Technical Contents

Engineering Guide: Black Closed Cell Foam

Engineering Insight: Material Selection in Black Closed Cell Foam Applications

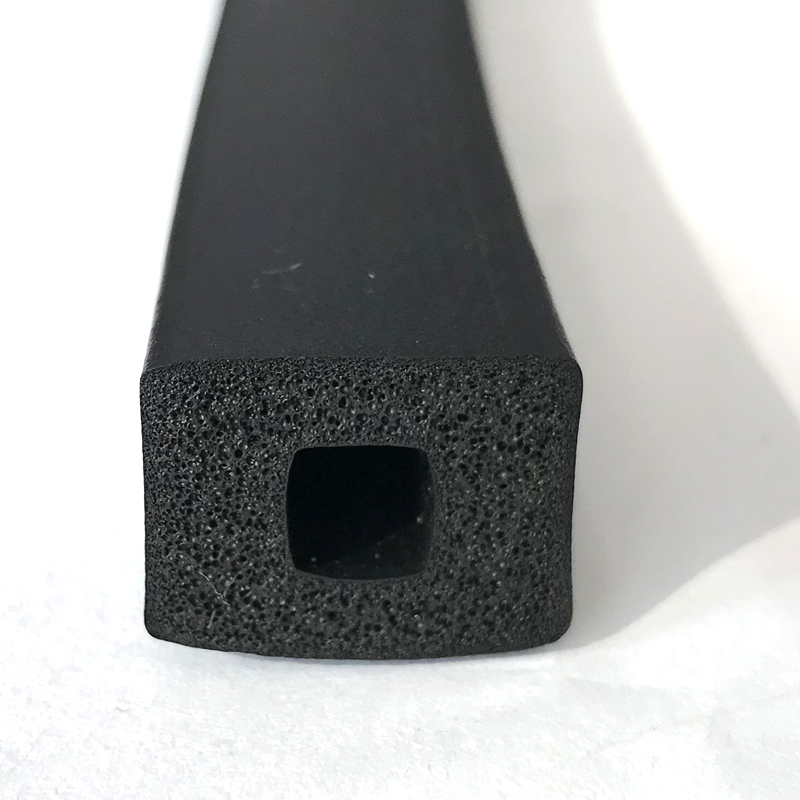

In industrial environments where performance, durability, and environmental resistance are non-negotiable, black closed cell foam is frequently specified for sealing, gasketing, insulation, and vibration damping. While the material’s inherent properties—low water absorption, high compressibility, and chemical resistance—make it an attractive choice, real-world performance is heavily dependent on precise material formulation and customization. Off-the-shelf solutions, though cost-effective in the short term, often fail to meet the exacting demands of specialized applications due to inadequate control over raw material inputs, curing profiles, and physical performance parameters.

Generic black closed cell foams are typically compounded using standardized recipes designed for broad commercial use. These formulations often prioritize cost reduction over performance consistency, leading to variability in density, cell structure, and aging characteristics. In critical applications such as automotive under-hood sealing, marine insulation, or HVAC duct gasketing, such variability can result in premature compression set, loss of sealing integrity, or susceptibility to environmental degradation. For example, exposure to UV radiation, ozone, or temperature cycling can accelerate surface cracking in low-grade compounds lacking optimized stabilizer packages.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection as a foundational step in product development. Our approach begins with a thorough analysis of the operational environment: temperature range, fluid exposure, mechanical load, and service life expectations. This enables the development of custom formulations that balance elastomeric base polymers—such as EPDM, neoprene, or butyl—with reinforcing fillers, crosslinking agents, and protective additives. The result is a closed cell structure with uniform cell size, consistent density, and superior resilience under dynamic stress.

Moreover, closed cell foam performance is not solely determined by chemistry. Manufacturing processes such as continuous vulcanization, die-cutting precision, and post-cure conditioning significantly influence dimensional stability and long-term performance. Off-the-shelf products often lack traceability in these processes, increasing the risk of batch-to-batch inconsistency.

