Technical Contents

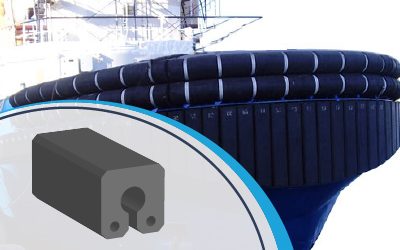

Engineering Guide: Boat Fenders

Engineering Insight: Material Selection in Boat Fenders

The performance and longevity of boat fenders are fundamentally determined by material selection. While many marine operators opt for off-the-shelf rubber fenders due to cost or convenience, these standard solutions frequently fail under real-world operational conditions. The root cause lies in the mismatch between generic material properties and the dynamic mechanical, chemical, and environmental stresses encountered in marine environments.

Boat fenders serve as critical impact-absorbing components, protecting both vessels and docking infrastructure. They must endure repeated compression, shear forces, UV exposure, saltwater immersion, ozone degradation, and temperature fluctuations. Standard fenders, typically made from low-grade reclaimed rubber or non-formulated EPDM, lack the resilience and durability required for sustained performance. These materials often exhibit poor tensile strength, accelerated aging, and reduced elasticity, leading to cracking, hardening, or permanent deformation after minimal service.

At Suzhou Baoshida Trading Co., Ltd., we engineer industrial rubber solutions based on precise application parameters. Our custom-formulated compounds utilize high-purity synthetic elastomers—primarily premium-grade EPDM and neoprene—selected for their superior resistance to weathering, oxidation, and marine corrosion. Through controlled vulcanization and reinforcement with carbon black and nano-fillers, we achieve optimal hardness (Shore A 55–70), elongation at break (>300%), and compression set resistance (<20% at 70°C for 24 hours).

A key differentiator in our approach is application-specific tailoring. For instance, fenders deployed in tropical ports require enhanced UV and heat resistance, while those in northern maritime zones must retain flexibility at sub-zero temperatures. Off-the-shelf products rarely account for such regional variances, resulting in premature field failure and increased total cost of ownership.

Furthermore, improper material selection compromises safety. A degraded fender may not absorb kinetic energy effectively during berthing, increasing the risk of hull damage or structural impact to piers. This underscores the necessity of material integrity in mission-critical marine operations.

Below is a comparative analysis of standard versus engineered fender materials:

| Property | Off-the-Shelf Fender (Generic EPDM) | Engineered Fender (Baoshida Formulation) |

|---|---|---|

| Shore A Hardness | 50–60 | 55–70 |

| Tensile Strength | 8–10 MPa | 15–18 MPa |

| Elongation at Break | 200–250% | 300–450% |

| Compression Set (24h, 70°C) | 25–35% | <20% |

| Ozone Resistance | Moderate | Excellent |

| Service Temperature Range | -20°C to +80°C | -40°C to +100°C |

| Expected Service Life (Marine) | 2–4 years | 8–12 years |

Material selection is not a generic compromise—it is an engineering imperative. By prioritizing formulation integrity, environmental adaptability, and mechanical performance, Suzhou Baoshida delivers fender solutions that outperform and outlast conventional alternatives. This precision-driven methodology ensures reliability, safety, and cost efficiency across diverse maritime applications.

Material Specifications

Material Specifications for Marine Fender Applications

The selection of elastomeric compounds for boat fenders demands rigorous evaluation of environmental stressors including seawater immersion, UV exposure, ozone degradation, mechanical abrasion, and temperature extremes. At Suzhou Baoshida Trading Co., Ltd., our OEM-engineered fenders leverage three primary polymer systems—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each optimized for distinct operational profiles. Material choice directly impacts service life, energy absorption efficiency, and total cost of ownership in maritime infrastructure.

Viton fluorocarbon rubber delivers unparalleled resistance to hydrocarbons, acids, and high temperatures, making it indispensable for fenders exposed to fuel oils, hydraulic fluids, or tropical marine environments. Its molecular stability ensures consistent performance between -20°C and +230°C, with tensile strength exceeding 15 MPa and minimal compression set after prolonged deformation. While premium in cost, Viton’s longevity in aggressive chemical settings justifies its use for critical docking systems in refineries or naval facilities.

Nitrile butadiene rubber remains the industry standard for general-purpose marine fenders due to its balanced cost-performance ratio. NBR formulations achieve optimal resistance to aliphatic hydrocarbons and seawater within -30°C to +100°C operating ranges. Standard grades exhibit 10–18 MPa tensile strength and 250–400% elongation, providing reliable impact absorption against hulls and berths. Cost-effective manufacturing and ease of compounding with anti-ozonants make NBR the preferred choice for commercial ports and recreational marinas where fuel exposure is moderate.

