Technical Contents

Engineering Guide: Bed Molding Vs Crown Molding

Engineering Insight: Material Selection in Bed Molding vs Crown Molding

In the precision-driven domain of custom molded rubber parts, the distinction between bed molding and crown molding extends beyond tooling geometry—it fundamentally hinges on material behavior under compression, flow, and cure dynamics. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration but a primary engineering determinant in process success. Off-the-shelf rubber compounds often fail in these applications due to unoptimized viscoelastic properties, inconsistent cure kinetics, and poor compatibility with mold design constraints.

Bed molding, where the rubber is compressed between two flat or contoured platens, demands materials with high green strength and controlled flow characteristics. The absence of a cavity wall in traditional bed molds means the compound must resist excessive lateral spread while achieving uniform density. Standard rubber grades, such as generic SBR or NR compounds, typically exhibit uncontrolled flow and inconsistent shrinkage, leading to dimensional inaccuracies and flash formation. In contrast, engineered formulations with tailored filler dispersion—such as reinforced NBR or peroxide-cured EPDM—deliver the structural integrity required for high-reliability bed molding.

Crown molding, characterized by a domed or arched cavity, introduces additional challenges related to air entrapment and non-uniform wall thickness. Here, the rubber must exhibit excellent flow-to-cure balance to fill the apex of the crown without voids or incomplete cure. Conventional materials often cure too rapidly at the mold surface (scorch risk) or too slowly in the core (under-cure), particularly in thick-section parts. This results in compromised physical properties and reduced service life. Our technical evaluations confirm that specialty silicone and fluorosilicone compounds, formulated with precise catalyst systems and low-compression-set additives, outperform generic alternatives in crown molding applications.

The failure of off-the-shelf solutions is further exacerbated by environmental exposure requirements. Many standard compounds lack resistance to oils, ozone, or thermal cycling—critical factors in automotive, aerospace, and industrial sealing applications. Custom compounding allows for targeted enhancement of these properties, ensuring long-term performance under operational stress.

Below is a comparative analysis of key material performance metrics in bed and crown molding processes:

| Property | Bed Molding Requirement | Crown Molding Requirement | Preferred Material (Bed) | Preferred Material (Crown) |

|---|---|---|---|---|

| Green Strength | High | Moderate | Reinforced NBR | Liquid Silicone Rubber (LSR) |

| Flow Control | Critical | High | Peroxide-cured EPDM | Fluorosilicone |

| Cure Uniformity | Moderate | Critical | High-temperature cured VMQ | Platinum-cured LSR |

| Compression Set | <15% (70 hrs, 70°C) | <20% (70 hrs, 100°C) | Filled EPDM | High-purity VMQ |

| Thermal Stability | Up to 120°C | Up to 200°C | HNBR | FVMQ |

Material selection is not a one-size-fits-all proposition. At Suzhou Baoshida, we integrate material science with mold design to deliver custom rubber solutions that meet exacting OEM specifications. Relying on generic compounds risks process instability, increased scrap rates, and field failures—outcomes that are avoidable through engineered material selection.

Material Specifications

Material Selection Fundamentals for Precision Rubber Molding

Material selection critically determines the performance longevity and manufacturability of custom rubber components in both bed and crown molding processes. At Suzhou Baoshida Trading Co., Ltd., we prioritize polymer chemistry alignment with end-use requirements, ensuring dimensional stability under compression set and resistance to environmental stressors. Viton fluorocarbon rubber excels in extreme temperature applications ranging from -20°C to 230°C continuous exposure, offering unparalleled resistance to aggressive chemicals including jet fuels, hydraulic fluids, and aromatic hydrocarbons. Its high cost is justified in aerospace and semiconductor sealing where failure is untenable, though its stiff durometer range (60–90 Shore A) demands precise mold design to avoid flash in intricate crown molding geometries.

