Technical Contents

Engineering Guide: As568A O Ring Sizes

Engineering Insight: AS568A O-Ring Sizes and Material Selection Imperatives

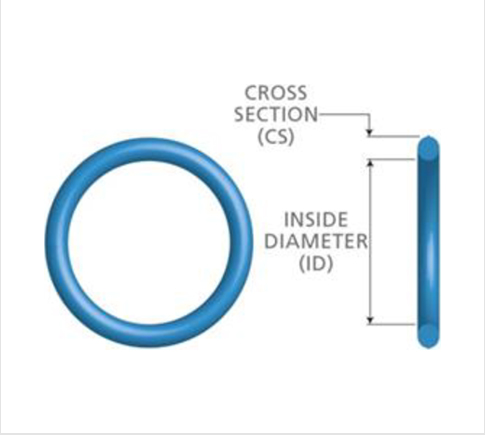

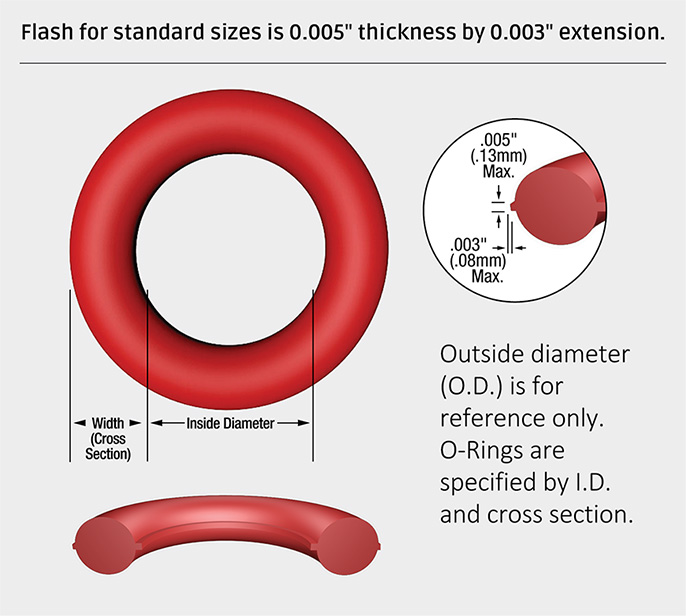

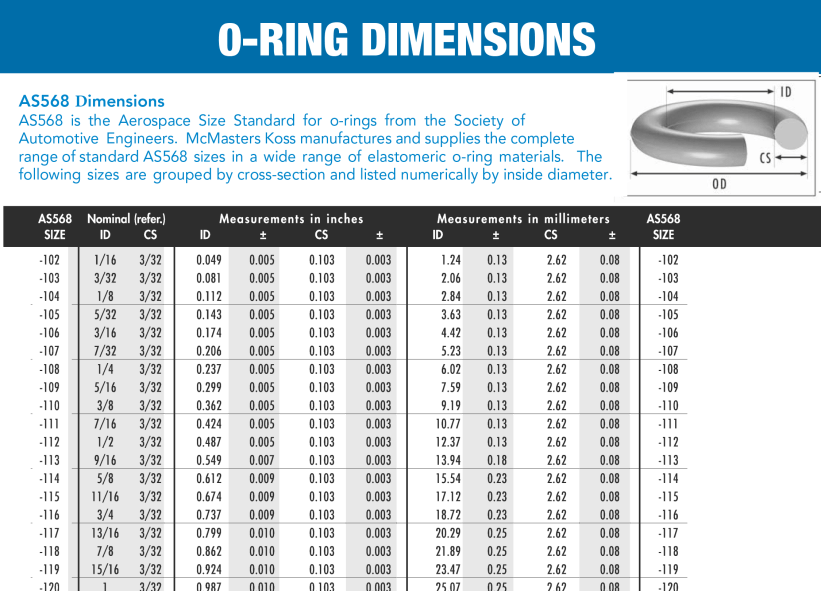

The AS568A standard provides critical dimensional uniformity for O-rings across global supply chains, ensuring interchangeability for inner diameter, cross-section, and tolerance bands. However, strict adherence to AS568A dimensions alone is insufficient for reliable sealing performance in demanding industrial applications. Material selection constitutes the paramount engineering decision, often overlooked when specifying off-the-shelf catalog items. Generic O-rings selected solely by size frequently fail prematurely due to incompatibility with specific operational environments, leading to costly downtime, safety hazards, and reputational damage. The polymer compound dictates fundamental properties like chemical resistance, temperature stability, compression set, and extrusion resistance – factors dimensionally identical O-rings from different material families cannot satisfy uniformly.