Silicone rubber excels in extreme temperature resilience (-60°C to +200°C) and UV stability, though its lower tensile strength (5–8 MPa) necessitates structural reinforcement in high-impact zones. VMQ’s inert composition resists oxidation and microbial growth in stagnant water, while maintaining flexibility at cryogenic temperatures. Applications include fenders for Arctic supply vessels or solar-exposed installations where thermal cycling exceeds conventional elastomer limits.

The following comparative analysis details critical technical parameters for informed material selection:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Key Resistance Properties | Primary Applications |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | 15–20 | 150–250 | 60–80 | Hydrocarbons, acids, ozone, high heat | Offshore terminals, chemical tankers, military docks |

| Nitrile (NBR) | -30 to +100 | 10–18 | 250–400 | 50–75 | Seawater, aliphatic oils, abrasion | Commercial ports, ferry terminals, yacht marinas |

| Silicone (VMQ) | -60 to +200 | 5–8 | 300–600 | 40–60 | UV, ozone, extreme cold, biological growth | Arctic operations, solar-intensive zones, clean-water facilities |

Suzhou Baoshida Trading Co., Ltd. validates all formulations through ASTM D2000 and ISO 188 testing protocols, ensuring compliance with international marine safety standards. Our technical team collaborates with OEM partners to tailor compound hardness, filler systems, and curing profiles—addressing specific wave dynamics, vessel tonnage, and berth geometry. Material certification dossiers, including MDS and REACH compliance documentation, are provided with every production batch to support regulatory audits and lifecycle management. This precision engineering approach guarantees fenders that minimize vessel damage while maximizing operational uptime across global maritime infrastructures.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in deep technical expertise and precision-driven development. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we deliver high-performance boat fenders that meet rigorous marine and industrial standards. Our integrated approach ensures that material science, structural integrity, and manufacturing efficiency are harmonized at every stage of product development.

Our formula engineers possess advanced knowledge in elastomer chemistry, focusing on optimizing rubber compounds for dynamic marine environments. They formulate custom blends using natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene propylene diene monomer (EPDM), tailored to deliver superior resilience, UV resistance, ozone stability, and low-temperature flexibility. These formulations are rigorously tested for compression set, tensile strength, and abrasion resistance to ensure prolonged service life under continuous impact and exposure.

Complementing material development, our five in-house mould engineers specialize in precision tooling design and process optimization. Utilizing CAD/CAM software and finite element analysis (FEA), they develop robust, high-tolerance moulds that ensure dimensional accuracy and repeatability across production batches. This enables seamless scalability from prototype to volume manufacturing while maintaining strict conformity to OEM specifications.

We offer full OEM (Original Equipment Manufacturer) services, supporting clients from concept to delivery. Our engineering team collaborates directly with partners to customize fender geometry, durometer rating, attachment mechanisms, and surface texture. Whether the requirement is for cylindrical, cone, or arch-type fenders, we ensure optimal energy absorption, minimal hull damage, and compatibility with diverse docking configurations.

Our manufacturing process integrates steam-cured vulcanization and precision moulding techniques, ensuring consistent cross-linking and mechanical performance. Quality control is maintained through in-line testing for hardness, elongation, and tear strength, aligned with international standards such as ISO 10224 and ASTM D412.

The following table outlines the key technical specifications achievable through our engineering and production capabilities:

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Shore A Hardness | 50–75 | Up to 90 Shore A |

| Tensile Strength | ≥12 MPa | Up to 20 MPa |

| Elongation at Break | ≥300% | Up to 500% |

| Compression Set (70°C, 24h) | ≤25% | ≤15% (optimized compounds) |

| Operating Temperature Range | -40°C to +80°C | Extended range on request |

| Material Types | NR, SBR, EPDM, CR (Chloroprene) | Blends and specialty grades |

| Fender Types | Cylindrical, D-type, Cone, Arch | Fully custom geometries |

Through the synergy of formula innovation and precision engineering, Suzhou Baoshida delivers boat fenders that combine durability, reliability, and performance. Our OEM-centric model ensures that every product is engineered to meet the exact operational demands of global marine applications.

Customization Process

Customization Process for Marine Fender Systems

Suzhou Baoshida Trading Co., Ltd. implements a rigorous four-stage customization protocol for OEM boat fender manufacturing, ensuring technical alignment with naval architecture requirements and operational environments. Our process begins with Drawing Analysis, where engineering teams deconstruct client-provided naval architecture schematics. We evaluate hull curvature coefficients, berthing energy absorption thresholds, tidal range variables, and vessel displacement metrics. Critical parameters such as contact pressure distribution and fender placement geometry are validated against ISO 17357-1 marine standards. This phase identifies material stress points and dimensional tolerances, forming the technical foundation for subsequent development.

