 300% | ASTM D412 | Accommodates substrate movement without cracking |

| Coefficient of Friction (Wet) | ≥ 0.70 | ASTM F2913 | Meets or exceeds stringent safety standards for slip resistance on wet surfaces |

These specifications are not static targets but starting points for tailored development. We excel in customizing formulations to meet your exact substrate requirements, desired aesthetic integration (color, texture), production methods (extrusion, molding), and regional safety regulations. Our commitment extends to rigorous in-house testing of tribological properties under simulated real-world conditions, providing you with data-driven confidence before product launch. Suzhou Baoshida operates as a true extension of your engineering and procurement teams, offering rapid prototyping, scalable manufacturing capacity, and responsive technical support to accelerate your time-to-market.

Initiate the process of elevating your composite decking’s safety and performance profile immediately. Contact Mr. Boyce, our dedicated point of contact for technical and commercial inquiries regarding anti-slip solutions. Provide your specific project requirements, target performance metrics, and volume expectations to receive a detailed technical consultation and formal quotation. Mr. Boyce possesses the authority and expertise to facilitate seamless collaboration between your engineering department and our formulation specialists. Do not compromise on the critical safety element of slip resistance; partner with the engineering precision of Suzhou Baoshida. Reach out directly via email at [email protected] to schedule a technical discussion and secure the optimal rubber solution for your next-generation composite decking product line. Your commitment to superior deck safety begins with this essential connection.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).