Off-the-shelf solutions fail primarily because standard catalogs prioritize dimensional availability over application-specific chemistry. An NBR O-ring meeting AS568A-214 dimensions may seal hydraulic fluid adequately at 80°C but catastrophically degrade when exposed to phosphate ester fluids or ozone at elevated temperatures. Similarly, a standard FKM compound might resist jet fuel but exhibit excessive compression set in hot water applications where EPDM excels. Material limitations manifest as hardening, cracking, swelling, or permanent deformation, directly compromising the seal interface defined by the AS568A geometry. Compression set failure – the inability to recover shape after prolonged compression – is a critical, often underestimated, consequence of material mismatch. A 20% compression set in a standard compound under continuous heat exposure can reduce sealing force below critical thresholds, causing leaks even if the O-ring physically fits the gland.

Suzhou Baoshida Trading Co., Ltd. emphasizes that successful sealing requires matching the elastomer’s molecular structure to the specific service conditions. Critical evaluation must include fluid composition, temperature extremes (both continuous and transient), pressure cycles, dynamic movement, and atmospheric exposure. The following table highlights key material considerations beyond AS568A dimensions:

| Material Type | Temperature Range (°C) | Key Fluid Resistance | Critical Compression Set Risk | Common Off-the-Shelf Failure Modes |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | Mineral oils, aliphatic hydrocarbons | Moderate (above 100°C) | Swelling in esters/ketones; ozone cracking; hardening at high temp |

| FKM (Viton®) | -20 to +200 | Aromatics, fuels, acids, oils | Low (up to 200°C) | Poor hot water/steam resistance; high compression set in glycols; costly for mild services |

| EPDM | -50 to +150 | Water, steam, brake fluids, alkalis | Very Low (up to 150°C) | Swelling in petroleum oils/fuels; poor ozone resistance in some grades |

| VMQ (Silicone) | -60 to +200 | Ozone, UV, water | Moderate (long-term high temp) | Poor tear strength; swelling in fuels/oils; permeability issues |

Material science dictates that no single elastomer satisfies all requirements. Relying on standard catalog offerings risks deploying a dimensionally correct but chemically incompatible seal. Suzhou Baoshida Trading Co., Ltd. partners with OEMs to engineer bespoke rubber formulations precisely aligned with application physics and chemistry. We analyze fluid compatibility charts, conduct accelerated aging tests per ASTM D2000, and optimize cure systems to minimize compression set – transforming AS568A dimensional compliance into guaranteed functional reliability. True sealing integrity demands moving beyond the catalog number to master the material science within the O-ring.

Material Specifications

Material Specifications for AS568A O-Ring Sizes

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber seals compliant with the AS568A standard, ensuring dimensional uniformity and interchangeability across global applications. Material selection is a critical factor in determining seal performance under specific environmental and operational conditions. Among the most widely used elastomers in industrial sealing applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages in terms of temperature resistance, chemical compatibility, and mechanical properties, making them suitable for different operational environments.

Viton, a fluorocarbon-based elastomer, exhibits exceptional resistance to high temperatures, ozone, and a broad range of chemicals, including fuels, oils, and many acids. It maintains structural integrity in continuous service temperatures up to 200°C and can withstand peak exposures up to 250°C. This makes Viton the preferred choice for aerospace, automotive, and chemical processing industries where exposure to aggressive media is common. However, its lower flexibility at sub-zero temperatures and higher cost compared to other elastomers may limit its use in less demanding applications.

Nitrile rubber, also known as Buna-N, is one of the most commonly used O-ring materials due to its excellent resistance to petroleum-based oils and fuels, good abrasion resistance, and cost-effectiveness. It performs well in temperature ranges from -30°C to 120°C, making it ideal for hydraulic systems, fuel delivery components, and general industrial machinery. While Nitrile offers superior mechanical strength and compression set resistance, it is less effective in environments involving polar solvents, strong acids, or prolonged exposure to ozone and UV radiation.

Silicone rubber provides outstanding thermal stability across a wide temperature range, typically from -60°C to 200°C, with short-term resistance up to 250°C. It demonstrates excellent resistance to ozone and UV degradation, making it suitable for outdoor and high-purity applications such as medical devices, food processing, and semiconductor manufacturing. However, silicone has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure or oil-lubricated systems.

Selection of the appropriate material must consider fluid compatibility, operating temperature, pressure, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. ensures all AS568A O-rings are manufactured to stringent quality standards, with full traceability and material certifications available upon request.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 120 | -60 to 200 (up to 250 short-term) |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 70–90 | 60–90 | 40–80 |

| Fluid Resistance (Oils/Fuels) | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Good | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

Manufacturing Capabilities

Engineering Precision for AS568A O-Ring Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers uncompromising precision in AS568A standard O-ring production through integrated material science and advanced tooling expertise. Our dedicated engineering team comprises five specialized mold designers and two certified rubber formula engineers, ensuring every component meets stringent aerospace, automotive, and industrial fluid system requirements. This dual-discipline structure enables holistic control from polymer chemistry to final geometry, eliminating cross-departmental inefficiencies common in standard supply chains.

