Technical Contents

Engineering Guide: Beach Doormat

Engineering Insight: Material Selection in Industrial Beach Doormat Manufacturing

In industrial and commercial environments, the performance of a beach doormat extends far beyond basic functionality. It serves as the first line of defense against dirt, moisture, and debris ingress, directly impacting facility hygiene, safety, and maintenance costs. Despite this critical role, many facilities rely on off-the-shelf rubber doormats sourced without engineering oversight—leading to premature degradation, slip hazards, and increased lifecycle expenses. The root cause lies in inadequate material selection, where generic elastomers fail to meet the dynamic demands of real-world conditions.

Standard consumer-grade doormats are typically formulated from reprocessed rubber or low-grade SBR (Styrene-Butadiene Rubber), optimized for cost rather than performance. These materials exhibit poor resistance to UV radiation, saltwater, ozone, and thermal cycling—conditions inherent to coastal and high-traffic installations. As a result, rapid surface cracking, delamination, and loss of traction occur within months of deployment. In industrial settings, such failure compromises safety compliance and increases liability exposure.

At Suzhou Baoshida Trading Co., Ltd., we approach beach doormat engineering as a precision material science challenge. Our formulations are based on high-vinyl nitrile rubber (HNBR) and EPDM (Ethylene Propylene Diene Monomer), selected for their superior weatherability, tensile strength, and resistance to environmental aging. HNBR provides exceptional oil and abrasion resistance, making it ideal for marine-adjacent applications where salt spray and organic contaminants are prevalent. EPDM, with its saturated backbone, delivers unmatched UV and ozone stability—critical for long-term outdoor exposure.

Material performance is further enhanced through controlled cross-linking density and filler integration. We utilize nano-dispersed silica and carbon black hybrid systems to optimize tread durability without sacrificing flexibility. This engineered balance ensures consistent scraping efficiency across varying footwear types while maintaining structural integrity under thermal expansion and contraction.

Below is a comparative analysis of material performance metrics relevant to industrial beach doormat applications.

| Property | Standard SBR (Off-the-Shelf) | HNBR (Baoshida Formula) | EPDM (Baoshida Formula) |

|---|---|---|---|

| Tensile Strength (MPa) | 8–12 | 22–26 | 18–21 |

| Elongation at Break (%) | 250–300 | 400–450 | 380–420 |

| Shore A Hardness | 55–60 | 65–70 | 60–65 |

| Heat Resistance (°C) | 70 (short-term) | 150 (continuous) | 135 (continuous) |

| UV/Ozone Resistance | Poor | Good | Excellent |

| Saltwater Immersion Stability | Low (swelling >15%) | High (<5%) | High (<3%) |

| Abrasion Loss (mm³) | 180 | 65 | 75 |

These specifications reflect the engineered advantage of purpose-built elastomers. Off-the-shelf solutions may appear cost-effective initially, but their shortened service life and safety risks result in higher total cost of ownership. By contrast, Baoshida’s rubber formulations are designed for a minimum 7-year service life in harsh coastal environments, validated through accelerated aging and real-world field testing.

Material selection is not a commodity decision—it is a foundational engineering imperative. For industrial clients, the integrity of a doormat is a direct reflection of material intelligence.

Material Specifications

Material Specifications for Industrial Beach Doormat Applications

Selecting the optimal elastomer for beach doormats requires rigorous analysis of environmental stressors including saltwater immersion, abrasive sand particulates, intense UV exposure, and thermal cycling. Suzhou Baoshida Trading Co., Ltd. engineers rubber formulations to exceed OEM performance thresholds under these conditions. Viton fluoroelastomers (FKM) provide unparalleled resistance to salt-induced degradation and oxidative aging. With a continuous service temperature range of -20°C to +230°C, Viton maintains structural integrity against chlorinated seawater and UV radiation where conventional rubbers fail. Its high fluorine content minimizes swelling in saline environments, critical for doormats subjected to daily tidal exposure. Shore A hardness is typically formulated between 60–80 for optimal sand-shedding and tread durability.

