Technical Contents

Engineering Guide: Anti-Slip Floor Sheets

Material Selection: The Core Determinant of Anti-Slip Performance

Industrial anti-slip floor sheets face extreme operational demands—chemical exposure, heavy foot traffic, thermal cycling, and mechanical abrasion. Generic off-the-shelf solutions frequently fail because they prioritize cost reduction over engineered resilience. These products typically utilize standardized rubber compounds with inadequate polymer matrices and filler systems. The consequence is rapid surface degradation, inconsistent traction, and premature delamination under real-world stressors. Material science dictates that slip resistance is not merely a surface texture attribute but a holistic function of compound formulation, cross-link density, and environmental adaptability.

Off-the-shelf variants often employ low-grade SBR (Styrene-Butadiene Rubber) with excessive plasticizers to cut costs. This compromises tensile strength and accelerates oxidation when exposed to UV light or ozone. Fillers like calcium carbonate are poorly dispersed, creating weak points that erode under abrasive forces. Crucially, the grit profile—whether aluminum oxide or ceramic—is mechanically bonded rather than chemically integrated, leading to particle loss within months. This results in dangerously smooth surfaces in high-moisture environments like food processing plants or marine decks, directly violating ISO 22196 slip resistance standards. The economic impact extends beyond replacement costs; facility downtime and liability risks from slip incidents far exceed initial material savings.

Suzhou Baoshida addresses these failures through OEM-driven compound customization. We formulate proprietary SBR/EPDM blends with nano-silica reinforcement for superior tear strength and thermal stability. Critical parameters are rigorously optimized for client-specific conditions, as demonstrated below:

| Critical Performance Parameter | Off-the-Shelf Risk | Baoshida Engineered Solution |

|---|---|---|

| Shore A Hardness | 70-80 (Excessive rigidity causes cracking) | 55-65 (Optimal balance of flexibility and wear resistance) |

| Abrasion Loss (DIN 53516) | >180 mm³ (Rapid grit loss) | ≤95 mm³ (Nano-silica enhanced durability) |

| Operating Temperature Range | -10°C to +70°C (Fails in extreme cold/heat) | -40°C to +120°C (EPDM co-polymer stability) |

| Chemical Resistance (Hydraulic Oil) | Severe swelling (>25% volume gain) | <8% volume gain (Saturated polymer chains) |

| Coefficient of Friction (Wet ASTM D2047) | 0.35-0.45 (Sub-safety threshold) | ≥0.65 (Consistent high-traction profile) |

Our process begins with client site audits to map chemical exposure, load dynamics, and environmental variables. Compounds are then validated through accelerated aging tests simulating 5+ years of operational stress. This precision engineering ensures the rubber matrix and embedded abrasives function as a unified system, maintaining ISO-certified slip resistance throughout the product lifecycle. For industrial facilities, this translates to sustained safety compliance and elimination of unplanned maintenance cycles. Material selection is not a commodity decision—it is the foundation of operational continuity and risk mitigation in high-stakes environments. Partnering with an OEM specialist transforms anti-slip flooring from a recurring cost into a permanent engineered asset.

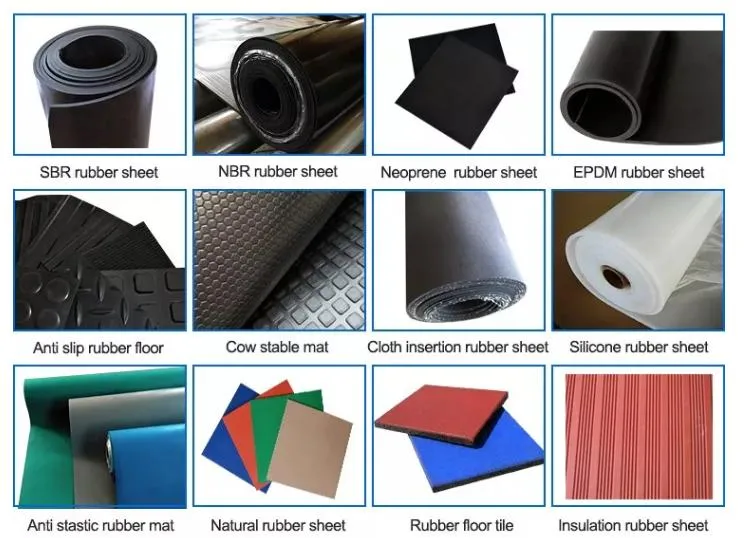

Material Specifications

Material Specifications for Anti-Slip Floor Sheets

Anti-slip floor sheets are critical components in industrial environments where safety, durability, and chemical resistance are paramount. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions engineered to meet the rigorous demands of manufacturing, automotive, chemical processing, and food-grade facilities. Our anti-slip floor sheets are manufactured using three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct performance characteristics tailored to specific operational conditions.

