Technical Contents

Engineering Guide: Black Weather Stripping Door

Engineering Insight: Material Selection in Black Weather Stripping for Doors

In industrial and commercial applications, the performance of a black weather stripping door component is not solely determined by its shape or fit—it is fundamentally governed by the precision of its material selection. Off-the-shelf weather stripping solutions, while cost-attractive, frequently fail under real-world operating conditions due to generic material formulations that do not account for environmental stressors, mechanical fatigue, or long-term exposure to UV, ozone, and temperature extremes. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions tailored to application-specific demands, ensuring durability, sealing integrity, and lifecycle cost efficiency.

Standard weather strips are often manufactured from low-grade EPDM or recycled rubber compounds that exhibit poor tensile strength, limited compression set resistance, and inadequate resilience. These shortcomings manifest in premature cracking, hardening, or permanent deformation—especially in dynamic door systems subjected to repeated compression cycles. In contrast, high-performance black weather stripping requires a carefully balanced elastomer formulation. For door applications, premium-grade EPDM (ethylene propylene diene monomer) remains the material of choice due to its exceptional resistance to weathering, thermal stability from -40°C to +135°C, and low compression set. When compounded with carbon black reinforcement, the material achieves enhanced UV resistance and tensile strength, critical for exterior-facing door seals.

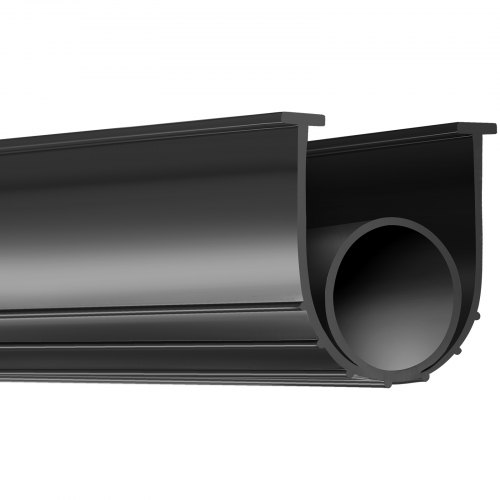

Another critical factor is durometer selection. A Shore A hardness between 55 and 70 ensures optimal balance: soft enough to conform to irregular door frames and maintain a tight seal, yet firm enough to resist extrusion and maintain structural integrity over time. Off-the-shelf products often default to a single hardness across applications, leading to either insufficient sealing pressure or excessive door closing force. Custom engineering allows for zoned hardness profiles—softer sealing lips with a firmer carrier body—maximizing both performance and longevity.

Additionally, adhesion and substrate compatibility must be considered. Many standard strips fail at the interface between rubber and mounting surface due to inadequate bonding agents or improper surface preparation. Our engineered solutions incorporate co-extruded adhesive layers or integrated metal inserts for mechanical anchoring, ensuring long-term retention under vibration and thermal cycling.

The following table outlines key material specifications for high-performance black weather stripping in door applications:

| Property | Test Standard | Typical Value | Importance |

|---|---|---|---|

| Material | ASTM D1418 | EPDM (Type 3) | Weather, heat, and ozone resistance |

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 | Balanced sealing and durability |

| Tensile Strength | ASTM D412 | ≥14 MPa | Resistance to tearing and mechanical stress |

| Elongation at Break | ASTM D412 | ≥350% | Flexibility and recovery |

| Compression Set (22h, 100°C) | ASTM D395 | ≤25% | Maintains sealing force over time |

| Temperature Range | ISO 1817 | -40°C to +135°C | Operational reliability in extreme climates |

| UV/Ozone Resistance | ASTM D1149 | No cracking (70h, 50pphm O₃) | Long-term outdoor stability |

In conclusion, the failure of off-the-shelf weather stripping is not inevitable—it is preventable through intelligent material engineering. At Suzhou Baoshida Trading Co., Ltd., we deliver industrial rubber solutions where every compound is validated for its operational environment, ensuring that black weather stripping for doors performs reliably over its intended service life.

Material Specifications

Material Specifications for Black Weather Stripping Door Applications

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered black weather stripping solutions for door systems, leveraging advanced elastomer formulations to ensure durability, sealing integrity, and environmental resistance. Our OEM-managed production adheres to stringent industrial standards, with material selection directly impacting performance in dynamic sealing environments. The black coloration, achieved through carbon black reinforcement, provides critical UV stability and abrasion resistance while maintaining consistent aesthetic integration across architectural and industrial door assemblies. Below, we detail the core material options—Viton, Nitrile, and Silicone—optimized for thermal cycling, compression load, and chemical exposure inherent in door weather stripping applications.