Nitrile butadiene rubber (NBR) remains the industrial standard for cost-sensitive oil and fuel resistance, operating effectively between -40°C and 120°C. With tensile strengths of 15–30 MPa and elongation at break exceeding 300%, it accommodates complex bed molding cycles for automotive O-rings and gaskets. However, its vulnerability to ozone degradation and limited high-temperature resilience necessitates careful formulation with antiozonants for outdoor applications. Silicone rubber provides exceptional flexibility across -60°C to 200°C with minimal compression set (≤20% per ASTM D395), making it ideal for medical and food-grade components requiring repeated sterilization. Its low surface energy reduces mold adhesion in crown molding but requires specialized release agents to prevent tearing during demolding.

The following comparative analysis details critical material specifications per ASTM D2000 standards:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 10–20 | 15–30 | 5–12 |

| Elongation at Break (%) | 150–300 | 300–600 | 200–800 |

| Compression Set (70h/150°C) | ≤25% | ≤35% | ≤20% |

| Key Chemical Resistance | Fuels, Acids, Ozone | Aliphatic Hydrocarbons, Water | Water, Steam, Alcohols |

| Typical Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

Material choice directly impacts molding cycle parameters: Viton’s high viscosity requires elevated bed molding pressures (1500–2500 psi) to fill thin sections, while Silicone’s low viscosity risks premature flow in crown molds without precise gate control. NBR’s balanced flow characteristics simplify processing but mandate strict moisture control during preform preparation. Suzhou Baoshida’s engineering team collaborates with OEM partners to validate material-process synergies through DFM analysis, ensuring first-pass yield in high-volume production. We recommend accelerated aging tests per ISO 188 for critical applications, particularly when selecting lower-cost NBR variants for extended service life. Our technical documentation includes full material traceability and RoHS/REACH compliance data to support your quality assurance protocols.

Manufacturing Capabilities

Engineering Excellence in Custom Rubber Molding: Bed Molding vs Crown Molding

At Suzhou Baoshida Trading Co., Ltd., our engineering team brings precision and innovation to every custom rubber molding project. With five dedicated mold engineers and two specialized rubber formula engineers, we combine advanced tooling design with material science expertise to deliver optimized solutions in both bed molding and crown molding processes. Our OEM capabilities ensure seamless integration into client manufacturing workflows, supporting industries ranging from automotive to industrial equipment.