Viton rubber is a fluorocarbon-based synthetic elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains structural integrity in environments with continuous exposure to aromatic and chlorinated hydrocarbons, making it ideal for petrochemical and aerospace applications. With a temperature resistance range from -20°C to +250°C, Viton provides long-term stability under extreme thermal cycling. Its inherent anti-slip properties are enhanced through surface texturing during the calendaring process, ensuring reliable traction even in oily or solvent-laden environments.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used for its excellent resistance to aliphatic hydrocarbons, greases, and water-based fluids. It offers a balanced performance profile with good mechanical strength and abrasion resistance. Operating effectively between -30°C and +120°C, NBR is a cost-efficient solution for industrial flooring in automotive workshops, machinery rooms, and maintenance bays. The material’s high tensile strength ensures longevity under repeated foot and cart traffic, while its surface can be molded with aggressive tread patterns to maximize slip resistance in wet or greasy conditions.

Silicone rubber (VMQ) excels in extreme temperature applications, with a functional range from -60°C to +230°C. It is non-toxic, inherently flame-resistant, and compliant with food and pharmaceutical industry standards (FDA, USP Class VI). Silicone is particularly suitable for cleanroom environments, food processing plants, and cold storage facilities where hygiene and thermal stability are essential. While its mechanical strength is lower than Viton or Nitrile, silicone provides outstanding resistance to ozone, UV radiation, and weathering. Surface treatments such as embossing or grit coating are applied to enhance slip resistance without compromising cleanability.

Selection of the appropriate material depends on environmental exposure, regulatory requirements, and mechanical stress factors. The following table summarizes key performance metrics to guide material selection.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +250°C | -30°C to +120°C | -60°C to +230°C |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Fluid Resistance (Oil/Fuel) | Excellent | Good | Poor |

| Water/Steam Resistance | Good | Fair | Excellent |

| Abrasion Resistance | Good | Excellent | Moderate |

| FDA Compliance | Limited grades | No | Yes |

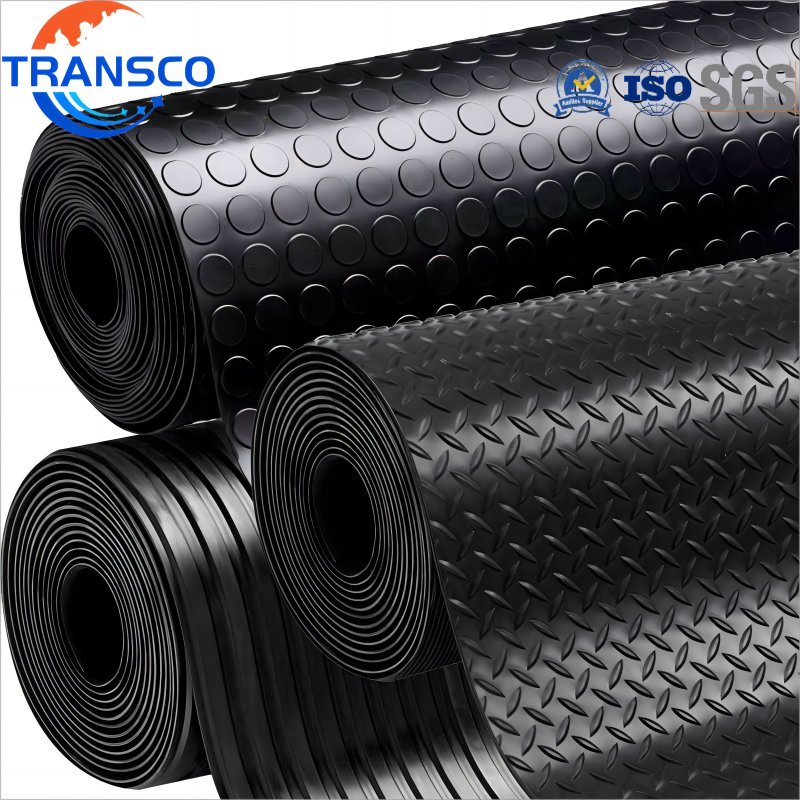

Each material is available in custom thicknesses (2–10 mm), roll or sheet formats, and with adhesive backing or interlocking tile designs. All products are manufactured under ISO 9001 standards to ensure consistency and reliability.

