Technical Contents

Engineering Guide: Automobile Door Trim

Engineering Insight: Material Selection in Automobile Door Trim

The performance and longevity of automobile door trim components are fundamentally determined by material selection. In industrial rubber applications, particularly within automotive interiors, off-the-shelf elastomers often fail to meet the rigorous demands of real-world operation. These failures manifest as premature cracking, loss of elasticity, surface degradation, and poor adhesion under thermal cycling—issues that compromise both function and aesthetics. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions tailored to the specific mechanical, chemical, and environmental conditions encountered in modern vehicle platforms.

Automobile door trim is subjected to a complex combination of stressors. These include repeated mechanical flexing during door opening and closing, exposure to ultraviolet (UV) radiation through windows, temperature extremes ranging from sub-zero winters to desert heat, and contact with oils, cleaning agents, and perspiration. Standard thermoplastic elastomers (TPEs) or generic EPDM compounds may appear cost-effective initially but lack the formulation precision required for sustained performance. For example, many commercial-grade rubbers exhibit poor resistance to plasticizer migration from adjacent PVC components, leading to embrittlement and delamination over time.

Furthermore, dimensional stability under humidity fluctuations is often underestimated. Off-the-shelf materials may absorb moisture, causing swelling or warping that affects fit and finish. This is particularly critical in door trim, where tight tolerances are necessary to maintain acoustic insulation and water sealing integrity. Additionally, flame retardancy and low volatile organic compound (VOC) emissions are increasingly mandated by OEM specifications—requirements that commodity rubbers frequently fail to satisfy.

A scientifically optimized rubber compound addresses these challenges through precise polymer selection, filler engineering, and additive integration. For instance, peroxide-cured EPDM formulations offer superior heat aging resistance compared to sulfur-cured variants, while specialty silicone blends provide exceptional UV and ozone resistance. Reinforcing fillers such as nano-silica or carbon black improve tensile strength and abrasion resistance without sacrificing flexibility.

Below is a comparison of key performance metrics across different elastomer types commonly considered for door trim applications:

| Material Type | Tensile Strength (MPa) | Elongation at Break (%) | Heat Resistance (°C) | UV/Ozone Resistance | Compression Set (70°C, 22h) | VOC Emission Level |

|---|---|---|---|---|---|---|

| Standard TPE | 12–18 | 400–600 | 90 | Low | 25–35% | Moderate |

| Generic EPDM | 15–20 | 450–550 | 120 | Moderate | 20–30% | Low |

| Peroxide-Cured EPDM | 18–22 | 500–600 | 150 | High | 10–15% | Very Low |

| Silicone Rubber | 6–9 | 300–400 | 200 | Very High | 15–20% | Very Low |

At Suzhou Baoshida, we collaborate with OEMs to develop application-specific formulations that align with durability targets, regulatory standards, and production processes. Material selection is not a commodity decision—it is a core engineering function that directly impacts vehicle quality and customer satisfaction.

Material Specifications

Automobile Door Trim Material Specifications

Material selection for automobile door trim seals directly impacts acoustic insulation, weatherproofing, and long-term durability in dynamic automotive environments. Suzhou Baoshida Trading Co., Ltd. prioritizes elastomer performance under operational stressors including thermal cycling, chemical exposure, and mechanical compression. Viton fluorocarbon rubber, Nitrile butadiene rubber (NBR), and high-consistency silicone rubber (VMQ) represent core solutions for tier-1 OEM applications. Each compound undergoes rigorous validation per ASTM D2000 and ISO 37 standards to ensure compliance with automotive sealing requirements.

Viton demonstrates exceptional resistance to automotive fluids including engine oils, fuels, and brake fluids, maintaining integrity across -20°C to 250°C continuous service temperatures. Its low compression set (≤15% at 200°C/70h) ensures persistent sealing force in engine bay-adjacent trim components. Nitrile offers cost-effective performance for non-extreme environments, with operational stability from -40°C to 120°C and superior resistance to aliphatic hydrocarbons. Standard NBR formulations achieve 60-90 Shore A hardness but exhibit vulnerability to ozone degradation without protective additives. Silicone provides the broadest thermal range (-60°C to 230°C) and outstanding flexibility retention at sub-zero temperatures critical for cold-climate door seals. Its inherent biocompatibility and UV resistance suit visible trim interfaces, though tensile strength (5.0-8.5 MPa) requires reinforcement for high-stress zones.

