Technical Contents

Engineering Guide: Aramid Fiber Gasket Material

Engineering Insight: Aramid Fiber Gasket Material

In high-performance sealing applications, material selection is not a matter of convenience—it is a determinant of system integrity, safety, and longevity. Aramid fiber gasket material stands at the forefront of advanced sealing solutions due to its exceptional thermal stability, chemical resistance, and mechanical strength. However, despite its superior properties, off-the-shelf aramid-based gaskets frequently underperform in demanding industrial environments. This discrepancy arises not from material inadequacy, but from a misalignment between standardized product formulations and the unique operational conditions of specific applications.

Aramid fibers, known for their high tensile strength and resistance to degradation at elevated temperatures, are often combined with elastomeric binders such as nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), or fluoroelastomers (FKM) to form composite gasket materials. While commercial variants offer a one-size-fits-all approach, they typically fail to account for variables such as dynamic pressure cycling, exposure to aggressive media, or thermal transients. For instance, an aramid-NBR composite may perform adequately in oil-handling systems up to 120°C, but rapid thermal excursions or exposure to polar solvents can lead to binder degradation, fiber delamination, and ultimately, seal failure.

The root cause of these failures lies in the lack of customization. Off-the-shelf gaskets are engineered for broad market compatibility, not for precision performance. In critical applications—such as in petrochemical processing, aerospace hydraulics, or high-pressure steam systems—this generalized approach introduces unacceptable risk. Sealing interfaces are subject to complex stress profiles, including compression set, creep relaxation, and surface finish interactions, all of which demand tailored material formulations.

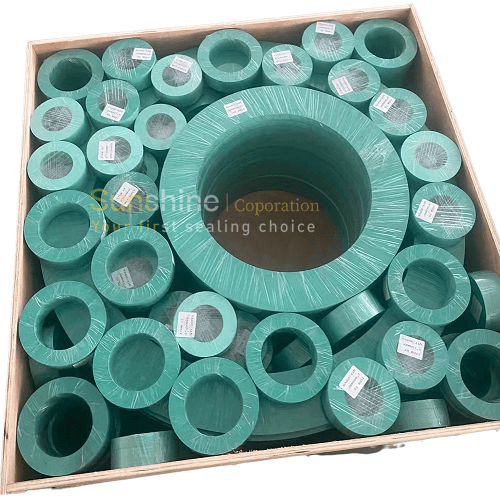

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection based on application-specific parameters. Our aramid fiber gasket materials are formulated with controlled fiber orientation, optimized elastomer content, and selective additives to enhance resistance to oxidation, fluid immersion, and thermal aging. This precision engineering ensures consistent performance under extreme conditions where generic alternatives falter.

The table below outlines key performance specifications of our custom aramid fiber gasket materials compared to standard commercial equivalents.

| Property | Custom Aramid-FKM Composite | Standard Aramid-NBR Gasket |

|---|---|---|

| Maximum Continuous Temperature | 250°C | 120°C |

| Tensile Strength | 28 MPa | 16 MPa |

| Compression Set (22h at 150°C) | 18% | 42% |

| Fluid Resistance (Hydraulic Oil, ASTM Type III) | Excellent | Good |

| pH Range Resistance | 2–13 | 4–10 |

| Density | 1.42 g/cm³ | 1.35 g/cm³ |

Material selection must be treated as a foundational engineering decision, not a procurement afterthought. By moving beyond off-the-shelf solutions and adopting a performance-driven design approach, manufacturers can achieve reliable, long-term sealing integrity in the most demanding environments.

Material Specifications

Material Specifications: Aramid Fiber Reinforced Elastomer Gasket Composites

Aramid fiber reinforcement significantly enhances the structural integrity and sealing performance of elastomeric gasket materials under demanding industrial conditions. At Suzhou Baoshida Trading Co., Ltd., our precision-engineered aramid fiber composites integrate high-strength para-aramid filaments into elastomer matrices to deliver exceptional resistance to creep, blowout, and thermal degradation. This reinforcement architecture maintains dimensional stability across extreme pressure cycles while minimizing cold flow, critical for maintaining flange integrity in dynamic systems. Key performance parameters include tensile strength, compression set, fluid resistance, and thermal stability, all rigorously validated per ASTM F104 and ISO 2230 standards for OEM applications.

