Technical Contents

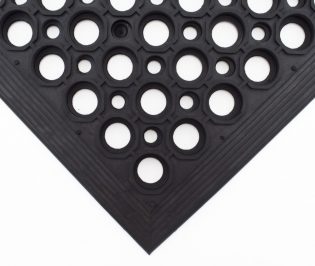

Engineering Guide: Black Foam Matting

Engineering Insight: Material Selection in Black Foam Matting

In industrial applications, black foam matting is frequently deployed for vibration damping, thermal insulation, noise reduction, and surface protection. While many manufacturers offer off-the-shelf foam solutions, these generic products often fail under real-world operational conditions. The root cause lies in inadequate material selection—prioritizing cost and availability over performance specifications tailored to the application environment.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that material composition directly governs a foam mat’s resilience, compression set, chemical resistance, and temperature tolerance. Standard commercial foams, typically based on low-density polyethylene (LDPE) or ethylene-vinyl acetate (EVA), may appear cost-effective but lack the structural integrity required in demanding industrial settings. These materials degrade rapidly when exposed to oils, UV radiation, or sustained mechanical stress, leading to premature failure and increased downtime.

True performance begins with engineered elastomeric compounds. Our black foam matting solutions utilize closed-cell nitrile rubber (NBR), neoprene (CR), or EPDM blends—each selected for specific environmental challenges. NBR offers superior resistance to hydrocarbons and is ideal for automotive or machinery undercarriage applications. Neoprene provides balanced performance across temperature ranges (–40°C to +120°C) and resists ozone and weathering, making it suitable for outdoor or marine environments. EPDM excels in UV and steam resistance, commonly used in construction and HVAC systems.

Compression recovery is another critical factor often overlooked in standard foam products. Off-the-shelf mats may initially meet thickness requirements but exhibit poor recovery after prolonged load, resulting in permanent deformation. Our formulations are engineered to maintain dimensional stability under continuous compression, ensuring long-term functionality.

Additionally, fire performance and regulatory compliance must be considered. Many generic foams fail to meet industrial safety standards such as UL 94 HF-1 or ASTM E662 for smoke density. Our engineered black foam matting is available in flame-retardant grades that comply with international safety regulations, providing both performance and peace of mind.

Customization does not end at base polymer selection. Additives for anti-static properties, enhanced UV stabilizers, or antimicrobial agents can be integrated during compounding to meet precise operational demands. This level of control is unattainable with mass-produced alternatives.

Ultimately, the failure of off-the-shelf foam matting stems from a one-size-fits-all approach to a problem that demands engineering rigor. At Suzhou Baoshida, we collaborate with OEMs to analyze load profiles, environmental exposure, and lifecycle expectations—ensuring every foam solution is as unique as the application it serves.

| Material | Temperature Range (°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|

| Nitrile Rubber (NBR) | –30 to +120 | Oils, fuels, abrasion | Automotive gaskets, machinery pads |

| Neoprene (CR) | –40 to +120 | Ozone, weathering, mild chemicals | Outdoor enclosures, marine insulation |

| EPDM | –50 to +150 | Steam, UV, polar solvents | HVAC systems, construction seals |

| LDPE (Standard Foam) | –30 to +80 | Low moisture absorption | Packaging, temporary protection |

Material Specifications

Material Specifications for Industrial Black Foam Matting

Selecting the appropriate elastomeric compound for black foam matting is critical for performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer formulations using Viton (FKM), Nitrile (NBR), and Silicone (VMQ) to meet rigorous OEM requirements. Each material offers distinct advantages in thermal stability, chemical resistance, and mechanical properties. Carbon black reinforcement is universally integrated across these compounds to ensure UV resistance, ozone protection, and structural integrity in black foam products. Density ranges from 0.35–0.65 g/cm³ depending on cell structure and application demands, while hardness typically spans 30–70 Shore A. Compression set values are optimized to ≤30% after 22 hours at maximum service temperature, guaranteeing long-term sealing efficacy.

Viton foam excels in extreme chemical and thermal exposure, maintaining functionality between -20°C and 250°C. Its perfluorinated structure resists aggressive solvents, acids, and jet fuels, making it ideal for aerospace and chemical processing seals. Nitrile foam delivers superior resistance to oils, greases, and hydraulic fluids within -30°C to 120°C operating ranges. With tensile strength up to 8.5 MPa and abrasion resistance exceeding 120 mm³ loss (DIN 53516), it is the standard for automotive gaskets and machinery vibration dampening. Silicone foam provides unmatched flexibility across -60°C to 230°C, with exceptional electrical insulation properties and biocompatibility. Its low compression set (<20% at 150°C) suits medical device seals and extreme-temperature electronics insulation.