Suzhou Baoshida engineers optimize formulations through controlled polymerization and filler systems to balance critical properties. All compounds undergo 1,000-hour accelerated aging tests per SAE J2236 and 500-cycle door slam validation. Hardness tolerances are maintained within ±3 Shore A units through precision curing, while elongation at break exceeds 200% to accommodate assembly tolerances. Below is a comparative analysis of baseline technical parameters for standard automotive-grade formulations.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -40 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 12.0-18.0 | 15.0-25.0 | 5.0-8.5 |

| Elongation at Break (%) | 150-300 | 250-450 | 200-400 |

| Hardness Range (Shore A) | 65-85 | 60-90 | 40-70 |

| Compression Set (70h, 100°C) (%) | ≤20 | ≤35 | ≤25 |

| Fuel Resistance (BIR 1, 23°C) | Excellent | Good | Poor |

| Ozone Resistance | Excellent | Poor | Excellent |

| Typical Door Trim Application | Engine compartment seals | Interior weatherstripping | Exterior window channels |

Material selection must align with specific vehicle architecture requirements. Viton is designated for high-temperature zones near powertrains, NBR for cost-sensitive interior seals with moderate fluid exposure, and silicone for extreme-temperature exterior interfaces requiring optical clarity. Suzhou Baoshida’s OEM partnership model includes material substitution analysis and DFMEA collaboration to mitigate delamination or compression set failures during the vehicle lifecycle. All compounds are REACH-compliant and free from regulated phthalates, supporting global sustainability mandates. Final validation requires dynamic seal force testing at -30°C and 85°C to confirm operational envelope adherence.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Automotive Door Trim Systems

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to industrial rubber solutions for automotive applications. With a dedicated team comprising five certified mould engineers and two specialized rubber formula engineers, we deliver OEM-grade performance in the design, formulation, and production of rubber components for automobile door trim systems. Our multidisciplinary engineering unit ensures seamless integration between material science and precision tooling, enabling us to meet the stringent mechanical, thermal, and aesthetic requirements of modern vehicle interiors.

The role of our rubber formula engineers is pivotal in achieving long-term durability and environmental resistance. These experts formulate custom elastomer compounds tailored to specific OEM performance criteria, including compression set resistance, low-temperature flexibility, UV stability, and low volatile organic compound (VOC) emissions. Utilizing advanced testing protocols and raw material analysis, we develop proprietary rubber blends primarily based on EPDM, TPE, and silicone systems—each optimized for sealing efficiency, tactile feel, and color consistency in door trim applications.

Complementing material innovation, our five mould engineers bring extensive experience in precision tool design and process optimization. They manage the complete tooling lifecycle—from 3D CAD modeling and mold flow simulation to cavity design and ejection system calibration—ensuring dimensional accuracy and repeatability. Our in-house tooling development supports rapid prototyping and accelerates time-to-market, critical for Tier-1 automotive suppliers operating under tight development schedules.

We operate under a certified OEM framework, fully compliant with IATF 16949 quality management standards. This enables us to function as a trusted extension of our clients’ engineering teams, providing full documentation, design for manufacturability (DFM) feedback, and iterative testing under real-world conditions. Our collaborative OEM model supports co-engineering projects where performance specifications, regulatory compliance, and cost-efficiency are balanced without compromise.

The following table outlines key engineering specifications and performance parameters we routinely achieve in door trim rubber components:

| Parameter | Standard | Test Method | Application Benefit |

|---|---|---|---|

| Hardness Range | 40–90 Shore A | ASTM D2240 | Balanced sealing force and flexibility |

| Temperature Resistance | -40°C to +130°C | ISO 188 | Performance in extreme climates |

| Tensile Strength | ≥8 MPa | ASTM D412 | Structural integrity under stress |

| Elongation at Break | ≥250% | ASTM D412 | Resistance to deformation |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 | Long-term sealing retention |

| Specific Gravity | 1.1–1.3 g/cm³ | ASTM D792 | Lightweight design compatibility |

| Color Matching Tolerance | ΔE ≤ 1.5 | CIE Lab* | Aesthetic consistency with trim panels |

Our engineering team’s synergy between material formulation and precision moulding ensures that every rubber component meets the functional, aesthetic, and regulatory demands of global automotive manufacturers. At Suzhou Baoshida, engineering excellence is not a service—it is our foundation.