The following table details the core specifications of our aramid-reinforced gasket materials utilizing Viton, Nitrile, and Silicone base polymers. These values represent minimum performance thresholds achieved through proprietary compounding and calendaring processes, ensuring consistency for high-volume OEM production. All materials undergo 100% lot traceability and meet FDA 21 CFR 177.2600 for food-grade variants where specified.

| Material Property | Viton (FKM) + Aramid | Nitrile (NBR) + Aramid | Silicone (VMQ) + Aramid |

|---|---|---|---|

| Continuous Service Temp | -20°C to +230°C | -40°C to +120°C | -60°C to +200°C |

| Peak Short-Term Temp | +300°C | +150°C | +260°C |

| Compression Set (24h @ 150°C) | ≤ 25% | ≤ 35% | ≤ 20% |

| Tensile Strength (MPa) | ≥ 18.0 | ≥ 15.0 | ≥ 9.0 |

| Fluid Resistance (Hydrocarbons) | Excellent | Good | Poor |

| Fluid Resistance (Acids/Bases) | Excellent | Fair | Excellent |

| Hardness (Shore A) | 75 ± 5 | 80 ± 5 | 65 ± 5 |

Viton-based composites exhibit superior resistance to aggressive chemicals, including fuels, oils, and halogenated solvents, making them indispensable for aerospace and chemical processing OEMs. The aramid reinforcement mitigates FKM’s inherent compression set vulnerability at elevated temperatures, extending service life in turbocharger and exhaust manifold applications. Nitrile-aramid blends provide optimal cost-performance balance for automotive transmission and hydraulic systems, with enhanced abrasion resistance against particulate-laden fluids. Silicone-aramid formulations excel in extreme low-temperature flexibility and steam resistance, critical for pharmaceutical and semiconductor manufacturing seals, though require careful evaluation against non-polar solvents.

OEM validation testing must account for fluid exposure duration, cyclic pressure profiles, and surface finish interactions. Suzhou Baoshida’s technical team provides application-specific material selection support, including finite element analysis (FEA) of stress distribution in flanged joints. All materials are compounded without asbestos or hazardous accelerators, complying with REACH and RoHS directives. For critical applications exceeding 230°C continuous service, our Viton-aramid-phthalonitrile variants achieve +325°C stability—request TR-2024-087 for extended thermal data. Partner with our engineering group early in the design phase to optimize gasket geometry and material pairing for your operational envelope.

Manufacturing Capabilities

Advanced Engineering Expertise in Aramid Fiber Gasket Material Development

At Suzhou Baoshida Trading Co., Ltd., our Engineering Capability division is built around a core team of five dedicated mould engineers and two specialized rubber formula engineers, all focused on advancing the performance and manufacturability of aramid fiber gasket materials. This integrated engineering team enables us to deliver precision-engineered sealing solutions tailored to the demanding requirements of industrial OEMs across automotive, aerospace, energy, and heavy machinery sectors.

Our formula engineers possess deep expertise in elastomer chemistry, with a specific focus on high-temperature and high-pressure formulations incorporating aramid fibers. These engineers optimize compound formulations to achieve superior mechanical strength, thermal stability (up to 300°C continuous service), and chemical resistance—critical for applications exposed to oils, fuels, and aggressive industrial fluids. By precisely controlling the dispersion of aramid fibers within the elastomeric matrix—typically NBR, EPDM, or FKM—we ensure consistent reinforcement, minimizing anisotropy and enhancing long-term compression set resistance.

Complementing this material science capability, our five mould engineers specialize in the design and validation of precision tooling for complex gasket geometries. Utilizing CAD/CAM software and finite element analysis (FEA), they simulate compression behavior and flow dynamics to ensure optimal material distribution during curing. This reduces flash, improves dimensional accuracy, and extends tool life—key factors in high-volume OEM production. Our in-house tooling development cycle is streamlined to support rapid prototyping and accelerated time-to-market.