Viton fluoroelastomers (FKM) represent the premium solution for extreme-condition door seals, particularly in aerospace, chemical processing, and high-temperature industrial facilities. With a molecular architecture resistant to oxygen, ozone, and aggressive fluids, Viton maintains sealing force across -20°C to 250°C operational ranges. Its low compression set (<20% per ASTM D395) ensures long-term recovery after deflection, critical for doors subjected to frequent cycling. Viton’s inherent flame resistance (UL 94 V-0) further suits safety-critical installations, though its higher raw material cost necessitates targeted application engineering.

Nitrile rubber (NBR) offers the optimal balance of performance and cost-efficiency for general-purpose commercial and automotive door weather stripping. Standard formulations withstand temperatures from -40°C to 120°C, with acrylonitrile content adjustable to enhance resistance to oils, greases, and aliphatic hydrocarbons. NBR’s high tensile strength (15–25 MPa) and abrasion resistance make it ideal for high-traffic entry systems. While compression set values (25–35%) are higher than Viton, strategic plasticizer selection mitigates permanent deformation in static sealing scenarios.

Silicone rubber (VMQ) excels in applications demanding ultra-wide temperature resilience and consistent flexibility. Its service range spans -60°C to 230°C, with minimal stiffness variation at sub-zero temperatures—essential for cold-storage facility doors. Silicone’s inert composition provides biocompatibility and resistance to steam sterilization, though it exhibits lower tensile strength (6–10 MPa) and susceptibility to撕裂 without reinforcement. Compression set remains moderate (20–30%), but its non-flammable nature and electrical insulation properties support specialized architectural glazing systems.

The comparative specifications below guide material selection based on operational demands:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Temp Range (°C) | -20 to 250 | -40 to 120 | -60 to 230 |

| Compression Set (%) | <20 | 25–35 | 20–30 |

| Fluid Resistance | Excellent | Good (Oil) | Poor (Oils) |

| UV/Ozone Resistance | Excellent | Good | Excellent |

| Typical Door Use Case | Chemical plants | Commercial buildings | Freezer units |

Material selection must align with fluid exposure, temperature extremes, and lifecycle cost analysis. Suzhou Baoshida’s engineering team validates each formulation through accelerated aging tests per ISO 188 and compression stress relaxation per ASTM D6147 to guarantee field performance. Our OEM management ensures traceability from raw polymer batches to finished extruded profiles, with black weather stripping consistently meeting ASTM D2000 M2BA 710 A14 B14 EF11 EF12 requirements. Partner with us to translate application-specific challenges into resilient sealing solutions.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Innovation in Rubber Formulation and Mold Design

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and manufacturing of black weather stripping for doors. With a dedicated team of five mold engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific sealing products that meet the rigorous demands of global OEMs.

Our mold engineering team possesses extensive expertise in precision tooling design for EPDM and TPE-based extrusion and molding processes. Each engineer brings over a decade of experience in optimizing die profiles for dimensional accuracy, compression set resistance, and long-term sealing performance. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate material flow and stress distribution during the molding phase to preemptively correct potential defects such as flash, voids, or uneven curing. This proactive approach reduces prototyping cycles and accelerates time-to-market for our clients.

Complementing our mold design strength is our in-house rubber formulation capability. Our two formula engineers specialize in custom compounding for weather resistance, UV stability, ozone resistance, and low-temperature flexibility—critical factors for door seals exposed to harsh environmental conditions. By controlling the polymer matrix, filler dispersion, vulcanization system, and additives, we tailor material properties to meet specific OEM performance benchmarks. For instance, our proprietary EPDM formulations achieve a Shore A hardness range of 55–70 while maintaining a compression set below 25% after 70 hours at 70°C, ensuring long-term resilience and sealing integrity.

We operate under strict quality control protocols aligned with ISO 9001 standards, with full traceability from raw material sourcing to finished product inspection. Our facility supports small-batch prototyping and high-volume production, enabling seamless transition from concept to mass manufacturing.

OEM collaboration is central to our engineering process. We work directly with automotive, construction, and appliance manufacturers to co-develop weather stripping solutions that integrate seamlessly into final assembly lines. Our team provides full technical documentation, including material data sheets, mold flow reports, and DFMEA support, ensuring compliance with industry regulations and performance expectations.

The following table outlines key technical specifications achievable with our engineered rubber compounds and mold systems:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–70 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥300% |

| Compression Set (70h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Density | ASTM D297 | 1.15–1.25 g/cm³ |

| Durometer Tolerance | ISO 48-4 | ±2 Shore A |

Through integrated mold and material engineering, Suzhou Baoshida delivers high-performance black weather stripping solutions that combine durability, precision, and environmental resilience—engineered to OEM specifications and manufactured with industrial rigor.