Manufacturing Capabilities

Engineering Capabilities for Anti-Slip Floor Sheet Manufacturing

Suzhou Baoshida Trading Co., Ltd. integrates advanced polymer science with precision tooling to deliver mission-critical anti-slip floor sheets for industrial environments. Our core strength lies in the seamless collaboration between dedicated Formula Engineering and Mould Engineering teams, ensuring every product meets exacting performance and safety standards. This vertically integrated approach eliminates third-party dependencies, accelerating time-to-market while maintaining uncompromised quality control.

Polymer Formulation Expertise

Our two certified Rubber Formula Engineers specialize in elastomer compounding for extreme traction and durability. They develop proprietary blends using EPDM, SBR, and specialty polymers, optimizing Shore A hardness (65±3), coefficient of friction (≥0.85 wet/dry), and chemical resistance. Each formulation undergoes rigorous accelerated aging tests per ISO 188 and ASTM D2240, ensuring stability across -40°C to +120°C operational ranges. Custom additives—including ceramic grit, silica microparticles, or recycled rubber granules—are precisely dosed to achieve target slip resistance (ASTM F2913) without compromising flexibility or longevity. This scientific methodology allows us to tailor compounds for oil-lubricated factories, food processing zones, or marine decks, where standard solutions fail.

Precision Mould Engineering

Five in-house Mould Engineers execute complex tooling designs for consistent surface topography and dimensional accuracy. Utilizing SolidWorks and Moldflow simulations, we engineer multi-cavity molds with micron-level tolerances (±0.05mm) to replicate intricate anti-slip patterns—such as pyramid, diamond, or directional groove profiles—critical for hydroplaning resistance. Advanced thermal management systems within molds ensure uniform vulcanization, preventing defects like sink marks or inconsistent texture depth. This capability supports high-volume production (50,000+ units/month) while maintaining repeatability across batches, a non-negotiable requirement for OEM partners in automotive assembly or logistics facilities.

End-to-End OEM Integration

As a certified OEM manufacturer, we manage every phase from concept to certification. Clients provide performance parameters (e.g., load capacity, color fastness, fire ratings), and our engineers co-develop solutions within 15 days, including finite element analysis (FEA) for stress points under dynamic loads. All custom projects undergo third-party validation per ISO 9001 and IATF 16949 protocols, with full traceability of raw materials (e.g., FDA 21 CFR 177.2600 for food-grade variants). Our facility supports low-volume prototyping to mass production, with flexible MOQs starting at 500 units.

Key Performance Specifications

| Property | Standard Specification | Customizable Range |

|---|---|---|

| Shore A Hardness | 65 ± 3 | 50–80 |

| Coefficient of Friction | ≥0.85 (wet) | ≥0.75–1.20 |

| Temperature Resistance | -40°C to +120°C | -60°C to +150°C |

| Thickness Tolerance | ±0.2mm | ±0.05mm to ±0.5mm |

This engineering discipline ensures anti-slip sheets exceed ANSI B101.3 and EN 13036-4 standards, directly reducing workplace incident rates. By controlling both molecular structure and physical geometry, Suzhou Baoshida transforms safety requirements into engineered realities—proven across 200+ global OEM partnerships.

Customization Process

Customization Process for Anti-Slip Floor Sheets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the precise functional and environmental demands of our B2B clients. The customization process for anti-slip floor sheets follows a rigorous four-stage workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material performance, and long-term durability under industrial conditions.

The process begins with Drawing Analysis, where technical blueprints provided by the client are evaluated for dimensional tolerances, surface profile requirements, load-bearing specifications, and installation environment. Our engineering team conducts a comprehensive review to identify critical performance zones, such as high-traffic areas or chemical exposure regions. This stage also includes substrate compatibility assessment to ensure adhesion integrity on steel, concrete, or composite flooring.

Following drawing validation, the Formulation phase commences. Our rubber formula engineers develop a proprietary elastomer blend tailored to the application. Key variables include hardness (Shore A), coefficient of friction (COF), resistance to oils, acids, and temperature extremes, as well as anti-static or flame-retardant properties if required. We primarily utilize SBR, NBR, or EPDM base polymers, reinforced with silica or carbon black, and modified with anti-slip fillers such as aluminum oxide or ceramic grit. The formulation is optimized using accelerated aging tests and dynamic mechanical analysis (DMA) to predict long-term performance.

Once the compound is finalized, we proceed to Prototyping. Using precision die-cutting or compression molding techniques, small-batch samples are produced in accordance with the approved drawings. These prototypes undergo rigorous in-house testing, including slip resistance measurement (ASTM F2913), abrasion resistance (DIN 53516), and peel adhesion strength. Clients are provided with physical samples and full test reports for validation. Any necessary adjustments to texture, thickness, or backing system are implemented at this stage.