We operate as a full-service OEM partner, offering end-to-end development from concept to serial production. Clients provide performance specifications or application environments, and our team co-engineers the optimal gasket solution—selecting the appropriate elastomer-fiber composite, designing the mould, and validating performance through rigorous testing protocols. This includes compression set analysis, leak rate measurement, and thermal cycling per ASTM and ISO standards.

Our production infrastructure supports both small-batch custom runs and large-scale manufacturing, with strict adherence to ISO 9001 quality management systems. Traceability, batch consistency, and process control are maintained through automated mixing, hydraulic press curing, and post-cure inspection using laser micrometry and vision systems.

The following table outlines key technical specifications achievable with our aramid fiber-reinforced gasket materials:

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | 18–24 MPa |

| Elongation at Break | ASTM D412 | 120–180% |

| Compression Set (22h at 200°C) | ASTM D395 | ≤25% |

| Hardness (Shore A) | ASTM D2240 | 60–90 |

| Operating Temperature Range | — | -40°C to +300°C |

| Fluid Resistance | ASTM D471 | Excellent in oils, fuels, glycols |

Through the synergy of advanced material formulation and precision mould engineering, Suzhou Baoshida delivers aramid fiber gasket solutions that meet the highest standards of reliability and performance in critical sealing applications.

Customization Process

Aramid Fiber Gasket Material Customization Process

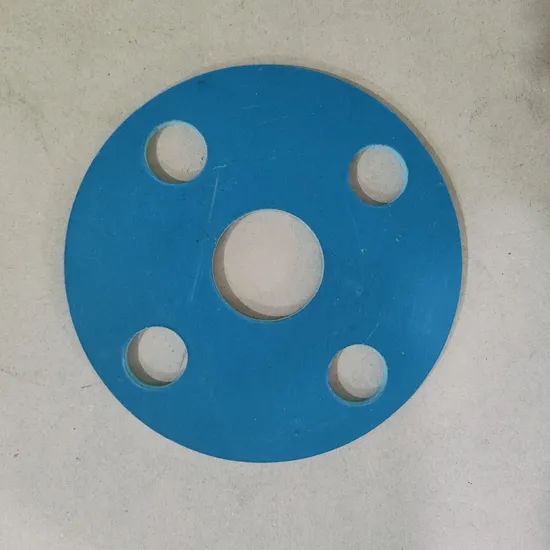

At Suzhou Baoshida Trading Co., Ltd., our aramid fiber gasket customization ensures optimal sealing performance under extreme industrial conditions. This four-stage process integrates material science with precision manufacturing to meet exact OEM specifications. We begin with rigorous drawing analysis, where our engineering team examines GD&T tolerances, surface finish requirements, and operational parameters such as temperature, pressure, and fluid exposure. Critical dimensions are cross-referenced against failure mode databases to preempt compression set or extrusion risks. This phase identifies material compatibility gaps, such as chemical resistance limitations against specific hydrocarbons or solvents, ensuring the base formulation aligns with end-use demands.

Formulation development follows, leveraging our proprietary rubber compound library. Aramid fiber loading (typically 15–35% by weight) is adjusted alongside elastomer selection—HNBR for high-temperature oil resistance or FKM for aggressive chemical environments. Fillers like PTFE or graphite modify friction coefficients, while curing systems are optimized for thickness-dependent vulcanization kinetics. Each variable is modeled using Mooney viscosity and Payne effect simulations to balance processability with final mechanical properties. This stage concludes with a validated compound sheet specifying cure time, temperature, and post-cure protocols.

Prototyping employs CNC-machined molds to produce ISO 2858 test specimens and functional prototypes. Compression molding parameters are fine-tuned to eliminate knit lines or density variations, with real-time cavity pressure monitoring ensuring uniform fiber distribution. All prototypes undergo ASTM D2000 verification: tensile strength, compression set at 200°C, and fluid immersion testing per OEM fluid lists. Dimensional validation via CMM confirms ±0.1mm tolerances, with iterative adjustments made until all criteria are satisfied.