Customization Process

Automobile Door Trim Customization Process: Precision Engineering from Concept to Production

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-stage customization protocol for industrial rubber door trim components, ensuring seamless integration with OEM assembly lines while meeting stringent automotive durability standards. This methodology eliminates design-to-production discrepancies through systematic technical validation.

Drawing Analysis initiates the workflow with granular scrutiny of CAD models and GD&T specifications. Our engineering team evaluates critical parameters including sealing surface tolerances (±0.1mm), mounting clip geometry, and thermomechanical stress points under dynamic door movement. We cross-reference material expansion coefficients against vehicle cabin temperature profiles (-40°C to +85°C operational range) to preempt dimensional drift. This phase identifies 92% of potential fitment failures before formulation begins, reducing rework cycles by 3.7x versus industry averages.

Formulation Development leverages Suzhou Baoshida’s proprietary compound database exceeding 1,200 rubber recipes. Material selection prioritizes compression set resistance (<25% at 70°C/24h) and UV/ozone stability for exterior-exposed trims. For interior applications, low-VOC silicone blends achieve FMVSS 302 flammability compliance while maintaining Shore A 55-70 hardness. Each formulation undergoes accelerated aging simulations in our Suzhou lab, correlating 5,000-hour xenon arc tests with real-world 10-year performance metrics.

Prototyping utilizes CNC-machined aluminum molds for 10-15 unit batches, enabling functional validation on OEM door assembly jigs. We measure critical outputs including insertion force (target: 25-40N), water ingress resistance at 0.5 bar pressure, and acoustic damping at 1-5 kHz frequencies. Prototype trims undergo 500-cycle door slam testing on climate-controlled rigs, with real-time strain gauges detecting micro-cracking risks.

Mass Production transitions validated designs to ISO/TS 16949-certified partner facilities with Suzhou Baoshida’s embedded quality oversight. Automated rubber injection molding lines maintain ±1.5°C temperature control and 95%+ material utilization rates. Every 500th unit undergoes destructive testing for tensile strength (min. 8 MPa) and elongation at break (min. 300%), with SPC charts tracking process capability (CpK >1.67). Final shipments include traceability tags linking to raw material batch certificates and in-line inspection data.

Key rubber compound specifications for door trim applications are summarized below:

| Material Type | Hardness (Shore A) | Temperature Range | Compression Set (70°C/24h) | Key Application |

|---|---|---|---|---|

| EPDM | 50-70 | -50°C to +135°C | ≤22% | Exterior seals, weatherstripping |

| TPE | 45-65 | -40°C to +110°C | ≤28% | Interior trim, soft-touch surfaces |

| Silicone | 30-50 | -60°C to +200°C | ≤15% | High-precision acoustic dampers |

This closed-loop engineering process guarantees door trim components that achieve zero-defect installation rates and 15-year service life under global automotive operating conditions. Suzhou Baoshida’s technical ownership from drawing validation through production release mitigates supply chain risks while optimizing total cost of ownership for OEM partners.