The following table details comparative technical parameters for precision material selection:

| Property | Viton (FKM) Foam | Nitrile (NBR) Foam | Silicone (VMQ) Foam |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 6.0–7.5 | 6.5–8.5 | 4.0–6.0 |

| Elongation at Break (%) | 150–250 | 200–350 | 200–400 |

| Compression Set (ASTM D395) | ≤25% (200°C/70h) | ≤30% (100°C/22h) | ≤20% (150°C/22h) |

| Fluid Resistance | Excellent (aromatics, acids) | Excellent (oils, fuels) | Poor (hydrocarbons) |

| Density Range (g/cm³) | 0.40–0.60 | 0.35–0.55 | 0.45–0.65 |

| Typical Hardness (Shore A) | 40–60 | 30–50 | 35–70 |

All formulations undergo stringent ASTM D2000 and ISO 3302 validation for dimensional stability and aging resistance. Suzhou Baoshida prioritizes custom compounding to balance cost-efficiency with application-specific performance—whether for automotive under-hood components requiring NBR’s fuel resilience or semiconductor manufacturing demanding Viton’s plasma resistance. Our OEM partnership model ensures material certification against client-specified test protocols, including permeation rates and dynamic fatigue cycles. Final product validation includes batch traceability per IATF 16949 standards, guaranteeing repeatability in high-volume production. Consult our engineering team to align foam matting specifications with your operational lifecycle requirements.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance black foam matting. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we maintain full in-house control over material science, tooling design, and manufacturing optimization. This integrated technical structure enables us to deliver precision-engineered products tailored to demanding industrial applications.

Our formula engineers focus on the molecular design of rubber compounds, ensuring that each batch of black foam matting meets exact performance criteria such as compression set resistance, thermal stability, and environmental durability. By leveraging advanced polymer chemistry and rigorous testing protocols, we develop closed-cell and open-cell foam formulations that balance resilience, density, and cost-efficiency. These formulations are optimized for specific end-use conditions, including vibration damping, moisture resistance, and long-term sealing performance.

Complementing material development, our mould engineering team specializes in precision tooling for complex foam profiles and custom geometries. Utilizing CAD/CAM software and CNC machining, the team designs and maintains high-tolerance moulds that ensure dimensional accuracy and repeatability across production runs. This capability is critical in OEM applications where consistency, part fit, and functional reliability are non-negotiable.

As an OEM-focused manufacturer, Suzhou Baoshida provides end-to-end engineering support—from concept and prototyping to mass production and quality assurance. We work directly with clients to interpret technical drawings, refine product specifications, and conduct DFM (Design for Manufacturability) analysis. This collaborative approach minimizes development time and reduces time-to-market for new products.

Our facility supports rapid prototyping with small-batch production, enabling clients to validate designs before full-scale rollout. All processes adhere to ISO 9001 quality standards, with real-time monitoring of curing cycles, material consistency, and physical properties. This ensures that every meter of black foam matting meets the required mechanical and environmental performance benchmarks.

Through the synergy of formula science and precision engineering, we deliver not just products, but engineered solutions that enhance the performance and reliability of our clients’ end applications.

Typical Technical Specifications of Black Foam Matting (Customizable)

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 30–70 | ASTM D2240 |

| Density (g/cm³) | 0.35–0.65 | ASTM D3574 |

| Tensile Strength (MPa) | 1.5–3.5 | ASTM D412 |

| Elongation at Break (%) | 150–300 | ASTM D412 |

| Compression Set (22h, 70°C) | ≤35% | ASTM D395B |

| Operating Temperature Range | -40°C to +100°C | — |

| Cell Structure | Closed-cell or Open-cell | Visual/Microscopy |

| Available Thickness Range | 1 mm – 50 mm | Custom Tooling |

Customization Process

Customization Process for Industrial Black Foam Matting

At Suzhou Baoshida Trading Co., Ltd., our customization process for black foam matting integrates material science rigor with precision manufacturing to meet exact industrial specifications. This four-phase workflow ensures optimal performance, durability, and cost-efficiency for demanding applications such as vibration damping, thermal insulation, or protective surfacing.

Drawing Analysis

We initiate with a comprehensive technical review of client-provided drawings and performance requirements. Our engineering team scrutinizes dimensional tolerances, load-bearing expectations, environmental exposure (e.g., UV, ozone, temperature extremes), and regulatory standards (ISO, ASTM). Critical factors like compression deflection curves, cell structure density, and adhesion compatibility are evaluated to identify potential failure points. This phase includes collaborative dialogue to refine ambiguous specifications, ensuring the design aligns with both functional needs and manufacturability constraints.