Customization Process

Customization Process for Black Weather Stripping Door Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for black weather stripping door seals integrates rigorous material science with precision manufacturing. This structured workflow ensures optimal performance in sealing efficiency, durability, and environmental resistance while meeting OEM specifications. The sequence begins with comprehensive drawing analysis, where engineering teams dissect client-provided CAD files and technical schematics. Critical dimensions, tolerances (GD&T), and functional interfaces are cross-referenced against application requirements such as door closure force, compression depth, and installation geometry. Finite element analysis (FEA) may be deployed to simulate stress points under operational loads, identifying potential failure modes before physical prototyping.

Material formulation follows as the core differentiator. Our rubber compounding laboratory tailors EPDM or TPE blends to achieve target properties, prioritizing UV stability, ozone resistance, and low-temperature flexibility for exterior door applications. Key parameters include Shore A hardness, compression set, and thermal expansion coefficients. Formulations are validated through accelerated aging tests per ASTM D2000 and ISO 188 standards, ensuring 15,000+ cycle durability under simulated weathering. Critical material specifications for black weather stripping are summarized below.

| Property | Target Range | Test Standard | Significance for Door Seals |

|---|---|---|---|

| Shore A Hardness | 60–70 | ASTM D2240 | Balances sealing force and compression recovery |

| Compression Set (22h/70°C) | ≤ 25% | ASTM D395 | Prevents permanent deformation after closure |

| Low-Temperature Flex | -40°C (brittle point) | ISO 812 | Ensures flexibility in freezing climates |

| Tensile Strength | ≥ 10 MPa | ASTM D412 | Resists tearing during installation/use |

| Ozone Resistance | 50 pphm, 20% strain, 48h | ASTM D1149 | Critical for outdoor UV/ozone exposure |

Prototyping transitions validated formulations into physical samples using CNC-machined molds or extrusion dies. Each prototype undergoes dimensional verification via CMM (Coordinate Measuring Machine) against the original drawing, with tolerances held to ±0.15 mm for critical sealing surfaces. Functional testing includes air/water infiltration checks under dynamic pressure cycles and adhesion validation for co-extruded substrates. Client feedback loops refine geometry or material tweaks within 7–10 days, minimizing time-to-approval.

Mass production leverages statistical process control (SPC) to maintain consistency. Real-time monitoring of extrusion line parameters—temperature profiles, vulcanization time, and die swell—is coupled with hourly batch sampling for hardness and visual inspection. Every production run includes traceability via lot-coded material certificates and final QA dossiers documenting compression set results, dimensional reports, and material compliance (REACH/RoHS). This end-to-end control guarantees that Suzhou Baoshida’s weather stripping seals deliver OEM-grade reliability across 500,000+ unit volumes, with zero field failures attributed to material or dimensional variance in the past 36 months.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber components, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision rubber formulation and OEM manufacturing. Specializing in industrial rubber solutions, we deliver engineered products tailored to demanding applications across automotive, construction, and transportation sectors. Our expertise in EPDM, silicone, and thermoplastic elastomers ensures that every component meets stringent durability, sealing, and environmental resistance standards.