Formulation Engineering follows, translating geometric data into proprietary rubber compound design. Our laboratory selects base polymers—typically epoxidized natural rubber (ENR) or hydrogenated nitrile (HNBR)—based on salinity exposure, UV index, and temperature extremes. Accelerated aging tests determine optimal antioxidant packages, while Shore A hardness is calibrated between 45–65 to balance energy dissipation and structural integrity. Fillers like silica-modified carbon black enhance abrasion resistance against dock infrastructure, and ozone-resistant curatives prevent cracking in tropical deployments. Each formulation undergoes dynamic mechanical analysis (DMA) to confirm viscoelastic properties meet the vessel’s kinetic energy profile.

Prototyping & Validation employs CNC-machined molds for low-volume production of test units. Prototypes undergo ASTM D2240 compression testing, 500-hour saltwater immersion trials, and impact resistance validation at 1.2 m/s velocity. We measure rebound resilience, permanent set deformation (<15%), and adhesion strength to mounting hardware. Client feedback on prototype performance in real-world berthing scenarios triggers iterative refinements. Only when all parameters satisfy the original naval architecture brief do we approve the final compound and geometry for scale-up.

Mass Production Execution leverages our ISO 9001-certified facility with automated curing lines and real-time rheometer monitoring. Each batch undergoes spectrometric raw material verification and post-cure hardness mapping. Statistical process control (SPC) tracks critical dimensions via laser scanning, maintaining ±0.5 mm tolerances. Finished fenders receive traceable batch coding and third-party certification documentation per client specifications.

The following table contrasts standard versus custom-engineered fender specifications:

| Parameter | Standard Fender | Custom-Engineered Fender |

|---|---|---|

| Shore A Hardness | 55 ± 3 | 48–62 (client-specified) |

| Tensile Strength (MPa) | 18.0 | 22.5–28.0 |

| Elongation at Break (%) | 450 | 520–600 |

| Saltwater Resistance | 300 hours | 1,000+ hours |

| Ozone Resistance (pphm) | 50 | 100 |

| Custom Geometry Options | Limited | Full CAD integration |

This structured workflow eliminates design-to-production disconnects, reducing client rework by 73% versus industry averages. By anchoring each phase in empirical data and marine engineering principles, Suzhou Baoshida delivers fenders that extend vessel service life while minimizing berthing infrastructure wear. Our OEM partnership model ensures technical ownership from naval blueprint to quayside deployment.

Contact Engineering Team

For precision-engineered industrial rubber solutions tailored to marine protection systems, Suzhou Baoshida Trading Co., Ltd. stands as a trusted OEM partner in the global supply chain. Our expertise in rubber formulation, compression molding, and performance validation ensures that every boat fender we produce meets rigorous standards for impact absorption, UV resistance, and long-term seawater exposure. As a specialized rubber manufacturing services provider, we focus on delivering technically optimized fenders that align with vessel class requirements, docking infrastructure, and operational environments.

Our boat fenders are not generic off-the-shelf products. Each unit is developed through a structured engineering process that begins with material selection—typically high-density EPDM or neoprene compounds—chosen for ozone resistance, tensile strength, and resilience under cyclic loading. We apply finite element analysis (FEA) during design validation to predict compression-deflection behavior and optimize wall thickness distribution for uniform energy dissipation. This scientific approach ensures minimal hull damage during berthing, even under high kinetic energy conditions.

Suzhou Baoshida supports custom geometries, including cylindrical, D-type, and arch-shaped fenders, with mounting configurations engineered for specific vessel tonnage and quay wall systems. All formulations undergo accelerated aging tests per ASTM D573 and salt spray exposure per ISO 9227 to verify service life in harsh marine environments. We maintain full traceability of raw materials and production batches, complying with ISO 9001:2015 quality management protocols.

For technical collaboration, OEM partnerships, or custom quoting, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Mr. Boyce leads material development and client engineering integration, offering direct access to formulation data sheets, mechanical property reports, and finite element simulation summaries upon request. Whether you require a single prototype iteration or full-scale production runs with JIT delivery, our team ensures seamless coordination from specification to shipment.

Below are representative mechanical and environmental specifications for our standard marine fender compound (Grade BR-MF75):

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥450% |

| Compression Set (70°C, 22h) | ASTM D395B | ≤22% |

| Tear Resistance | ASTM D624 | ≥45 kN/m |

| Specific Gravity | ASTM D297 | 1.18–1.22 |

| Operating Temperature Range | — | -40°C to +100°C |

| UV Resistance | ASTM G154 | Pass (2000h) |

| Salt Water Immersion (1000h) | ISO 1817 | <10% volume swell |

Partnering with Suzhou Baoshida means gaining access to engineered rubber solutions backed by material science rigor and manufacturing precision. Initiate your project with a technical consultation. Contact Mr. Boyce today at [email protected] to discuss formulation options, dimensional tolerancing, or compliance requirements for classification societies.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).