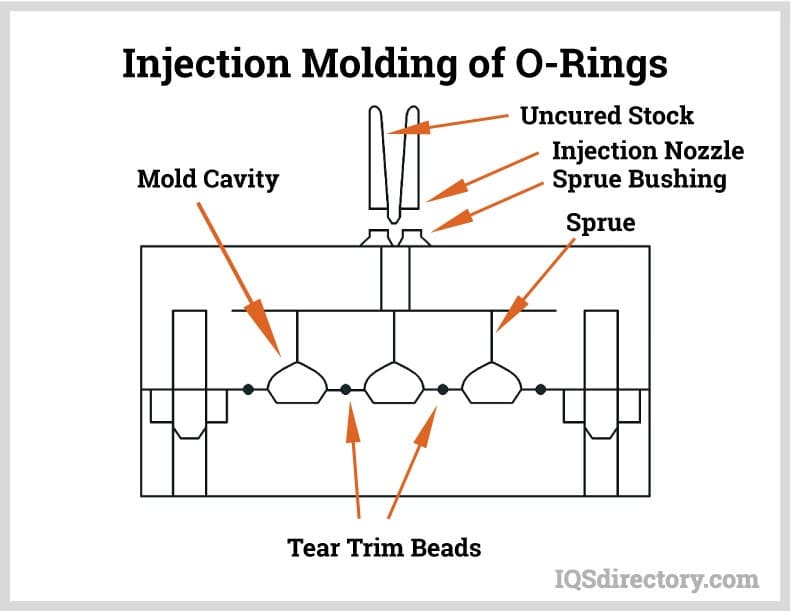

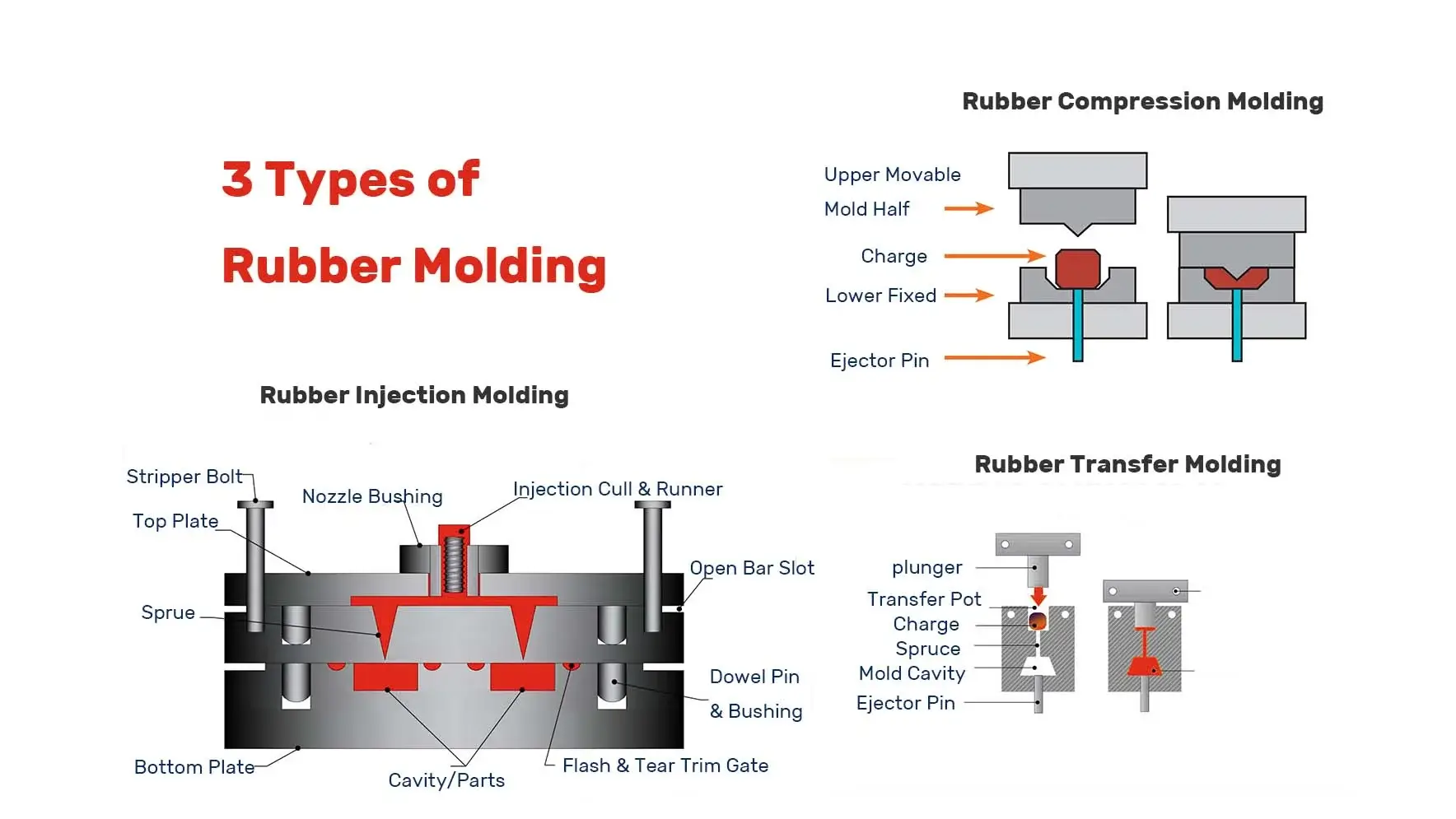

Bed molding, also known as compression molding, involves placing pre-measured uncured rubber into an open mold cavity. The mold closes under heat and pressure, allowing the material to flow and fill the cavity. This method is ideal for large, low-volume parts with less stringent tolerance requirements. At Baoshida, our mold engineers utilize finite element analysis (FEA) to predict flow behavior and minimize flash, ensuring consistent part geometry. Our formula engineers tailor compound formulations to enhance flow characteristics and cure kinetics, improving yield and reducing cycle times.