Nitrile rubber (NBR) offers a cost-effective solution for moderate coastal environments. Standard hydrogenated NBR grades withstand temperatures from -30°C to +120°C with strong abrasion resistance against granular sand. While exhibiting moderate saltwater resistance, prolonged immersion may induce slight swelling; Baoshida mitigates this through proprietary acrylonitrile content optimization (45–50%) and anti-degradation package integration. Shore A hardness ranges from 50–75, balancing flexibility for debris release with sufficient rigidity for structural stability. NBR remains the preferred choice for OEMs prioritizing economic efficiency without compromising 3–5 year service life in non-extreme beach settings.

Silicone rubber (VMQ) delivers exceptional low-temperature flexibility down to -60°C and high-temperature resilience up to +200°C. Its hydrophobic molecular structure prevents salt crystallization within the matrix, reducing surface erosion from desiccated salt deposits. Silicone’s inherent smoothness facilitates rapid sand runoff but requires surface texturing to maintain slip resistance. Limited abrasion resistance compared to NBR necessitates Baoshida’s reinforced formulations with precipitated silica fillers. Shore A hardness is precisely controlled at 40–65 to ensure comfort underfoot while resisting deformation from heavy foot traffic.

The comparative analysis below details critical performance metrics for industrial beach doormat selection.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Saltwater Resistance | Excellent (0.5% swell) | Good (3–5% swell) | Excellent (1% swell) |

| Abrasion Resistance | High | Very High | Moderate |

| Shore A Hardness Range | 60–80 | 50–75 | 40–65 |

| UV/Ozone Resistance | Exceptional | Moderate | Excellent |

| Relative Cost Index | 3.0 | 1.0 | 2.2 |

Suzhou Baoshida’s OEM engineering team tailors compound formulations to specific coastal microclimates. We validate all materials per ASTM D2000 standards for physical properties and ISO 1817 for fluid resistance. For high-traffic resort installations, Viton’s longevity justifies premium investment, while NBR serves municipal boardwalk projects requiring rapid deployment. Silicone excels in luxury residential applications demanding aesthetic versatility. Partner with Baoshida to convert environmental data into engineered rubber solutions meeting ISO 9001-certified production protocols. Our technical dossier includes accelerated weathering reports per ASTM G154 for client validation.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber manufacturing, delivering engineered rubber solutions tailored to the exacting demands of global B2B clients. Our Engineering Capability division is anchored by a dedicated team of five specialized mould engineers and two advanced rubber formulation scientists, enabling us to deliver fully integrated OEM services—from concept to mass production—within compressed development cycles.

Our mould engineering team possesses extensive expertise in precision tooling design for rubber compression, transfer, and injection moulding processes. Each engineer utilizes advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop robust, high-tolerance mould systems optimized for durability, part consistency, and cycle efficiency. Specialized focus is placed on venting design, parting line optimization, and ejection mechanisms to ensure defect-free production of complex geometries. All tooling is validated through in-house prototyping and dimensional inspection, guaranteeing conformity to ISO 9001 standards.

Complementing our tooling expertise, our two rubber formula engineers bring deep knowledge in polymer chemistry and material performance optimization. They formulate custom rubber compounds based on application-specific requirements such as abrasion resistance, UV stability, temperature resilience, and compliance with environmental regulations (e.g., REACH, RoHS). Our in-house laboratory conducts rigorous testing on hardness, tensile strength, elongation, and compression set to ensure long-term performance under real-world conditions. This dual capability—precise mould design and advanced material science—enables us to produce high-performance beach doormats that combine aggressive dirt-scraping profiles with exceptional resilience to saltwater, sand, and thermal cycling.