Formulation Development

Leveraging our expertise in polymer chemistry, we engineer bespoke rubber compounds using SBR, EPDM, or NBR bases tailored to the application. Key variables include carbon black grade for UV resistance, foaming agent type for cell uniformity, and crosslinking density for resilience. Formulations are optimized via lab-scale mixing and rheometry to achieve target properties such as compression set, thermal stability, and abrasion resistance. All raw materials undergo stringent batch testing to eliminate contaminants that could compromise foam integrity.

Prototyping and Validation

Prototypes are produced using client-approved tooling under controlled vulcanization conditions. We conduct accelerated aging tests, dynamic compression analysis, and chemical resistance trials per ASTM D395 and ISO 1856. Critical performance metrics are validated against the initial requirements, with deviations triggering iterative reformulation. Clients receive detailed test reports and physical samples for field evaluation, ensuring real-world suitability before scaling.

Mass Production

Upon prototype approval, we transition to high-volume manufacturing with embedded quality controls. Production lines utilize real-time monitoring of temperature, pressure, and cure time to maintain consistency. Every batch undergoes inline checks for density, hardness, and thickness deviation. Final inspection includes 100% visual screening for surface defects and statistical sampling for mechanical properties. Traceability is maintained via batch-coded documentation, enabling full lifecycle accountability.

Key Performance Specifications Validated During Prototyping

| Parameter | Standard Test | Target Range | Measurement Unit |

|---|---|---|---|

| Density | ASTM D3574 | 80–200 | kg/m³ |

| Compression Set | ASTM D395 | ≤ 25% | % (70°C, 22h) |

| Hardness | ASTM D2240 | 30–70 | Shore A |

| Tensile Strength | ASTM D412 | ≥ 1.5 | MPa |

| Elongation at Break | ASTM D412 | ≥ 150 | % |

| Thermal Stability | ISO 188 | -40°C to +120°C | Continuous Use |

This systematic approach minimizes time-to-market while guaranteeing that each black foam matting solution delivers uncompromised reliability in industrial environments. Suzhou Baoshida’s commitment to scientific precision ensures your specifications translate into flawless performance at scale.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Black Foam Matting Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the exacting demands of modern manufacturing, automotive, electronics, and logistics sectors. Our black foam matting products are engineered for durability, vibration damping, thermal insulation, and surface protection across a broad spectrum of industrial applications. Whether you require custom thicknesses, specialized densities, or large-volume production runs, our team ensures consistent quality, precise formulation, and on-time delivery.

Our black foam matting is manufactured using advanced closed-cell rubber sponge technology, providing excellent resistance to moisture, ozone, and UV exposure. The material maintains structural integrity under continuous compression and performs reliably across extreme temperature ranges. These characteristics make it ideal for use in gasketing, equipment padding, anti-vibration mounts, and protective packaging for sensitive components.

We understand that industrial procurement demands both technical precision and supply chain reliability. That is why Suzhou Baoshida operates under strict quality control protocols, with full traceability from raw material sourcing to final product shipment. Our technical team works directly with OEMs and system integrators to optimize material specifications, ensuring compatibility with adhesives, coatings, and assembly processes.

To support your project requirements, we offer comprehensive material data sheets, sample testing kits, and formulation adjustments based on environmental and mechanical stress factors. Our global logistics network enables efficient delivery to North America, Europe, and Southeast Asia, supporting just-in-time manufacturing schedules without compromise.

For immediate assistance with product selection, quotation requests, or custom development, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 12 years of experience in industrial elastomer applications, Mr. Boyce provides technical guidance on material performance, cost-effective alternatives, and long-term durability testing protocols.

Reach out via email at [email protected] to initiate a technical consultation. We respond to all inquiries within 4 business hours and can arrange sample dispatch within 48 hours of request confirmation. Our team is fluent in English, Mandarin, and German, facilitating seamless communication across international operations.

Below are the standard technical specifications for our most widely deployed black foam matting series. Custom modifications are available upon request.

| Property | Test Method | Value |

|---|---|---|

| Material Composition | ASTM D2000 | CR/EPDM Blend (Closed-Cell) |

| Density | ASTM D3574 | 0.45–0.55 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 45 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 5.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 200% |

| Compression Set (22h @ 70°C) | ASTM D395 | ≤ 25% |

| Temperature Range | — | -40°C to +100°C (intermittent to +120°C) |

| Flame Resistance | UL 94 | HB Rated |

| Color | — | Jet Black (Pantone 19-0603 TCX) |

| Standard Thickness Range | — | 1 mm to 20 mm |

Initiate your next project with a partner committed to engineering excellence and responsive service. Contact Mr. Boyce today at [email protected] for technical collaboration and sample validation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).