Our formula engineers optimize elastomer compounds for specific AS568A applications, balancing critical properties such as compression set resistance, thermal stability, and chemical compatibility. Utilizing Fourier-transform infrared spectroscopy (FTIR) and rheometry, we validate formulations against ASTM D2000 and ISO 3601 standards, achieving consistent Shore A hardness tolerances of ±2 points. Concurrently, our mold engineering team employs finite element analysis (FEA) to simulate material flow and cure kinetics, minimizing flash and dimensional drift. This synergy reduces prototyping cycles by 40% compared to industry averages while maintaining ISO 3302-1 Class M2 tolerances on all critical dimensions.

OEM clients benefit from a streamlined development pathway where material selection and mold design occur in parallel. We initiate projects with application-specific requirement mapping, including fluid exposure, temperature range, and dynamic load profiles. Our engineers then co-develop proprietary compounds—such as custom hydrogenated nitrile (HNBR) for low-temperature aerospace seals or perfluoroelastomer (FFKM) variants for semiconductor tooling—paired with precision-ground cavity molds featuring thermal uniformity control within ±0.5°C. Full lot traceability, from raw polymer batch to finished part certification, ensures compliance with AS9100 and IATF 16949 frameworks.

Key dimensional specifications for AS568A O-rings manufactured at our Suzhou facility adhere to the following critical parameters:

| AS568A Dash No. | Inside Diameter (mm) | Cross-Section (mm) | ID Tolerance (mm) | CS Tolerance (mm) |

|---|---|---|---|---|

| -006 | 2.62 | 1.78 | ±0.13 | ±0.08 |

| -214 | 34.93 | 2.62 | ±0.18 | ±0.08 |

| -322 | 102.87 | 3.53 | ±0.25 | ±0.10 |

All tolerances comply with AS568A Class 1 standards, validated through automated optical inspection (AOI) systems with 5-micron resolution. Our facility maintains ±0.5°C ambient control during curing and post-bake stabilization, critical for achieving <15% compression set at 100°C per ASTM D395 Method B. This engineering rigor, combined with real-time statistical process control (SPC) monitoring, guarantees repeatability for high-volume OEM programs exceeding 500,000 units monthly. Clients receive comprehensive material test reports (MTRs) and first-article inspection (FAI) documentation, enabling seamless integration into mission-critical assembly lines. Suzhou Baoshida transforms AS568A standardization into a competitive advantage through scientific material innovation and disciplined process execution.

Customization Process

Drawing Analysis

The customization process for AS568A O-ring sizes begins with rigorous drawing analysis, a foundational step ensuring dimensional accuracy and functional compatibility. At Suzhou Baoshida Trading Co., Ltd., our engineering team evaluates customer-provided technical drawings or industry-standard AS568A specifications to confirm critical parameters including inner diameter, cross-sectional diameter, tolerance class, and surface finish requirements. Each AS568A size corresponds to a standardized dash number, which we cross-reference against aerospace, automotive, or industrial application standards to verify compliance. Any deviations from standard dimensions or special groove design requirements are flagged for engineering review. This stage also includes material compatibility assessment based on the intended operating environment, such as exposure to oils, fuels, or extreme temperatures, forming the basis for subsequent formulation decisions.

Formulation Development

Following drawing validation, our rubber formula engineers initiate material formulation tailored to the application’s performance demands. Standard AS568A O-rings are typically produced in nitrile (NBR), fluorocarbon (FKM), silicone (VMQ), or ethylene propylene diene monomer (EPDM), each selected based on chemical resistance, temperature range, and mechanical properties. For instance, NBR is preferred for hydraulic systems due to its excellent resistance to petroleum-based fluids, while FKM is chosen for high-temperature or aggressive chemical environments. Our in-house compounding laboratory develops custom rubber batches with precise filler, accelerator, and curing agent ratios to meet specific durometer (Shore A) requirements, typically ranging from 50 to 90. Each formulation undergoes preliminary testing for compression set, tensile strength, and elongation at break to ensure it meets ASTM D2000 or customer-defined material specifications.