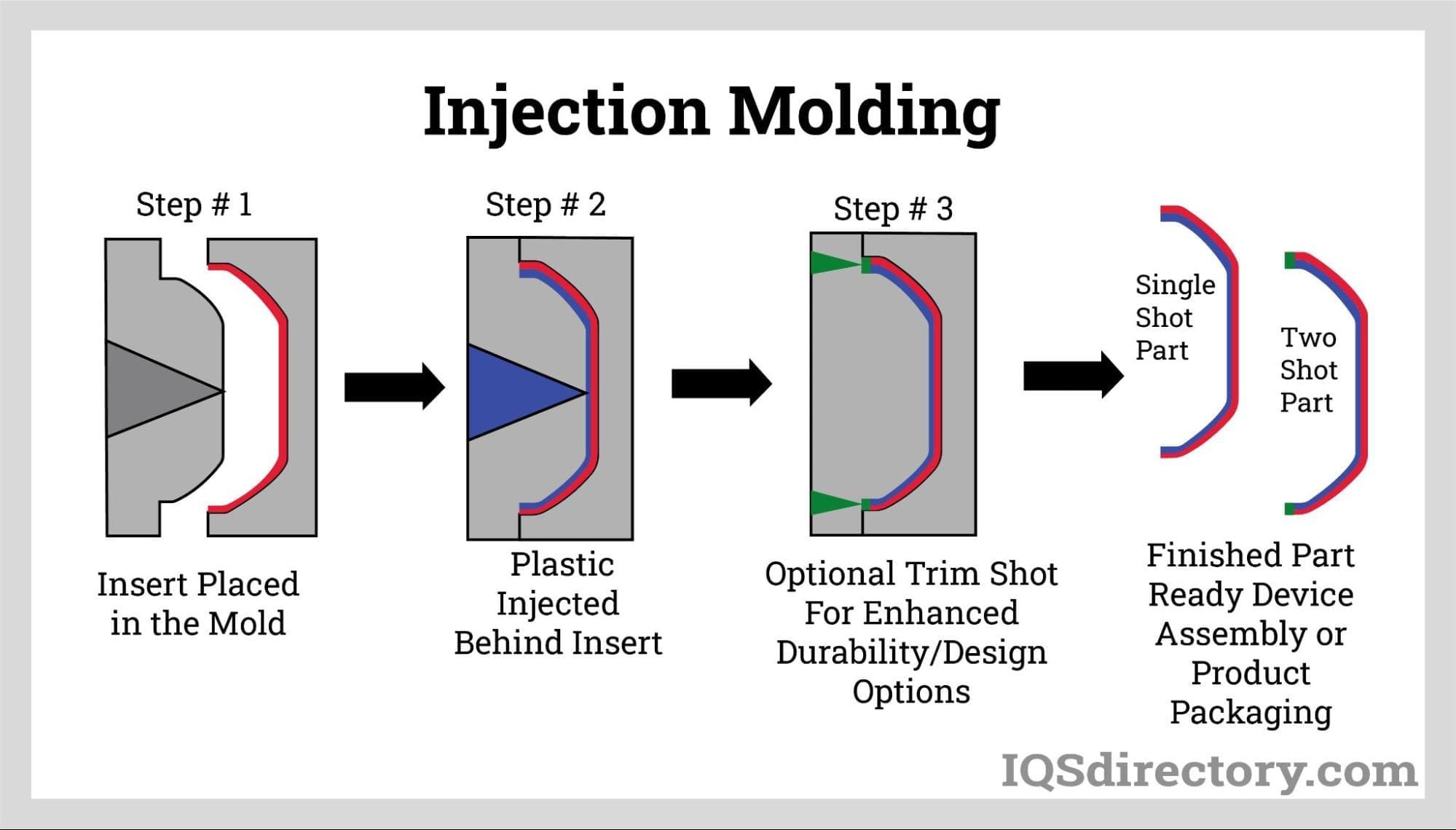

Crown molding, often referred to as transfer molding, uses a pot and plunger system to force rubber through runners into closed mold cavities. This process delivers superior dimensional control and is preferred for complex, high-precision components. Our team optimizes runner design and gate locations to eliminate air traps and ensure uniform fill. By integrating real-time process monitoring and DOE (Design of Experiments), we achieve repeatability and compliance with tight OEM specifications.

Our dual expertise in mold design and rubber compounding enables us to recommend the most efficient molding method based on part geometry, volume, performance requirements, and cost targets. Whether supporting prototype development or full-scale production, we maintain full control over material sourcing, tooling fabrication, and process validation.

The following table compares key technical parameters between bed molding and crown molding as executed in our facility:

| Parameter | Bed Molding (Compression) | Crown Molding (Transfer) |

|---|---|---|

| Typical Tolerance | ±0.5 mm | ±0.2 mm |

| Part Complexity | Moderate | High |

| Production Volume | Low to Medium | Medium to High |

| Tooling Cost | Lower | Higher |

| Material Waste (Flash) | Higher | Lower |

| Cycle Time | Longer | Shorter |

| Ideal Applications | Gaskets, Seals, Mounts | Precision Seals, Electrical Insulators |

| Material Compatibility | NR, SBR, EPDM, NBR, Silicone | Same, with enhanced flow control |

Our OEM framework supports co-engineering initiatives, allowing clients to leverage our technical team for DFM (Design for Manufacturing) feedback, rapid tooling iterations, and full documentation packages including PPAP and IMDS compliance. With in-house material testing and mold flow simulation, Suzhou Baoshida ensures every rubber component meets the highest standards of performance and reliability.

Customization Process

Customization Process for Precision Rubber Molding: Bed vs Crown Techniques