The following table outlines key performance specifications achievable through engineered black closed cell foam formulations, compared to typical commercial-grade alternatives.

| Property | Engineered Foam (Baoshida) | Commercial-Grade Foam | Test Standard |

|---|---|---|---|

| Density | 0.45–0.65 g/cm³ | 0.35–0.50 g/cm³ | ASTM D3574 |

| Compression Set (22 hrs, 70°C) | ≤15% | ≤30% | ASTM D395 |

| Water Absorption (24 hrs) | ≤0.5% | ≤3.0% | ASTM D1056 |

| Tensile Strength | ≥3.0 MPa | ≥1.8 MPa | ASTM D412 |

| Operating Temperature Range | -40°C to +120°C | -20°C to +90°C | ASTM D573 |

| Cell Structure Uniformity | High (microscopic analysis) | Variable (visual inspection) | Internal QA |

Material selection is not a commodity decision—it is an engineering imperative. By partnering with a technical supplier capable of formulation-level customization and process control, OEMs can avoid the hidden costs of premature failure and ensure long-term reliability in demanding applications.

Material Specifications

Material Specifications: Black Closed Cell Foam for Industrial Applications

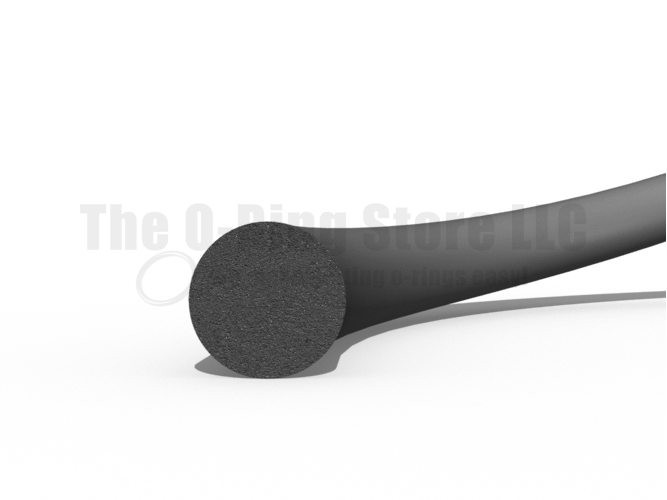

Black closed cell foam represents a critical class of thermally stable elastomeric materials engineered for demanding industrial sealing, insulation, and vibration damping applications. Its defining characteristic is a non-interconnected cellular structure that prevents fluid ingress, ensuring consistent performance under compression and exposure to harsh environments. At Suzhou Baoshida Trading Co., Ltd., our engineering team prioritizes precise formulation control to achieve uniform cell morphology, density, and surface integrity. These foams are inherently non-porous, offering superior resistance to moisture absorption, gas permeation, and microbial growth compared to open-cell alternatives. Key performance parameters include density, hardness, tensile strength, elongation at break, compression set, and thermal stability, all of which must align with OEM design requirements for longevity and safety.

Material selection directly dictates operational viability across diverse industrial scenarios. Viton (FKM) closed cell foam delivers exceptional resistance to high temperatures, aggressive chemicals, and fuels, making it indispensable in aerospace and automotive powertrain systems. Nitrile (NBR) foam provides cost-effective resilience against oils, greases, and aliphatic hydrocarbons, commonly deployed in hydraulic seals and gaskets. Silicone (VMQ) foam excels in extreme temperature cycling from severe cold to moderate heat, alongside outstanding UV and ozone resistance, ideal for outdoor electronics enclosures and medical device components. Each elastomer base requires tailored compounding with specialized blowing agents, stabilizers, and fillers to achieve the closed cell structure without compromising mechanical properties.

Suzhou Baoshida rigorously validates all black closed cell foam batches against ASTM D2000 and ISO 188 standards for physical and chemical performance. Critical quality control metrics include consistent crosslink density to minimize compression set, precise durometer tolerance (±5 Shore A), and homogeneous cell distribution verified via microscopy. Below is a comparative specification table for our core material formulations, reflecting typical production-grade values under controlled manufacturing conditions.