Prototyping and Validation

Once the formulation is finalized, a prototype batch of the specified AS568A O-ring size is produced using precision molding techniques. These prototypes are subjected to dimensional inspection via optical measuring systems and physical testing, including hardness, volume swell in designated fluids, and low-temperature flexibility (TR-10 or ASTM D1329). Functional testing may also be conducted in simulated operating conditions to validate sealing performance. Customer feedback is integrated at this stage, allowing for iterative adjustments in material or geometry before approval for mass production.

Mass Production and Quality Assurance

Upon prototype approval, the order transitions to automated mass production. Our manufacturing lines utilize hydraulic presses and CNC-machined molds to ensure consistency across thousands of units. Every production lot undergoes 100% visual inspection and statistical dimensional sampling per ISO 3302 and ISO 2859 standards. Final packaging is customized per client requirements, with traceability maintained through batch coding and material certificates.

| AS568A Dash No | Inner Diameter (in) | Cross Section (in) | Material Options | Standard Tolerance (±) |

|---|---|---|---|---|

| 102 | 0.100 | 0.070 | NBR, FKM, EPDM | 0.004 (ID), 0.003 (CS) |

| 214 | 1.188 | 0.139 | NBR, FKM, VMQ | 0.007 (ID), 0.004 (CS) |

| 326 | 3.500 | 0.280 | FKM, EPDM | 0.014 (ID), 0.006 (CS) |

Contact Engineering Team

Technical Partnership for AS568A O-Ring Implementation

Achieving flawless sealing performance in demanding industrial and aerospace applications requires precise adherence to dimensional standards and expert material science. The AS568A standard defines the critical cross-sections and inside diameters for 369 standardized O-ring sizes, ensuring interchangeability and reliability across global supply chains. Suzhou Baoshida Trading Co., Ltd. operates at the intersection of stringent dimensional compliance and advanced rubber compounding, providing OEMs with engineered sealing solutions that meet or exceed AS568A specifications under real-world operational stresses. Our manufacturing rigor extends beyond simple size replication; we integrate material selection, compression set resistance, and chemical compatibility analysis to deliver O-rings that maintain integrity across temperature extremes, pressure cycles, and exposure to aggressive media. Understanding the exact AS568A size designation is the foundational step, but optimal performance demands matching that geometry to the correct elastomer formulation for your specific application environment.

The following table presents essential dimensional data for representative AS568A sizes, critical for initial design validation and tolerance analysis. All dimensions are in inches as per the standard, with metric equivalents provided for international engineering reference. Suzhou Baoshida maintains inventory and production capability for the full AS568A size range, alongside custom tooling for non-standard requirements where precision tolerances are paramount.

| AS568A Dash Size | Inside Diameter (ID) | Cross-Section (CS) | ID (mm) | CS (mm) | Volume Swell Tolerance (ASTM D2000) |

|---|---|---|---|---|---|

| -001 | 0.029 ±0.003 | 0.040 ±0.003 | 0.74 | 1.02 | A00 B00 EF10 |

| -012 | 0.114 ±0.003 | 0.070 ±0.003 | 2.90 | 1.78 | A00 B00 EF14 |

| -104 | 0.484 ±0.004 | 0.070 ±0.004 | 12.29 | 1.78 | A00 B00 EF14 |

| -214 | 1.750 ±0.006 | 0.139 ±0.004 | 44.45 | 3.53 | A00 B00 EF21 |

| -222 | 2.438 ±0.007 | 0.139 ±0.004 | 61.93 | 3.53 | A00 B00 EF21 |

Suzhou Baoshida functions as your dedicated engineering extension for sealing challenges. We do not merely supply O-rings; we provide validated material solutions. Our in-house rubber formulation laboratory conducts rigorous testing per ASTM D2000, ISO 3601, and customer-specific protocols to ensure compounds meet exact fluid resistance, thermal stability, and dynamic performance criteria. When dimensional precision from the AS568A chart meets our proprietary elastomer science, the result is extended service life, reduced maintenance cycles, and elimination of costly leakage failures in hydraulic systems, pneumatic controls, fuel handling, and semiconductor manufacturing equipment.

Initiate your path to assured sealing performance by contacting Mr. Boyce directly. As your primary technical liaison at Suzhou Baoshida, Mr. Boyce possesses immediate access to our engineering team, production schedules, and material certification data. He will facilitate the rapid translation of your AS568A size requirements and operational parameters into a qualified O-ring solution, complete with full traceability documentation and batch-specific test reports. Do not compromise on sealing integrity when engineering expertise is readily available. Reach out to Mr. Boyce via email at [email protected] to discuss material selection, dimensional validation, prototype development, or urgent OEM production needs. Provide your specific AS568A dash size, application media, temperature range, and pressure conditions for a targeted technical response within one business day. Partner with Suzhou Baoshida for O-rings engineered to perform, not merely to fit. Your application’s reliability depends on the precision of the seal.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).