At Suzhou Baoshida Trading Co., Ltd., our OEM-driven customization process ensures optimal rubber part performance through rigorous scientific methodology. We distinguish between bed molding (utilizing a flat, open cavity) and crown molding (employing a contoured, enclosed cavity) based on geometric complexity, material behavior, and end-use demands. This structured workflow—Drawing Analysis, Formulation, Prototyping, and Mass Production—guarantees precision from concept to volume output.

Drawing Analysis initiates the process. Our engineers dissect CAD models to determine whether bed or crown molding aligns with the part’s structural requirements. Bed molding suits thick-sectioned, low-complexity geometries where uniform compression is critical, such as gaskets or seals. Crown molding excels for thin-walled, intricate profiles requiring precise material flow control, like automotive sensor housings. Key factors include cavity pressure distribution, flash minimization potential, and demolding feasibility. Tolerance analysis adheres strictly to ISO 3302 standards, with crown molding typically achieving tighter tolerances due to reduced material migration.

Formulation follows, where compound chemistry is tailored to the molding method. For bed molding, higher-viscosity compounds resist excessive flow under compression, maintaining dimensional stability in simple shapes. Crown molding demands lower-viscosity formulations to ensure complete cavity filling in complex contours without air entrapment. Our proprietary EPDM and silicone blends incorporate fillers and curatives adjusted for each process’s thermal profile, ensuring optimal cross-link density and mechanical properties per ASTM D2000 specifications.

Prototyping validates both geometry and material performance. We produce 5–10 samples via the selected molding technique, subjecting them to rigorous testing: compression set (ASTM D395), tensile strength (ISO 37), and dimensional metrology. Bed molding prototypes undergo flatness verification; crown molding prototypes are assessed for edge definition and wall thickness consistency. Iterations refine cavity design or compound viscosity before tooling finalization.