| Property | Viton (FKM) Foam | Nitrile (NBR) Foam | Silicone (VMQ) Foam |

|---|---|---|---|

| Density (kg/m³) | 450–550 | 400–500 | 400–600 |

| Hardness (Shore A) | 40–70 | 30–60 | 30–80 |

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 1.5–3.0 | 1.0–2.5 | 0.8–2.0 |

| Elongation at Break (%) | 150–300 | 200–400 | 200–500 |

| Fluid Resistance (Oils/Fuels) | Excellent | Excellent | Poor to Fair |

| Compression Set (22h, 70°C) | ≤25% | ≤35% | ≤20% |

OEM partners must consider fluid compatibility, dynamic load conditions, and regulatory compliance (e.g., FDA, UL) when specifying materials. Viton remains optimal for fuel-exposed high-heat zones despite higher cost, while NBR offers balanced economics for general industrial sealing. Silicone is unmatched for cryogenic flexibility and biocompatibility but requires reinforcement for high-tensile applications. Suzhou Baoshida’s technical team collaborates closely with clients to refine formulations—adjusting cell size, density gradients, or additive packages—to meet exacting functional and dimensional tolerances. All materials undergo accelerated aging tests per ASTM D573 to guarantee service life predictions. Precision in raw material sourcing and vulcanization control ensures repeatability across production runs, directly supporting our clients’ assembly line efficiency and product reliability.

Manufacturing Capabilities

Engineering Excellence in Closed Cell Foam Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance black closed cell foam. With a dedicated team of five specialized mould engineers and two advanced formula engineers, we maintain full in-house control over material formulation, tooling design, and process optimization. This integrated approach ensures precision, consistency, and rapid time-to-market for custom OEM solutions.

Our formula engineers possess deep expertise in rubber chemistry, focusing on nitrile (NBR), ethylene propylene diene monomer (EPDM), and proprietary blends tailored for specific thermal, mechanical, and environmental requirements. The development of black closed cell foam begins at the molecular level, where cellular structure, cross-link density, and additive integration are meticulously balanced to achieve targeted performance metrics such as compression set resistance, water absorption, and thermal conductivity. Each formulation is validated through rigorous laboratory testing, including aging cycles, tensile strength analysis, and closed cell content measurement per ASTM D2856.

Complementing our material science capabilities, our five mould engineers specialize in precision tooling for continuous and batch foaming processes. They design and optimize moulds for extrusion, calendering, and compression molding, ensuring dimensional accuracy and surface integrity across complex profiles. Advanced CAD/CAM systems and finite element analysis (FEA) are employed to simulate flow dynamics and curing behavior, minimizing defects and enhancing production efficiency. This synergy between material and mould engineering enables us to deliver consistent product quality across high-volume OEM contracts.

We support full OEM manufacturing services, from concept validation and prototype development to serial production and logistics. Our clients benefit from end-to-end technical ownership, with complete traceability, material certifications (including RoHS and REACH compliance), and process validation reports (PPAP, FMEA, CPK). Whether the application demands fire-retardant foam for transportation, low-temperature flexible seals for HVAC, or acoustically dampening gaskets for industrial machinery, our engineering team delivers engineered-to-spec solutions.

The following table outlines key technical specifications achievable with our black closed cell foam formulations:

| Property | Test Method | Typical Value Range |

|---|---|---|

| Density | ASTM D3574 | 40–120 kg/m³ |

| Hardness (Shore A) | ASTM D2240 | 25–70 |

| Tensile Strength | ASTM D412 | 1.2–3.5 MPa |

| Elongation at Break | ASTM D412 | 150–400% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤35% |

| Closed Cell Content | ASTM D2856 | ≥90% |

| Thermal Conductivity | ASTM C518 | 0.035–0.045 W/m·K |

| Water Absorption (24h) | ASTM D1056 | ≤0.5% |

Our engineering infrastructure, combined with rigorous quality systems and scalable production capacity, positions Suzhou Baoshida as a trusted technical partner in the global industrial rubber market.

Customization Process

Suzhou Baoshida Trading Co., Ltd. Customization Process for Black Closed Cell Foam

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, science-driven customization process for black closed cell foam, ensuring optimal performance for demanding industrial applications. As your OEM partner, we prioritize material integrity and dimensional precision from initial concept through to high-volume manufacturing. Our four-phase methodology guarantees that the final product meets exacting functional and environmental requirements.

Drawing Analysis constitutes the critical foundation. Our engineering team conducts a meticulous review of client-provided technical drawings and specifications. We assess geometric complexity, tolerance stack-ups, wall thickness variations, and potential draft angle challenges specific to closed cell foam molding. This phase identifies manufacturability constraints early, preventing costly iterations. We evaluate the intended application environment – including exposure to oils, ozone, temperature extremes, and compression loads – to inform subsequent material selection. Any ambiguities or potential failure points in the design are collaboratively resolved with the client before proceeding.