Upon client approval, the project transitions to Mass Production. Our manufacturing facility employs automated calendaring and vulcanization lines to ensure batch consistency and dimensional stability. Each production run is subject to real-time quality monitoring, with random sampling for hardness, thickness, and slip resistance. Packaging is customized based on logistics needs, with options for roll packing, sheet stacking, or palletized delivery.

Below is a representative specification table for a standard customized anti-slip floor sheet:

| Property | Test Standard | Typical Value |

|---|---|---|

| Material Base | — | NBR/SBR Blend |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Coefficient of Friction (Dry) | ASTM F2913 | ≥ 0.75 |

| Thickness | — | 3.0 mm ± 0.2 |

| Temperature Range | — | -30°C to +80°C |

| Abrasion Loss | DIN 53516 | ≤ 120 mm³ |

| Oil Resistance | ISO 1817 | Volume swell < 15% |

| Backing Type | — | Non-woven fabric |

This end-to-end customization framework enables Suzhou Baoshida to deliver high-performance anti-slip floor sheets that align precisely with industrial safety and operational requirements.

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Anti-Slip Floor Sheet Solutions

Selecting the correct anti-slip flooring solution is a critical engineering decision impacting workplace safety, operational continuity, and regulatory compliance. Generic off-the-shelf products often fail under demanding industrial conditions, leading to costly slip hazards, premature wear, and non-conformance with stringent safety standards such as ISO 13287 or ANSI A137.1. Suzhou Baoshida Trading Co., Ltd. specializes in scientifically formulated rubber compounds engineered specifically for high-performance anti-slip applications. Our solutions are not merely products; they represent precision material science tailored to your operational environment, load requirements, chemical exposure, and longevity targets. As your dedicated OEM partner, we integrate deeply with your manufacturing process, ensuring seamless material compatibility and consistent batch-to-batch reproducibility.

Our proprietary rubber formulations undergo rigorous validation in controlled laboratory settings and real-world industrial trials. We optimize key parameters including Shore A hardness, coefficient of friction across wet/dry/oily surfaces, tear resistance, and thermal stability to meet exacting client specifications. Unlike suppliers relying on standard blends, our team leverages advanced polymer chemistry and filler dispersion techniques to achieve superior grip retention even after prolonged exposure to hydraulic fluids, cleaning agents, or extreme temperatures. This scientific approach minimizes total cost of ownership by extending service life and reducing accident-related liabilities. The table below summarizes the core performance metrics achievable with our engineered anti-slip floor sheets:

| Property | Typical Value Range | Test Standard |

|---|---|---|

| Shore A Hardness | 65–75 | ASTM D2240 |

| Static CoF (Wet Steel) | ≥ 0.85 | ASTM F2913 |

| Dynamic CoF (Wet Steel) | ≥ 0.75 | ASTM F2913 |

| Tensile Strength | 12–18 MPa | ASTM D412 |

| Elongation at Break | 250–400% | ASTM D412 |

| Temperature Range | -40°C to +120°C | ISO 188 |

| Abrasion Loss (Taber) | ≤ 120 mg/1000 cycles | ASTM D5963 |

Partnering with Suzhou Baoshida means engaging directly with rubber formulation experts who understand the interplay between molecular structure and functional performance. We provide comprehensive technical documentation, including material safety data sheets (MSDS), compliance certifications, and batch-specific quality reports. Our OEM-centric model supports custom thicknesses, colors, surface textures (e.g., diamond plate, grit patterns), and adhesive backing configurations to align with your assembly line requirements. Every compound is developed through iterative testing with your engineering team, ensuring the final product integrates flawlessly into your end application without compromising safety or durability.

Initiate your project with a precise technical consultation. Contact Mr. Boyce, our dedicated OEM Manager, to discuss material specifications, prototyping timelines, and volume production capabilities. Provide details regarding your substrate material, environmental stressors, expected foot/vehicle traffic, and regulatory frameworks for a targeted solution proposal. Email Boyce directly at [email protected] with the subject line OEM Partnership Inquiry: [Your Company Name] – Anti-Slip Floor Sheet Specifications. Include relevant drawings, performance requirements, and target delivery schedules to expedite technical evaluation. Suzhou Baoshida commits to responding within 24 business hours with actionable data, not generic sales pitches. Elevate your product safety and reliability through engineered rubber science—contact us to transform your anti-slip flooring requirements into a validated manufacturing reality.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).