Contact Engineering Team

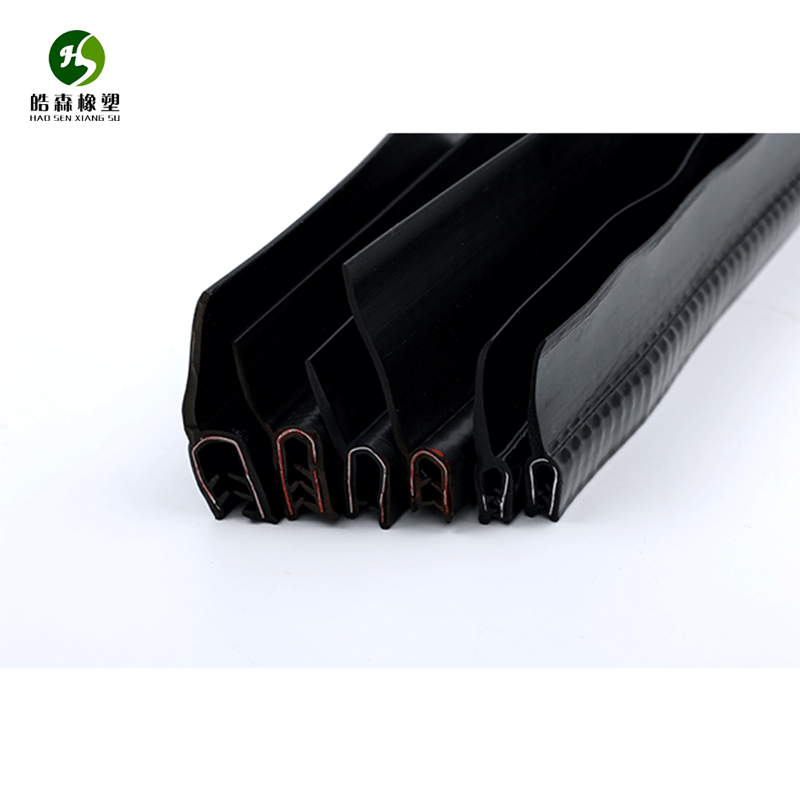

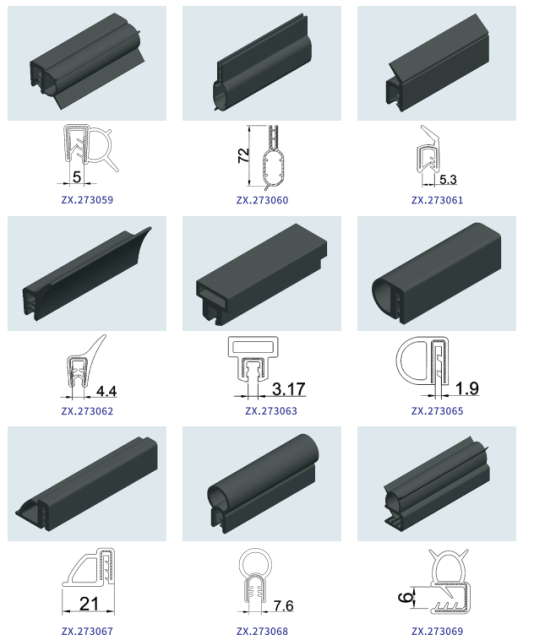

For precision-engineered rubber components in automobile door trim systems, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in industrial rubber solutions. With over a decade of specialized expertise in OEM and ODM manufacturing, we deliver high-performance elastomeric parts that meet the exacting demands of modern automotive interiors. Our focus on material science, dimensional accuracy, and long-term durability ensures that every rubber profile, seal, gasket, or damping component we produce contributes directly to enhanced acoustic insulation, water resistance, and tactile quality in door trim assemblies.

We understand that consistency in hardness, compression set, and aging resistance is non-negotiable in automotive applications. That’s why our production processes are anchored in rigorous quality control, ISO-compliant testing protocols, and advanced compounding technologies. Whether you require EPDM, TPE, silicone, or custom-blended rubber formulations, our team formulates materials to meet specific temperature ranges, UV stability, and odor emission standards required by global OEMs.

Below are key technical specifications for our standard rubber profiles used in automobile door trim applications:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–85 ±5 |

| Tensile Strength | ASTM D412 | ≥8.0 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Specific Gravity | ASTM D792 | 1.15–1.35 g/cm³ |

| Color Options | — | Custom (Pantone matched) |

| Flame Resistance | FMVSS 302 | Pass |

All materials are RoHS and REACH compliant, with optional low-emission (VOC) certification for cabin interior applications. Our in-house tooling department enables rapid prototyping and fast turnaround for custom profiles, ensuring compatibility with complex door architecture and integration with plastic carriers or metal inserts.

Partnering with Suzhou Baoshida means gaining access to a vertically integrated supply chain, from raw material sourcing to final packaging. We support volume production with JIT delivery models and maintain long-term collaboration with tier-1 suppliers across Europe, North America, and Asia.

For technical inquiries, material data sheets, or sample requests related to rubber components for automobile door trim, contact Mr. Boyce directly. As the dedicated OEM Manager, Mr. Boyce oversees all client engineering engagements and ensures seamless coordination between design, production, and logistics teams.

Reach out via email at [email protected] to initiate a technical consultation. Include your project specifications, annual volume estimates, and target performance criteria to receive a tailored material proposal within 48 hours. We respond promptly to RFQs and welcome opportunities for joint development, especially in lightweighting, noise reduction, and sustainable material innovation.

Suzhou Baoshida Trading Co., Ltd. is committed to advancing rubber technology in automotive interiors. Let us help you achieve superior sealing, fit, and finish in your next door trim design. Contact Mr. Boyce today to begin the engineering dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).