Formulation development leverages our deep expertise in elastomeric chemistry. Based on the Drawing Analysis findings, our Rubber Formula Engineers design a proprietary compound targeting the required physical properties. Key considerations include selecting the base polymer (typically EPDM, NBR, or CR for closed cell foams), optimizing the blowing agent system for uniform cell structure, and incorporating stabilizers for UV/ozone resistance. Critical additives are precisely dosed to achieve the necessary density, compression set resistance, and thermal stability. The target specifications for the formulation are defined as follows:

| Key Property | Target Range for Industrial Black Closed Cell Foam | Measurement Standard |

|---|---|---|

| Density | 0.15 – 0.60 g/cm³ | ASTM D3574 Test A |

| Compression Set (22h, 70°C) | ≤ 25% | ASTM D3574 Test D |

| Operating Temperature | -40°C to +120°C (continuous) | ISO 188 |

| Closed Cell Content | ≥ 90% | ASTM D2856 |

| Tensile Strength | ≥ 0.8 MPa | ASTM D412 |

Prototyping validates both the design and formulation. We fabricate functional prototypes using production-intent tooling, typically via compression or transfer molding. These samples undergo comprehensive in-house testing against the target specifications outlined in the table. Critical evaluations include dimensional inspection, compression deflection testing, fluid resistance checks, and accelerated aging studies. Client feedback on prototype performance and fitment is integrated, allowing for precise compound or minor tooling adjustments before final sign-off.

Mass Production commences only after prototype validation and client approval. We deploy stringent process control protocols across our ISO-certified manufacturing lines. Real-time monitoring of molding parameters – temperature, pressure, cure time, and foam expansion – ensures batch-to-batch consistency. Every production run undergoes rigorous first-article and in-process quality checks against the agreed specifications. Full traceability of raw materials and process data is maintained, providing assurance of product reliability for critical sealing, gasketing, or insulation applications. This systematic approach minimizes risk and delivers closed cell foam components engineered for long-term industrial service.

Contact Engineering Team

For industrial manufacturers seeking high-performance sealing, insulation, and vibration-damping solutions, black closed cell foam stands as a critical material across automotive, construction, HVAC, and marine sectors. At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering engineered rubber solutions that meet exacting international standards. Our black closed cell foam products are formulated for durability, resistance to moisture, and long-term structural integrity under dynamic environmental conditions.

Our formulations are based on advanced nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), or proprietary blends designed to deliver consistent cell structure, compressive strength, and thermal stability. These characteristics make our foam ideal for gasketing, weather stripping, pipe insulation, and acoustic damping applications where failure is not an option. Every batch undergoes rigorous quality control, including density verification, compression set testing, and aging resistance evaluation, ensuring compliance with ASTM D1056 and other relevant industrial benchmarks.

We understand that industrial clients require more than just raw materials—they demand technical partnership. Our engineering team provides comprehensive support from material selection to custom fabrication, including die-cutting, splicing, and lamination services. Whether you require low-volume prototyping or high-volume production runs, Suzhou Baoshida ensures on-time delivery and full traceability.

Below are key technical specifications for our standard black closed cell foam product line:

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D3574 | 0.06–0.12 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 30–60 |

| Tensile Strength | ASTM D412 | ≥1.0 MPa |

| Elongation at Break | ASTM D412 | ≥150% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤35% |

| Water Absorption (24h) | ASTM D1056 | <0.5% |

| Operating Temperature Range | — | -40°C to +100°C |

| Cell Structure | Visual/Microscopy | Uniform, non-interconnected |

These values are representative and can be tailored to meet specific OEM requirements. Custom densities, thicknesses (from 1 mm to 50 mm), and adhesive-backed configurations are available upon request.

To discuss your application requirements or request material samples, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over a decade of experience in rubber compounding and industrial supply chain coordination, ensuring technical alignment and seamless integration into your manufacturing process. He is available to provide full technical data sheets (TDS), certificates of conformance (COC), and support for qualification testing.

Reach out today to optimize your material performance with precision-engineered black closed cell foam. Contact Mr. Boyce directly at [email protected] to initiate a technical consultation or request a competitive quotation. At Suzhou Baoshida, we are committed to advancing industrial reliability through advanced rubber technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).