Mass Production leverages optimized parameters from prototyping. Bed molding achieves higher throughput for uncomplicated parts via automated press loading, while crown molding utilizes precision-guided transfer systems to maintain flow integrity in complex cavities. Real-time cavity pressure monitoring ensures consistency, with statistical process control (SPC) maintaining CpK >1.67 across batches.

Critical specifications for bed versus crown molding are summarized below:

| Parameter | Bed Molding | Crown Molding |

|---|---|---|

| Typical Part Geometry | Flat, thick sections (≥3mm) | Contoured, thin walls (0.5–2mm) |

| Tolerance Capability | ±0.25 mm | ±0.15 mm |

| Material Flow Pattern | Radial, uniform compression | Directional, controlled transfer |

| Common Applications | Static seals, vibration mounts | Dynamic seals, fluid connectors |

| Production Rate | 15–25 parts/cycle | 8–15 parts/cycle |

This systematic approach eliminates guesswork, ensuring Suzhou Baoshida delivers rubber components that meet exacting OEM performance criteria while minimizing time-to-market. Our process integrity stems from material science expertise fused with industrial-scale manufacturing discipline.

Contact Engineering Team

For engineered rubber components where precision, durability, and application-specific performance are critical, selecting the correct molding method is essential. At Suzhou Baoshida Trading Co., Ltd., we specialize in custom molded rubber parts using advanced techniques including bed molding and crown molding—two distinct processes suited to different production requirements and performance demands.

Bed molding, often referred to as compression molding, involves placing a pre-measured uncured rubber compound directly into a heated mold cavity. The mold is then closed under pressure, allowing the material to flow and fully conform to the cavity geometry. This method is ideal for medium to large parts with less stringent tolerance requirements and is commonly used for industrial seals, gaskets, and vibration dampeners. It offers lower tooling costs and is highly adaptable to a wide range of elastomers, including NBR, EPDM, silicone, and fluororubber.

Crown molding, while less commonly referenced in standard industry terminology, typically describes a variation of transfer or injection molding where the rubber is pre-loaded into a chamber (pot) and forced through runners into a closed mold cavity. This method provides tighter dimensional control, better repeatability, and improved material consistency, making it suitable for complex, high-precision components used in automotive, medical, and aerospace applications. Crown molding supports high-volume production and minimizes flash, resulting in parts that require little to no secondary trimming.

The choice between bed molding and crown molding depends on several technical factors, including part geometry, volume, material properties, and performance environment. At Suzhou Baoshida, our engineering team evaluates each project holistically to recommend the optimal process, material, and tooling strategy to meet OEM specifications.

We invite manufacturers, product designers, and procurement managers to contact Mr. Boyce at [email protected] to discuss your custom rubber molding needs. Whether you require low-volume prototypes or high-volume production runs, our facility in Suzhou is equipped with state-of-the-art molding presses, precision tooling capabilities, and rigorous QC protocols to ensure every component meets international standards.

Below is a comparison of key technical parameters between bed molding and crown molding to assist in initial process selection:

| Parameter | Bed Molding (Compression) | Crown Molding (Transfer/Injection) |

|---|---|---|

| Tolerance Control | ±0.5 mm | ±0.15 mm |

| Tooling Cost | Low to Medium | Medium to High |

| Production Volume | Low to Medium | Medium to High |

| Cycle Time | Longer | Shorter |

| Flash Formation | Moderate to High | Low |

| Part Complexity | Moderate | High |

| Material Waste | Higher | Lower |

| Typical Applications | Gaskets, Mounts, Seals | Precision Seals, Medical Components |

Partner with Suzhou Baoshida Trading Co., Ltd. for expert guidance and precision manufacturing in custom rubber solutions. Contact Mr. Boyce today at [email protected] to initiate a technical consultation, request material certifications, or submit a part drawing for quotation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).