We specialize in OEM manufacturing for industrial and commercial clients, offering full design-for-manufacturability (DFM) support, rapid prototyping, and scalable production across multiple rubber materials, including SBR, EPDM, and recycled rubber blends. Our facility supports low-volume pilot runs and high-volume production, with strict process controls and automated quality inspection systems.

The following table outlines key technical specifications and engineering parameters for our standard beach doormat product line, reflecting our precision manufacturing standards:

| Parameter | Specification |

|---|---|

| Material Options | SBR, EPDM, Recycled Rubber Blends |

| Hardness Range (Shore A) | 50–75 |

| Tensile Strength | ≥8 MPa |

| Elongation at Break | ≥250% |

| Operating Temperature Range | -40°C to +100°C |

| Compression Set (22 hrs, 70°C) | ≤25% |

| Mould Tolerance | ±0.1 mm |

| Surface Texture Options | Diamond tread, Waffle, Custom embossing |

| Standard Sizes | 40×60 cm, 60×90 cm, 90×150 cm (custom on request) |

| Colour Capability | Full Pantone matching, multi-colour molding |

This integrated engineering approach ensures that every beach doormat produced meets the highest benchmarks in durability, functionality, and aesthetic precision—engineered not just for performance, but for seamless integration into global supply chains.

Customization Process

Customization Process for Industrial Beach Doormat Manufacturing

Beach doormat performance hinges on precise material engineering and process control to withstand abrasive sand, saltwater exposure, and UV degradation. At Suzhou Baoshida Trading Co., Ltd., our customization process integrates polymer science with industrial manufacturing rigor, ensuring each product meets exact environmental and functional demands. We execute this through four disciplined phases.

Drawing Analysis initiates the workflow. Engineering teams dissect client-provided CAD files or technical sketches, validating dimensional tolerances, surface texture specifications, and drainage channel geometry. Critical parameters include edge durability for sand retention and groove depth for optimal debris capture. We cross-reference ISO 2768-mK standards for geometric tolerancing and simulate stress points using finite element analysis (FEA) to preempt deformation under foot traffic. Material thickness deviations beyond ±0.5mm trigger immediate client consultation to balance performance and cost.

Formulation follows, where our rubber chemists design compound matrices tailored to coastal conditions. Base polymers (EPDM or SBR) are selected for ozone/salt resistance, then modified with reinforcing fillers, UV stabilizers, and anti-aging agents. Shore A hardness targets 55–65 to maintain flexibility without compromising sand-scraping efficacy. Critical adjustments include optimizing carbon black dispersion for UV absorption and incorporating micro-silica to enhance abrasion resistance. Each formulation undergoes computational modeling to predict crosslink density and compression set behavior before lab-scale mixing.

Prototyping validates the formulation. Using precision CNC-machined molds, we produce 3–5 sample units under controlled curing parameters (160°C ±2°C, 10–12 minutes). Samples undergo accelerated aging per ASTM G154 (1,000-hour UV exposure), tensile testing (ASTM D412), and sand abrasion cycles. Performance deviations exceeding 5% from target specs trigger iterative reformulation. Client feedback on texture, weight, and water drainage is quantified before approval.

Mass Production deploys validated parameters across our automated lines. Compounded rubber is extruded into sheets, die-cut with laser-guided accuracy (±0.3mm), and vulcanized in multi-cavity presses. In-line spectrometers monitor cure state in real time, while automated vision systems inspect surface integrity. Every 500th unit undergoes destructive testing against baseline specs. Final lots ship with material traceability certificates and third-party compliance reports.