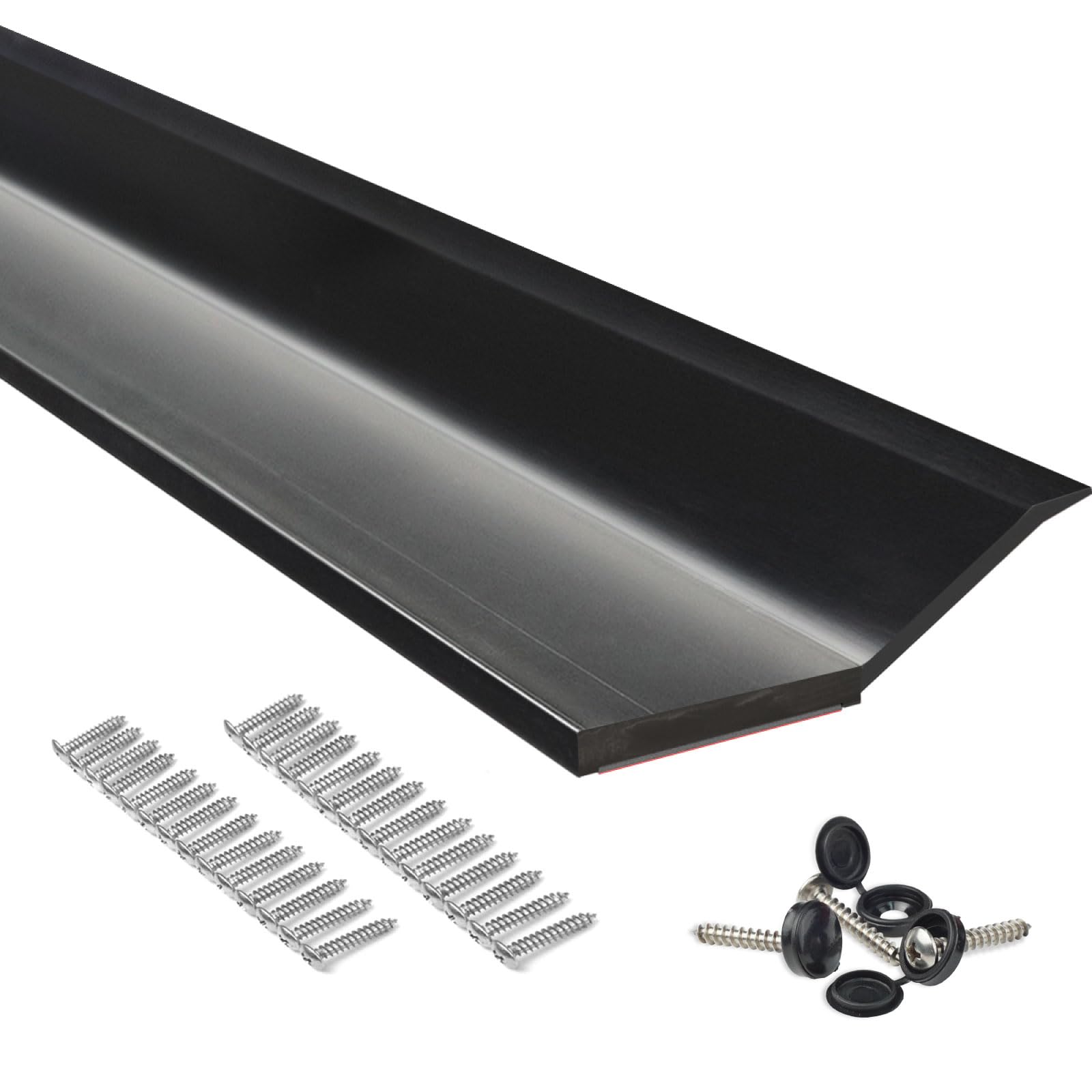

One of our core product lines includes black weather stripping for doors—critical components designed to provide long-term protection against moisture, dust, wind, and thermal transfer. These strips are formulated using advanced compounding techniques to ensure consistent density, compression set resistance, and UV stability. Whether used in commercial vehicles, industrial enclosures, or architectural applications, our weather stripping delivers reliable performance under extreme temperature fluctuations and prolonged outdoor exposure.

All products are developed in alignment with international quality benchmarks, including ISO 9001 and RoHS compliance. Our in-house R&D team works closely with clients to optimize material formulations, cross-sectional profiles, and adhesion properties based on specific application requirements. From prototype to mass production, Suzhou Baoshida maintains tight control over dimensional tolerances, surface finish, and batch-to-batch consistency.

We understand that performance in sealing applications is not just about material—it’s about precision engineering. That’s why our manufacturing process integrates computer-aided design (CAD), precision extrusion, and automated cutting to ensure every meter of weather stripping meets exact client specifications.

Below are the standard technical specifications for our black EPDM door weather stripping:

| Property | Specification |

|---|---|

| Material | EPDM (Ethylene Propylene Diene Monomer) |

| Color | Black (custom colors available) |

| Hardness (Shore A) | 55 ± 5 |

| Tensile Strength | ≥ 7.5 MPa |

| Elongation at Break | ≥ 250% |

| Compression Set (22 hrs @ 70°C) | ≤ 25% |

| Operating Temperature Range | -40°C to +135°C |

| UV and Ozone Resistance | Excellent |

| Flame Rating | UL94 HB (optional UL94 V-0) |

| Standard Lengths | 1m, 2m, 5m, or continuous reels |

| Custom Profiles | Available via CAD design input |

To ensure seamless integration into your production workflow, we offer full technical support, sample provisioning, and rapid turnaround for custom tooling. Our global logistics network enables timely delivery to North America, Europe, and Southeast Asia, with packaging options designed to prevent deformation during transit.

For technical inquiries, material certifications, or custom development projects, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. He leads client collaboration efforts with a focus on material science alignment and manufacturing scalability.

Reach out directly via email at [email protected] to discuss your sealing requirements, request samples, or initiate a technical consultation. Our team is prepared to support your next-generation product development with scientifically validated rubber solutions engineered for real-world performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).