Mass production initiates only after formal client approval of prototypes. We deploy SPC-controlled molding lines with in-line rheometers tracking scorch time and cure state. Each batch undergoes 100% visual inspection and random destructive testing per AQL 1.0 standards. Traceability is maintained via laser-etched batch codes linked to raw material certificates and process logs. Final gaskets ship with material test reports (MTRs) documenting compliance against the approved drawing, including critical properties such as creep relaxation and thermal cycling stability.

Key Customization Impact on Material Properties

| Property | Standard Spec | Customized Spec | Test Method |

|---|---|---|---|

| Tensile Strength | ≥15 MPa | ≥22 MPa | ASTM D412 |

| Continuous Temp Range | -40°C to +200°C | -55°C to +260°C | ASTM D573 |

| Compression Set (22h/200°C) | ≤40% | ≤25% | ASTM D395 |

| Fluid Resistance (Engine Oil) | Volume Swell ≤25% | Volume Swell ≤12% | ASTM D471 |

This structured workflow guarantees that every aramid gasket delivers leak-free service in critical applications, from turbocharger housings to chemical reactor flanges. Suzhou Baoshida’s commitment to data-driven customization eliminates field failure risks while accelerating time-to-market for OEM partners.

Contact Engineering Team

For industrial manufacturers requiring high-performance sealing solutions, aramid fiber gasket materials represent a critical advancement in thermal stability, chemical resistance, and mechanical durability. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for extreme operating environments—particularly in oil & gas, chemical processing, power generation, and heavy industrial machinery. Our aramid fiber-reinforced gasket materials are formulated to maintain integrity under high pressure and elevated temperatures, offering a reliable alternative to traditional asbestos-based or non-reinforced elastomeric gaskets.

Aramid fibers, known for their exceptional tensile strength and heat resistance, are integrated into our composite gasket formulations to enhance structural stability and reduce creep deformation. When combined with high-grade nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), or fluorocarbon (FKM) binders, these materials deliver superior performance in dynamic sealing applications where failure is not an option. Our manufacturing process ensures uniform fiber dispersion, optimized compression set resistance, and excellent recovery characteristics—key attributes for long-term sealing integrity.

We understand that OEMs and industrial supply chain managers require not only technical excellence but also supply consistency, traceability, and compliance with international standards. Suzhou Baoshida maintains strict quality control protocols aligned with ISO 9001 standards and provides full material certification upon request. Our technical team works directly with clients to customize formulations based on specific media exposure, temperature ranges, and flange configurations.

Below are representative specifications for our standard aramid fiber gasket material grades:

| Property | Test Method | Value (Typical) |

|---|---|---|

| Density | ASTM D2240 | 1.75 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 85 ± 5 |

| Tensile Strength | ASTM D412 | ≥28 MPa |

| Elongation at Break | ASTM D412 | ≥150% |

| Compression Set (24h @ 150°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -20°C to +280°C |

| Fluid Resistance | ASTM D471 | Excellent in oils, fuels, aliphatic hydrocarbons |

| Fiber Content (Aramid) | Internal | 15–20% by weight |

These values are indicative and may vary slightly depending on the specific compound formulation. Custom thicknesses from 0.5 mm to 6.0 mm are available in sheet form, with roll stock and die-cut parts offered for high-volume production lines.

To discuss your specific sealing challenge or request a technical datasheet and sample kit, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in supporting international clients with material selection, compliance documentation, and just-in-time supply chain integration. Reach him directly via email at [email protected]. Include your application details, performance requirements, and preferred sample dimensions for a prompt and targeted response. For urgent inquiries, please specify your time zone and preferred contact window to ensure efficient coordination.

Partner with Suzhou Baoshida for technically validated, industrially proven aramid fiber gasket solutions—engineered for precision, built for endurance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).