Key Rubber Compound Specifications for Beach Doormats

| Property | Target Value | Test Standard | Relevance to Beach Doormats |

|---|---|---|---|

| Shore A Hardness | 60 ± 5 | ASTM D2240 | Balances flexibility for sand removal and structural integrity |

| Tensile Strength | ≥ 12 MPa | ASTM D412 | Prevents tearing under foot traffic and sand abrasion |

| Abrasion Loss | ≤ 120 mm³ | ASTM D5963 | Ensures longevity against gritty sand wear |

| UV Resistance (ΔE) | ≤ 3.0 after 1k hrs | ASTM G154 | Minimizes surface cracking and color fade |

| Compression Set (24h) | ≤ 25% | ASTM D395 | Maintains groove depth for debris retention |

This end-to-end customization framework eliminates guesswork, transforming environmental challenges into engineered solutions. Suzhou Baoshida’s adherence to polymer precision and process validation guarantees beach doormats that perform reliably across 5+ years of coastal service, directly reducing client lifecycle costs through extended product tenure.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Industrial Rubber Doormat Solutions

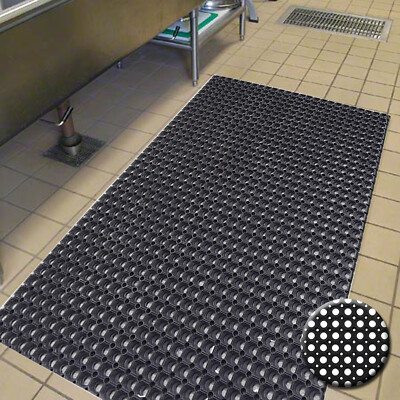

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, delivering high-performance solutions tailored to commercial and industrial environments. Our expertise in rubber compounding, precision molding, and material durability ensures that every product meets the rigorous demands of real-world applications. As a trusted OEM partner, we specialize in engineered rubber doormats designed for heavy-duty use in facilities, warehouses, transportation hubs, and public infrastructure. These mats are not only functional but built to resist abrasion, moisture, oils, and extreme temperatures—ensuring long-term performance and safety.

Our beach doormat solutions are formulated using advanced rubber polymers that provide superior grip, resilience, and weather resistance. Unlike standard mats made from coir or synthetic fibers, our rubber-based designs offer seamless integration with industrial flooring systems, easy maintenance, and compliance with safety standards. Each mat is manufactured under strict quality controls, ensuring dimensional accuracy, consistent texture, and resistance to deformation under continuous foot and vehicular traffic.

We understand that every industrial environment presents unique challenges. That’s why Suzhou Baoshida offers fully customizable rubber doormat solutions—from size and thickness to tread pattern and hardness. Whether you require anti-slip surfaces for wet processing areas or high-visibility safety edging for pedestrian zones, our engineering team works closely with clients to develop products that align precisely with operational requirements.

For technical inquiries, material specifications, or custom development projects, we invite you to contact Mr. Boyce, our dedicated OEM and technical liaison. With over 15 years of experience in industrial rubber applications, Mr. Boyce provides expert guidance on material selection, performance optimization, and scalable production planning. His role ensures seamless communication between your engineering team and our manufacturing unit, facilitating fast prototyping, rigorous testing, and on-time delivery.

Partnering with Suzhou Baoshida means gaining access to a vertically integrated supply chain, advanced testing laboratories, and a deep understanding of international compliance standards including REACH, RoHS, and ISO 9001:2015. We serve clients across Europe, North America, and Southeast Asia, supporting both private-label production and collaborative innovation.

To discuss your next industrial doormat project or request a sample, reach out directly to Mr. Boyce at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical consultations to accelerate your development timeline.

Below are typical technical specifications for our standard industrial rubber beach doormat series:

| Property | Value |

|---|---|

| Material | SBR/NR Blend (Custom Compounds Available) |

| Hardness (Shore A) | 55–75 |

| Thickness Tolerance | ±0.5 mm |

| Operating Temperature Range | -40°C to +80°C |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Abrasion Resistance (DIN) | ≤120 mm³ |

| Slip Resistance (R10–R13) | Yes (Custom Surface Profiles) |

| Fire Rating | UL94 HB (Optional Flame-Retardant) |

| Custom Colors & Logos | Available via Mold or Printing |

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).